Method for winding yarn on bobbin to form intersected coiled bobbin

A cross-winding and yarn technology, which is used in the field of winding the yarn onto the bobbin to form a cross-winding bobbin, can solve the problems of reducing the extraction speed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

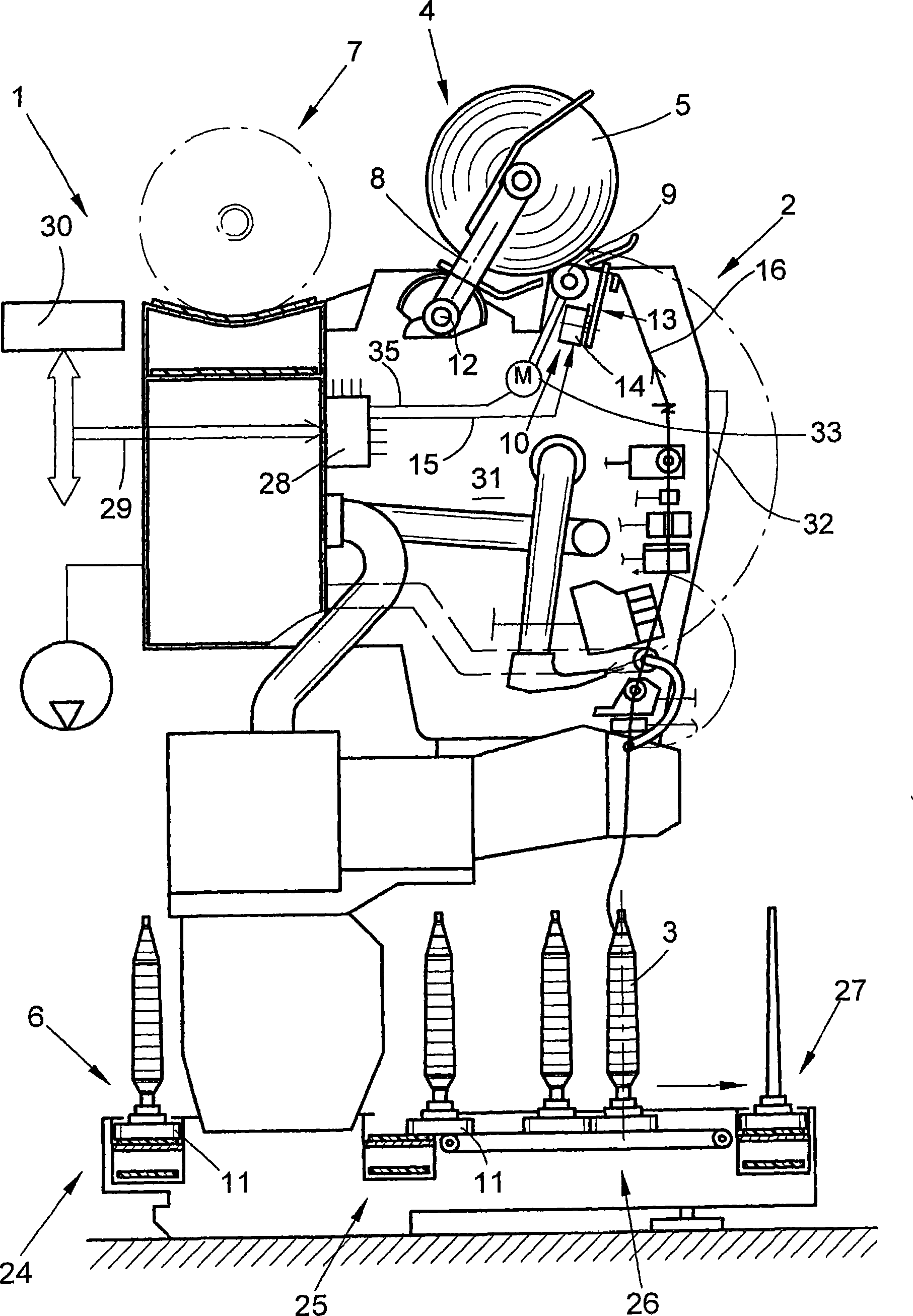

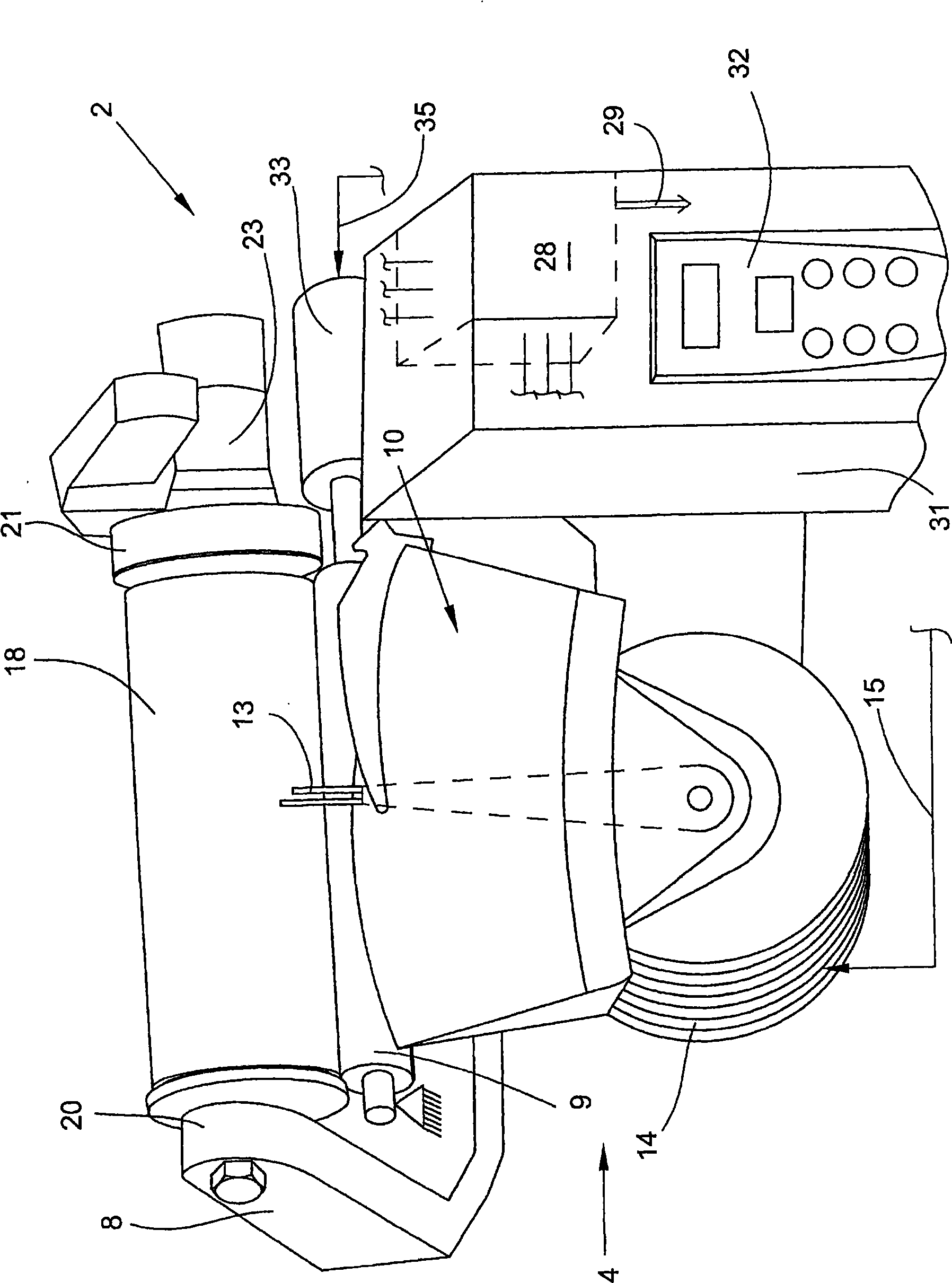

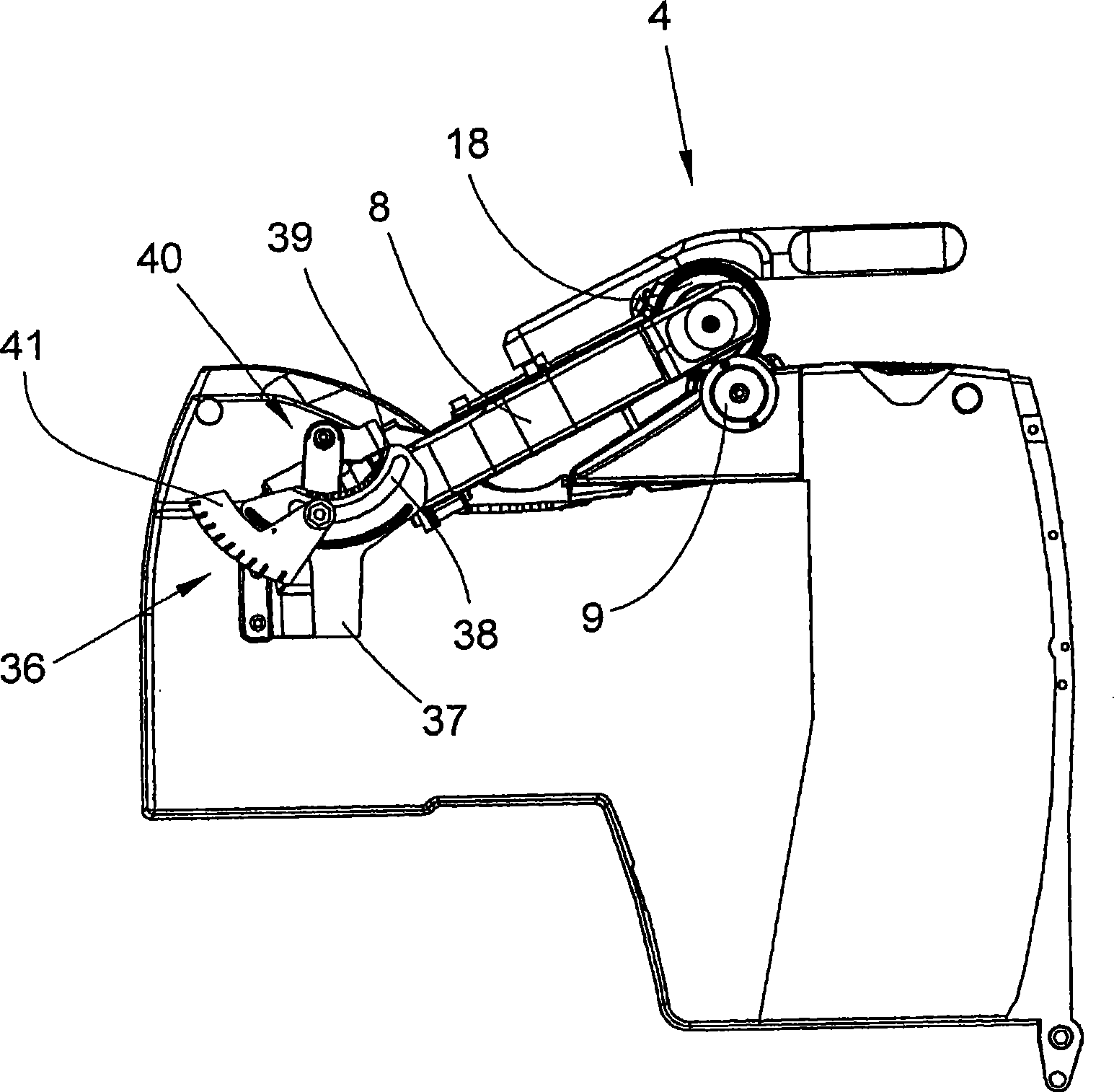

[0023] figure 1 A station 2 of a textile machine for producing cross-winding bobbins, which in the present embodiment is a so-called automatic cross-winding machine 1 , is shown schematically in side view. In station 2 of such an automatic cross-winding machine 1, the spinning bobbin 3 produced on the ring spinning machine with relatively little yarn material is rewound into a high-capacity cross-winding bobbin 5 . After its manufacture, the cross-winding bobbins 5 are handed over to the cross-winding bobbin conveyor 7 along the length of the machine by means of an automatically working service unit (not shown) and transported to the bobbin loading station arranged at the end side of the machine Wait.

[0024] Such an automatic crosswinder 1 usually also has a logistics mechanism in the form of a bobbin and bobbin delivery system 6 . In this bobbin and bobbin delivery system 6 , spinning bobbins 3 or empty bobbins are circulated on a delivery disc 11 . exist figure 1 Only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com