Patents

Literature

89results about How to "Reduce floor space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

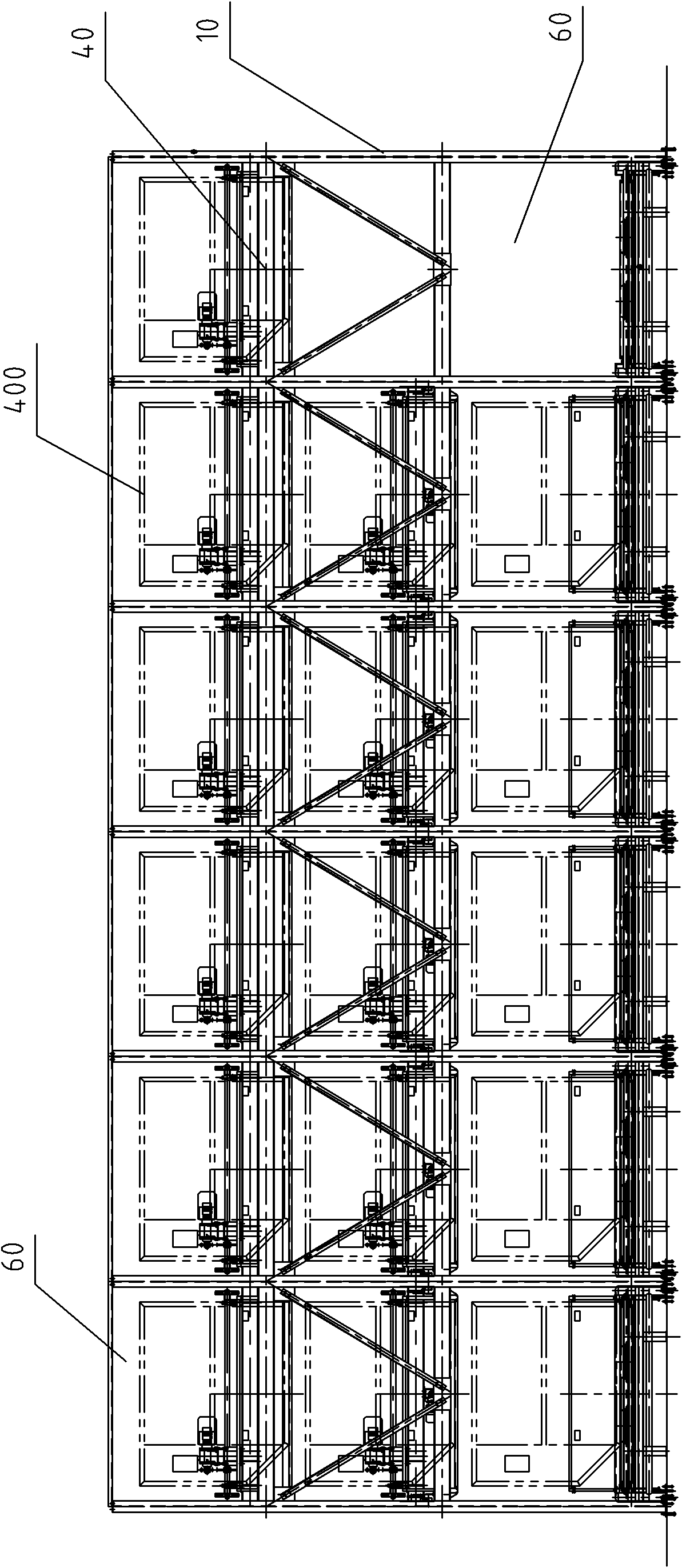

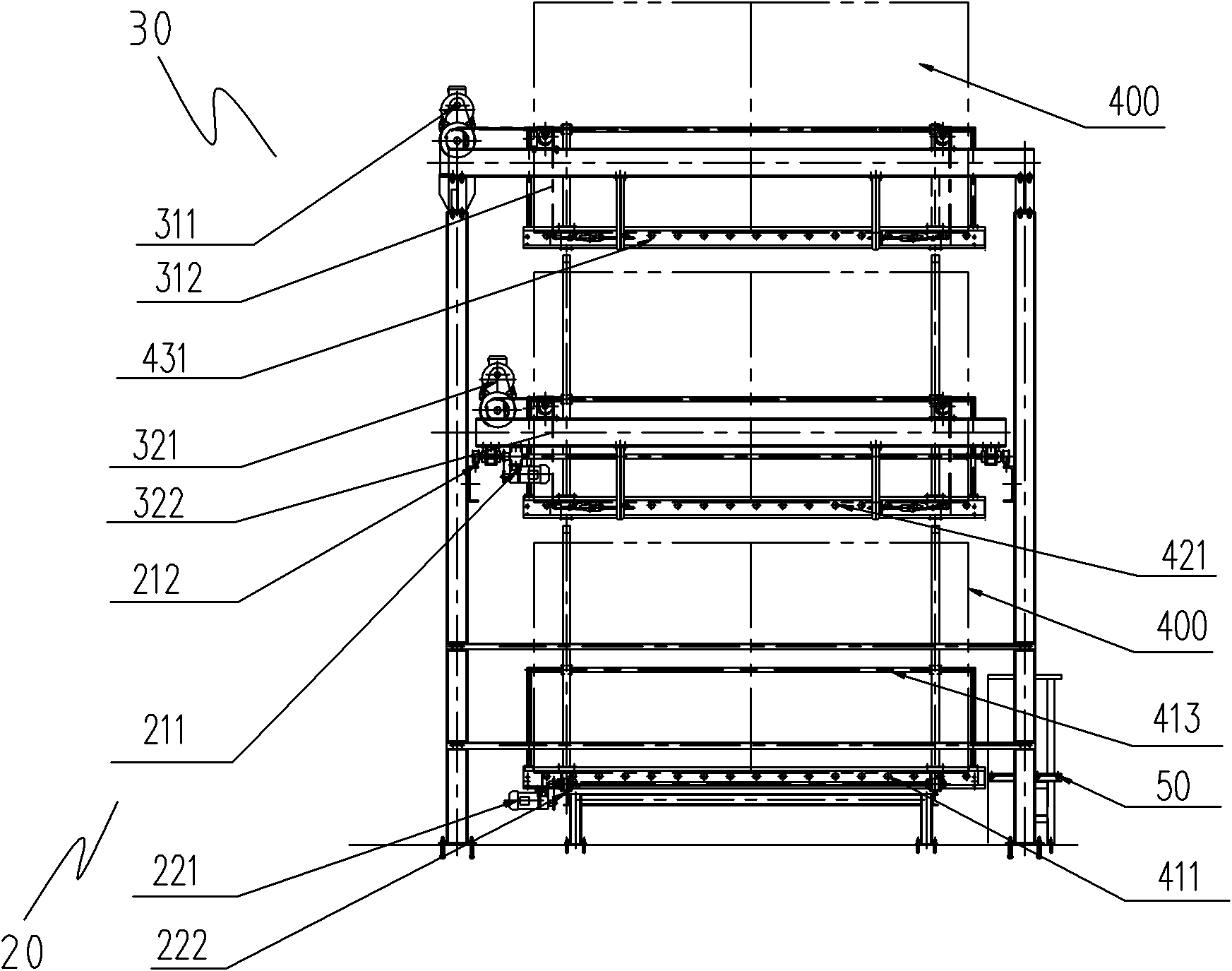

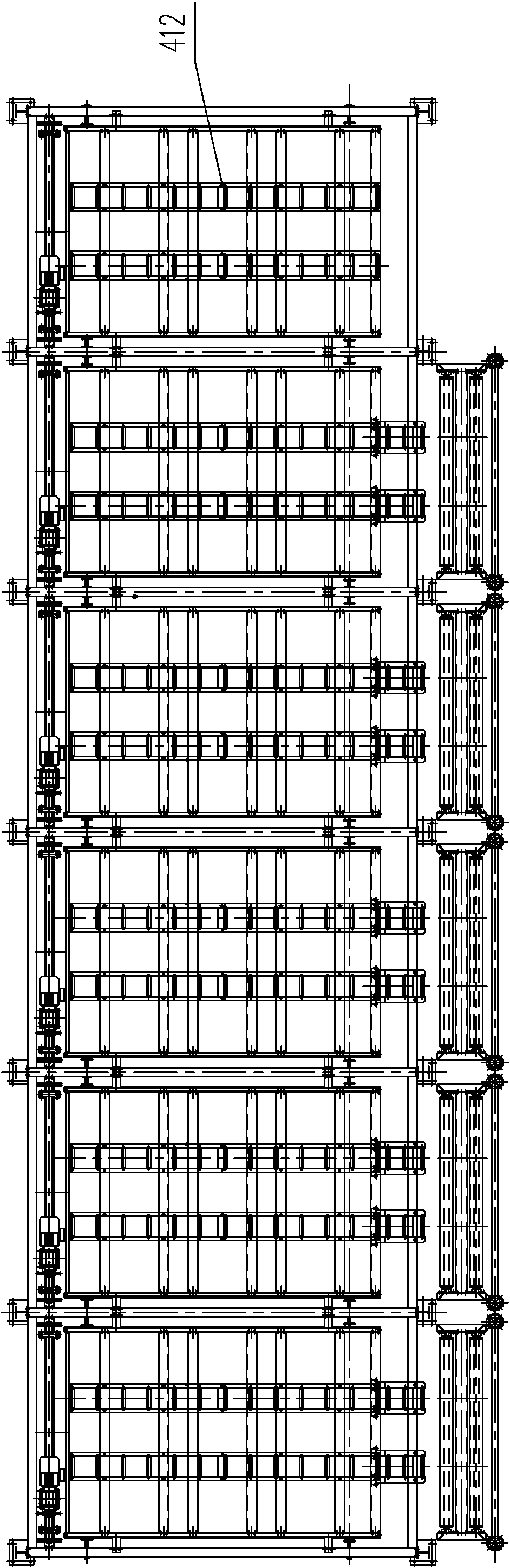

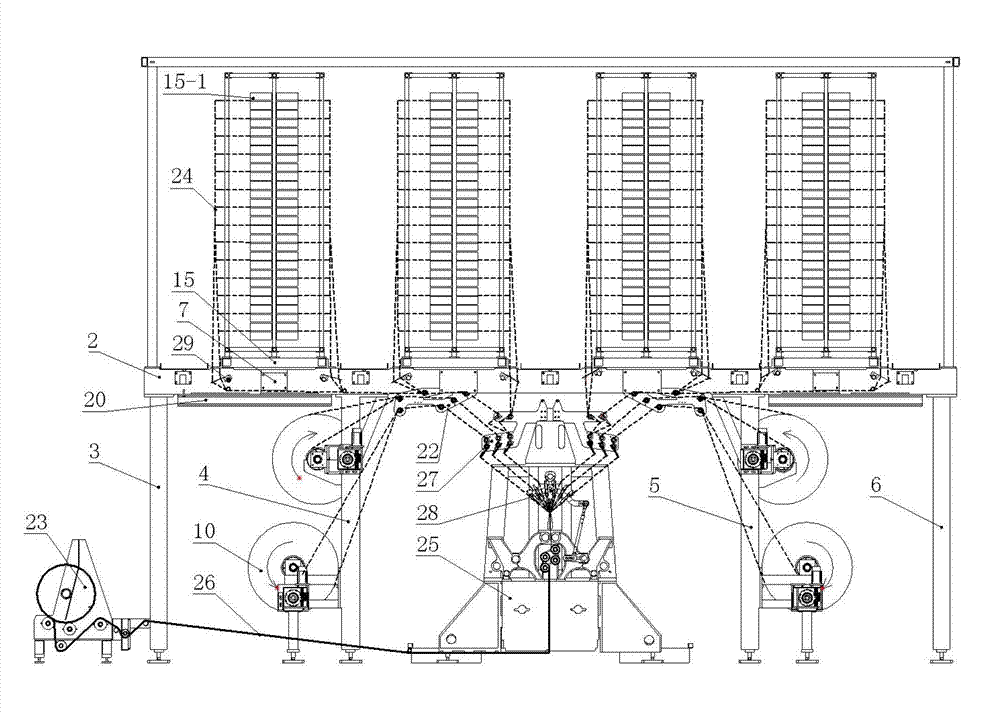

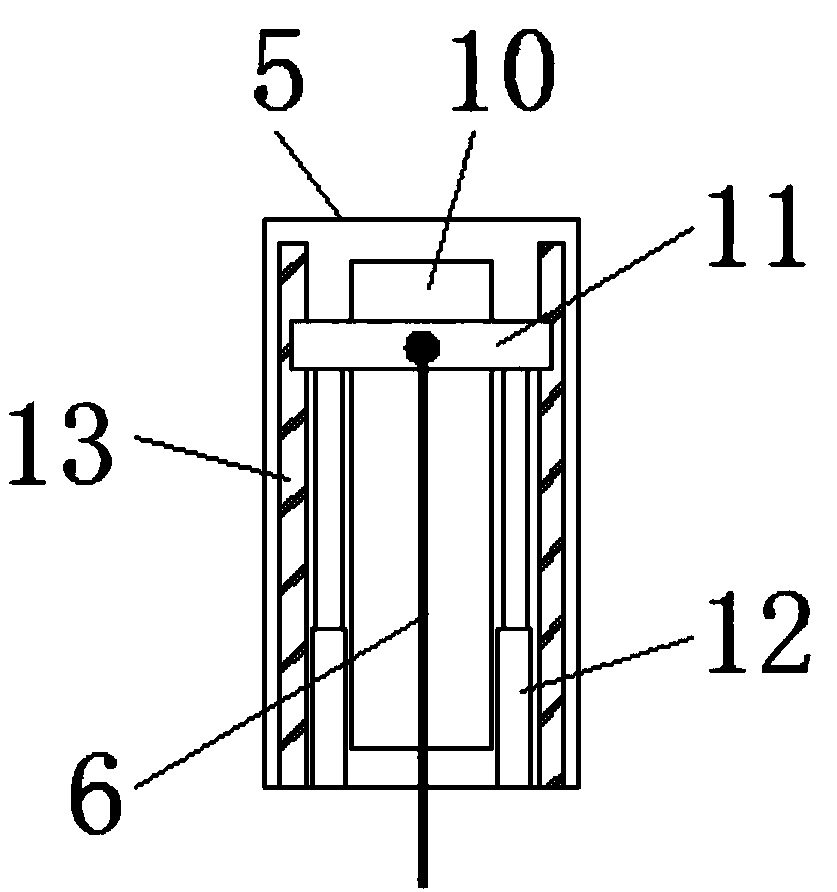

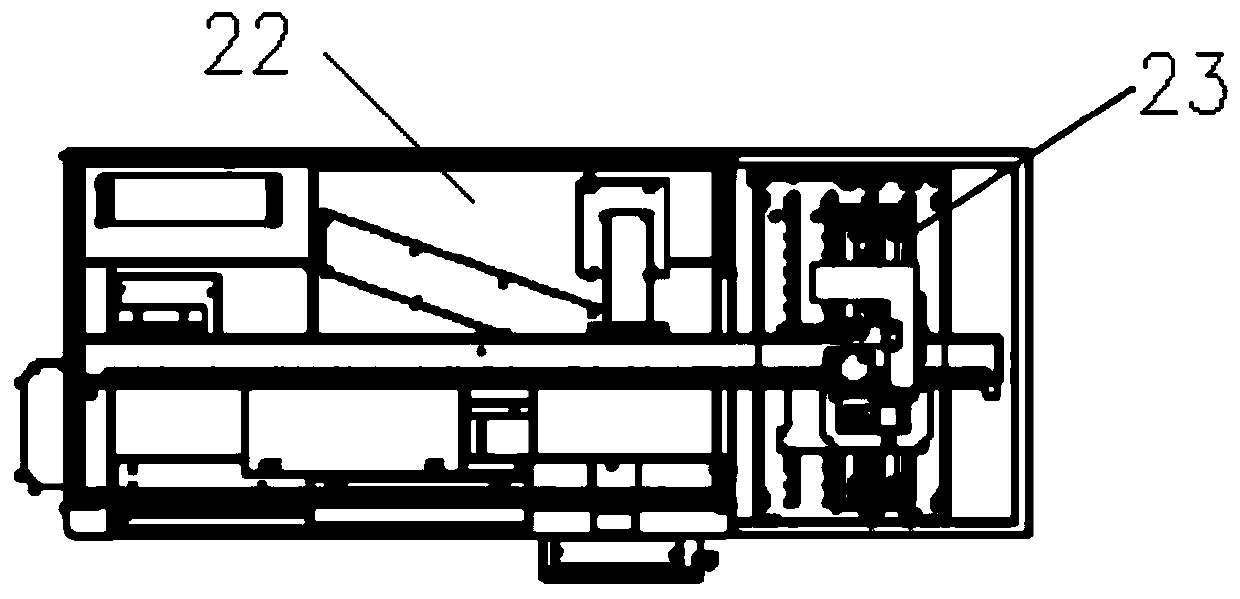

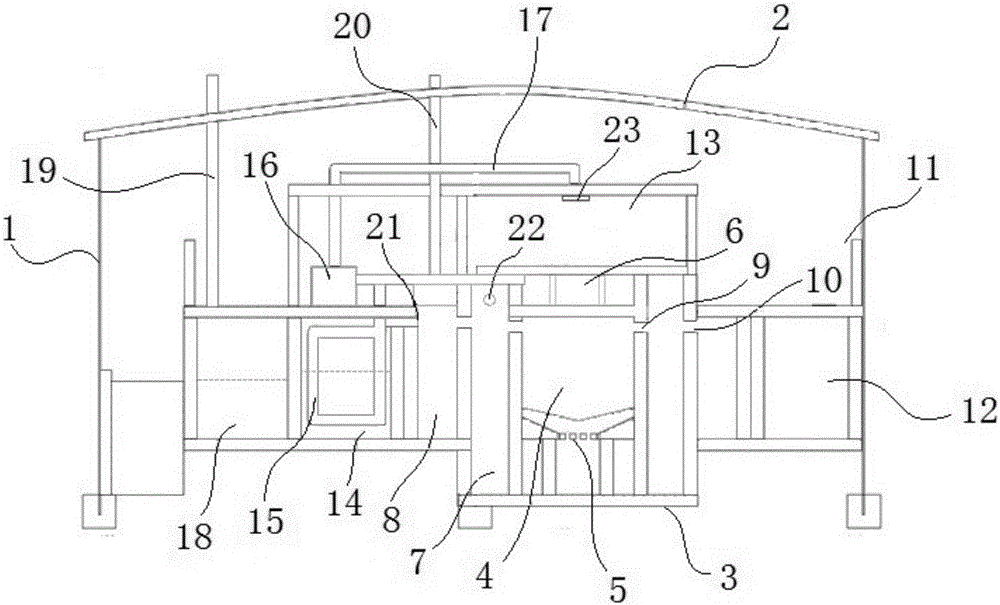

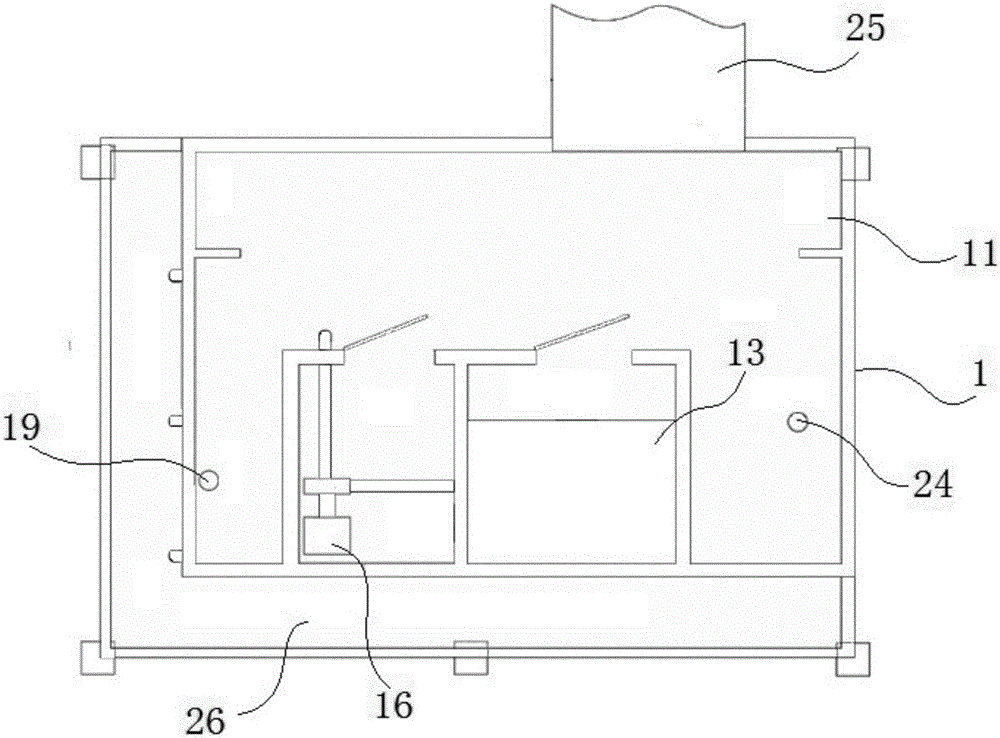

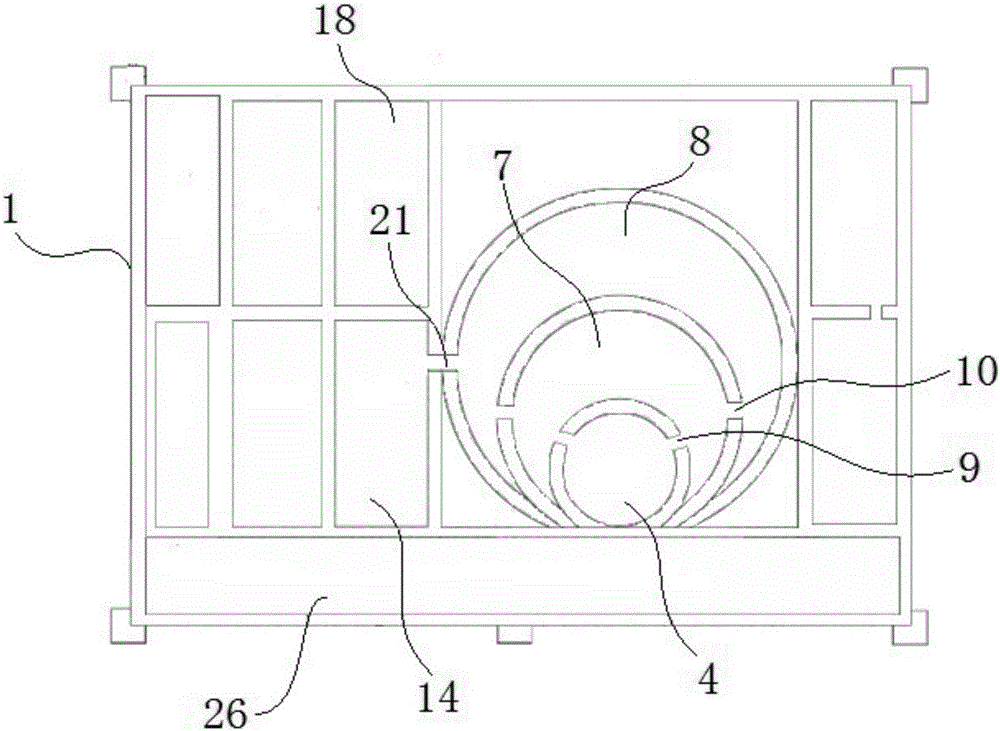

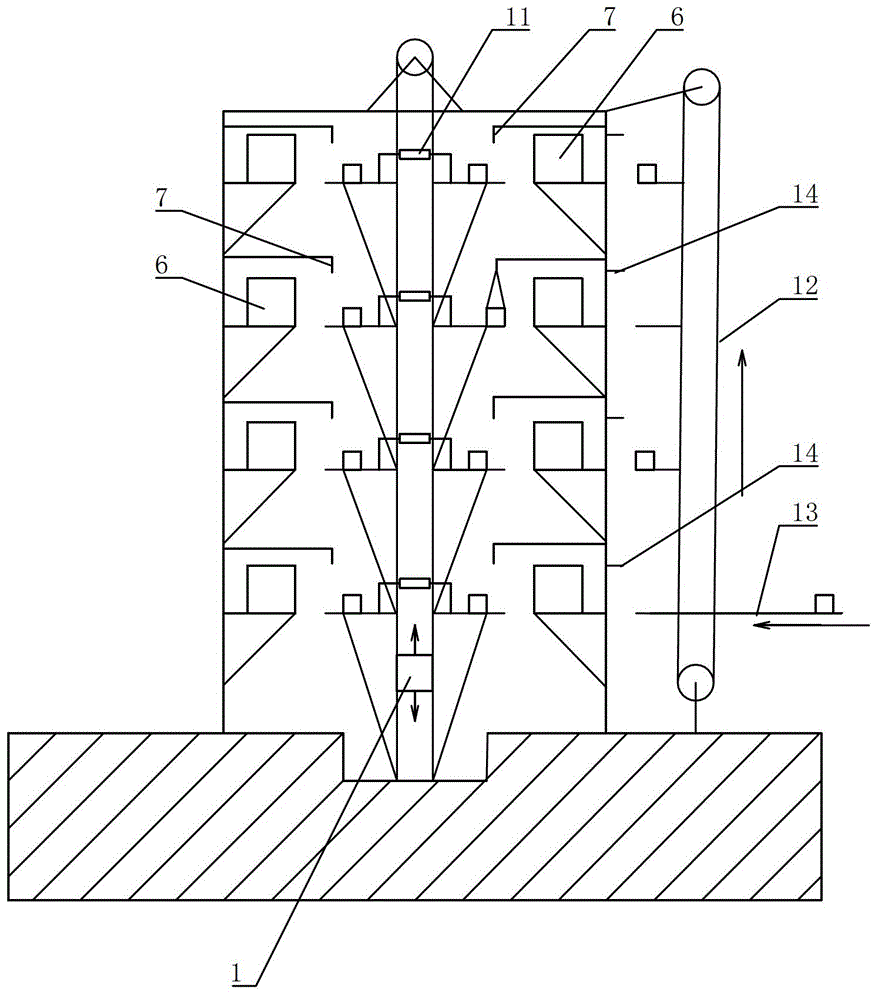

Automatic storage equipment, storage system and loading and unloading control method for air container

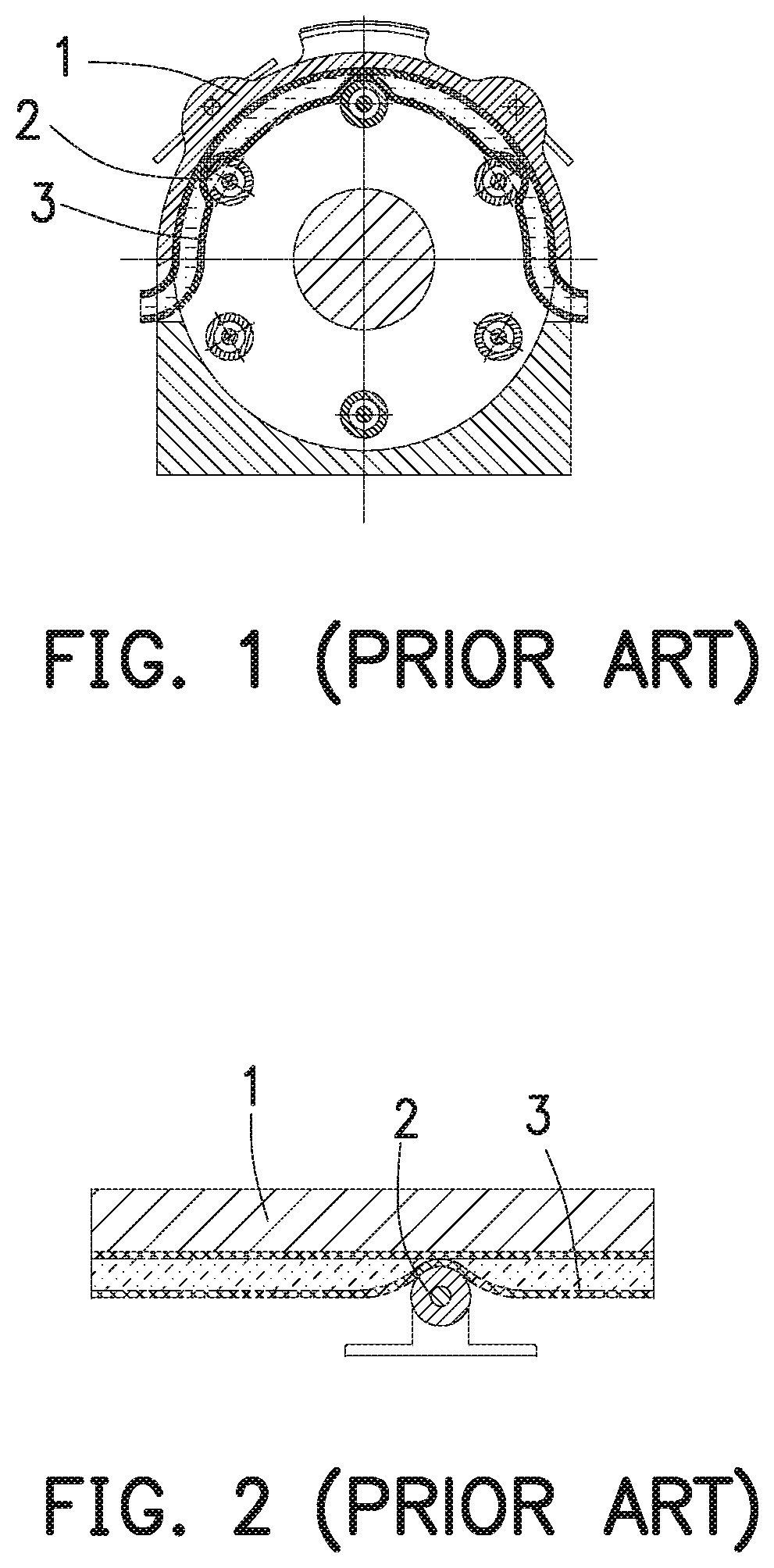

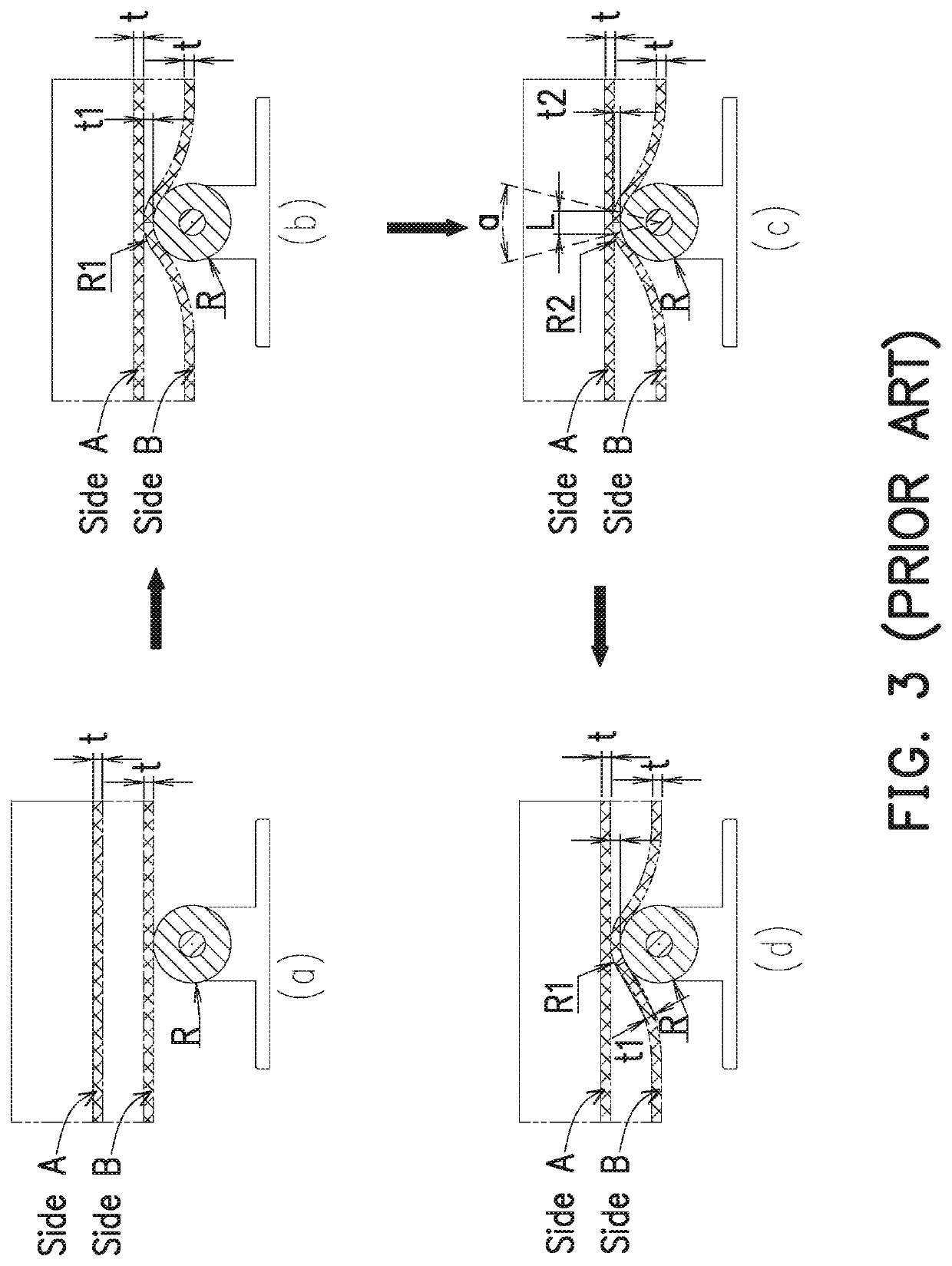

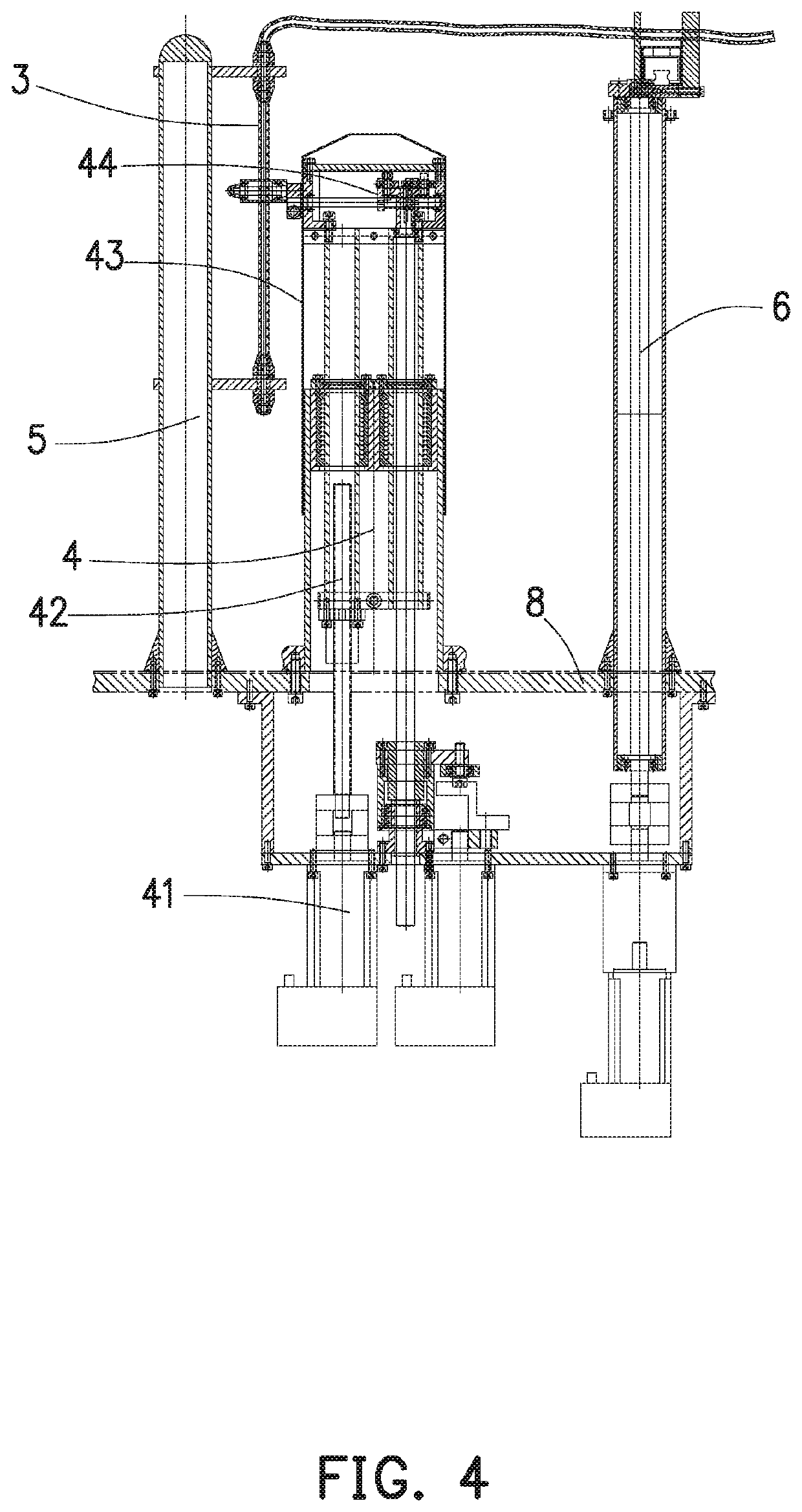

ActiveCN102040070AEasy accessReduce floor spaceStorage devicesAutomatic test equipmentLand resources

The invention relates to automatic storage equipment, an automatic storage system, a loading control method and an unloading control method for an air container. The storage equipment comprises a warehouse, a traversing mechanism and an elevating device, wherein a plurality of storage working positions which are distributed in lines and rows at intervals in the height direction are formed in the warehouse; a movable bracket platform is arranged at each storage working position; the traversing mechanism drives the bracket platform to move in the horizontal direction; and the elevating device drives the bracket platform to ascend and descend in the vertical direction. Through the automatic storage equipment, the automatic storage system, the loading control method and the unloading control method, containers can be stored and taken conveniently, management efficiency and level are improved, a good operating image of airport apron equipment is built, the floor area of the containers is reduced, container storage floor area ratio is increased, land resources are saved, other using machine tools are saved and the working intensity of production personnel is lowered.

Owner:CHINA IPPR INT ENG +1

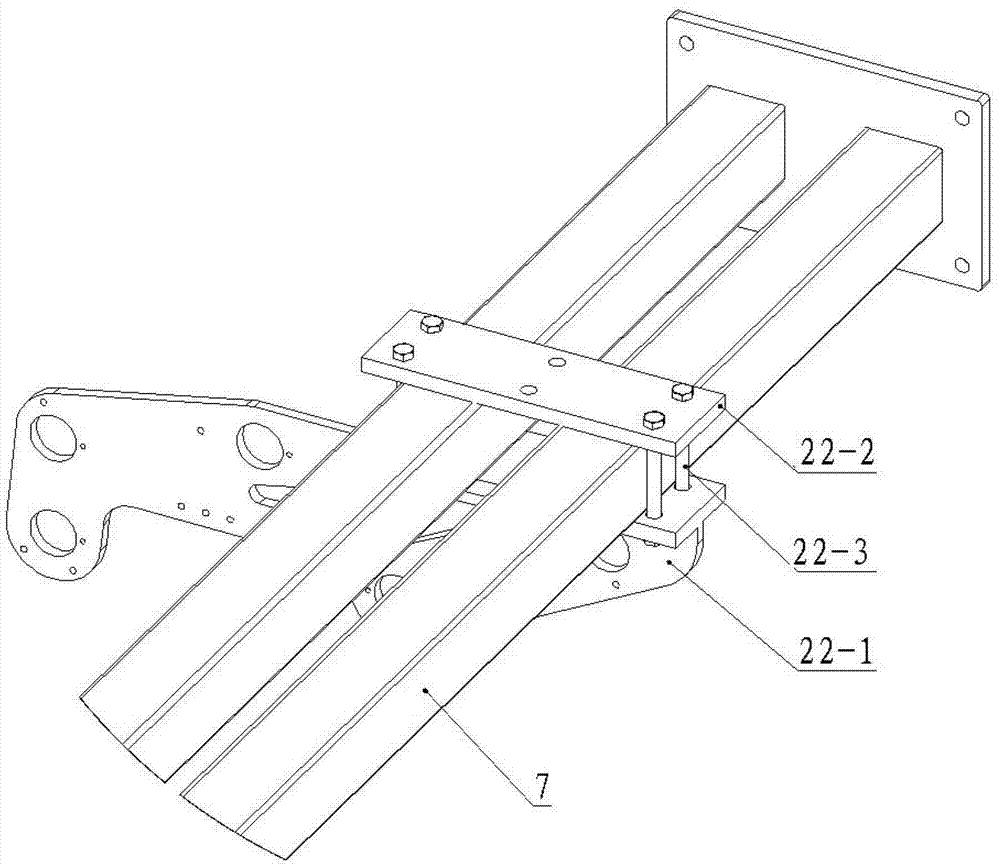

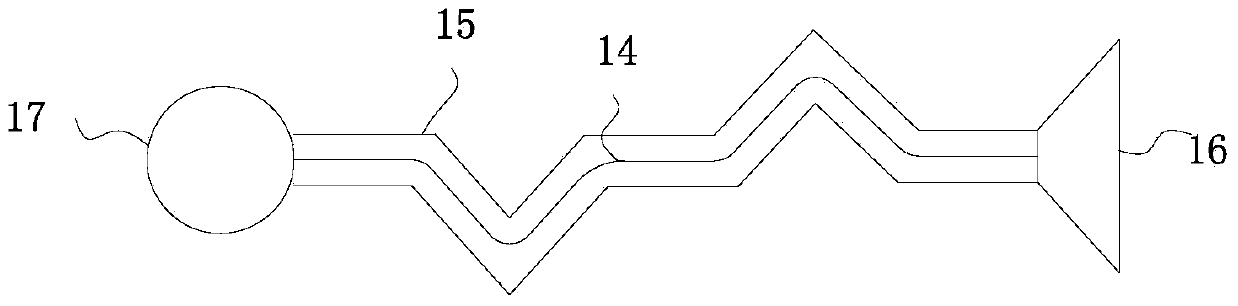

Let-off device of warp knitting machine

InactiveCN103243474AMeet weaving requirementsTake advantage ofWarp knittingTextile manufacturingBobbin

