Yarn splicing guide device of automatic bobbin winder

A technology of automatic winding machine and guiding device, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve the problem of lower knot quality, restriction of automatic winding machine potential, and yarn guiding function Instability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

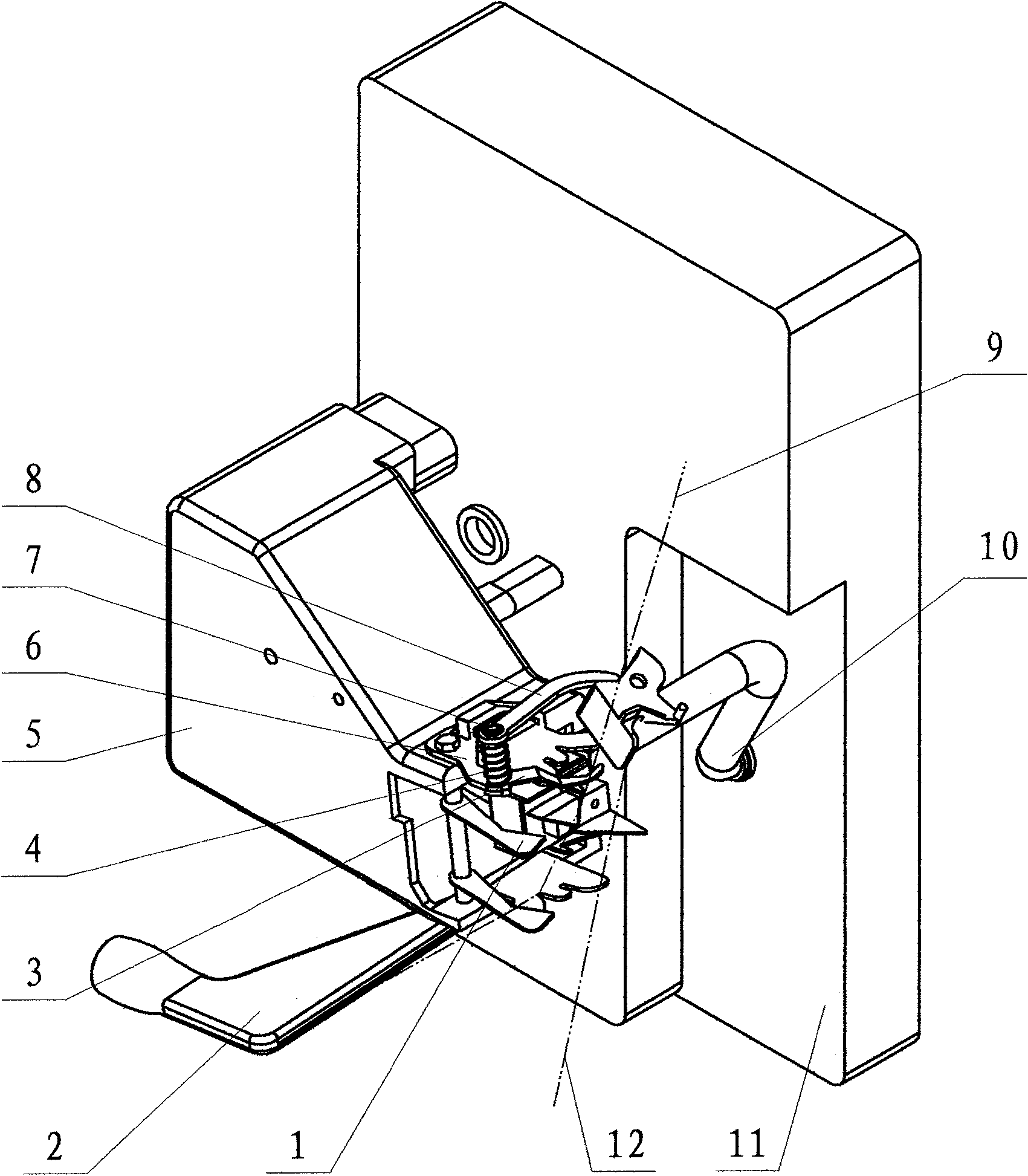

[0017] Such as figure 1 As shown, a splicer support 5 is fixedly installed on the automatic winder frame 11, and a splicer 1 is fixedly installed at the port position of the splicer support 5, and the splicer 1 adopts common air splicer. A small suction nozzle 10 is also rotatably arranged on the automatic winder frame 11, and the small suction nozzle 10 has a bent suction pipe and a suction nozzle positioned at the port of the suction pipe. Below the splicer 1, a large suction nozzle 2 that can turn upwards is arranged.

