Electric vehicle switch handle accessory automatic feeding machining device and machining method

A switch handle and processing device technology, which is applied to metal processing equipment, manufacturing tools, plastic recycling, etc., can solve the problems of difficult and precise feeding, small size and low size of cylindrical accessories, so as to improve the drilling processing efficiency and improve the The effect of production and processing efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

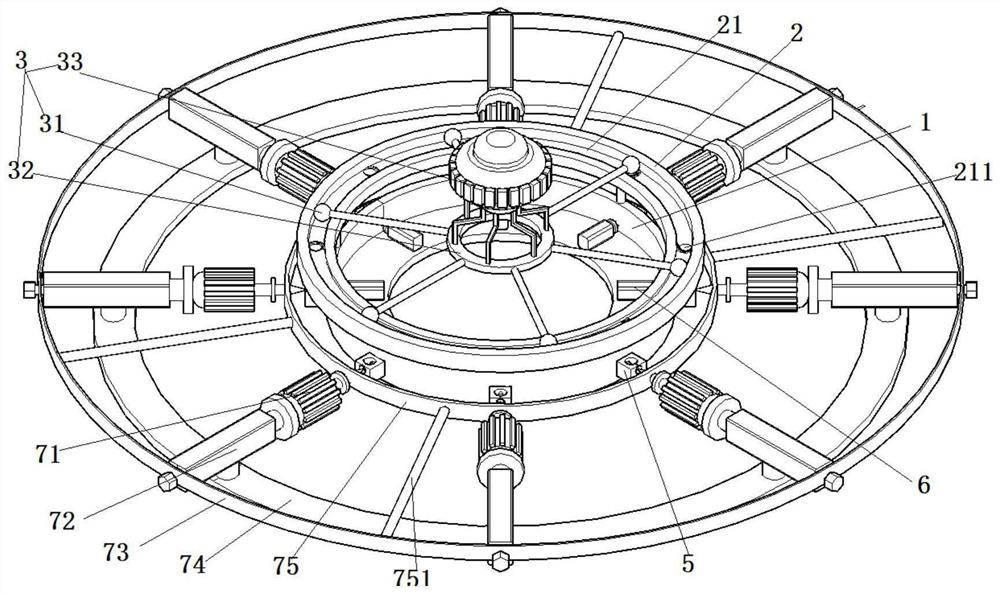

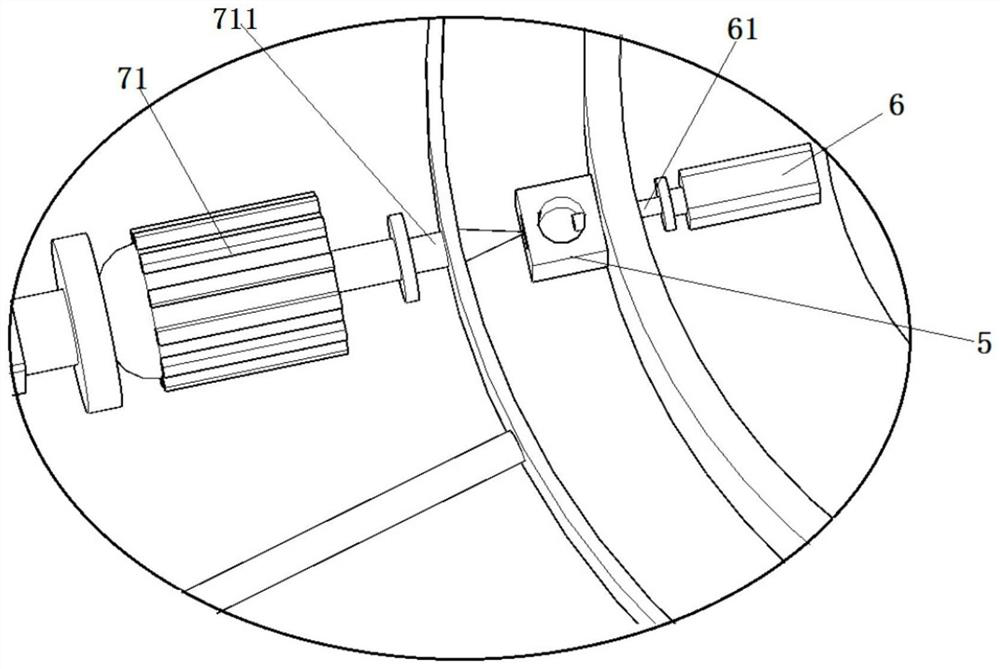

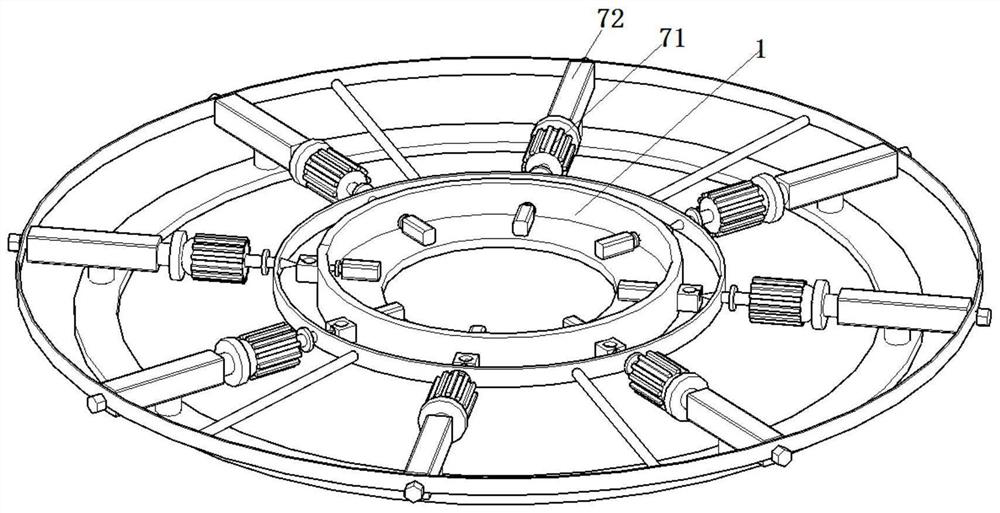

[0047] Such as Figure 1-9 As shown, an automatic blanking processing device for electric vehicle switch handle accessories, including a blanking ring 2, an annular trough 21 is opened in the blanking ring 2, and several annular arrays are arranged in the annular trough 21. The discharge hole 211; the cylindrical accessories that need to be processed are placed in the annular trough 21. In order to realize automatic blanking, the above-mentioned blanking ring 2 is assembled with a push blanking assembly 3, and the push blanking assembly 3 includes A plurality of pushing material rolling balls 31 rolling in the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com