The invention relates to a textile manufacturing machine, in particular to a let-off device of a warp knitting machine. The let-off device comprises a creel let-off unit and a beam creel let-off unit. The creel let-off unit is located above the beam creel let-off unit. A top support of the beam creel let-off unit is supported on a mounting face through side supports. A beam is mounted on the side supports through a beam mounting component. A guide rod component is mounted on the top support. The creel let-off unit comprises at least one creel set mounted on the top support of the beam creel let-off unit. A pan head on the beam and a bobbin on the creel device are let off yarns to the warp knitting machine through the guide rod component. The let-off device has the advantages that the different requirements on let-off amount and tension are met, the whole warp knitting machine is compact in structure, space is fully utilized, plane area is reduced, let-off length is shortened, and yarn breakage caused by the fact that the excessive let-off length makes tension difficult to control is avoided effectively.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

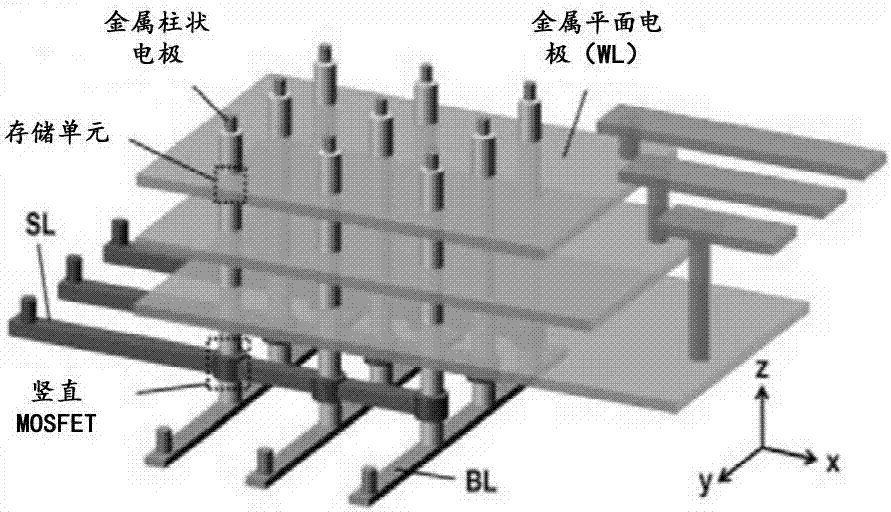

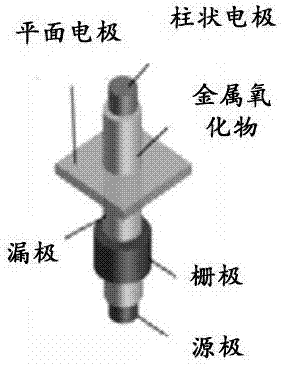

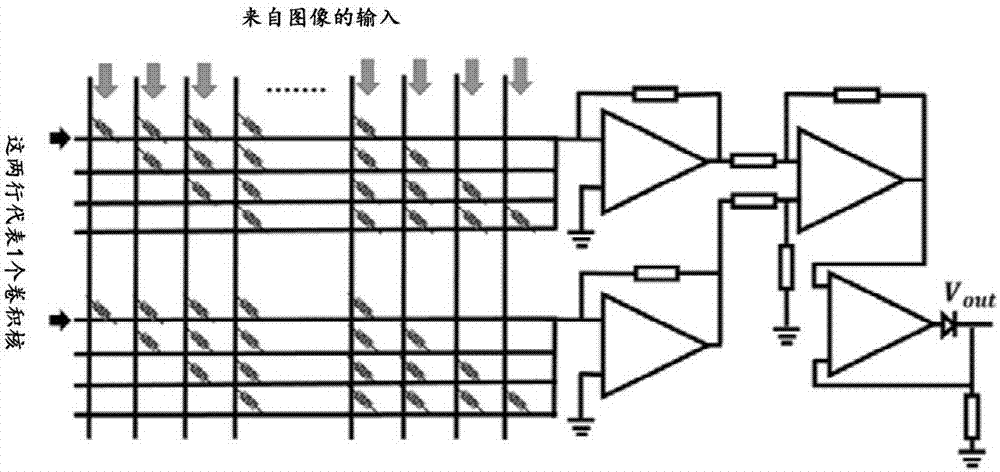

Convolution, pooling and activation circuit based on resistive random access memory (RRAM) three-dimensional intersection array

ActiveCN107368889AReduce floor spaceReduce power consumptionDigital storagePhysical realisationElectricityStatic random-access memory

The invention discloses a convolution, pooling and activation circuit based on a resistive random access memory (RRAM) three-dimensional intersection array, and the circuit comprises a convolution level which comprises the RRAM three-dimensional intersection array; a layer pooling level which comprises N layer pooling level input ends, a layer summation circuit and a layer pooling level output end, wherein the N layer pooling level input ends are connected to N layer convolution sum output ends at the same horizontal layer, and the layer summation circuit carries out the summation of the N layer convolution sums, and enables the summation result to serve as a pooling result and to be outputted to the layer pooling level output; a layer activation level which comprises a layer activation level input end, a layer comparison circuit and a layer activation level output end, wherein the layer activation level input end is connected to the layer pooling level output end, and the layer comparison circuit carries out the comparison of the pooling result and a reference level: outputs the pooling result when the pooling result is greater than the reference level, or else outputs a zero level. The circuit can reduce the power consumption, and reduce the plane occupied area of the circuit.

