Yarn tension constant compensation device

A compensating device, a technology for yarn tension, applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems of inability to achieve smooth, stable and continuous operation of equipment, long spring response time, strong yarn jitter, etc. Good shock absorption effect, high product quality, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

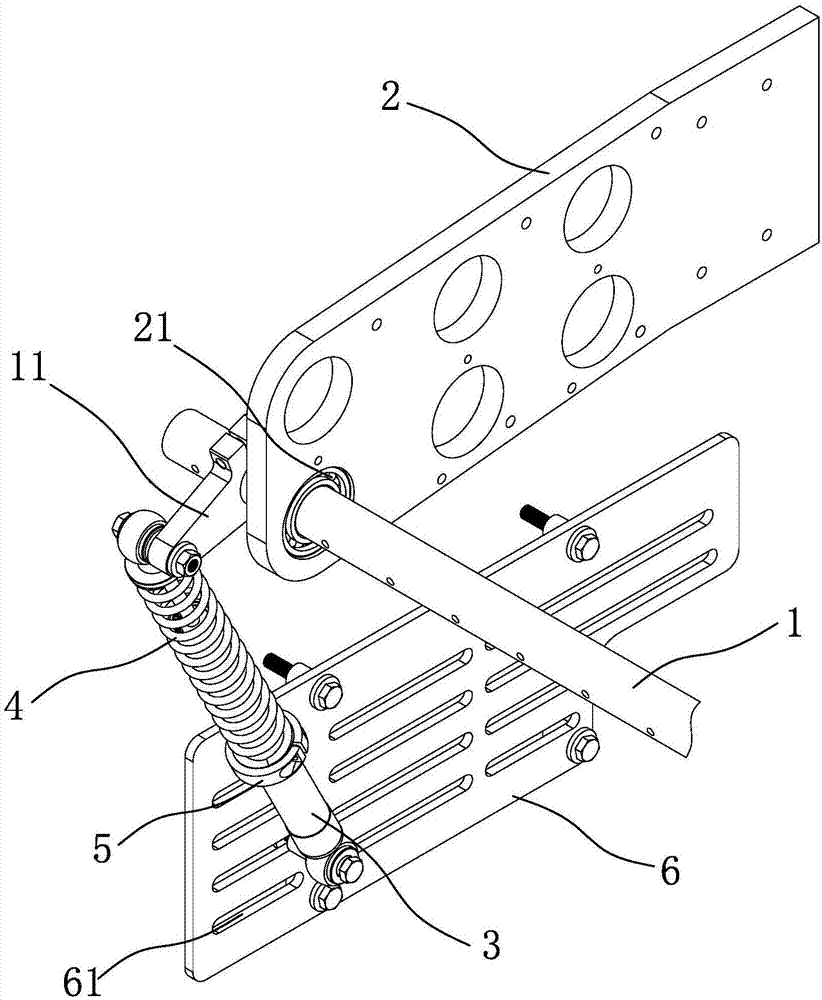

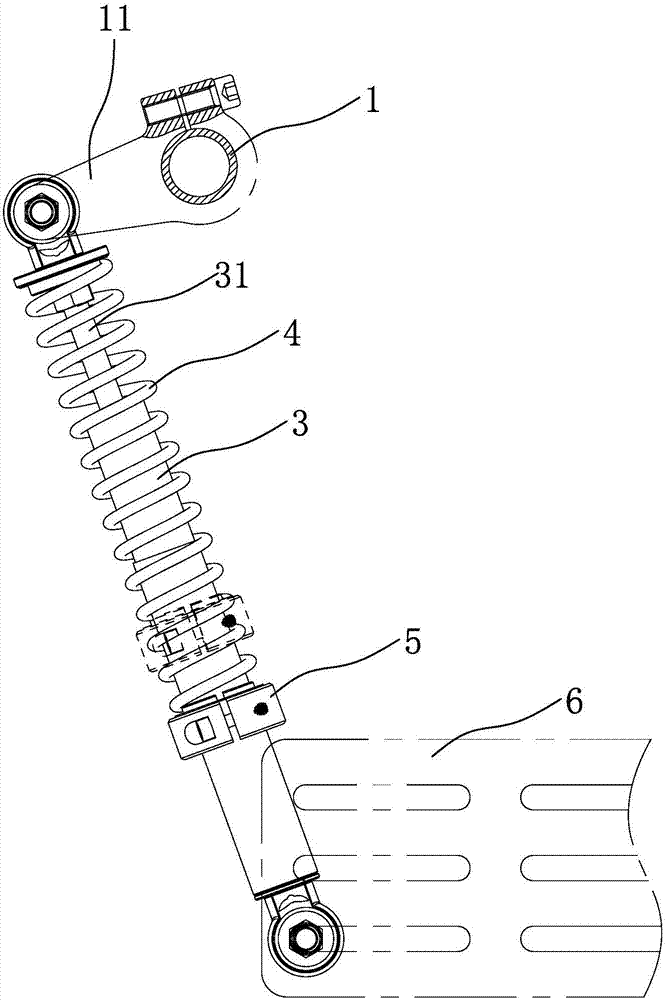

[0016] refer to figure 1 and figure 2 , a kind of yarn tension constant compensating device, comprises frame and six yarn guide rods 1 ( figure 1 Only one is shown as an example), the frame is provided with a support plate 2 with six mounting holes, and each yarn guide rod 1 is installed on the support plate 2 through self-aligning bearings 21;

