Heating remover for short piles on yarns

A technology of short staple and yarn, applied in the field of yarn short staple thermal drying and removing device, can solve the problems of yarn broken yarn, increase the time of downtime for repair, reduce production efficiency, etc., and achieve the effect of avoiding yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

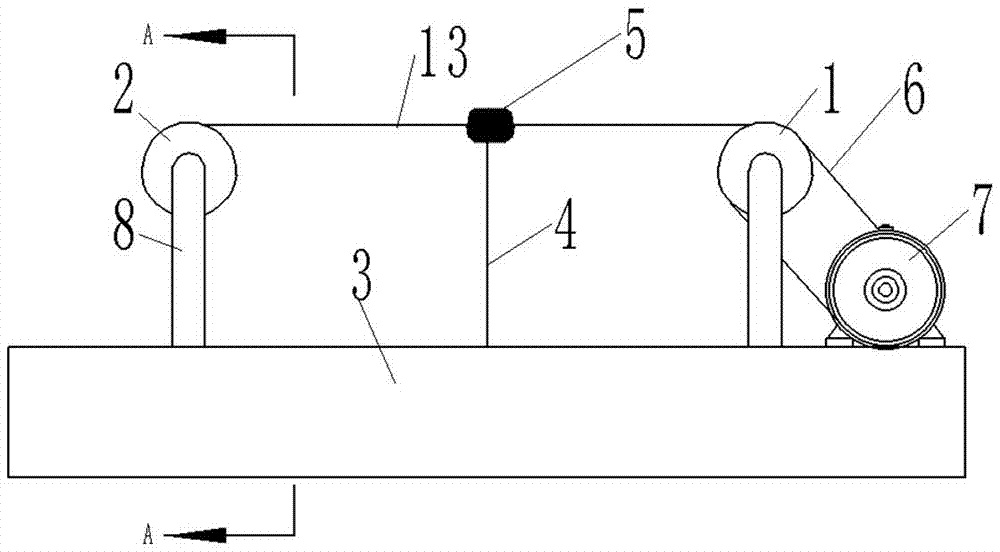

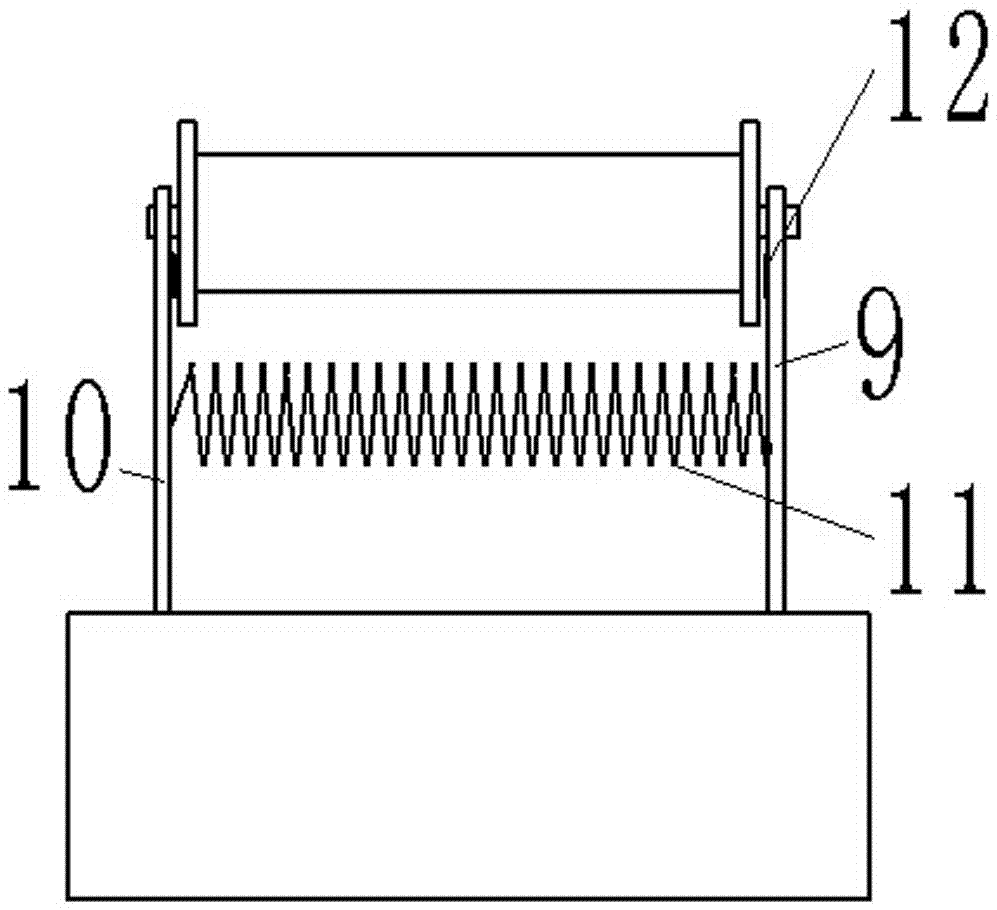

[0010] figure 1 , 2 Middle: active yarn bobbin 1, driven yarn bobbin 2, base 3, vertical rod 4, electric heating coil 5, belt transmission mechanism 6, motor 7, second connecting frame 8, first connecting piece 9, second connecting piece 10, Spring 11, friction skin 12.

[0011] A yarn linter thermal drying removal device, the yarn linter thermal removal device includes a driving yarn bobbin 1, a driven yarn bobbin 2, a base 3, a vertical rod 4, and an electric heating ring 5, and the active yarn bobbin 1 It is movably connected with the first connecting frame 5, the first connecting frame 5 is fixedly connected with the base 3, the active bobbin 1 is connected with the motor 7 through the belt transmission mechanism 6, and the motor 7 is installed on the base 3 , the driven bobbin 2 is movably connected with the second connecting frame 8, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com