Owner:PEKING UNIV

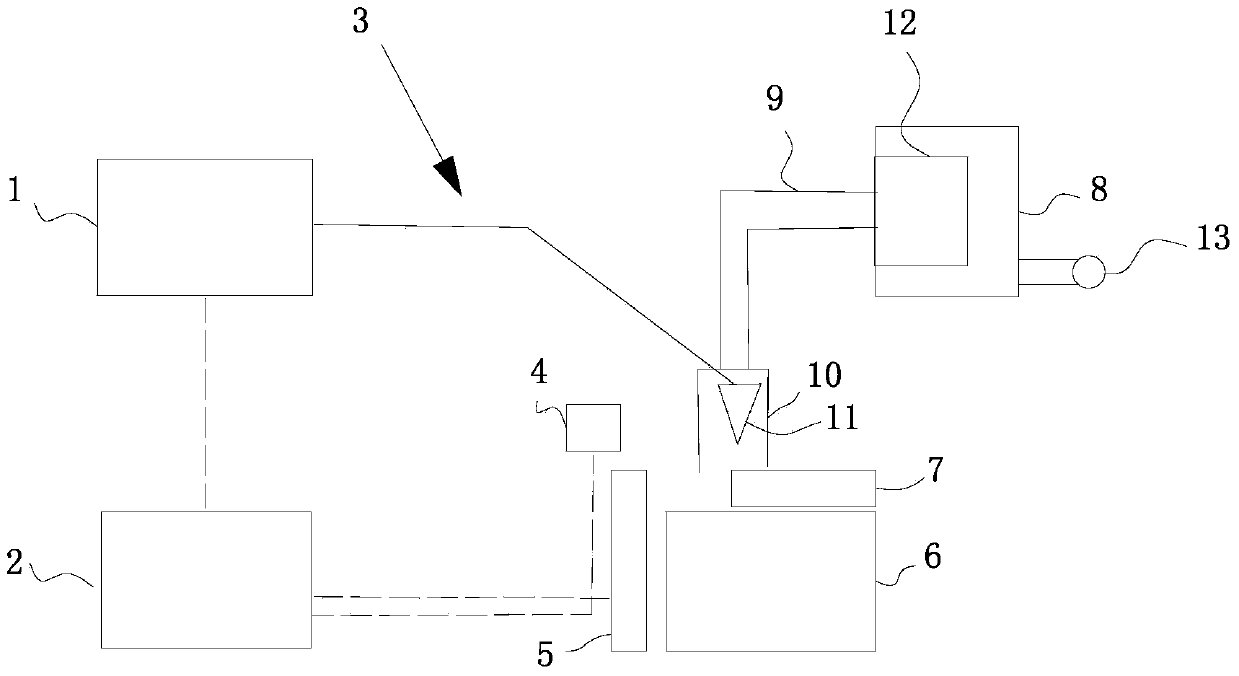

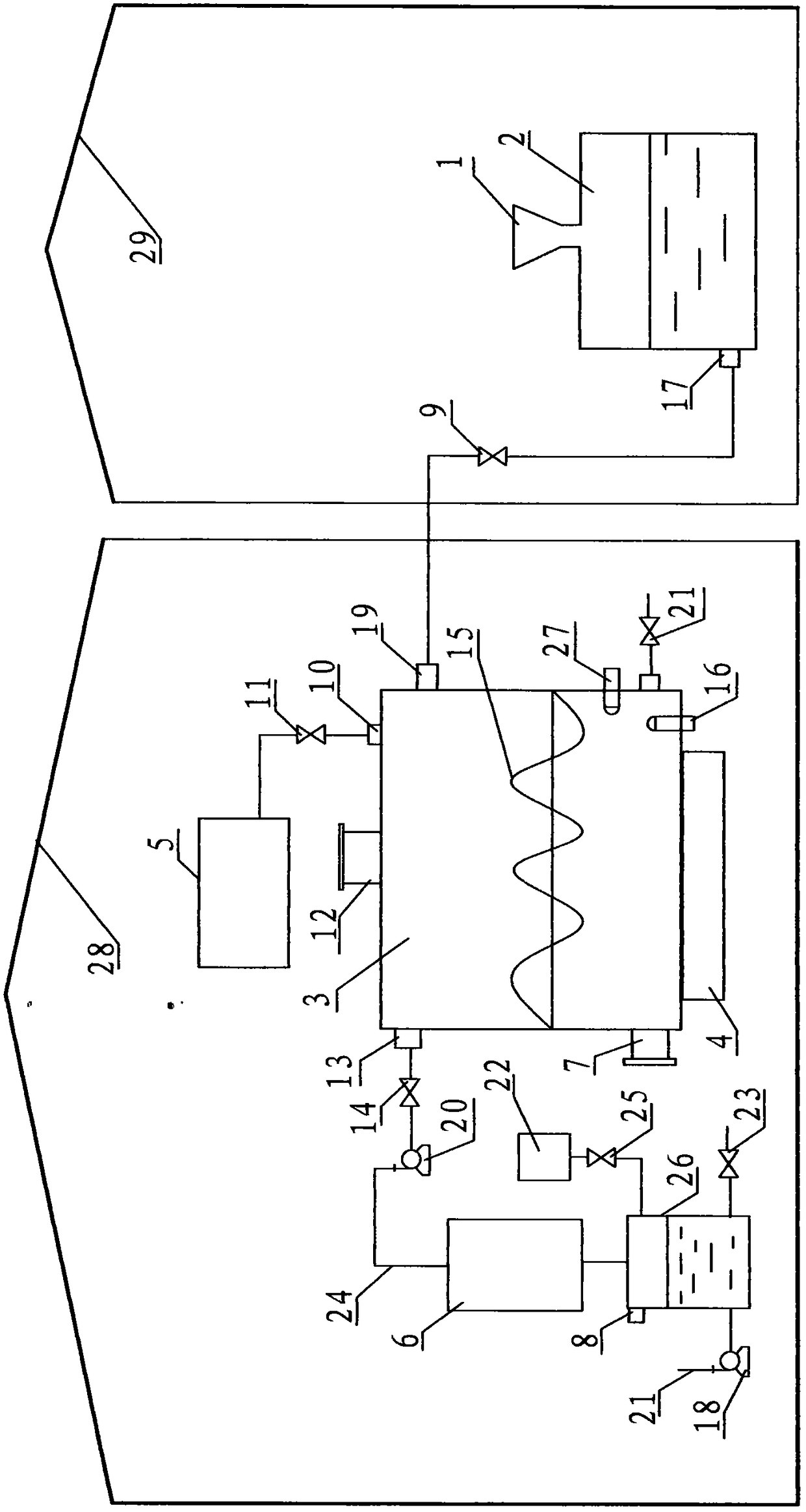

Laser cleaning system for removing nuclear power station radioactive contamination

ActiveCN103736693ARealize remote automation operationReduce the risk of being irradiatedCleaning processes and apparatusNuclear powerControl system

The invention relates to a laser cleaning system for removing nuclear power station radioactive contamination. The laser cleaning system comprises a laser generator, a laser transmitting device, a working monitoring system, a controlling system and a waste recycling system, the laser transmitting device is connected with a laser output port of the laser generator, the working monitoring system is arranged nearby target materials, the laser transmitting device comprises optical fibers, a mover, mechanical arms and an operating device, the optical fibers are connected with the laser output port of the laser generator and used for transmitting laser lights, the mover is used for moving laser output ports of the optical fibers onto the surfaces of radioactive contaminants, the operating device is arranged on the mechanical arms, the optical fibers are fixedly disposed in the mover, the laser output ports of the optical fibers are located at one end of the mover, one end of the mover is suspended in the air, the other end of the mover is installed on the mechanical arms, the operating device is used for controlling the mechanical arms and the mover to move, and the movement of the mover drives the laser output ports of the optical fibers to move.

Owner:SUZHOU NUCLEAR POWER RES INST +1

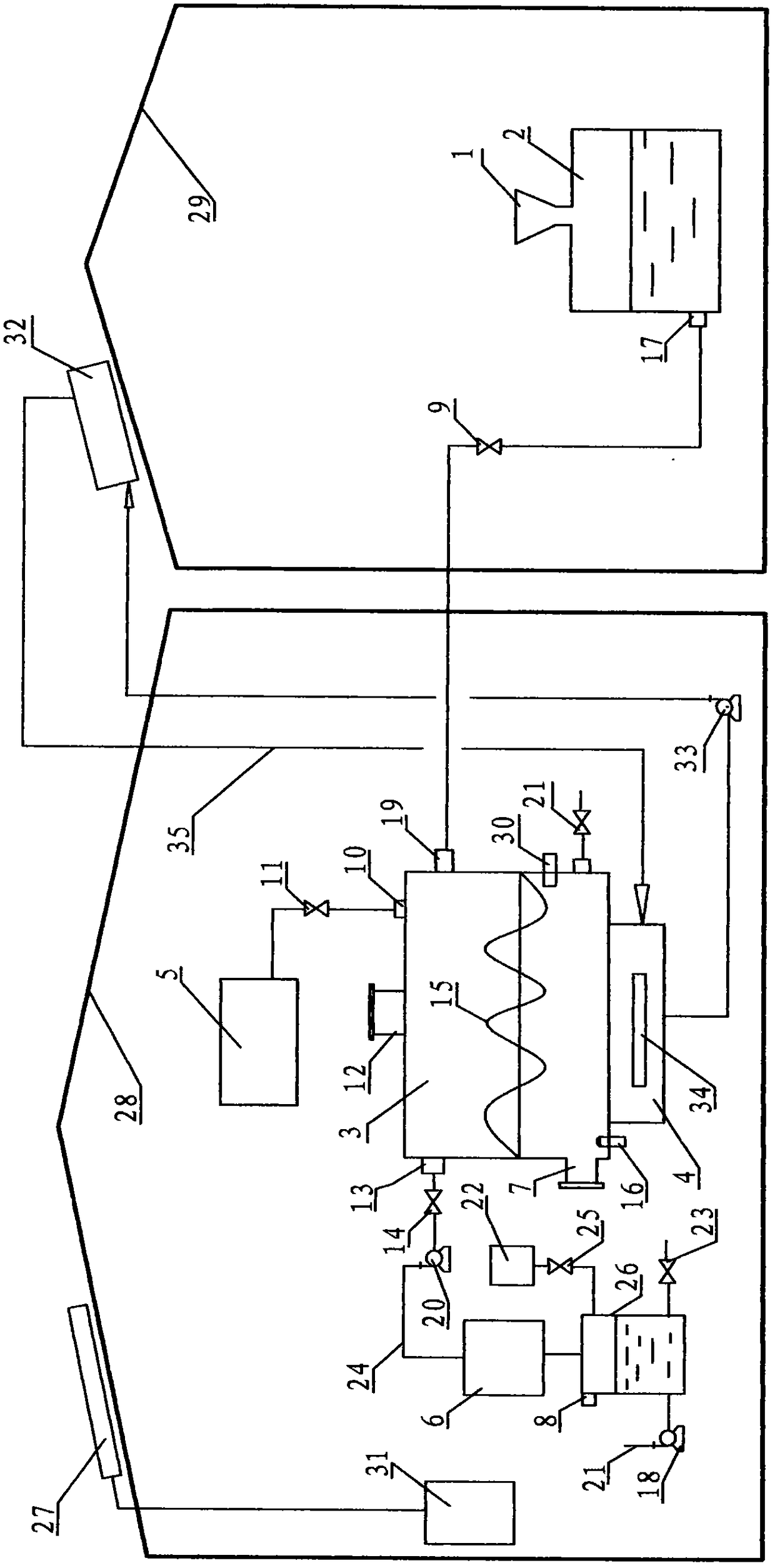

Solar ecological toilet realizing standard emission

The invention relates to a solar ecological toilet realizing standard emission. The solar ecological toilet is mainly composed of a squatting pan, an excrement collecting box, fermentation equipment provided with an interlayer heating chamber on the outer layer, vacuum equipment, a gas-water purifying tank, a vacuum adjusting valve, a moisture tester, a temperature detector, an electric heater, awater pump, a draught fan, a gas adjusting valve, a disinfectant box, a solvent pump, a gas-water separating tank, a solar cell panel, an excrement-purification standard treatment room, a toilet room,a solar photovoltaic power generation device and a solar heat collector heat-absorbing plate. The solar ecological toilet aims to utilize solar energy to conduct on-site standard emission on gas andwater after toilet urine and excrement are treated on site, and the excrement becomes organic fertilizer products.

Owner:周鼎力

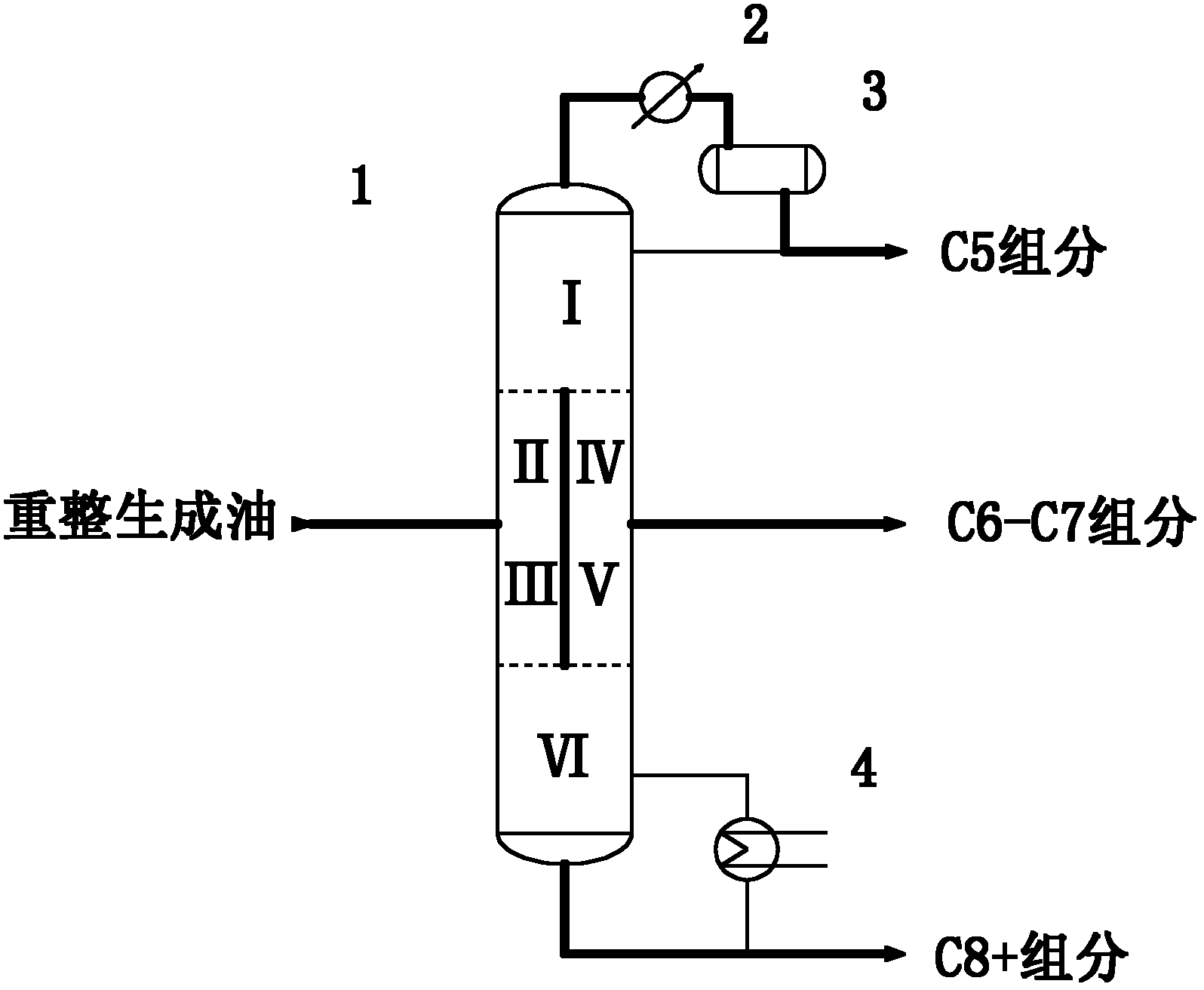

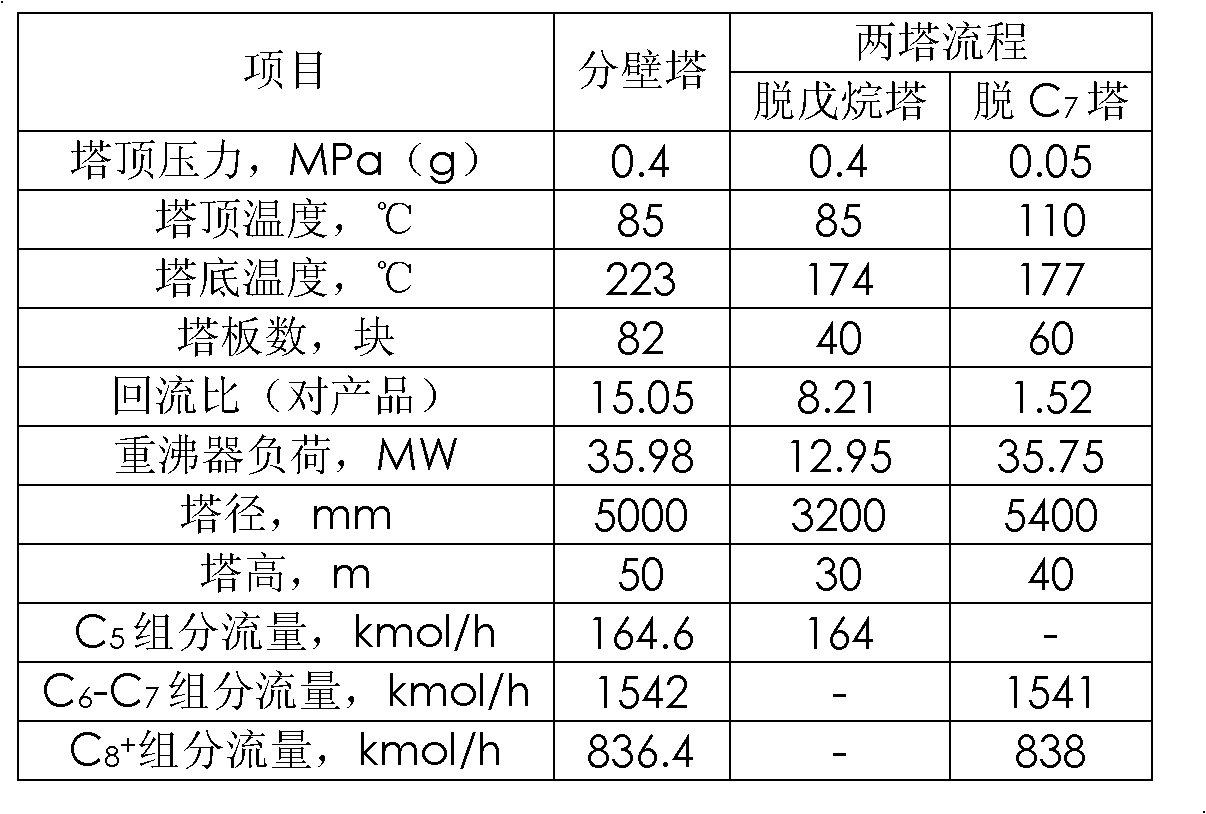

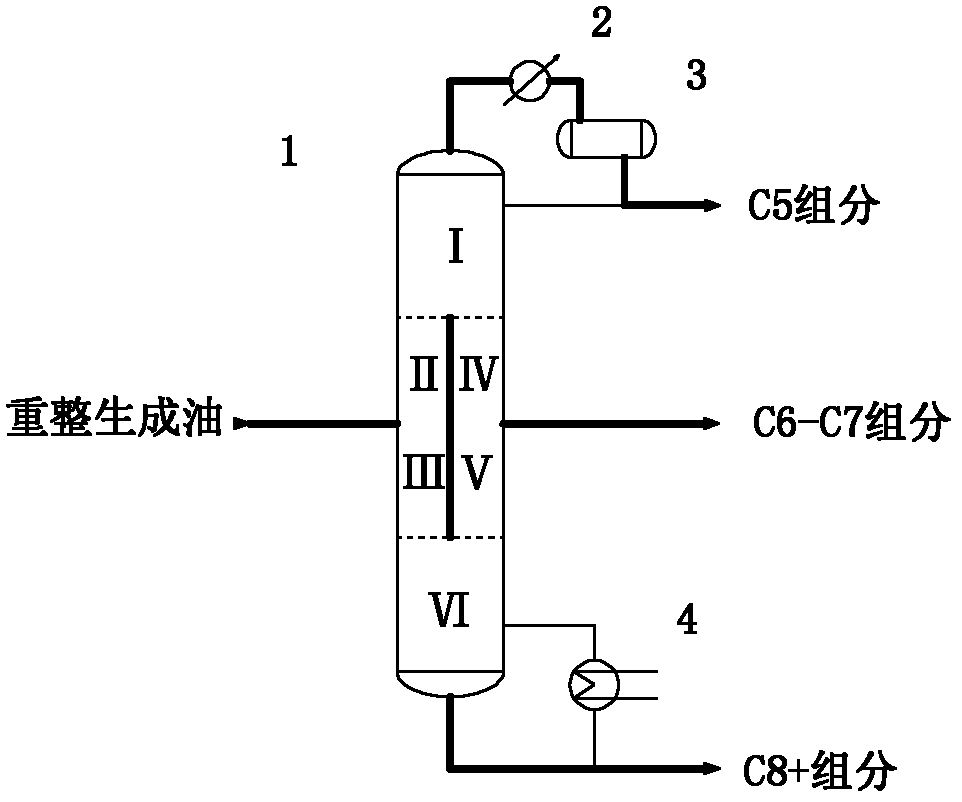

Equipment and method for separating reformed oil

ActiveCN102206504AReduce the number of devicesLow investment costHydrocarbon distillationEngineeringEnergy consumption

