Spinning devices

A yarn and yarn guide technology, which is applied to spinning machines, jointing devices, free-end spinning machines, etc., can solve the problems of reducing production efficiency, improve success rate, prevent yarn breakage, and increase yarn strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail according to the accompanying drawings.

[0021] Figure 5 It shows a spinning machine 1 with a plurality of spinning components 2 arranged side by side. In this spinning machine 1, a piecing device (piece trolley) 3 installed so as to be able to move freely between spinning members 2, a blow box 4, and a power frame 5 are installed.

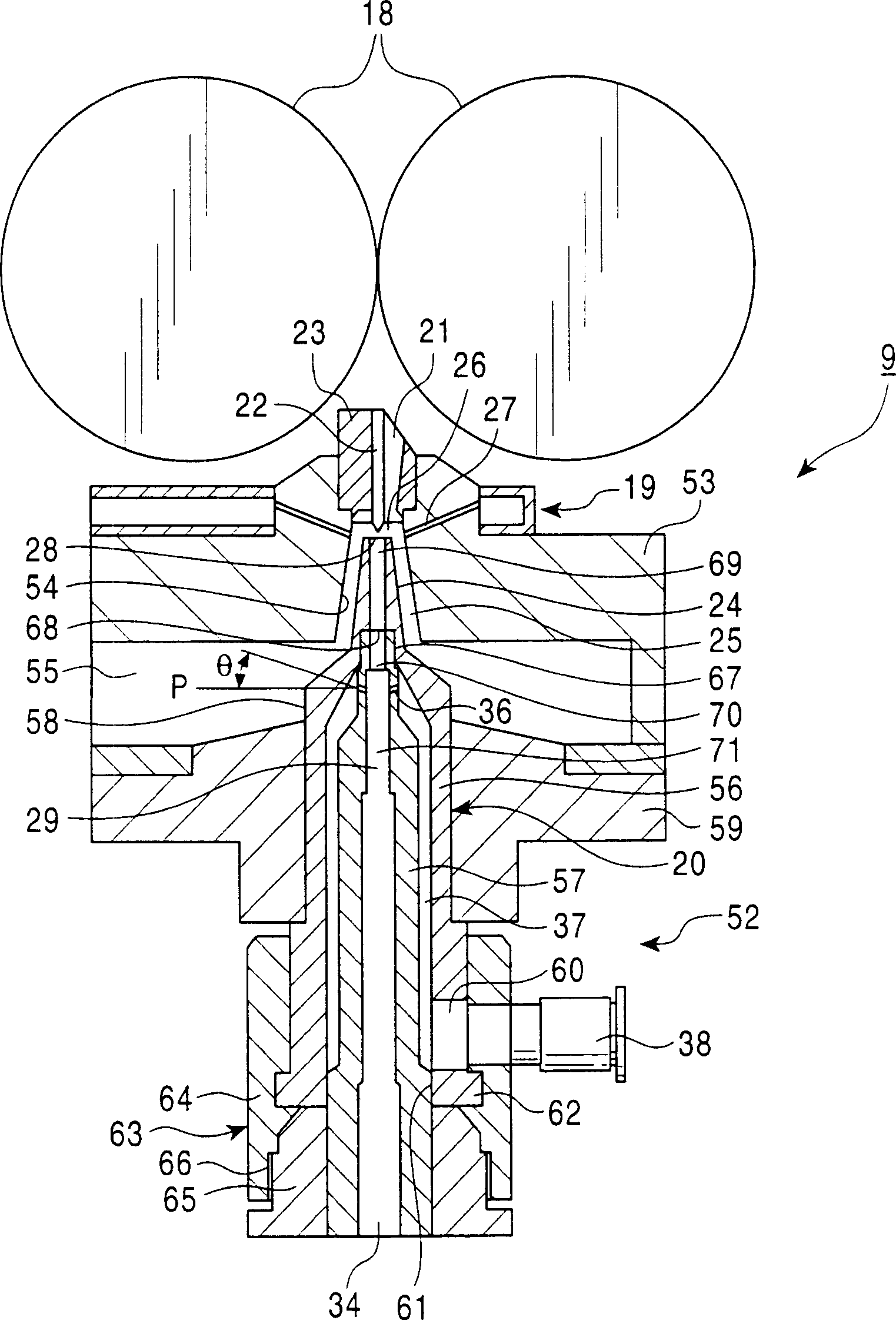

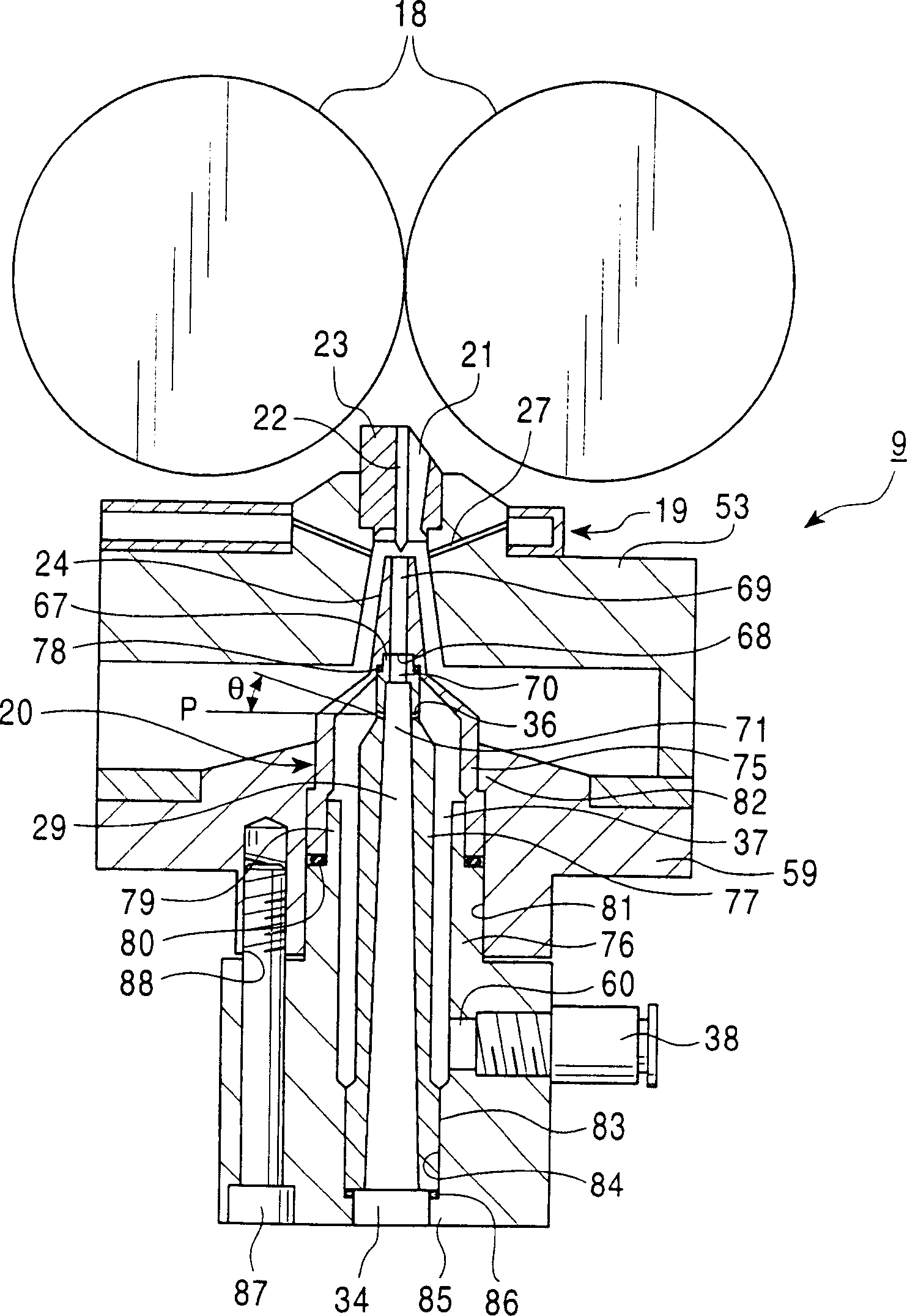

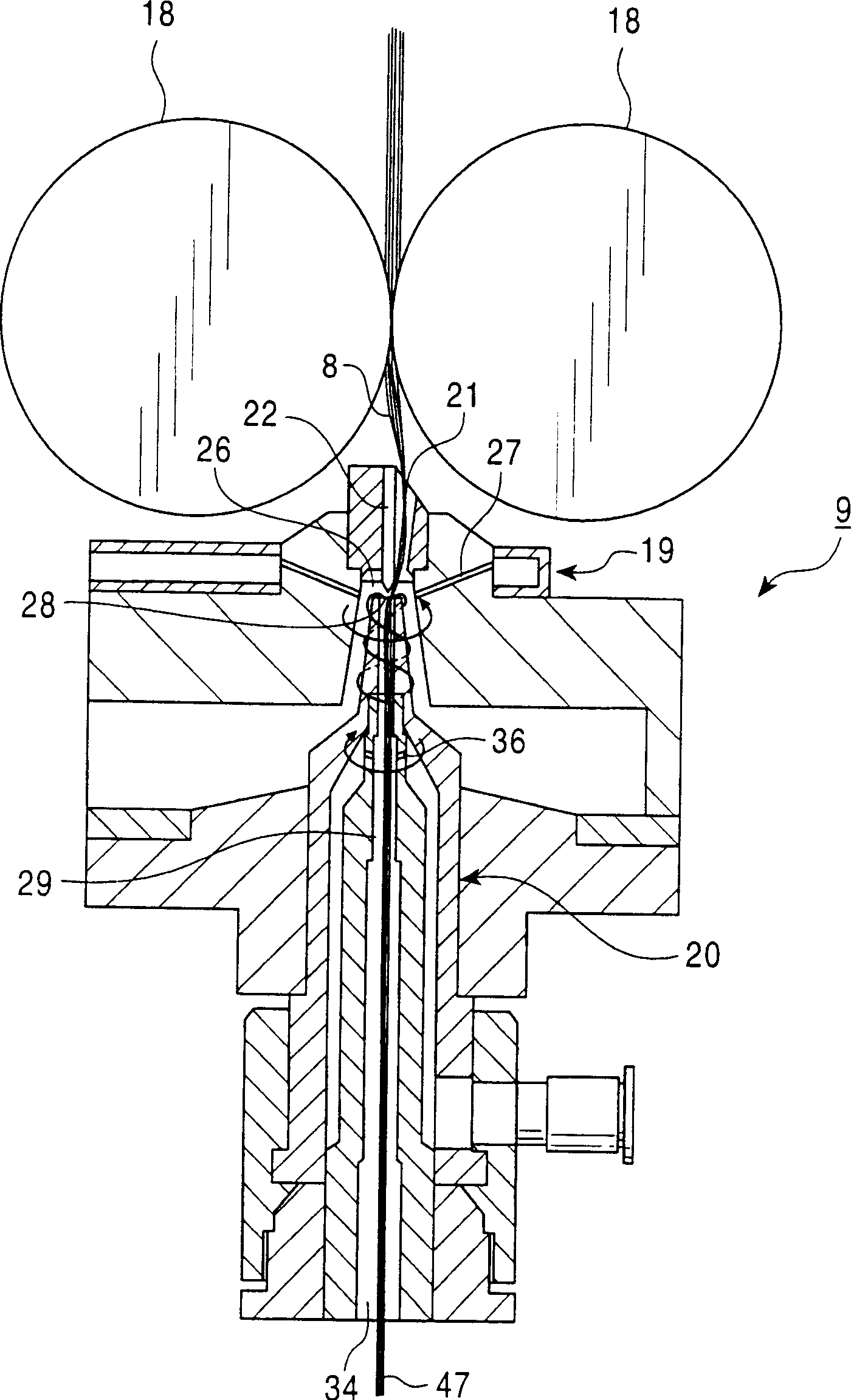

[0022] Such as Image 6 with Figure 7 As shown, each spinning component 2 is arranged on the casing 6 of the spinning machine 1 body, and the drafting device 7 arranged near the upper end of the casing 6 is arranged on the downstream side of the drafting device 7 and will be drawn from the drafting device 7. The spinning section 9 that spins the fiber bundle sent out by the device 7 into yarn, the yarn feeding device 11 that is installed on the downstream side of the spinning section 9 and conveys the spun yarn 10 discharged from the spinning secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com