Single yarn dyeing machine

A technology of dyeing machine and single yarn, which is applied in the direction of liquid/gas/steam yarn/filament processing, etc., and can solve the problems that customers cannot meet the needs of non-uniform segment dyed yarn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

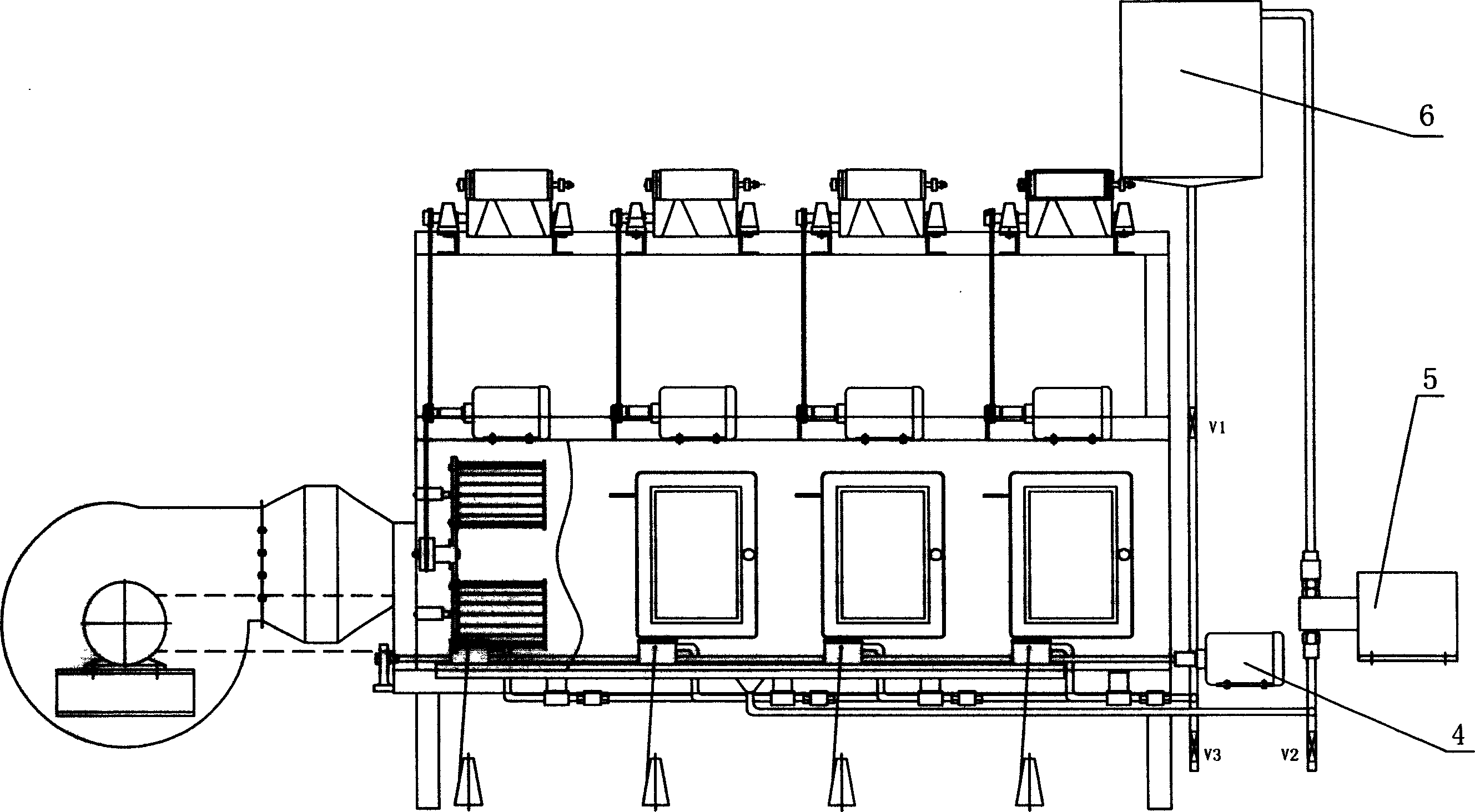

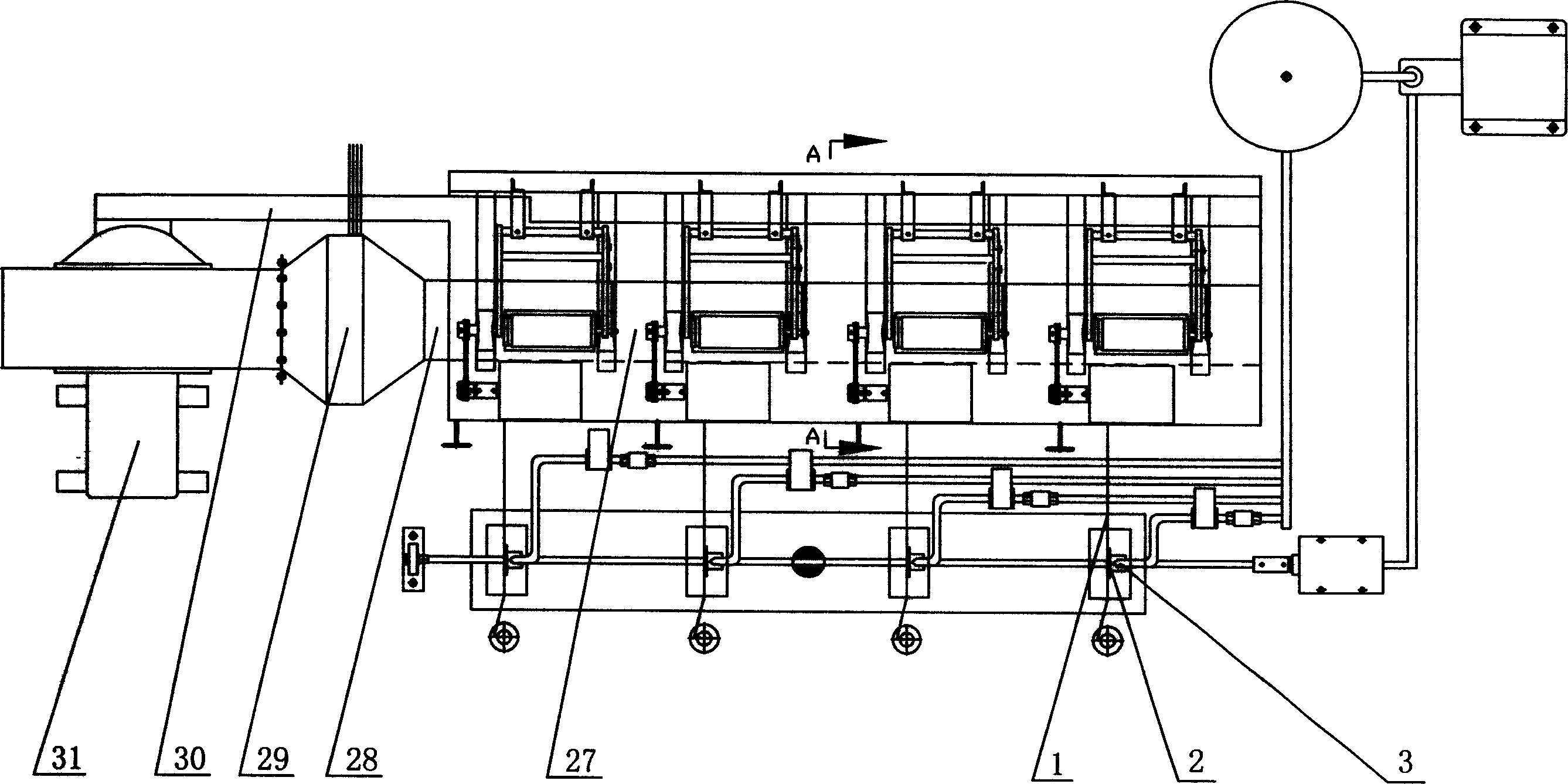

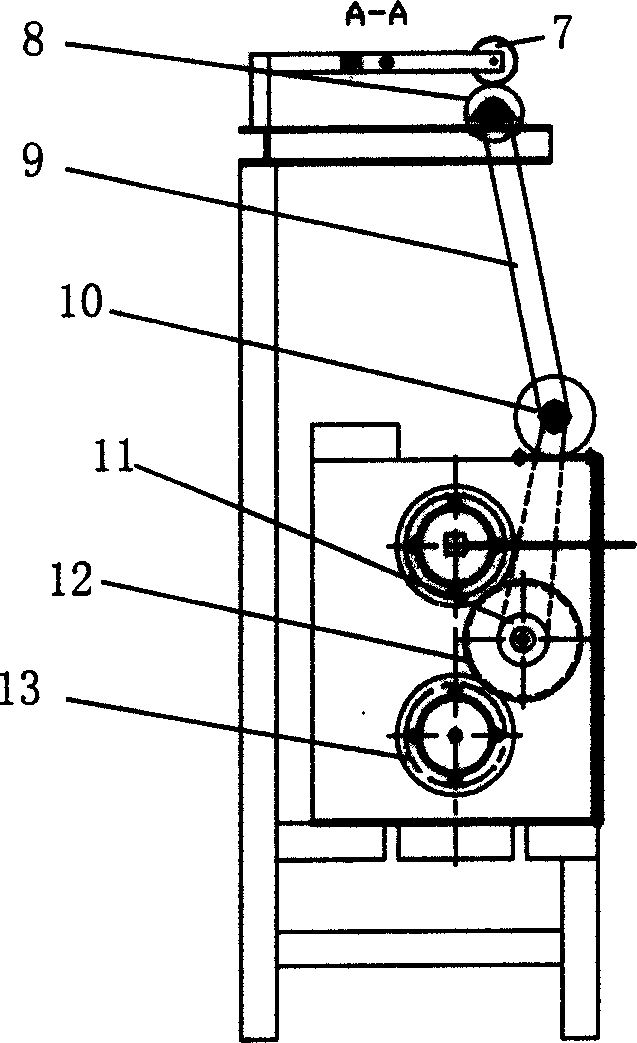

[0021] When implementing, refer to Figure 1 to Figure 8 , design and assemble the present invention according to production needs, each group of four nozzles can be combined in multiple groups according to the site and equipment, the key component of the present invention is the dyeing disc, and the spacing of the dyeing discs can be designed to be equal or different according to the dyeing needs. Fix it on the connection block 16 with bolt 14, cover the center of the dyeing disc with the rotating shaft 15, and then tighten the nail screw 17 to fix it, and the overrunning clutch mechanism of the winding unit can be pressed Figure 6 The design requirements of the production. The assembly of the whole machine can refer to the installation requirements of electrical appliances, machinery and pipelines Figure 1 ~ Figure 3 conduct. First, make the oven and the machine support frame, and press the air supply pipe, return air pipe, heat exchanger and fan into the figure 1 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com