The invention relates to equipment and a method for separating reformed oil. The method comprises the following steps of: separating three components, namely C5, C6-C7 and C8<+> in the reformed oil by using a bulkhead rectification column; adding the reformed oil prepared in a reforming device from a rectifying section of a feeding part and the middle part of a stripping section of the feeding part into the bulkhead rectification column; cooling the C5 component on the top of the column by using a condenser, and adding the cooled C5 component into a reflux tank, wherein a liquid phase at the bottom of the reflux tank is partially used as a C5 component product, and the rest liquid phase is used as back flow and flows back to a shared rectifying section on the upper part of the bulkhead rectification column; performing gas-phase side-line extraction on the C6-C7 component from a rectifying section of an extraction part of a side line product and the middle plate of a stripping section on the extraction part of the side line product; and performing condensation cooling and then feeding to an aromatics extraction device, wherein the C8<+> component is arranged at the bottom of the column. The feeding pressure is 0.5MPa (g), the operation pressure of the bulkhead rectification column is 0.4MPa (g), the energy consumption is low, the purity of the C6-C7 component can reach 99.7 percent, floor space is reduced by 40 percent, and the total investment on the equipment is saved by 20 percent.

Owner:PETROCHINA CO LTD +1

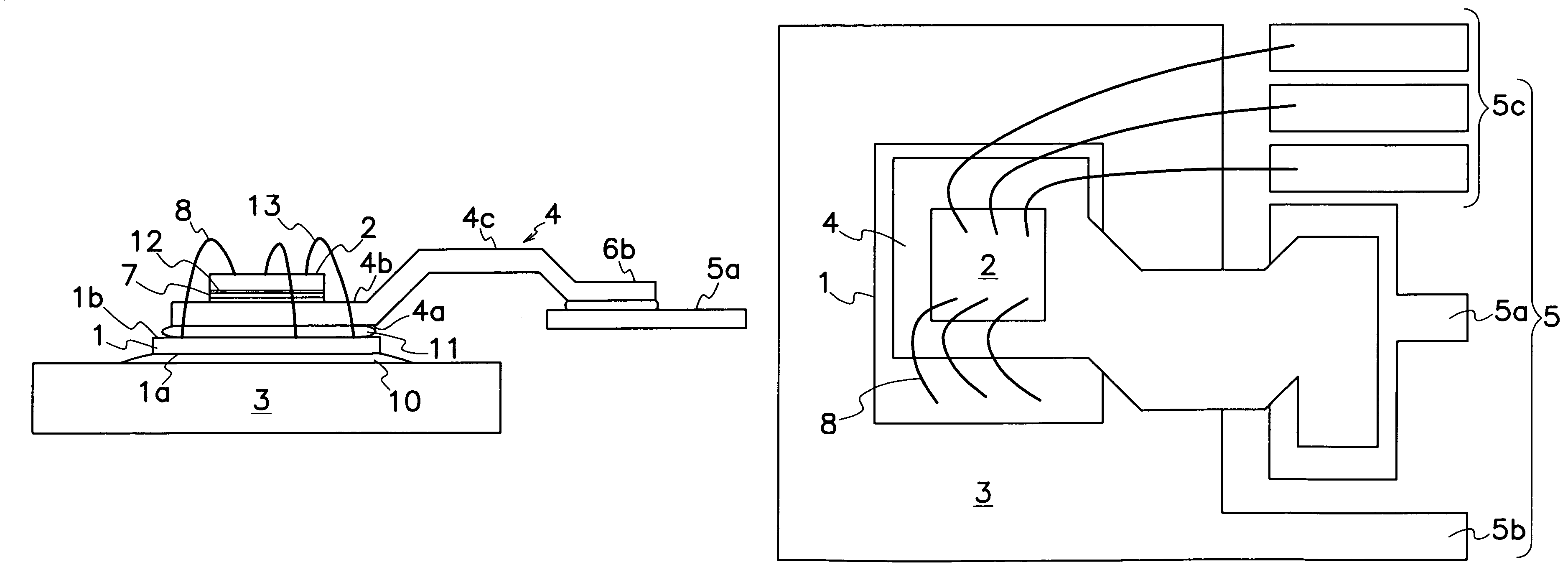

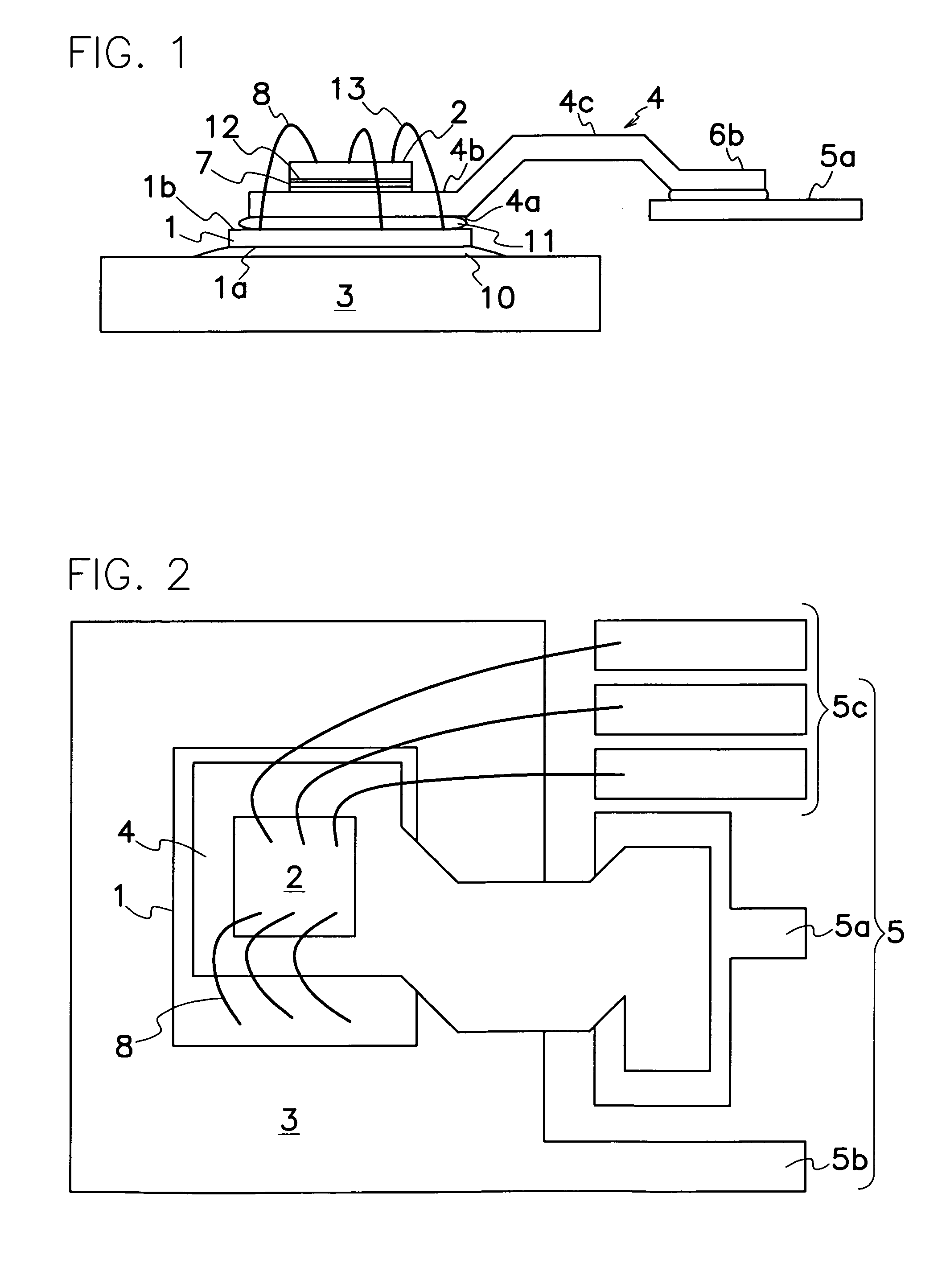

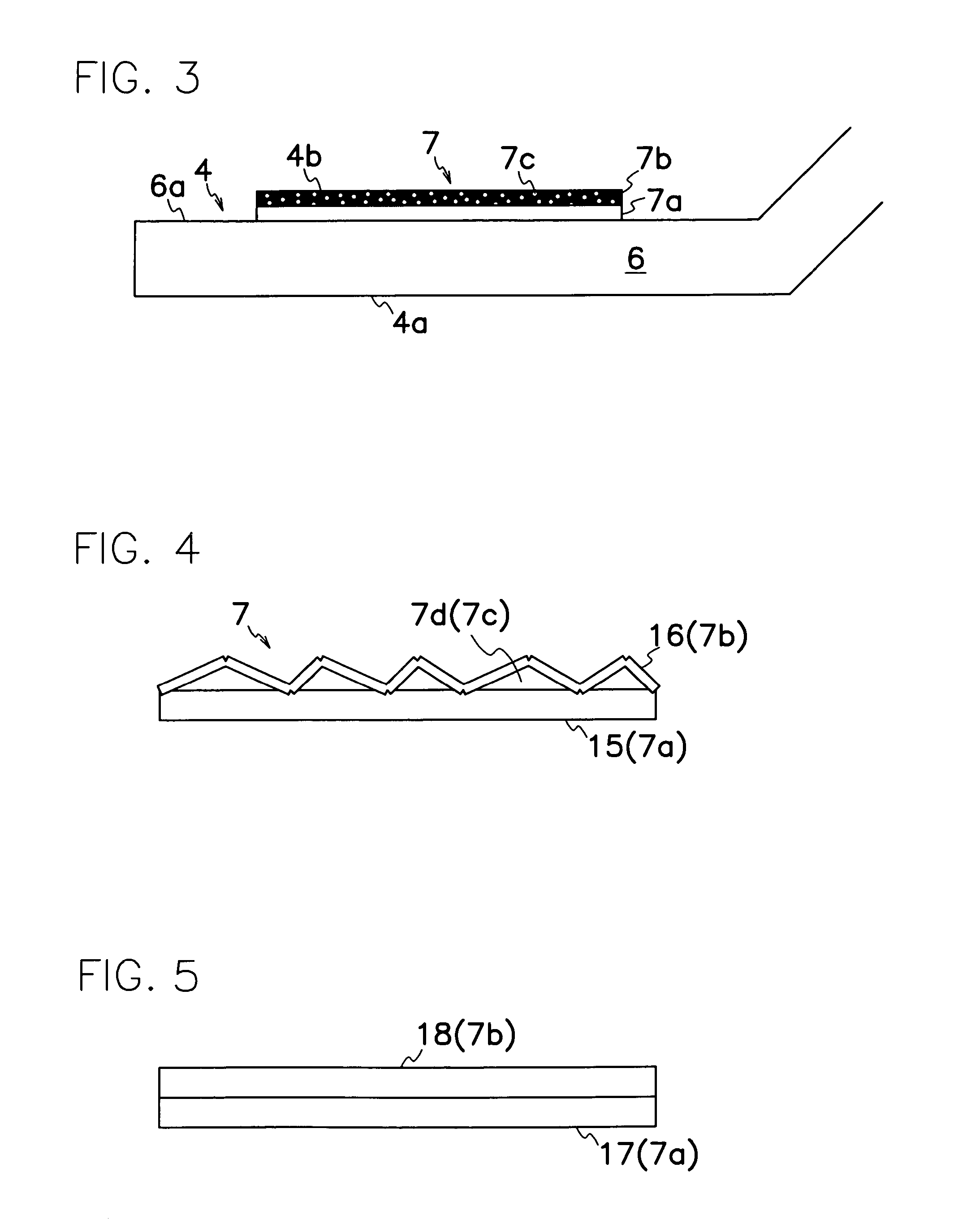

Semiconductor device

InactiveUS7382000B2Small and narrowed plane sizeReduce floor spaceSemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal radiation

Owner:SANKEN ELECTRIC CO LTD

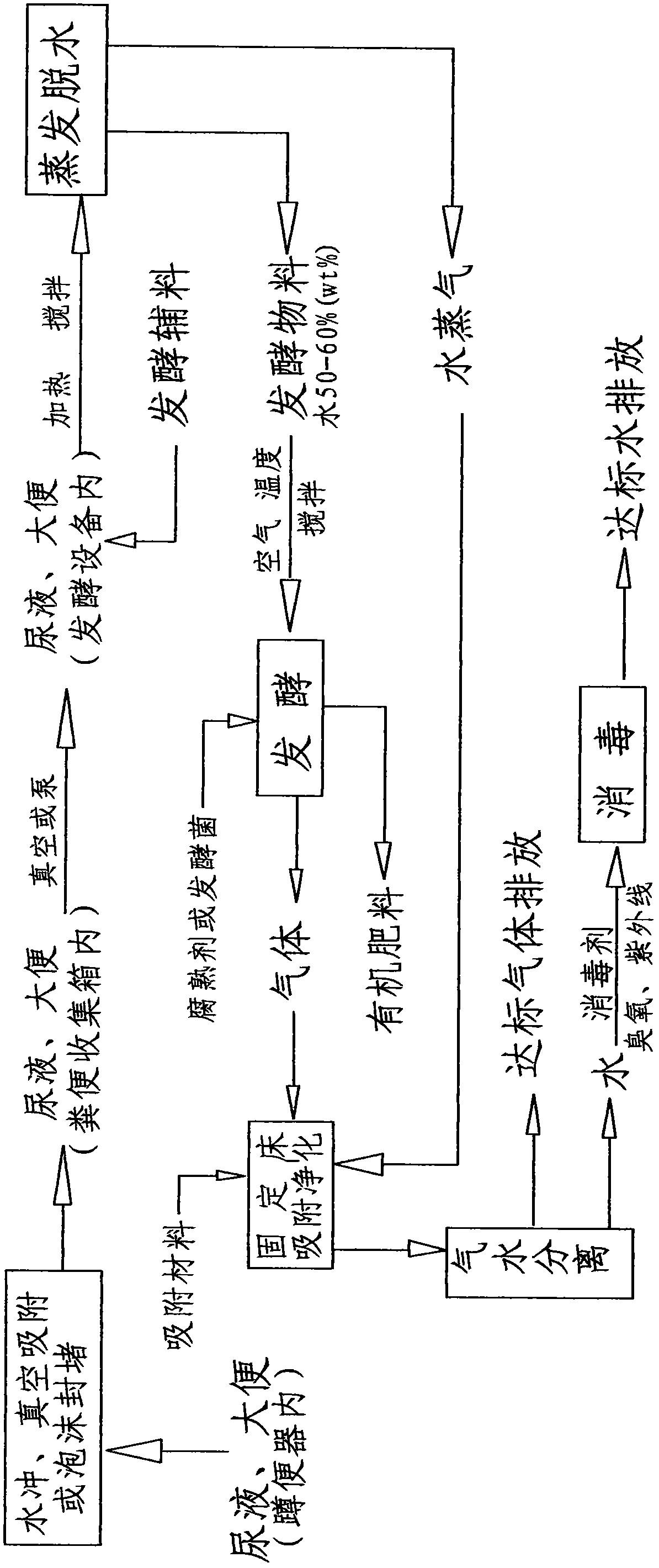

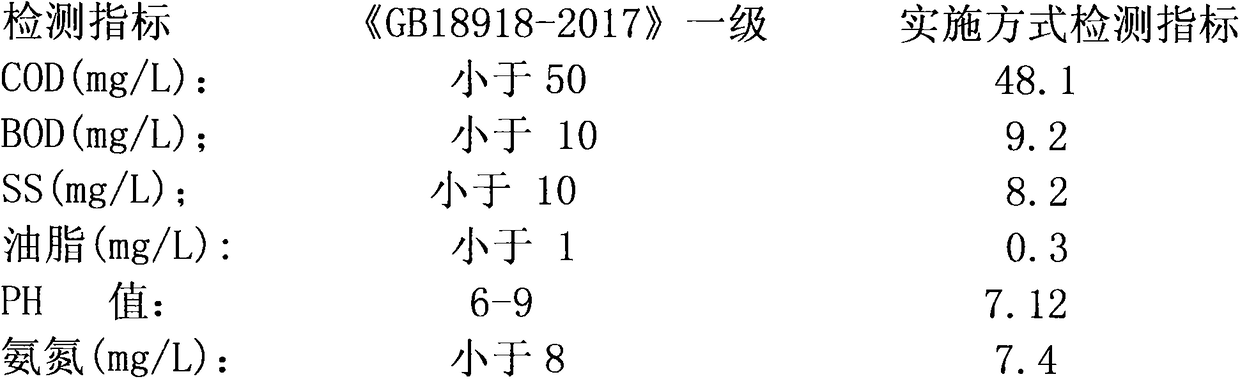

On-site purification up-to-standard processing method for toilet waste

PendingCN108545902AStreamline processSave waterWater/sewage treatment by irradiationSpecific water treatment objectivesMature technologyChemistry

The invention discloses an on-site purification up-to-standard processing method for toilet waste, to be more specific, urine and feces in a toilet are treated on site in the toilet, treated water quality reaches emission standards in national standard GB18918-2002, and a discharge gas reaches air pollutant discharge standards in DB11 501-2017. The water and gas meet the standards and discharged on site in the toilet, the feces is converted into organic fertilizer products that meet product standards in national NY525-2012. The feces collected in the toilet can be treated harmlessly without transported to other places, equipment used in the method belongs to conventional equipment, the equipment has reliable operation, mature technology, simple structure, easy operation, convenient maintenance and low cost; the on-site purification up-to-standard processing method has broad market application prospects and has creativity, novelty and good industrial applicability.

