Let-off device of warp knitting machine

A warp knitting machine and warp let-off technology, used in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of product type limitation, inability to meet, and inability to meet different requirements of warp let-off and density, and reduce the flatness The effect of occupying area, making full use of and avoiding yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

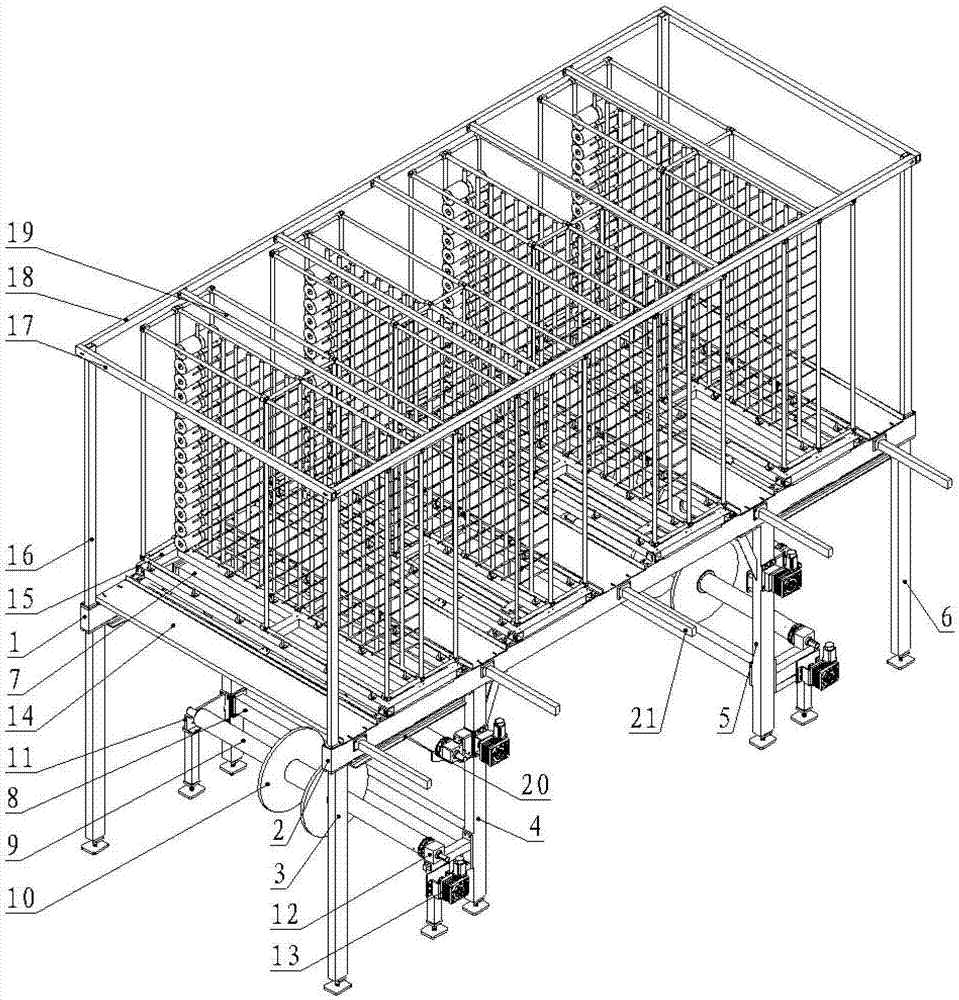

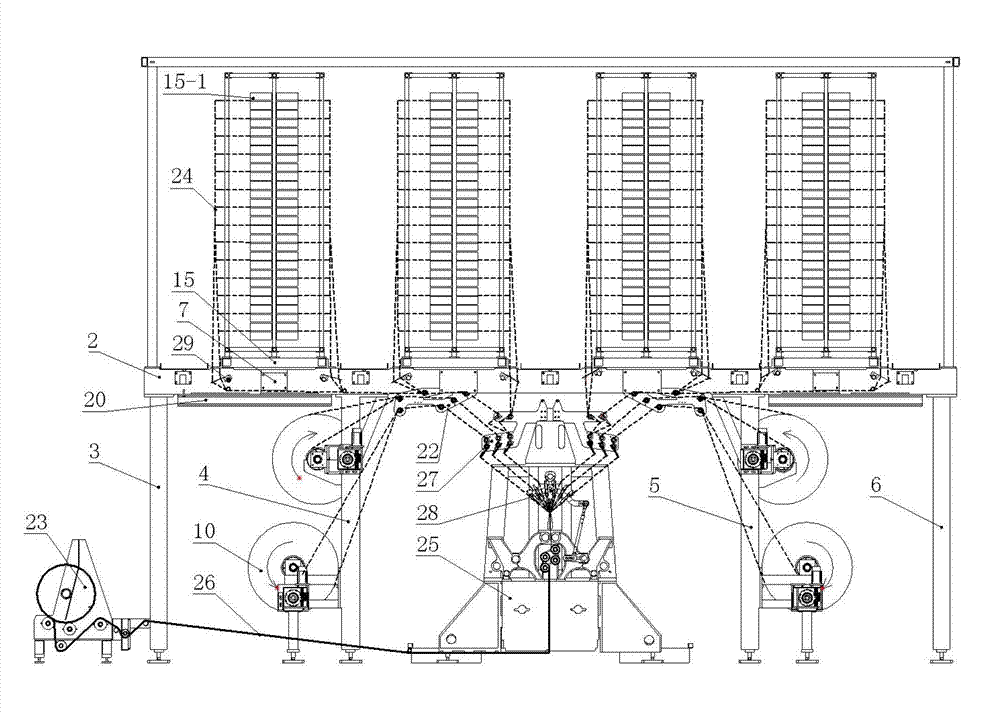

[0014] Such as figure 1 , 2 As shown in and 3, a let-off device of a warp knitting machine includes a creel let-off unit and a creel let-off unit, and the creel let-off unit is located above the creel let-off unit.

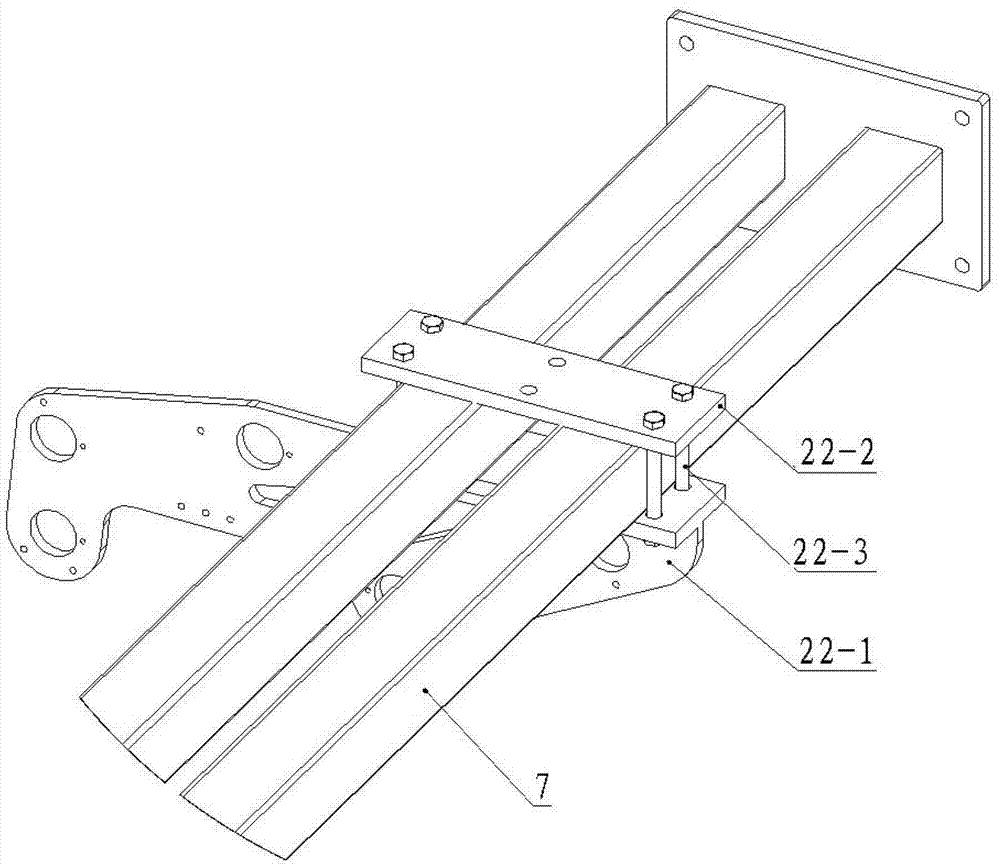

[0015] The beam frame let-off unit comprises a top bracket, a side bracket, a warp beam 9, a warp beam installation assembly and a yarn guide rod assembly 22, the top bracket is supported on the installation surface by the side bracket, and the warp beam 9 is installed on the side by the warp beam installation assembly. On the support, the yarn guide rod assembly 22 is installed on the top support, and the creel let-off unit includes at least one set of creel devices 15, and the creel device 15 is installed on the top support of the warp creel let-off unit, and the creel device 15 The bottom has a yarn dividing device 29, and the pan head 10 on the warp beam 9 sends yarn to the main frame 25 of the warp knitting machine through the yarn guide rod assembly 22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com