Automatic drafting machine and drafting method thereof

An automatic threading and heald machine technology, applied in the textile field, can solve the problems of difficult monitoring and high error rate of fine denier yarn threading, and achieve the effect of avoiding yarn breakage, reducing errors, and avoiding quality errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

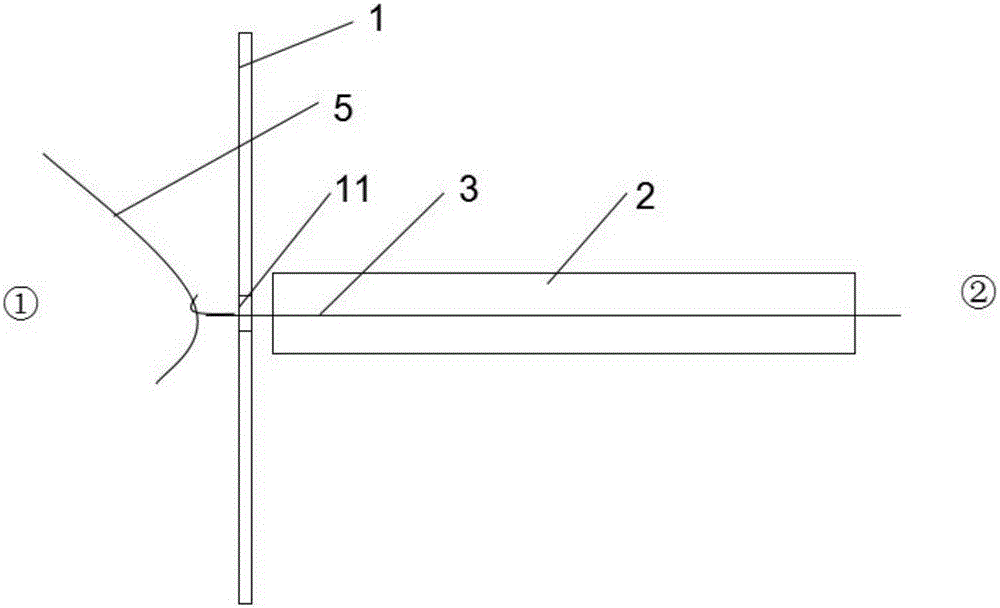

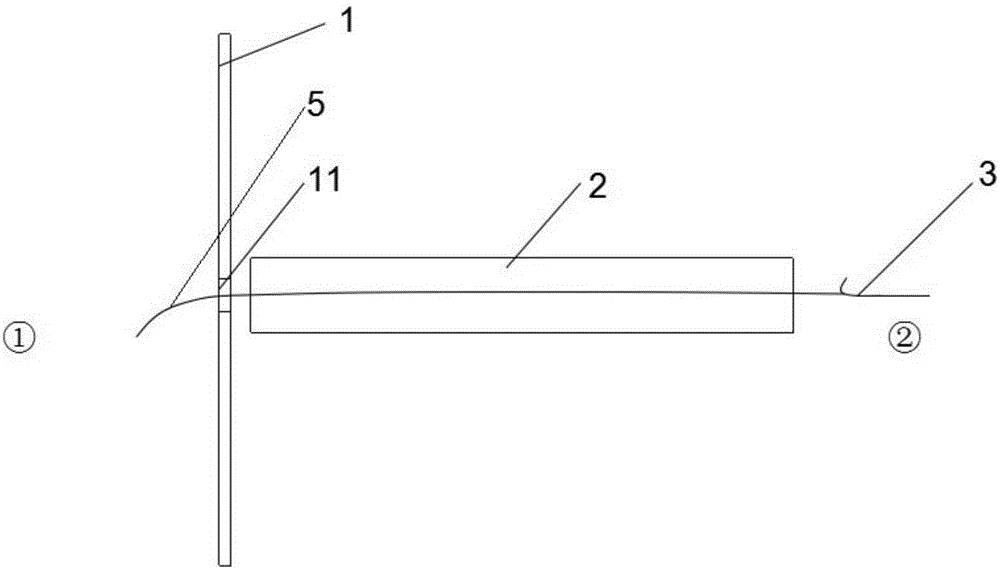

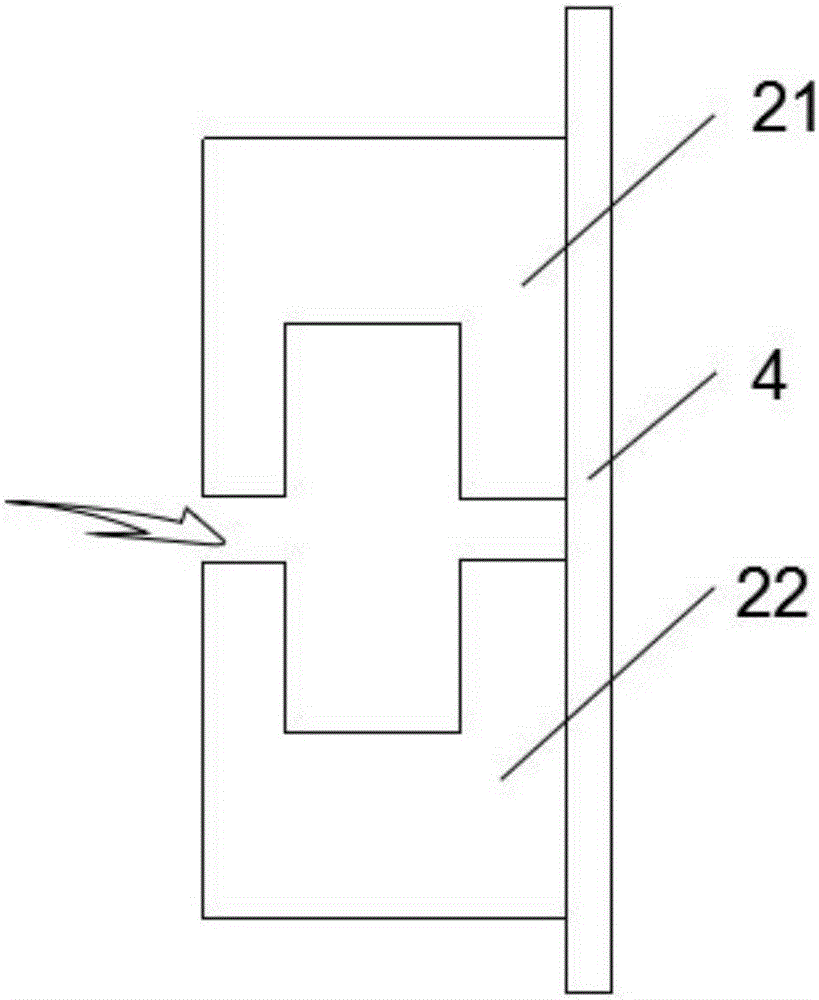

[0039] In order to offset the negative pressure generated by the crochet needle 3 during operation, prevent image 3 The outside air in the 2 enters into the track 2, and a jet device is provided on the side of the track 2 close to the wall plate 4. The jet device is provided with a jet hole 63, and the jet hole 63 faces the upper concave block 21 and the lower concave block 21. The connection between the blocks 22 is at the gap on the side away from the wall panel 4 . Here, the air jet device can adopt two ways of nozzle 6 or pipe 7 according to its shape, and there are two ways to use the nozzle 6 according to its positional relationship with the rail.

[0040] An automatic heald threading machine, comprising a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com