Owner:周鼎力

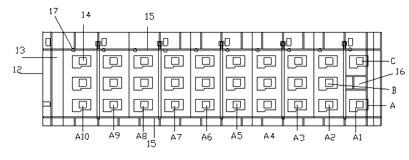

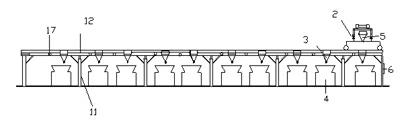

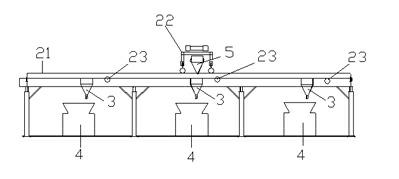

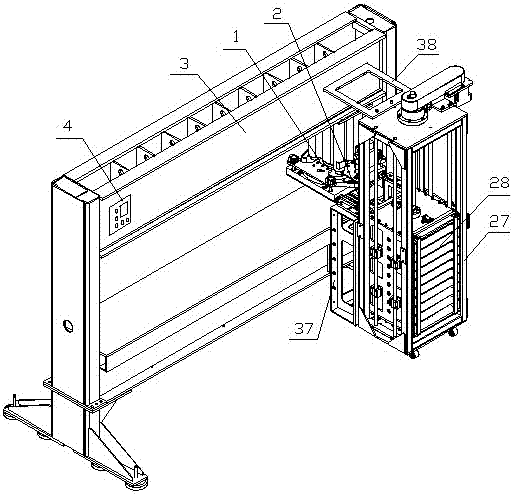

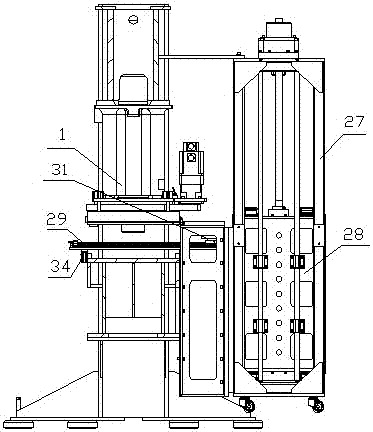

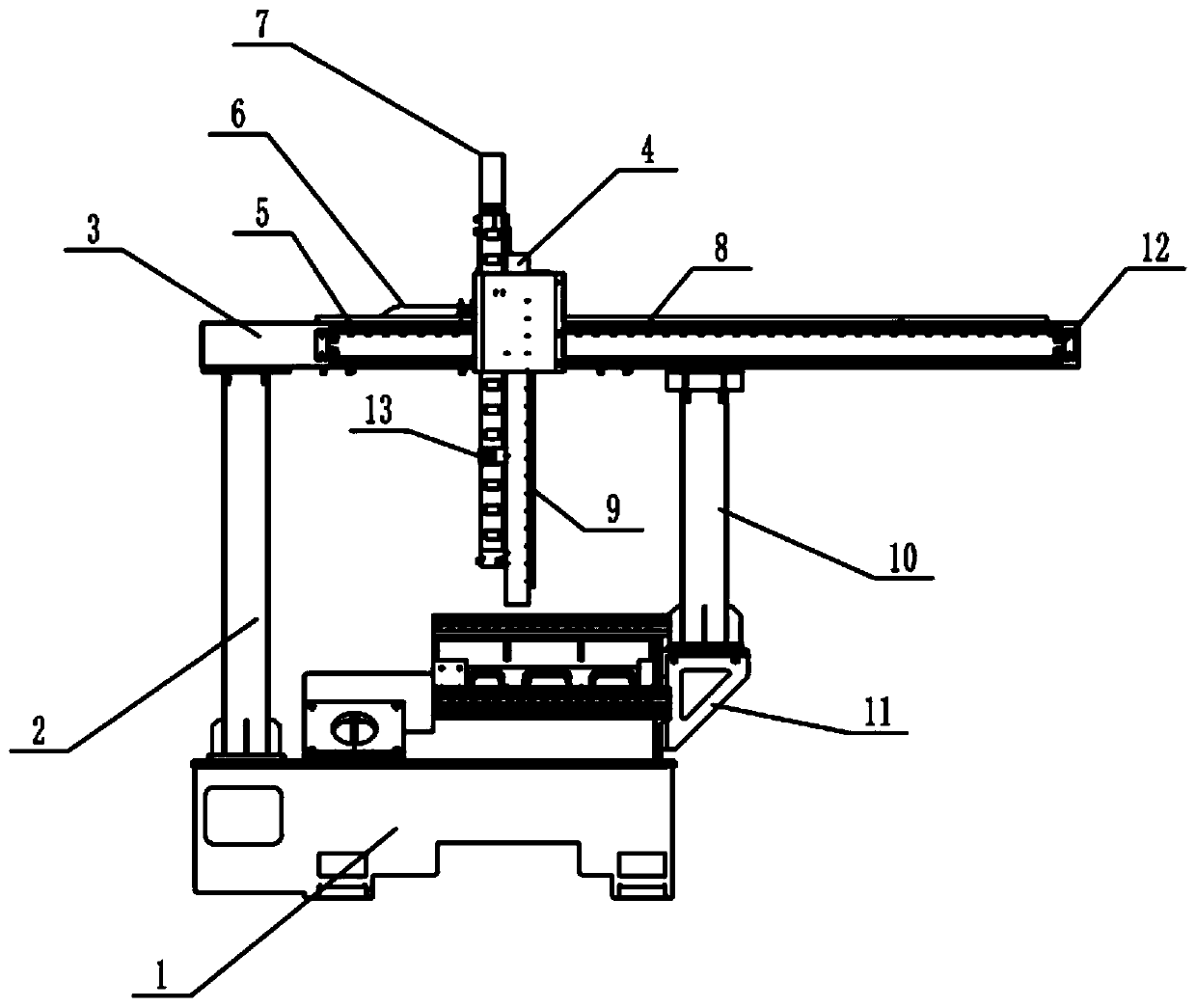

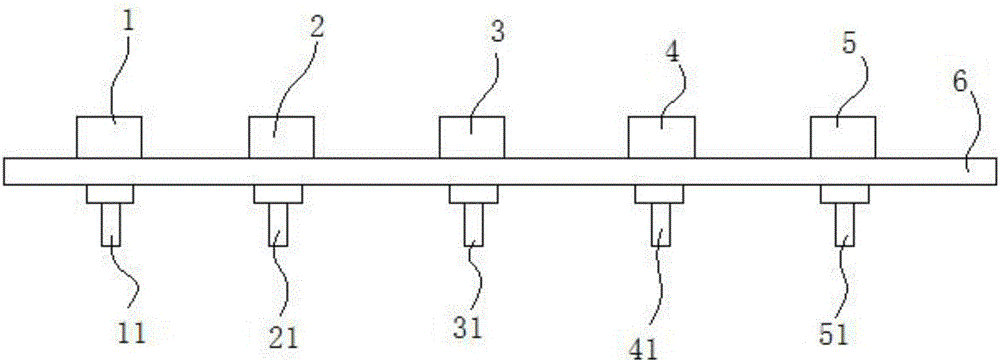

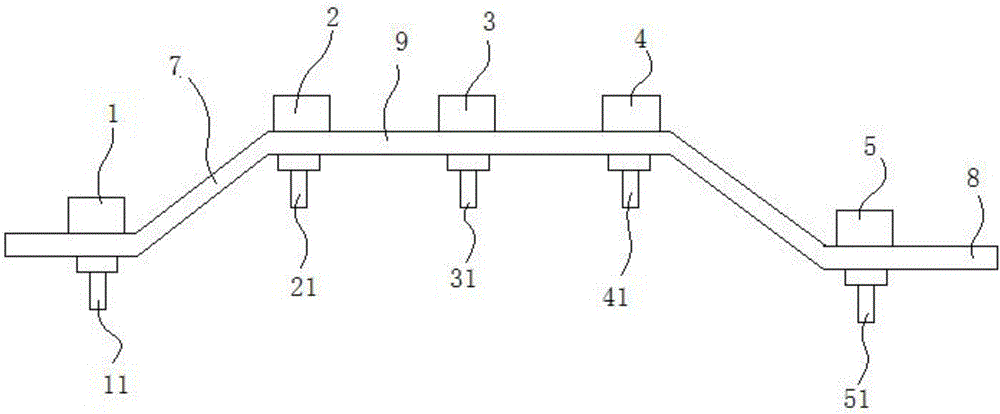

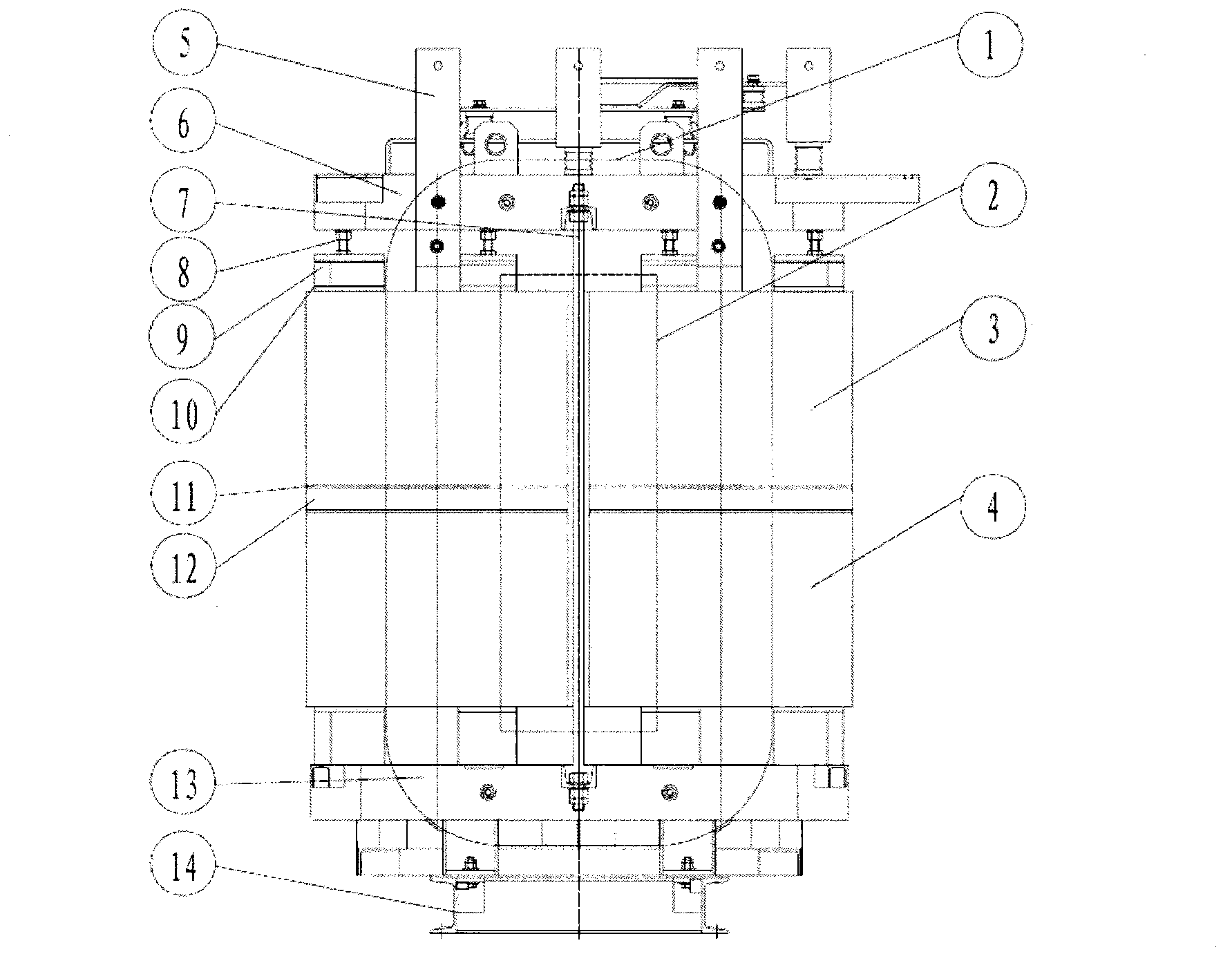

Automatic feeding system

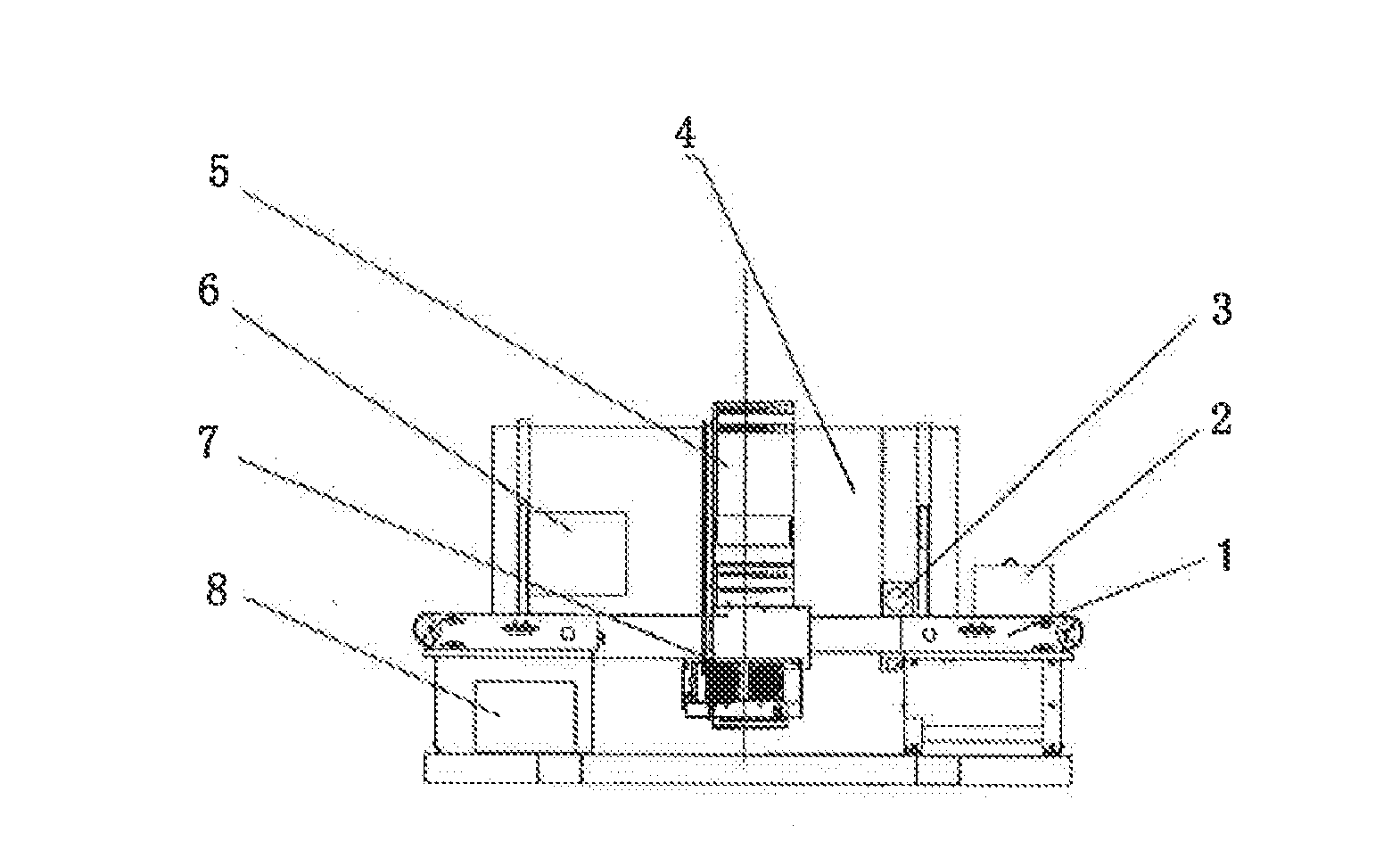

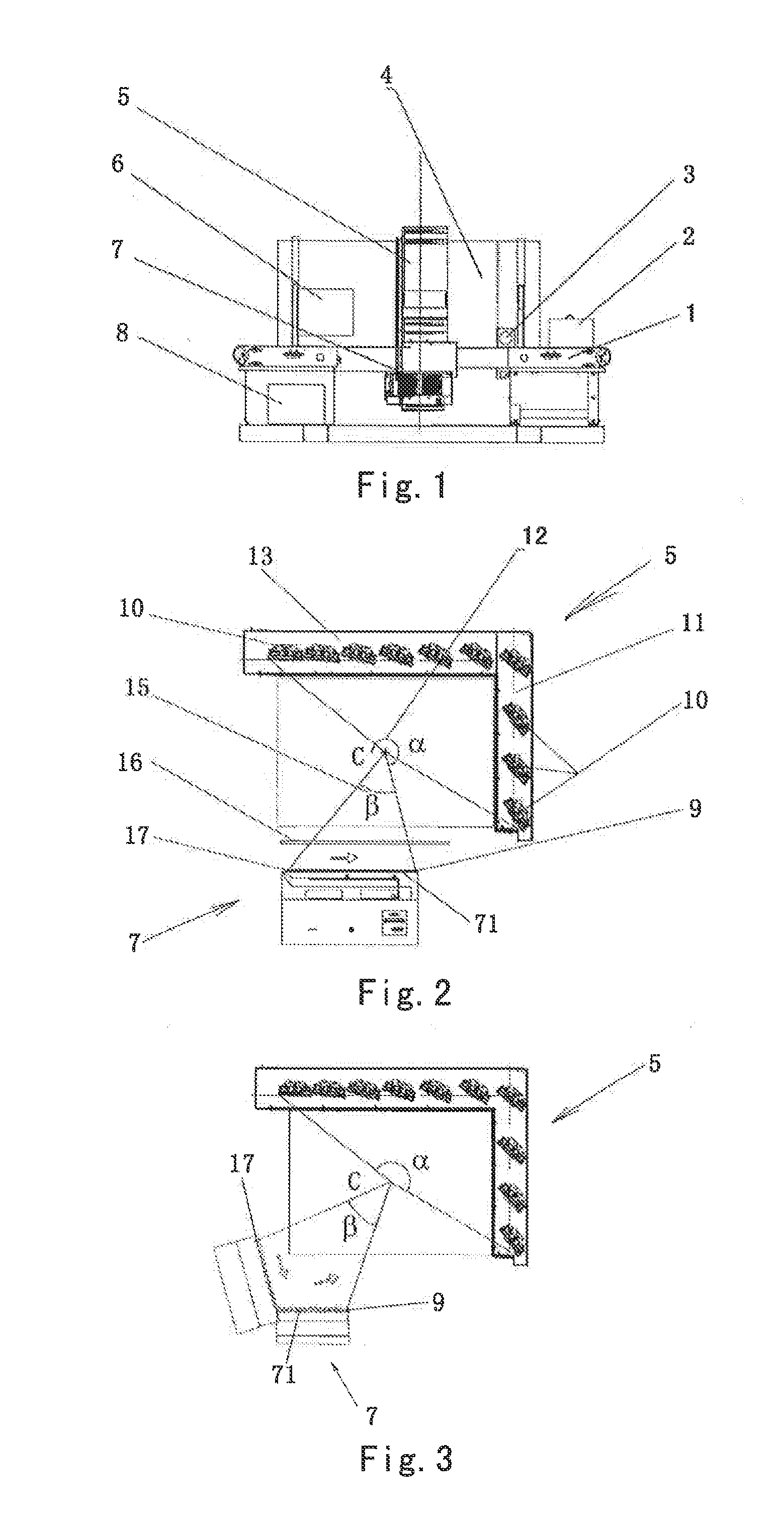

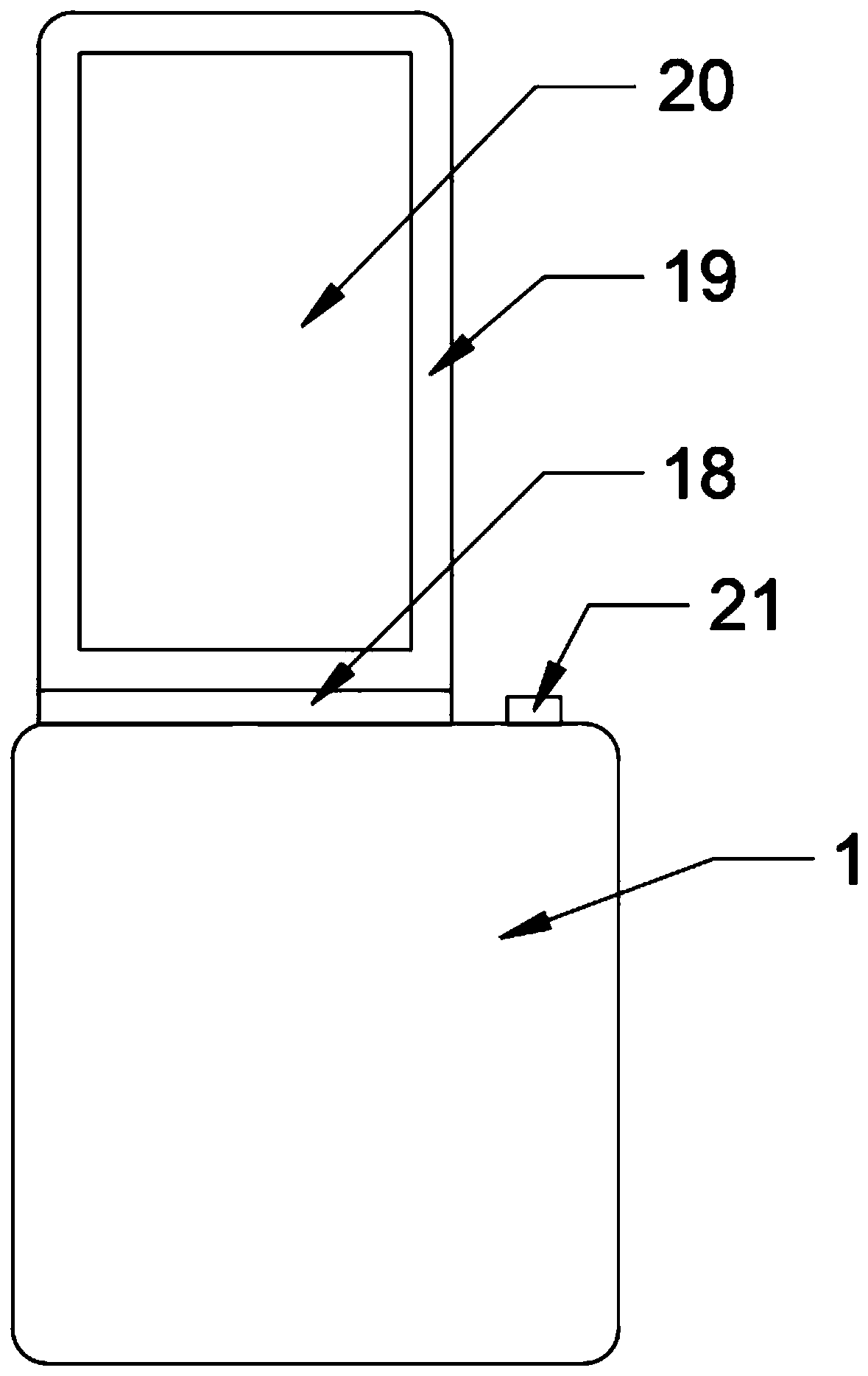

ActiveCN102133715AReduce floor spaceReduce labor intensityMetal working apparatusAutomaticityMechanical engineering

The invention relates to an automatic feeding system, which comprises a platform, a travelling crane system, a feeding mechanism, a feed box and a control cabinet, wherein the travelling crane system is arranged on the platform by a guide rail frame; a plurality of feed openings are formed on the platform; the feed box is arranged below the feed openings; a hanging basket is arranged on the travelling crane system; the control cabinet is arranged on the platform; the feeding mechanism comprises a driven well frame and a tilting mechanism; the tilting mechanism comprises a tilting pot buggy, a support and a bearing base; air cylinders are arranged on the support and the bearing base respectively; the support and the tilting pot buggy are jacked sequentially by the air cylinders, so that materials are poured into the hanging basket; the travelling crane system elevates the hanging basket to the upper side of the platform from the lower side of the platform; and the travelling crane system moves to convey the materials to the upper side of the feed openings from which the materials are needed to be fed, so that the materials are discharged in the feed box. In the automatic feeding system, the materials are discharged automatically by utilizing the feeding mechanism, and are conveyed by a travelling crane, so the automaticity is high, and the labor intensity of workers is relieved greatly; and the materials are stored in the feed box, so the occupation space of the ground is reduced; and a material-free detection device is arranged to remind of feeding materials in the feed box or not without artificial examination.

