Spinning machine comprising a plurality of workplaces and a suction appliance

A technology of spinning machine and air-jet spinning machine, applied in the field of spinning machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

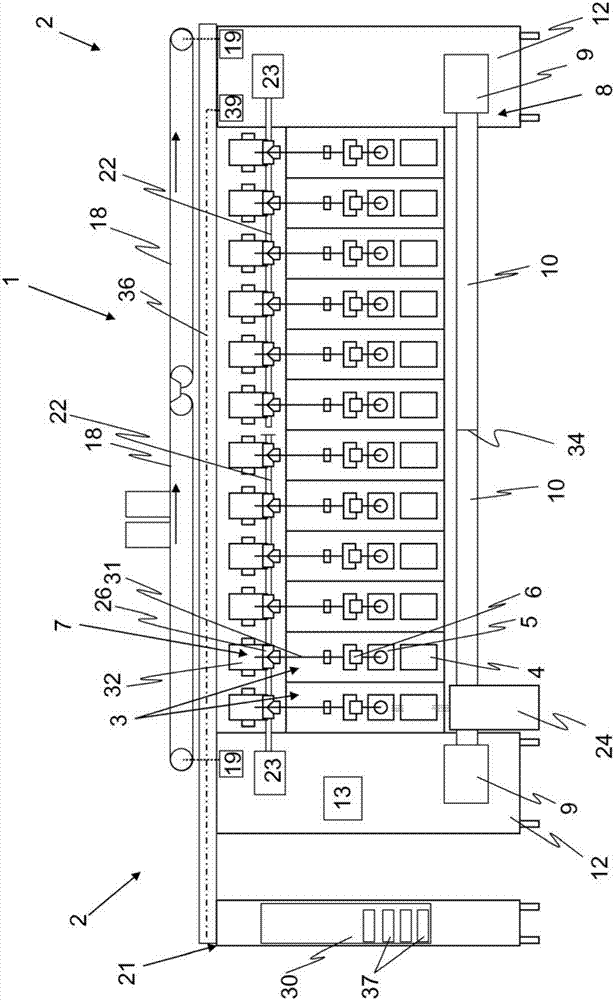

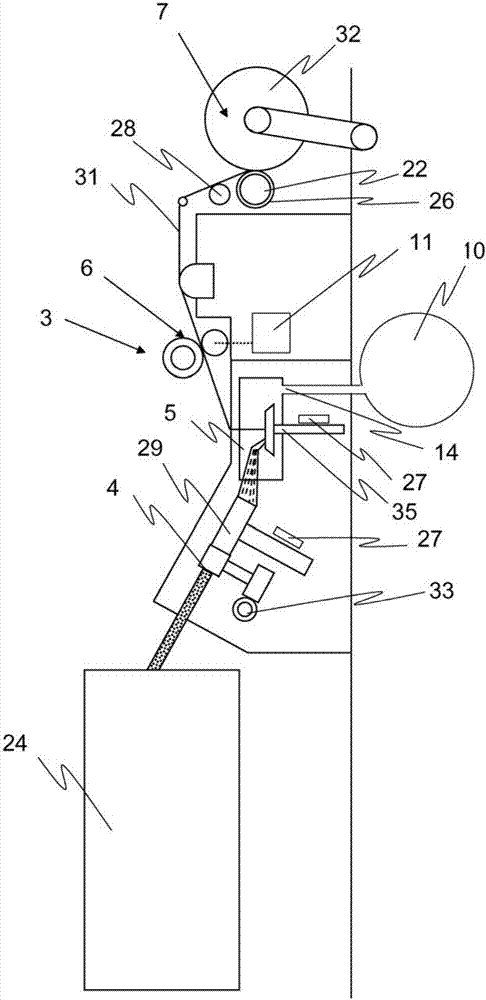

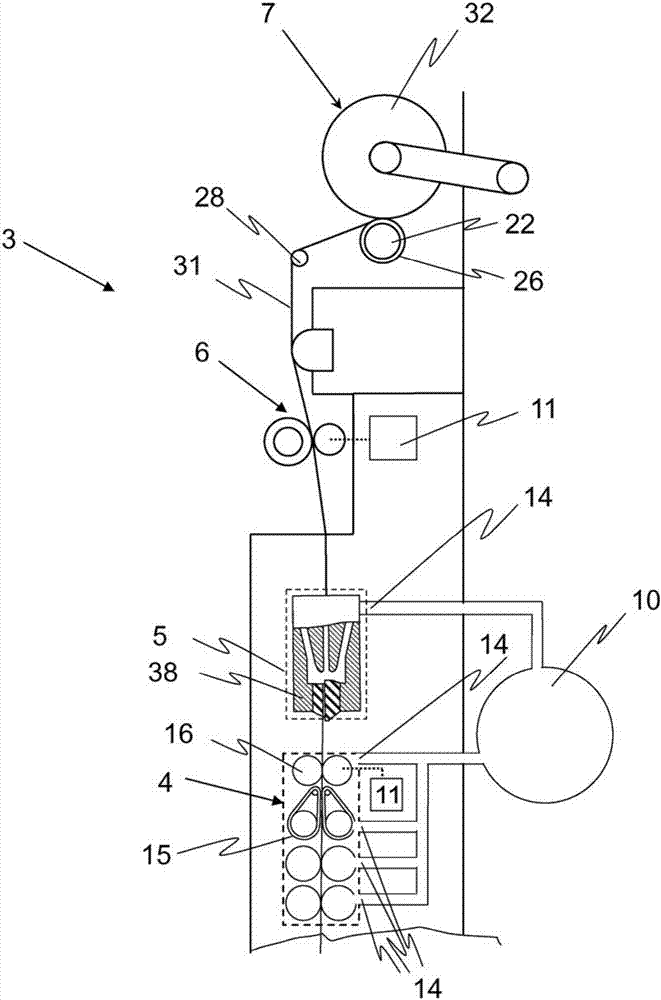

[0039] figure 1 A schematic illustration of a spinning machine 1 is shown, which is suitable in a special manner for arranging a plurality of work stations 3 side by side in the longitudinal direction of the spinning machine 1 . The workstations 3 are arranged side by side between the two front ends 2 and each have a known number of working means 4 , 5 , 6 , 7 for producing and winding the yarn 31 . Each station 3 has a conveying device 4 by means of which the fibrous material from the container 24 is conveyed to the spinning chamber 5 in which the fibrous material is spun into a yarn 31 . The yarn 31 is drawn out of the spinning chamber 5 by means of the yarn delivery device 6 and finally wound onto the bobbin 32 by means of the winding device 7 . Furthermore, the spinning machine 1 has a suction device 8 for supplying the station 3 with a low pressure and also for removing pollutants and waste from the station 3 when the yarn is attached and when the station 3 is maintained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com