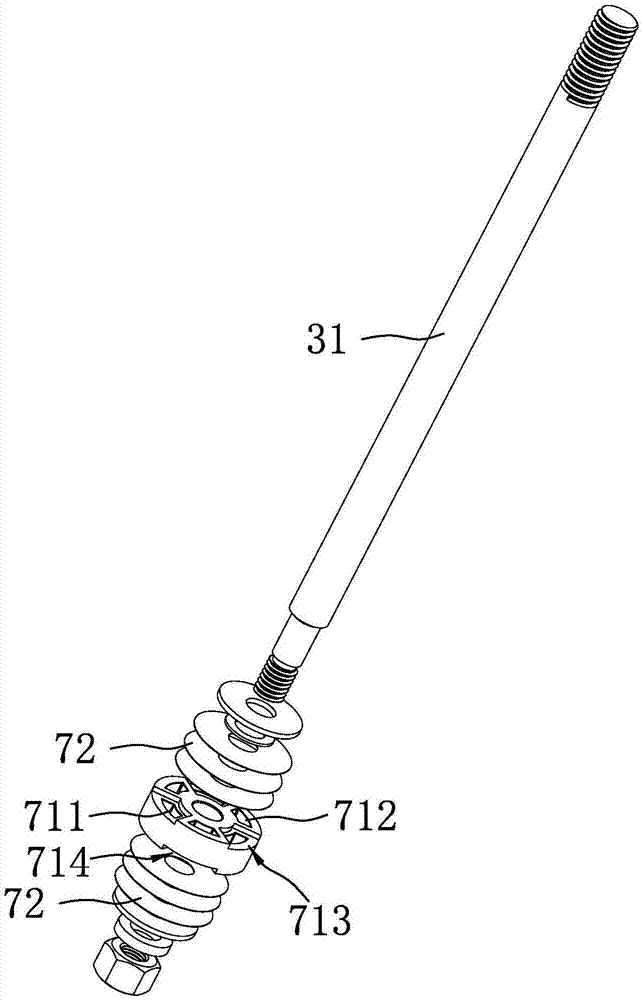

[0017] Each yarn guide rod 1 is connected with a tension compensation mechanism, and the tension compensation mechanism includes a damping cylinder 3, a spring 4 sleeved on the outer surface of the damping cylinder 3, and a clamp ring 5, and one end of the damping cylinder 3 is fixed on the frame. On a mounting plate 6, the other end is connected to the yarn guide rod 1 through a connecting lever 11, the spring 4 is clamped between the end of one end of the damping cylinder 3 and the clamping ring 5, and the clamping ring 5 is connected to the damping Cylinder 3 threaded connection. In this embodiment, the outer surface of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com