Owner:上海东风汽车专用件有限公司

Ct apparatus without gantry

ActiveUS20140185744A1Reduced footprintImprove usabilityMaterial analysis using wave/particle radiationRadiation/particle handlingCurve shapeX-ray

A CT apparatus without a gantry. The CT apparatus includes a scanning passage; a stationary X-ray source arranged around the scanning passage and including a plurality of ray emission focal spots; and a plurality of stationary detector modules arranged around the scanning passage and disposed opposite the X-ray source. At least some of the plurality of detector modules may be arranged substantially in an L shape, a semicircular shape, a U shape, an arc shape, a parabolic shape, or a curve shape when viewed in a plane intersecting the scanning passage. The invention ensures that the stationary gantry type CT system has a small size, and a high data identification accuracy.

Owner:NUCTECH CO LTD +1

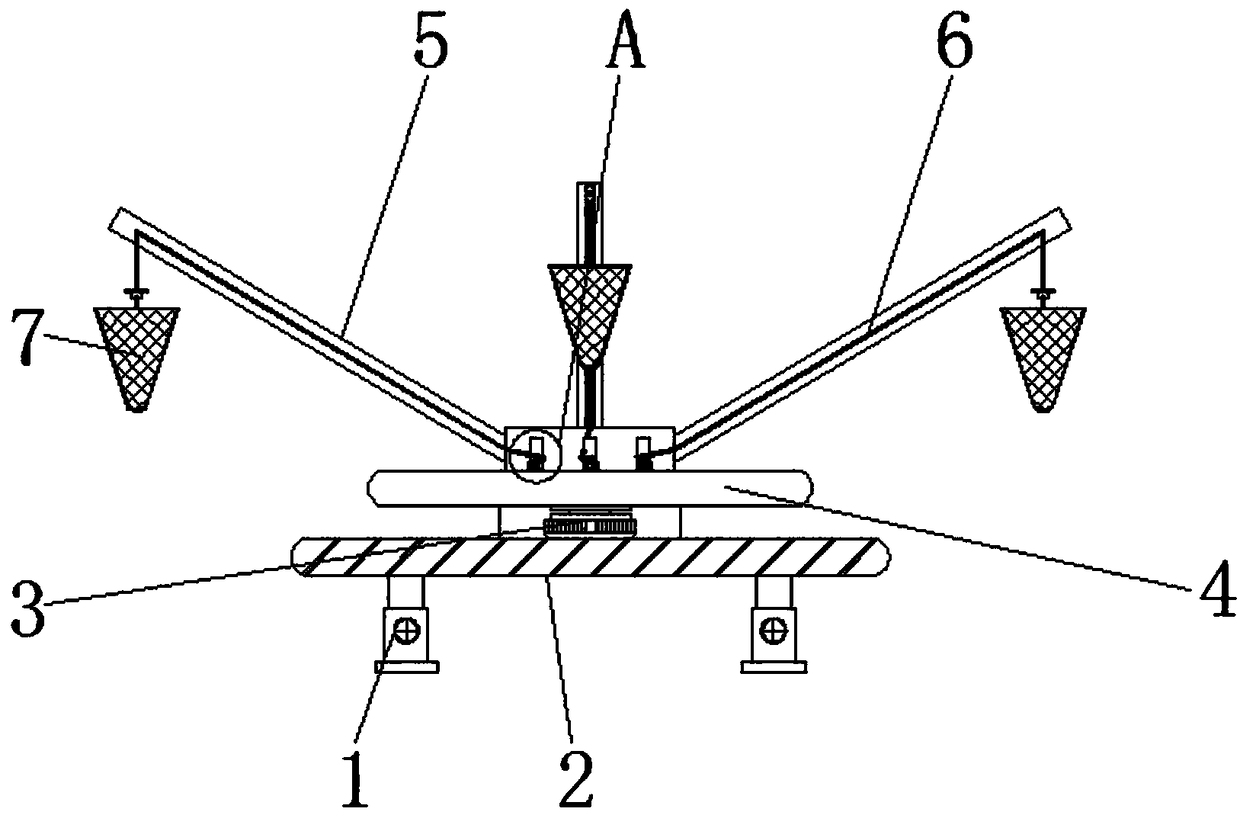

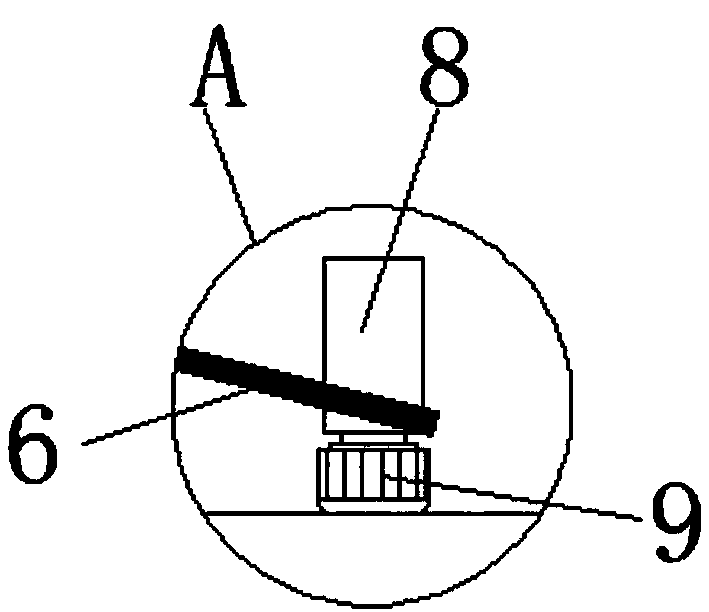

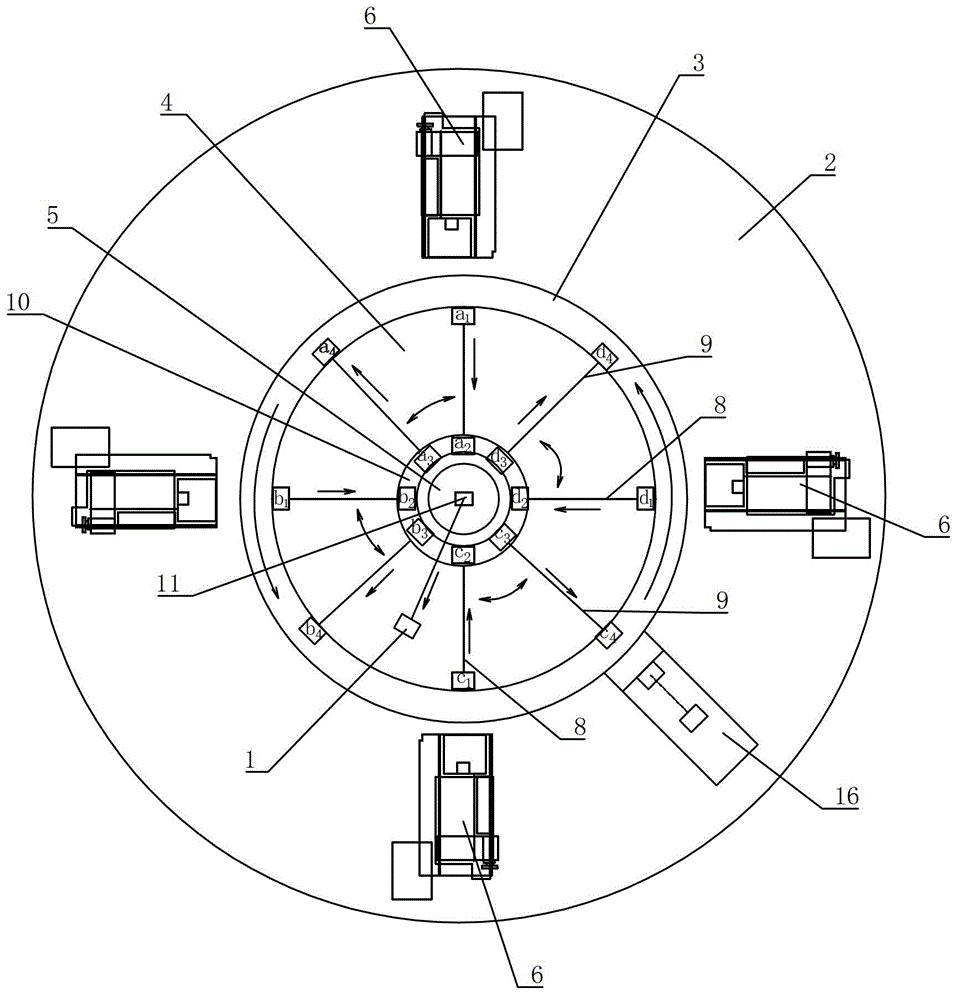

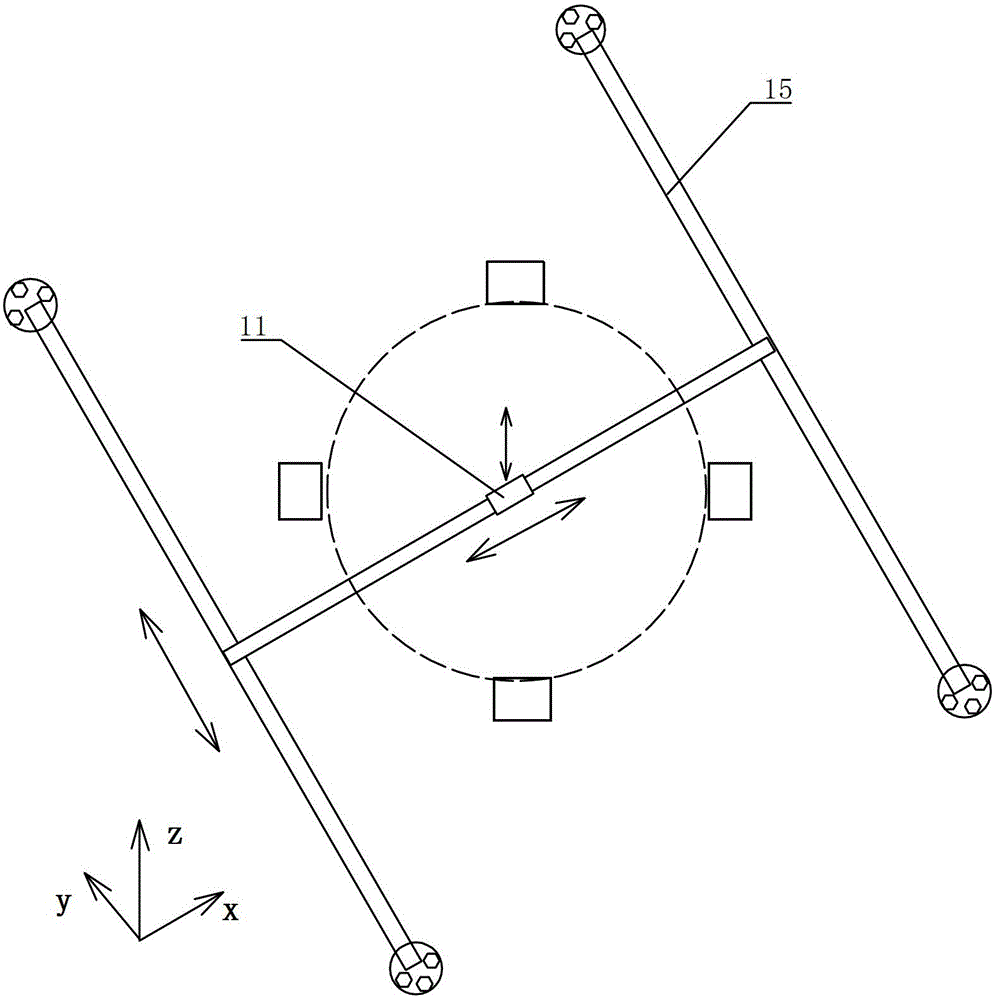

Rotary feed casting device for aquaculture

ActiveCN108112528ASmooth rotationEasy to shrinkClimate change adaptationPisciculture and aquariaHydraulic cylinderEngineering

The invention discloses a rotary feed casting device for aquaculture. The rotary feed casting device comprises telescopic bases, feeding funnels, wrapping posts and hangers, wherein a fixed table surface is fixedly mounted on the telescopic bases, and a first motor is arranged on the fixed table surface; fixed hanging rods are connected to the lower parts of pulling ropes, and through holes are formed in the middles of the fixed hanging rods in a penetration manner; fixed support rods are arranged on the feeding funnels; second motors are mounted under the wrapping posts, and a workable is fixed at the bottoms of the second motors; hollow slots are formed in the middles of the fixed support rods in a penetration manner, slots are formed in two sides of the hollow slots, sliding rods are arranged on the hollow slots, and hydraulic cylinders are arranged at the bottoms of the sliding rods; and the feeding funnels are mounted under the hangers. The rotary feed casting device for aquaculture is provided with the fixed table surface and the telescopic bases, so that the whole device can be placed in the center of an aquaculture environment and does not need to be frequently dismounted and mounted.

