Usage of double-needle bed 3D (three-dimensional) wig-dedicated warp knitting machine

A warp knitting machine and double-needle bed technology, applied in wigs, warp knitting, application, etc., can solve the problems of low production efficiency and cumbersome wig preparation process, and achieve the effect of good elasticity, beautiful hair style and excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A special warp knitting machine for 3D wigs with double needle beds and a method for preparing a 35 cm wig headgear, the steps are as follows:

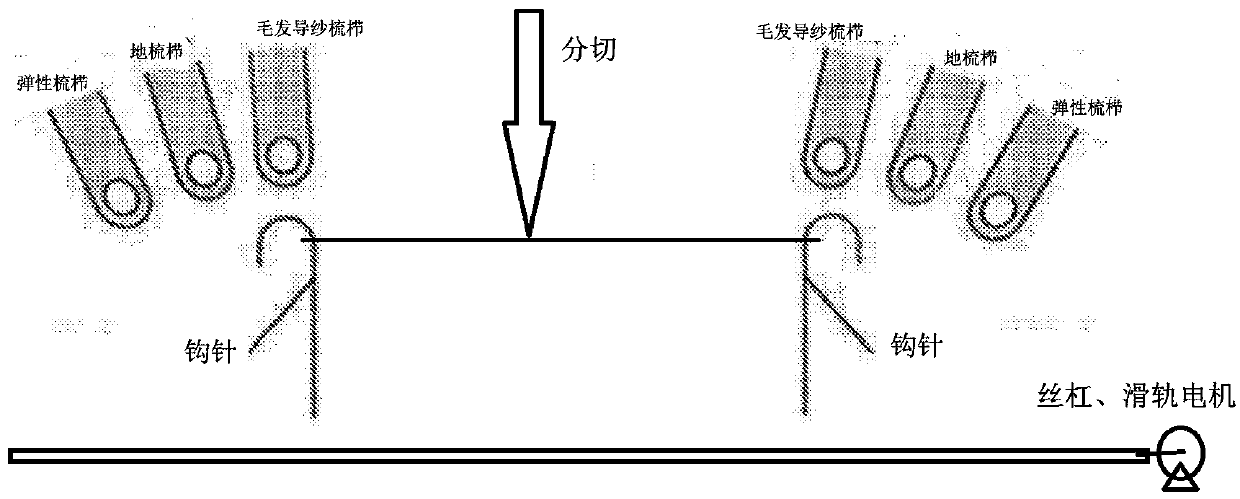

[0020] (1) On the warp knitting machine with double needle beds, thread the hair, ground yarn and elastic yarn into the hair guide bar, ground bar and elastic bar respectively;

[0021] (2) High-density stitches are used at the position that fits the wig's forehead, temples and the edge of the back of the head, and other parts are woven with low-density patterned structure base fabric;

[0022] (3) After the weaving of each row is completed, the length of each row of hair is cut by a fixed-length cutting device according to the design of each section of hair length to form a wig gray cloth, which is processed into a 3D wig in the subsequent process.

[0023] The let-off device of the warp knitting machine comprises a creel let-off unit and a creel let-off unit, and the creel let-off unit is located above the creel let-off unit;...

Embodiment 2

[0029] A special warp knitting machine for 3D wigs with double needle beds and a method for preparing a 45 cm wig headgear, the steps are as follows:

[0030] (1) On the warp knitting machine with double needle beds, thread the hair, ground yarn and elastic yarn into the hair guide bar, ground bar and elastic bar respectively;

[0031] (2) High-density stitches are used at the position that fits the wig's forehead, temples and the edge of the back of the head, and other parts are woven with low-density patterned structure base fabric;

[0032] (3) After the weaving of each row is completed, the length of each row of hair is cut by a fixed-length cutting device according to the design of each section of hair length to form a wig gray cloth, which is processed into a 3D wig in the subsequent process.

[0033] The let-off device of the warp knitting machine comprises a creel let-off unit and a creel let-off unit, and the creel let-off unit is located above the creel let-off unit;...

Embodiment 3

[0039] A special warp knitting machine for double-needle bed 3D wigs to prepare 3 cm false eyebrows, the steps are as follows:

[0040] (1) On the warp knitting machine with double needle beds, thread the hair, ground yarn and elastic yarn into the hair guide bar, ground bar and elastic bar respectively;

[0041] (2) High-density stitching is used at the position that fits the eyebrow peak, eyebrow tip and the edge of the eyebrow, and other parts are woven with low-density pattern structure base fabric;

[0042] (3) After each row of weaving is completed, the fixed-length cutting device is used to cut the length of each row of hair to form eyebrow fabric, which can be processed into 3D eyebrows in the subsequent process.

[0043] The let-off device of the warp knitting machine includes a creel let-off unit and a creel let-off unit, and the creel let-off unit is located above the warp creel let-off unit; the eyebrow let-off device includes a wig creel let-off unit and an eyebro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com