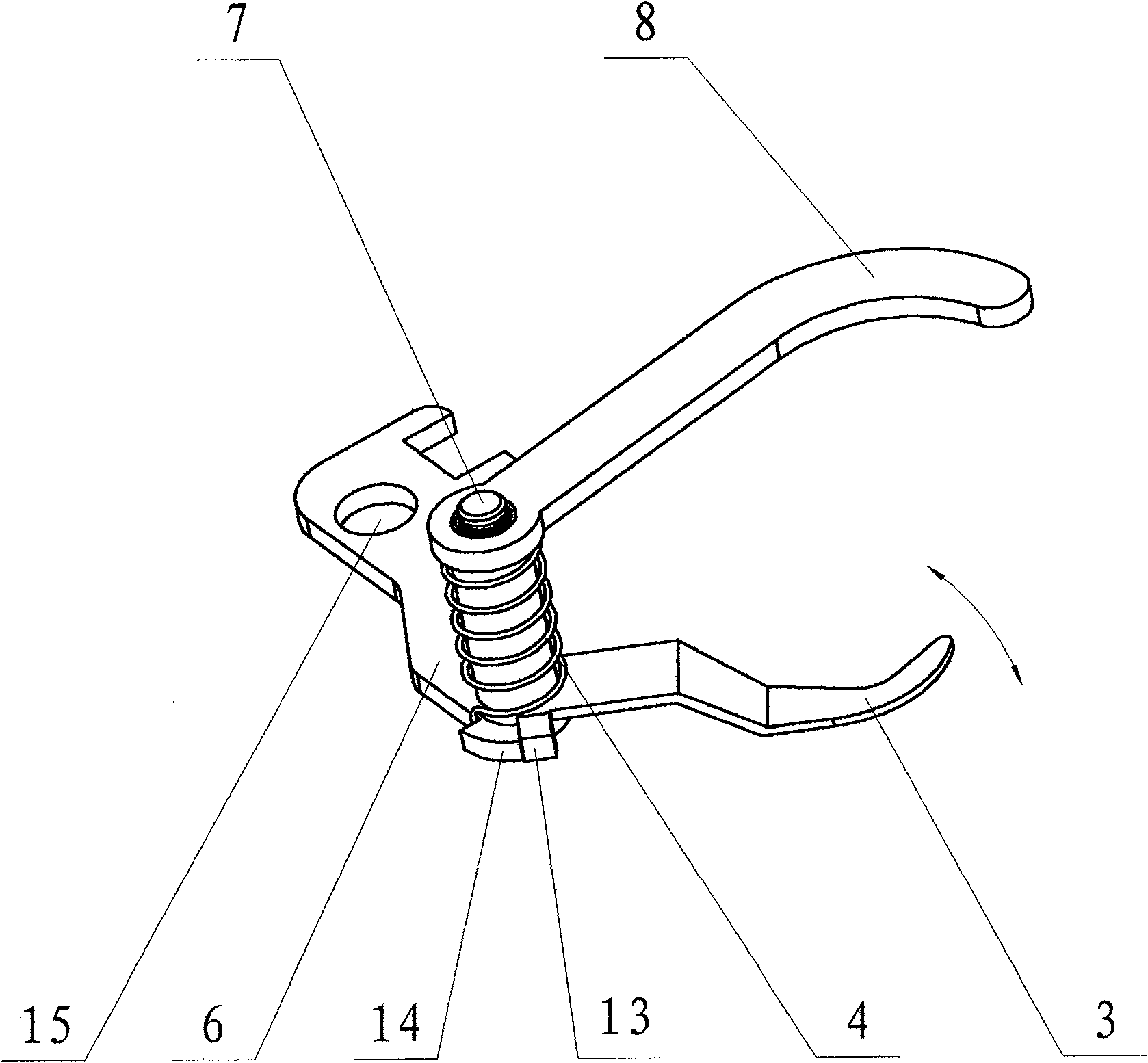

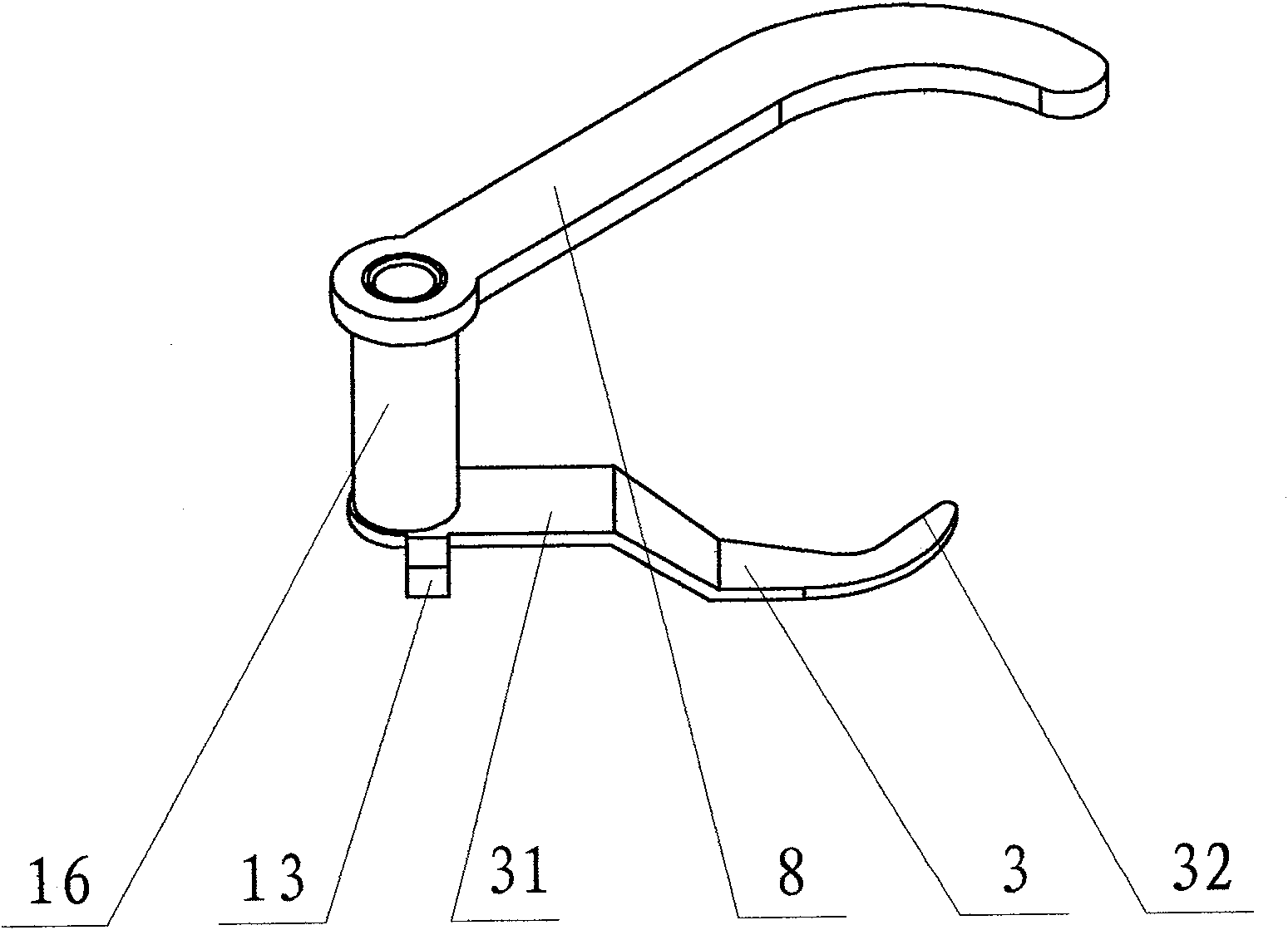

[0018] The top of the splicer 1 is provided with a yarn guide hook 3 and a guide swing arm 8 fixed to each other, the yarn guide hook 3 and the guide swing arm 8 are swingably supported on the guide bracket 6, the The guide bracket 6 is fixedly connected to the splicer support 5; therefore, the guide bracket 6 and the splicer 1 maintain a fixed positional relationship. The guide hook fulcrum 7 is vertically and fixedly arranged on the guide bracket 6 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com