Owner:HUNAN UNIV OF ARTS & SCI

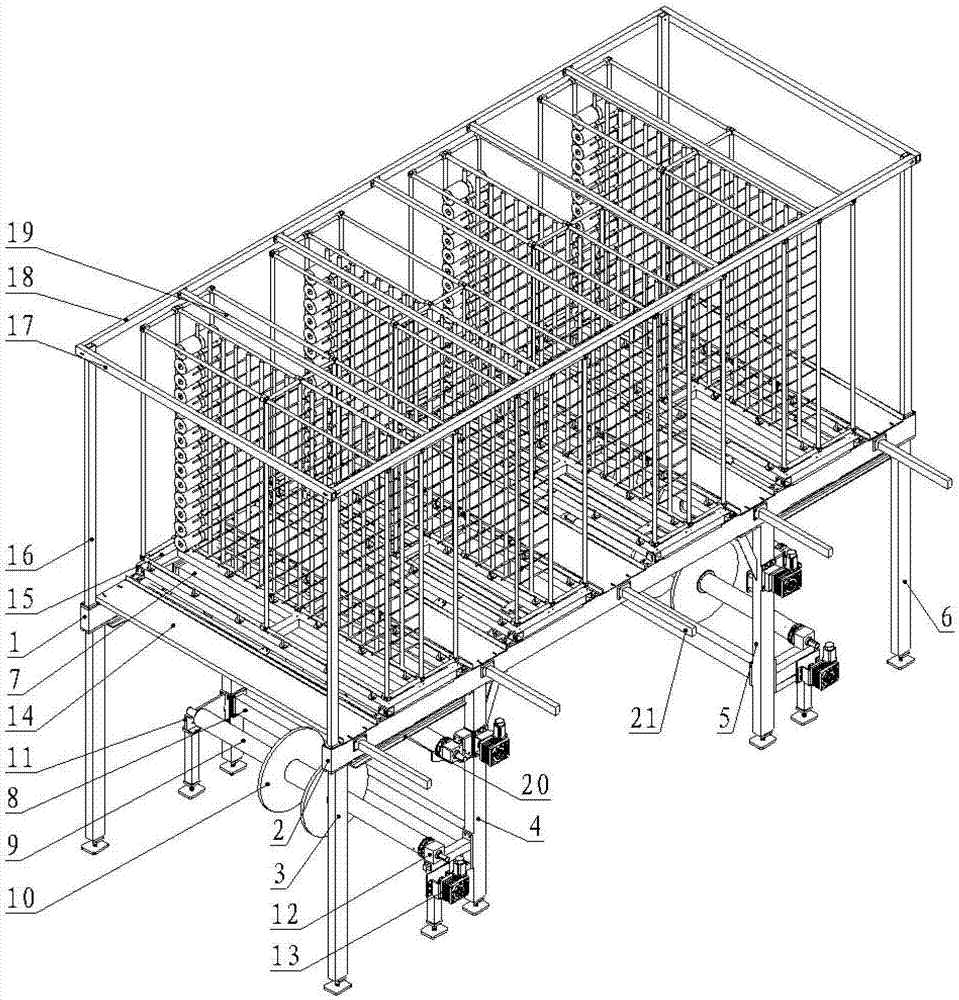

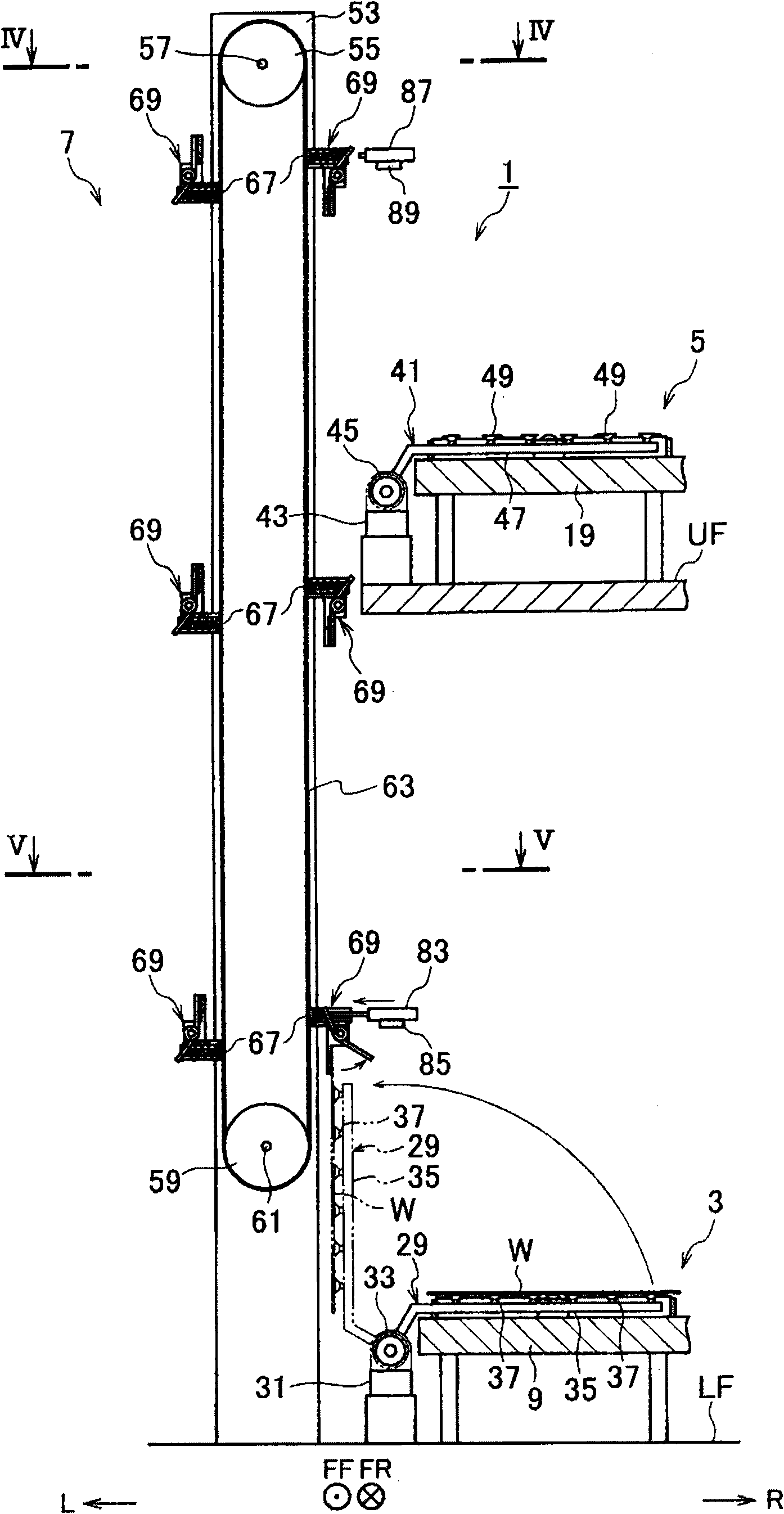

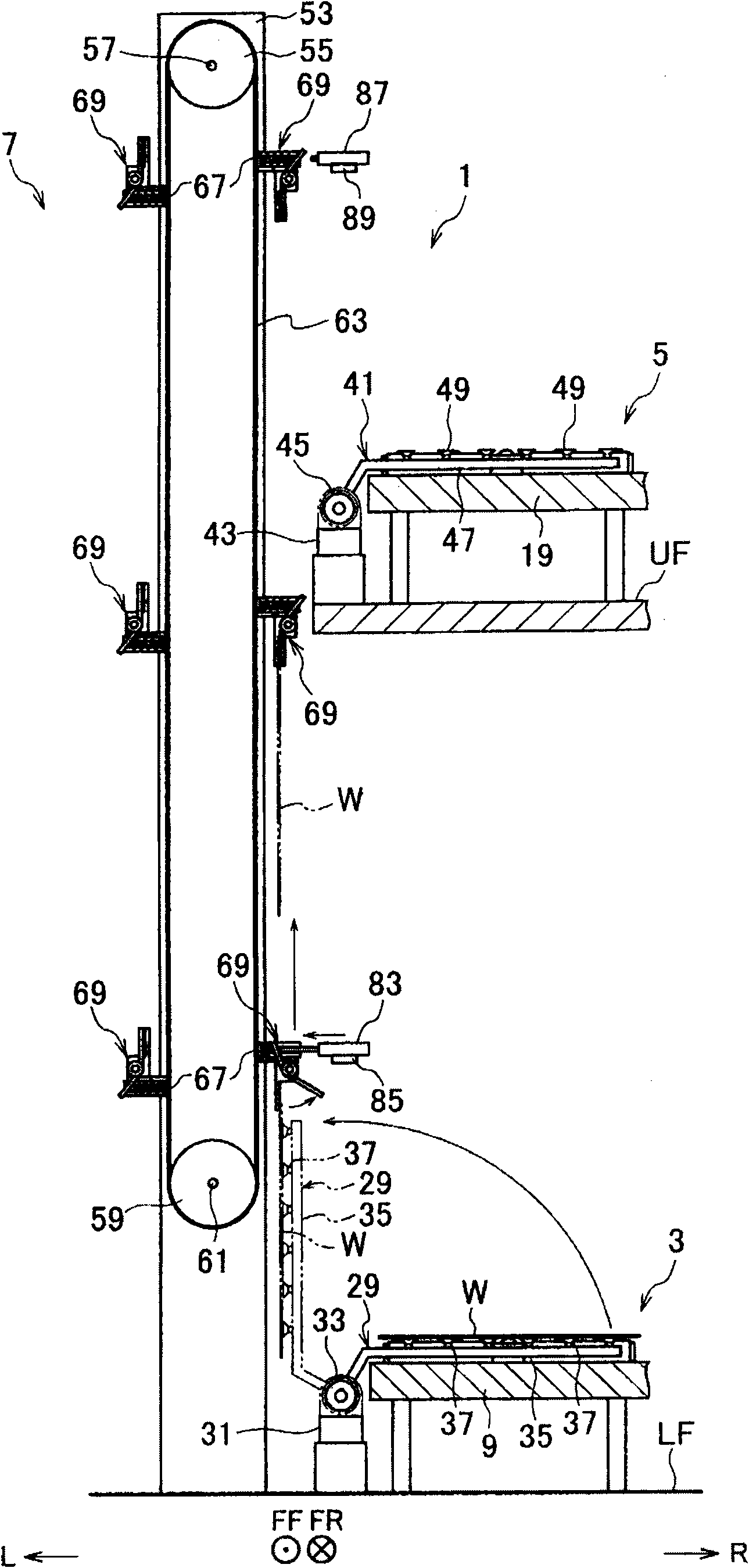

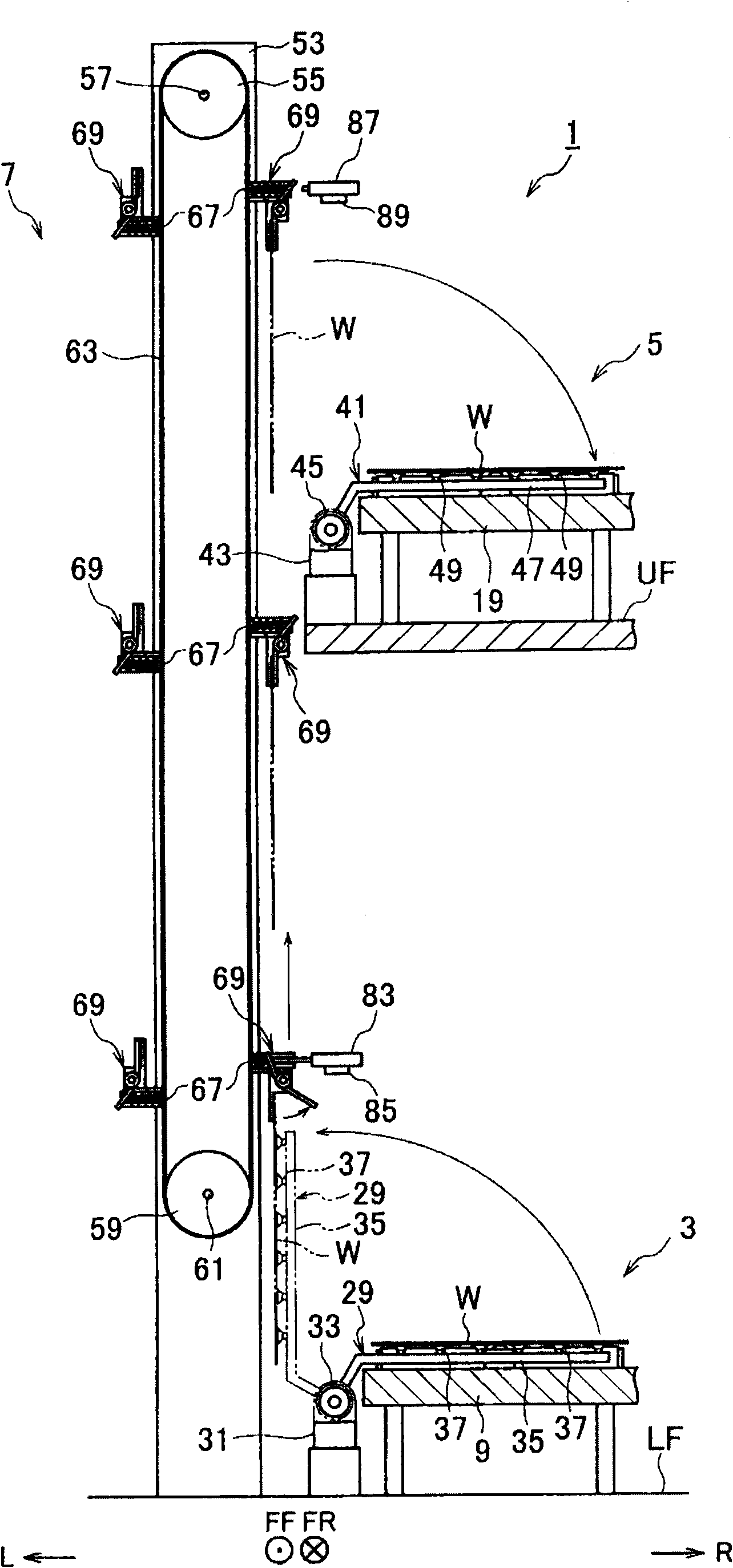

Substrate elevating transferring device and substrate processing transferring system

ActiveCN101853799AReduce floor spaceEfficient use ofSemiconductor/solid-state device manufacturingConveyor partsEngineeringMechanical engineering

In a substrate elevating transferring device, a first posture shifting member having a first posture shifting maintenance member is arranged on one side of a first substrate processing device in a way shaking around a horizontal axle center; a second posture shifting member having a second posture shifting maintenance member is arranged on one side of a second substrate processing device in a way shaking around a horizontal axle center; a circular member which extends along the vertical direction in a circulation walking way is vertically arranged on a supporting frame on one side of the first posture shifting member; and a plurality of elevating maintenance members are arranged on the circumference direction of the circular member at an interval. The substrate elevating transferring device can sufficiently reduce the plane area occupation and effectively use the space in the factory.

Owner:IHI CORP

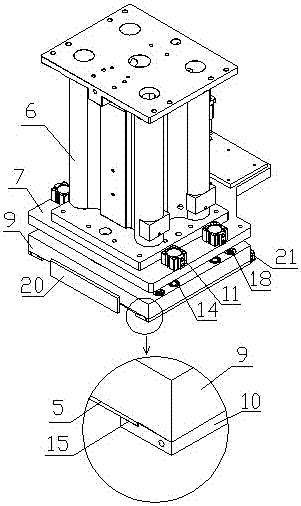

Efficient cutting machine for cutting sheets

The invention discloses an efficient cutting machine for cutting sheets. The efficient cutting machine comprises a punching head, a cutting die replacing mechanism, a tool changer, a rack, a support and a control cabinet. The punching head is arranged on the rack. The support is arranged at one end of the punching head. The tool changer is arranged in the support. The cutting die replacing mechanism is arranged between the tool changer and the punching head. A cutting die is arranged at the lower portion of the punching head. The control cabinet is arranged on the rack. By adoption of the efficient cutting machine for cutting sheets, the cutting die can be very conveniently replaced, the punching head can be used for punching materials from various angles for multiple times, the tool changer is scientific and reasonable in position, and positioning is more accurate; the cutting die replacing mechanism adopts a servo ball screw for transmission, transmission positioning is accurate, stress is more scientific and reasonable, and the service life is prolonged; and a rodless cylinder enables the structure of the whole machine to be more compact, the occupied area is reduced, operation is more convenient, the fault rate is low, operation is smoother, the working efficiency is high, and unanimous praise from clients is obtained.

Owner:YANCHENG HUASEN MACHINERY

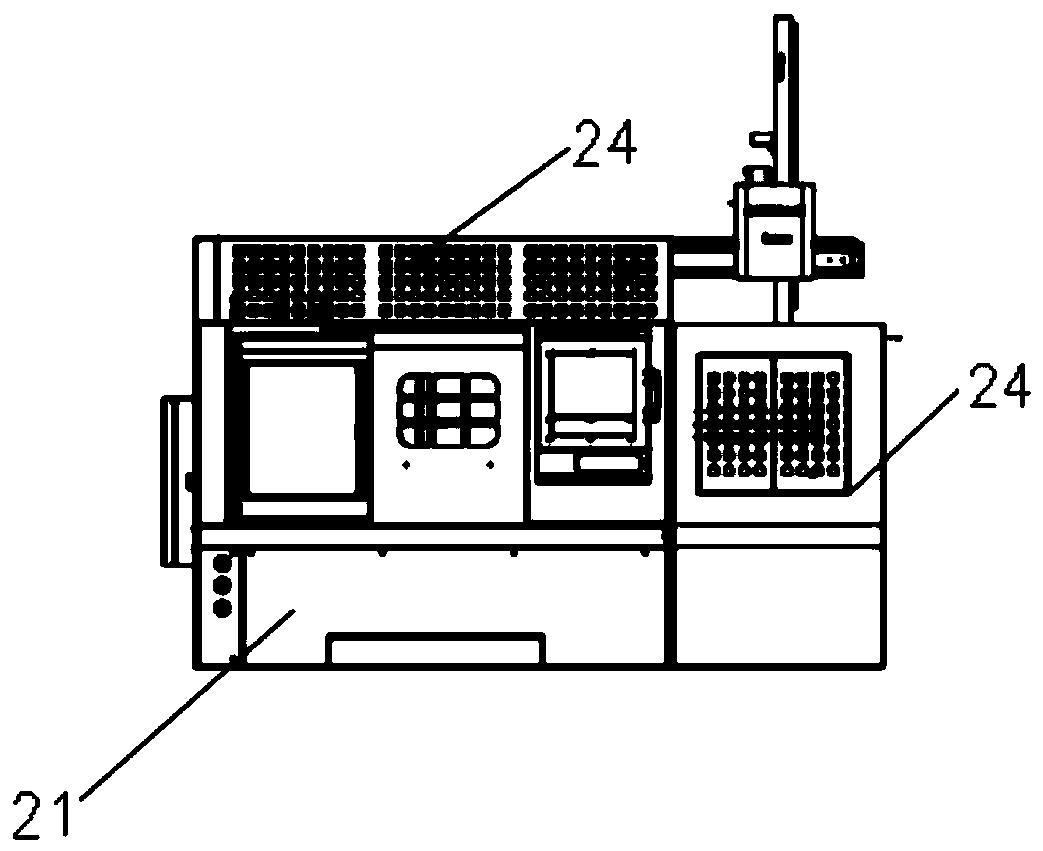

Novel truss all-in-one machine

InactiveCN110711864ANovel structural designReduce floor spaceAutomatic workpiece supply/removalMetal working apparatusStructural engineeringWhole systems

The invention discloses a novel truss all-in-one machine. The machine comprises a numerical control lathe, a truss and an interactive type stock bin. A safety protection net is installed outside the numerical control lathe, and the truss and the interactive type stock bin are installed inside the numerical control lathe. The structural design is novel, the numerical control lathe, the truss and the interactive type stock bin are integrated integrally, the floor area ratio is greatly lowered, the mechanisms are compactly connected due to the integrated design, the stability of the whole systemis improved, the safety of a user is sufficiently ensured due to the full-protection appearance design, the machine can effectively replace manual work for performing feeding and discharging work on amachine tool, the working efficiency is improved, and the production quality stability is improved.

Owner:JIANGSU BOSUNMAN IND EQUIP

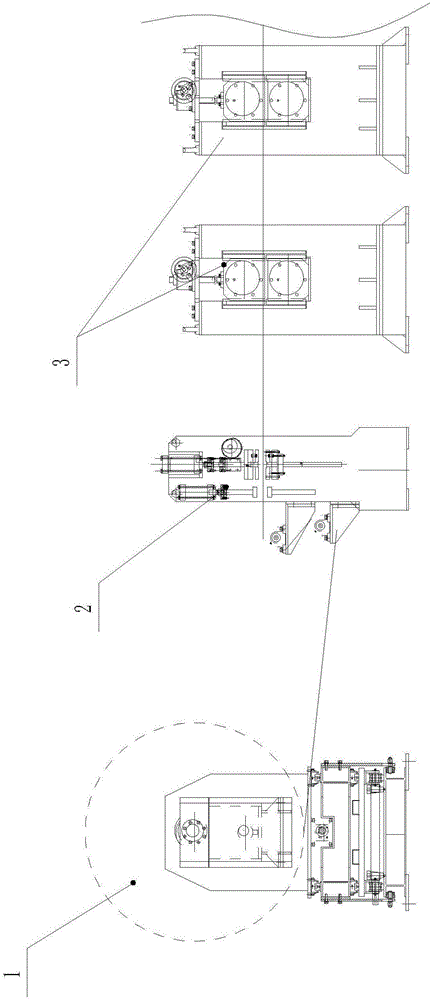

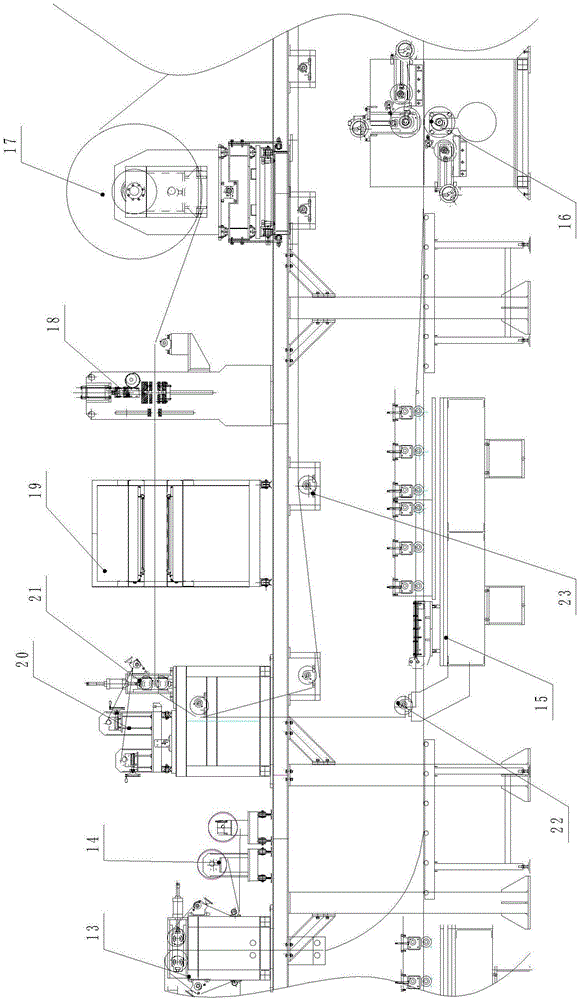

Composite production line of corrugated composite boards and honeycomb composite boards, and composite production process of composite production line

ActiveCN106427164AMeet production needsIncrease usageLamination ancillary operationsLaminationProduction lineHoneycomb

The invention discloses a composite production line of corrugated composite boards and honeycomb composite boards. The composite production line comprises a corrugated core layer molding unit, a honeycomb core layer molding unit, a first board molding unit, a second board molding unit, a third board molding unit and a multifunctional composite unit; when the corrugated composite boards are produced, first boards are taken as base materials for molding corrugated boards; when the honeycomb composite boards are produced, the first boards are taken as lower boards; the production line can be both used for producing the corrugated composite boards and the honeycomb composite boards; furthermore, the invention also discloses a composite production process based on the composite production line; the composite production process also has the functions and effects.

Owner:张家港市弘扬机械设备有限公司

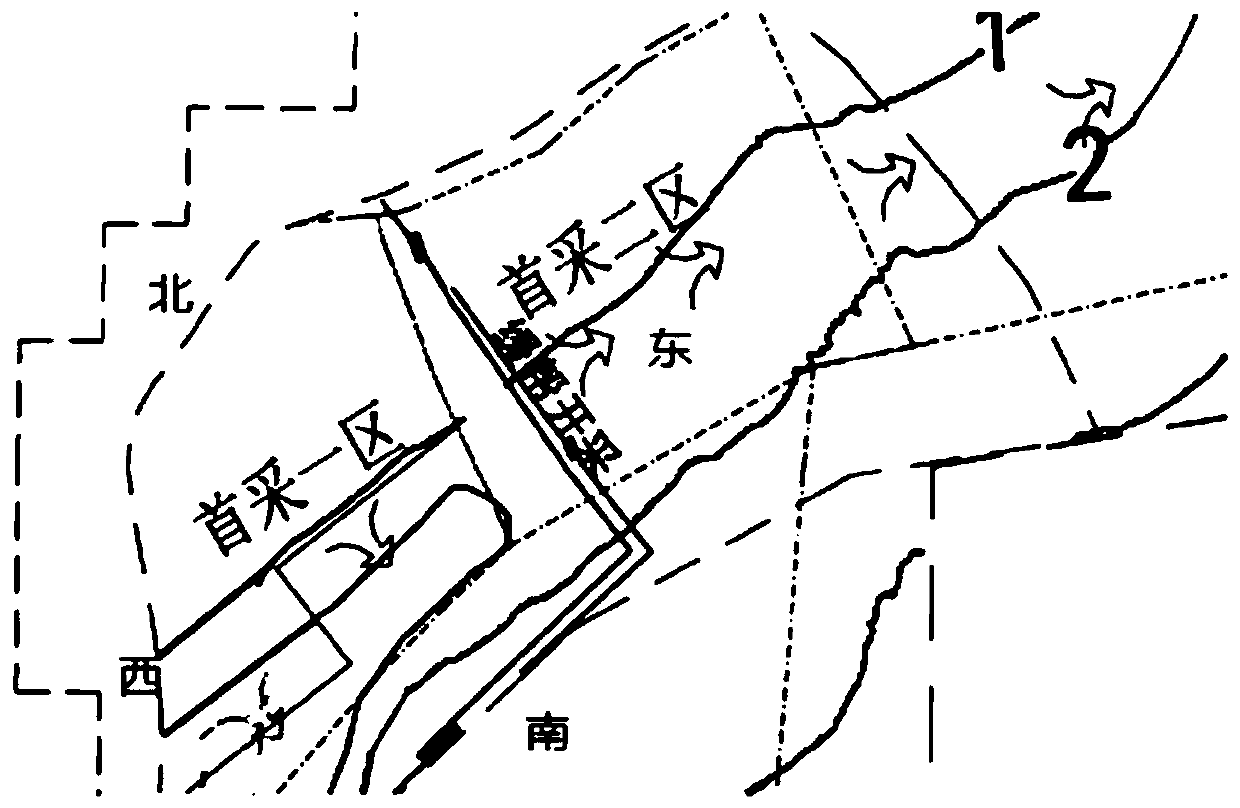

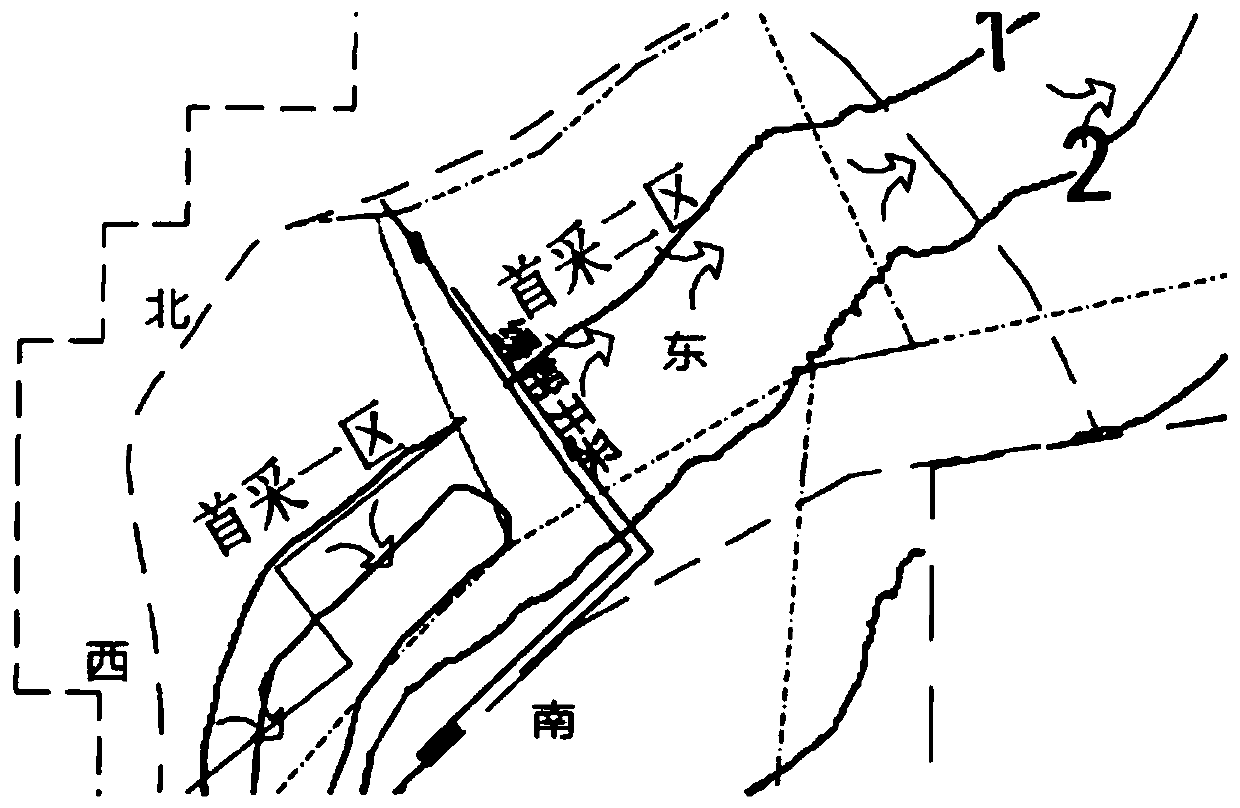

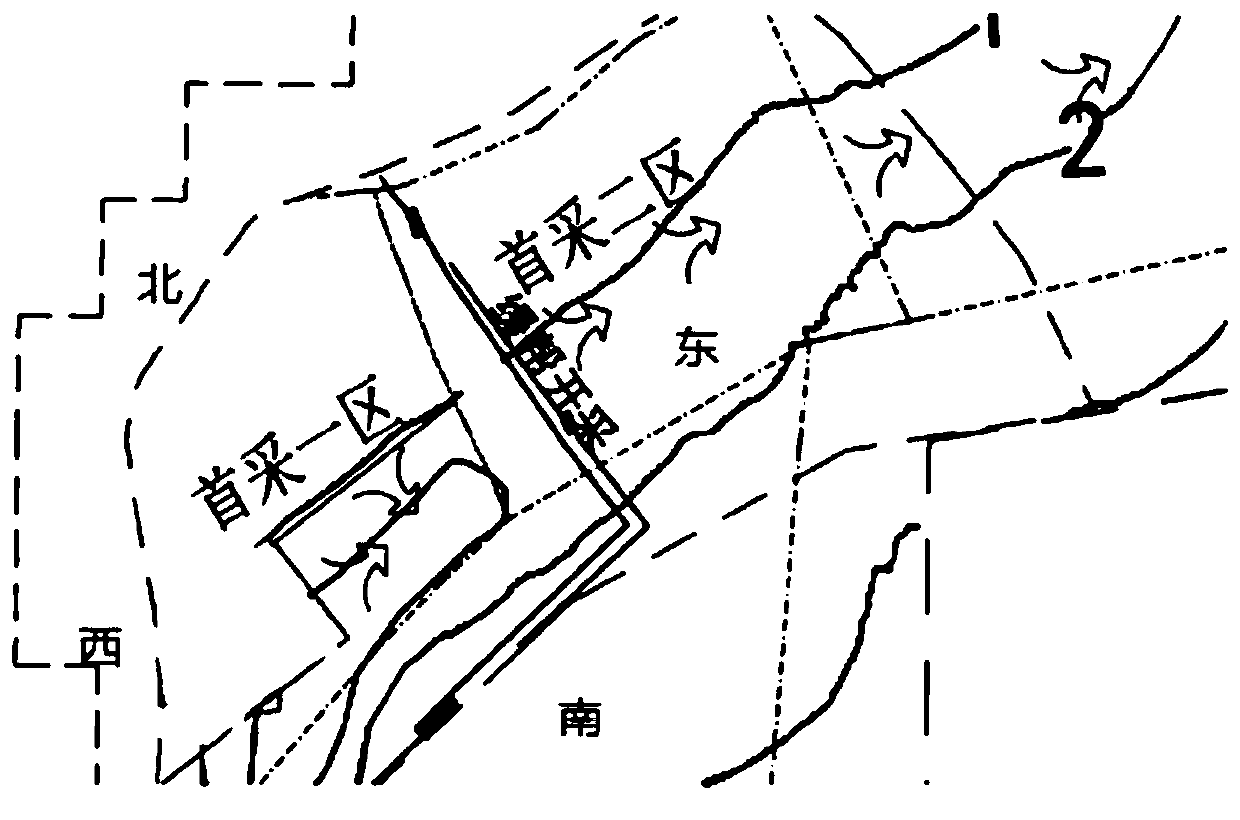

Hugely-thick inclined coal seam mining area steering method

ActiveCN110939446AIncrease the lengthImprove annual production capacityOpen-pit miningMining engineeringEconomic benefits

A hugely-thick inclined coal seam mining area steering method is used in open-air coal mine mining. The entire mining area is divided into two parts by using a working line, and coal seam striping isperformed along the two sides of a groove; when the coal seam in the north area is smaller than the coal seam in the south area, after mining of the coal seam in the north area is completed firstly, mining equipment of the coal seam in the north area is gradually transported to the working line of the coal seam in the south area and participates in subsequent mining, the number of mining equipmentis gradually increased at the west most side of the working line of the west section until the allowed maximum amount of the mining equipment is placed, so that the advance speed is increased, the original linear working line is changed into an arc working line for advance, and finally the working line rotating 90 degrees counterclockwise from the original working line is formed, so that the steering work is completely completed. The method has the beneficial effects that the steps are simple and the inner row space is released earlier, the soil discharging distance is shortened, and the transportation cost is remarkably reduced; and moreover, the length of the stripping and mining working line is increased, the annual mining capacity of an operation system is effectively improved, and therefore the economic benefit of the mine is increased.

Owner:CHINA UNIV OF MINING & TECH

Household garbage incinerator

The invention discloses a household garbage incinerator. The household garbage incinerator comprises a house body, an incinerator body, a smoke exhausting system, a sorting tank, a septic tank and a drying chamber, wherein the house body is divided into an upper storey and a lower storey; the incinerator body is arranged at the lower storey of the house body and comprises a combustion chamber, a primary smoke chamber and a secondary smoke chamber, an incinerator opening and a feed port are formed in the combustion chamber, the primary smoke chamber and the combustion chamber are internally tangent to the side where the incinerator opening is formed, a first smoke port communicated with the primary smoke chamber is formed in the combustion chamber, the secondary smoke chamber and the primary smoke chamber are internally tangent to the side where the incinerator opening is formed, a second smoke port communicated with the secondary smoke chamber is formed in the primary smoke chamber, and a first smoke exhaust outlet is formed in the secondary smoke chamber; the smoke exhausting system is connected with the first smoke exhaust outlet; the sorting tank is arranged at the upper storey of the house body; the septic tank is arranged at the lower storey of the house body, and a feed inlet of the septic tank is located at the upper storey of the house body; the drying chamber is arranged at the upper storey of the house body and above the incinerator body. With the adoption of the household garbage incinerator, household garbage can be classified, dried, composted and combusted, the smoke treatment effect is good, the land utilization rate is high, and the treatment cost can be reduced.

Owner:泰安泰山产业发展有限公司

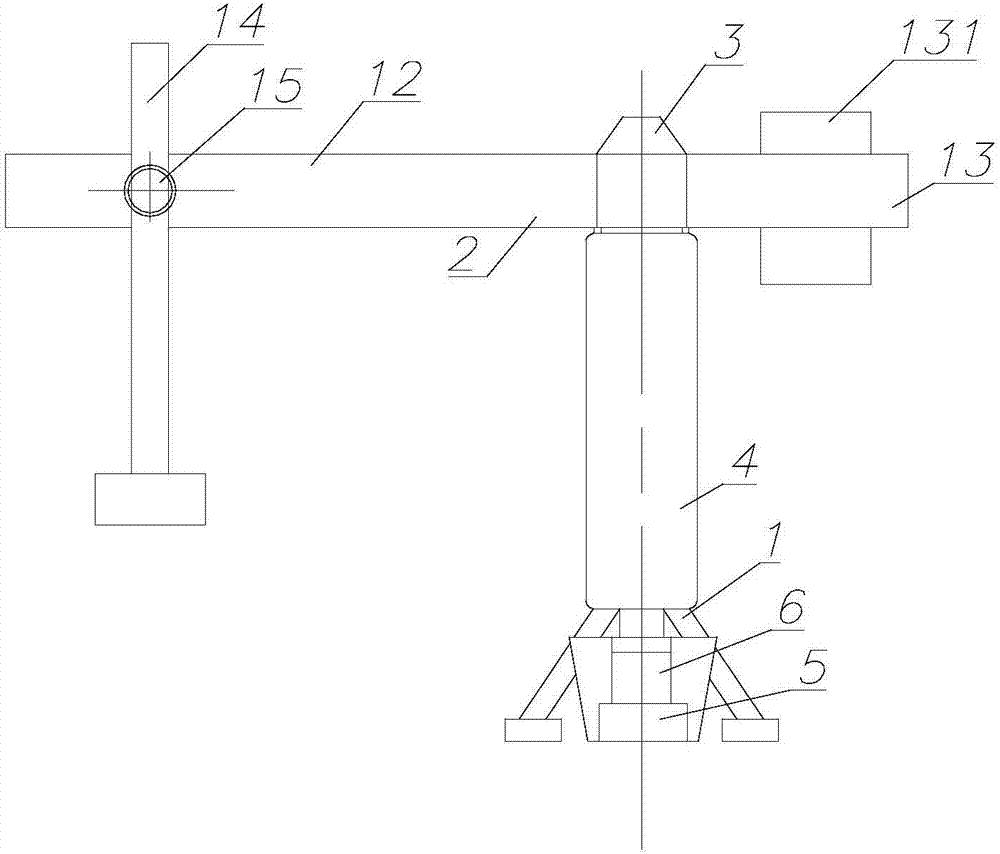

Building outline forming machine

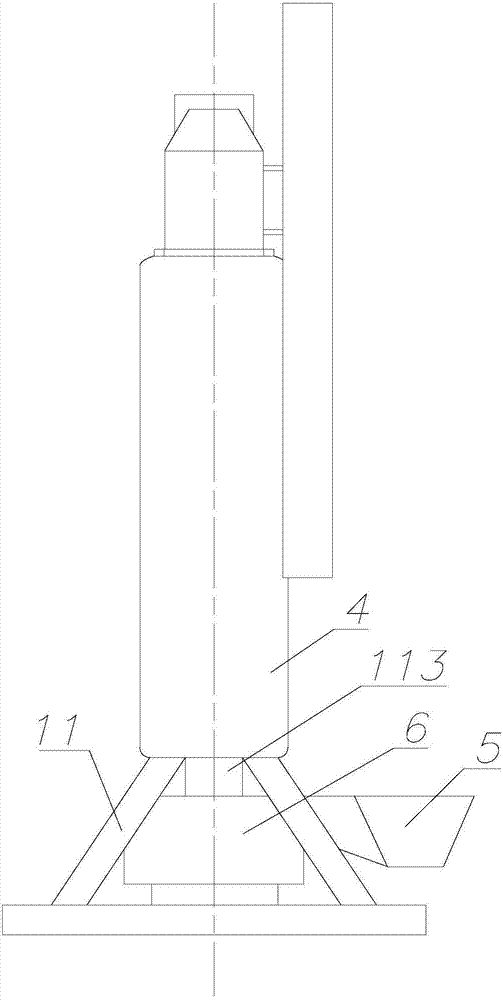

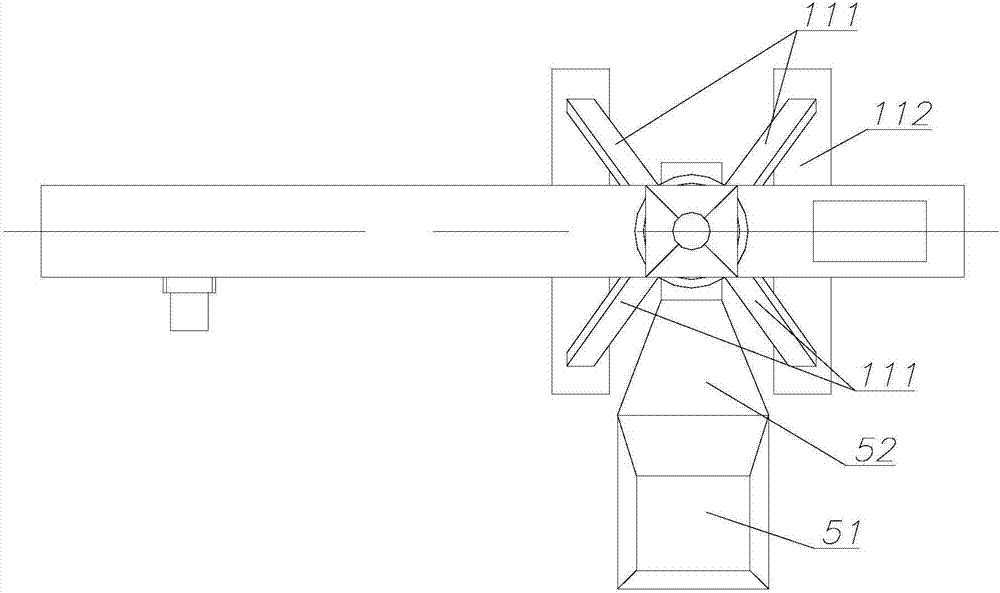

ActiveCN106907006AReduce floor spaceAvoid cloggingBuilding material handlingMolding machineEngineering

A building outline forming machine comprises a rotating platform and a base used for supporting the rotating platform. The rotating platform is mounted on the base through a rotary table and comprises a swing arm and a balance arm which are connected and separately arranged on the two sides of the rotary table. The balance arm is provided with a counterweight unit. The swing arm is provided with a cantilever which is connected with the swing arm through a mobile mechanism. The mobile mechanism drives the cantilever to horizontally move on the swing arm. The cantilever is provided with a 3D printing module. The rotating platform and the 3D printing module are supported aloft for operation through the base and the ground, the occupied using area of the whole machine can be effectively decreased, mounting of the building outline forming machine at a construction site is not limited by site factors, and the 3D printing module is driven to rotate around the base through the rotating platform so that a large operation range can be covered while the size of the whole machine is decreased, and the mounting position of the outline forming machine can be flexibly selected.

Owner:BUILDERA CONSTR TECH SHANGHAI CO LTD

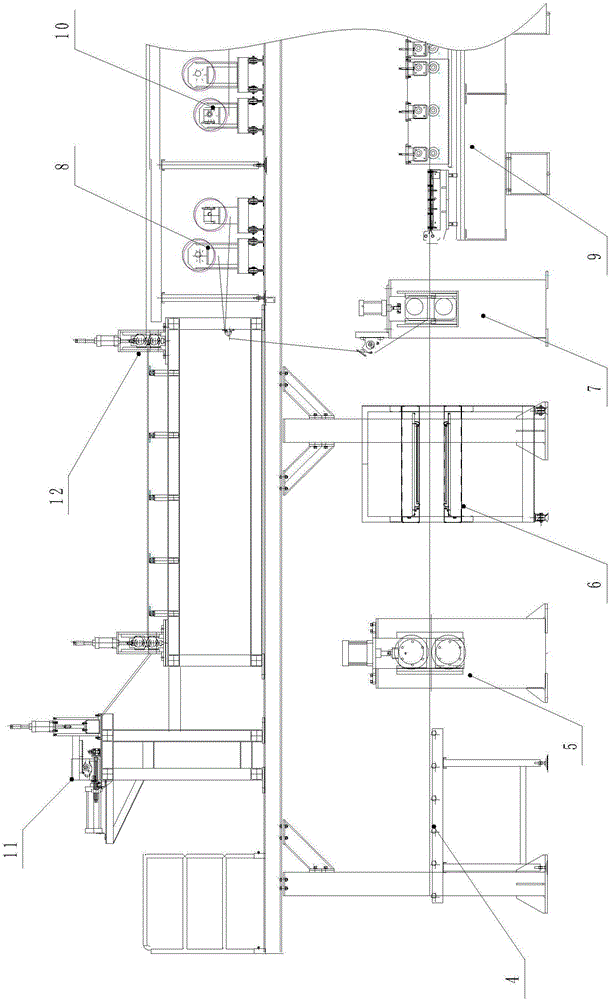

Workpiece slope production line

ActiveCN106824641AAvoid enteringAvoid pollutionPretreated surfacesCoatingsProduction lineEngineering

The invention provides a workpiece slope production line. The production line comprises a first environment procedure and a second environment procedure which are arranged in a sealing manner. The space of the first environment procedure and the space of the second environment procedure are isolated from each other. According to the workpiece slope production line, a pretreatment procedure with a pollution source and a packaging detection procedure with a pollution source are isolated from the paint spraying procedure space, the pollution source is effectively prevented from entering a paint spraying chamber and prevented from polluting the paint spraying procedure, the product quality is improved, and the production efficiency is high.

Owner:SUZHOU BOHAN PLASTIC IRONWARE

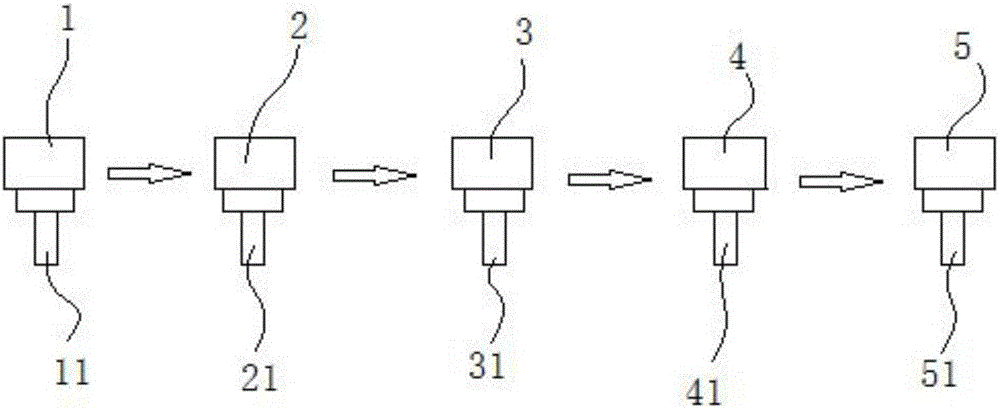

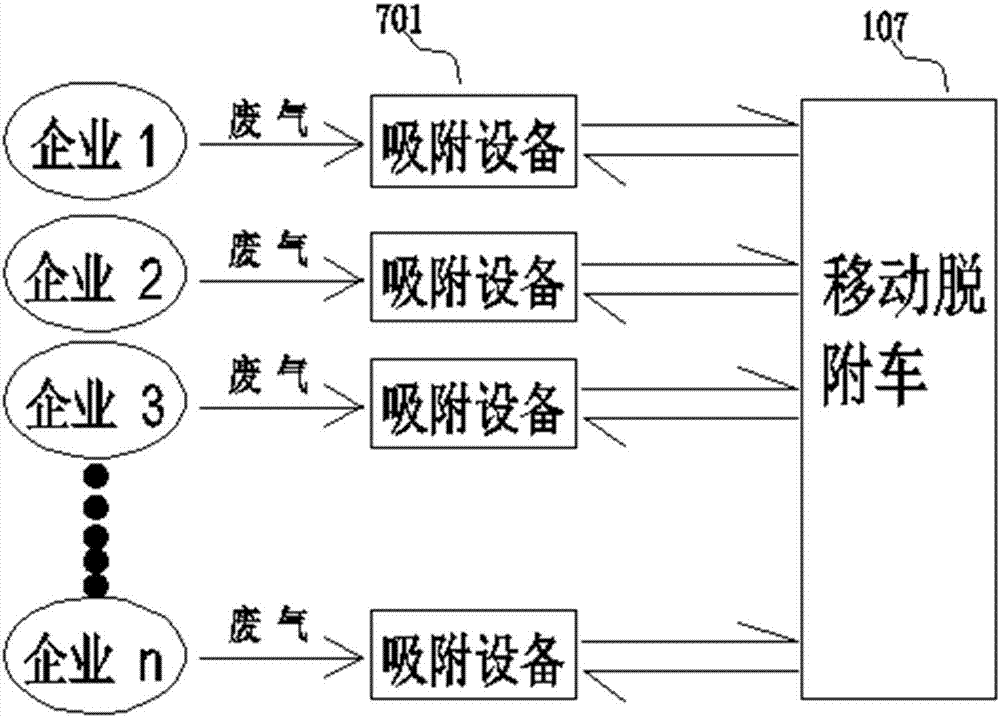

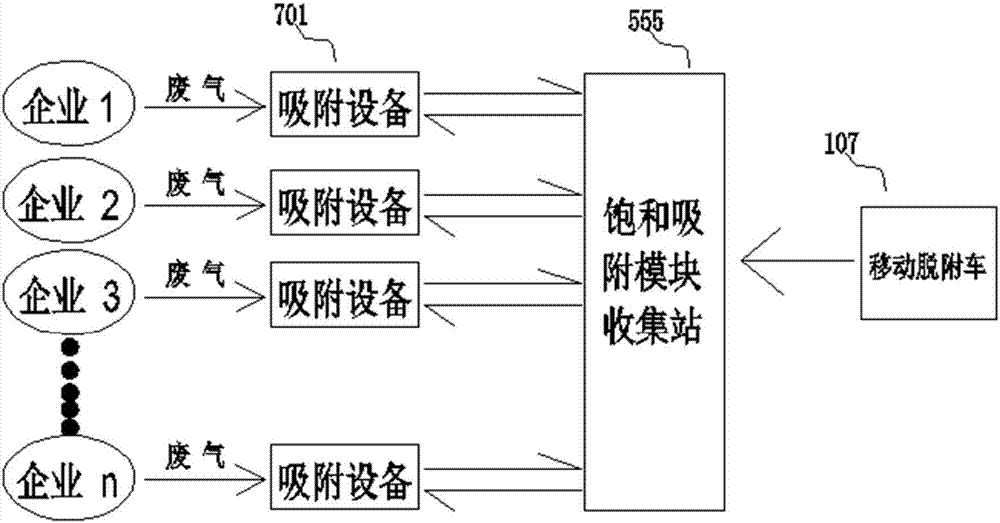

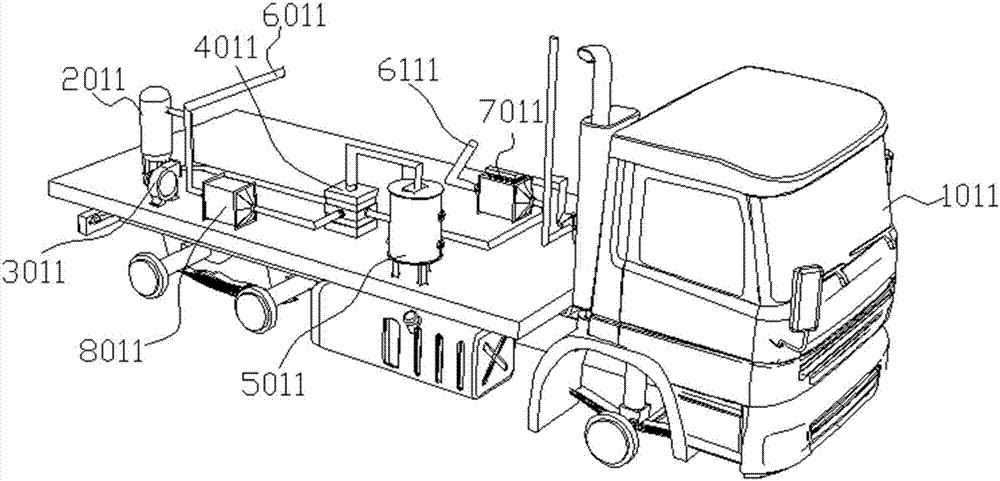

Treatment technique of scattered organic waste gas and equipment thereof

The invention discloses a treatment technique of scattered organic waste gas. The technique includes the steps of inputting VOCs waste gas on each scattered site into adsorption equipment on each scattered site for adsorption treatment separately; when an adsorption module in the adsorption equipment on one scattered site reaches a saturation state, adopting a moving desorption vehicle to reach the scattered site where the adsorption module is taken out, and collecting the adsorption modules for centralized desorption treatment to avoid the situation that since desorption is incomplete due toinstallation errors or uneven quality of moving desorption vehicles of multiple enterprises, secondary pollution is caused and the efficiency of the adsorption modules is decreased. The method can achieve centralized collection and adsorption treatment of waste gas of pollution enterprises, reduce treatment costs of the enterprises and is safe and free of secondary pollution.

Owner:广东雪迪龙环境科技有限公司

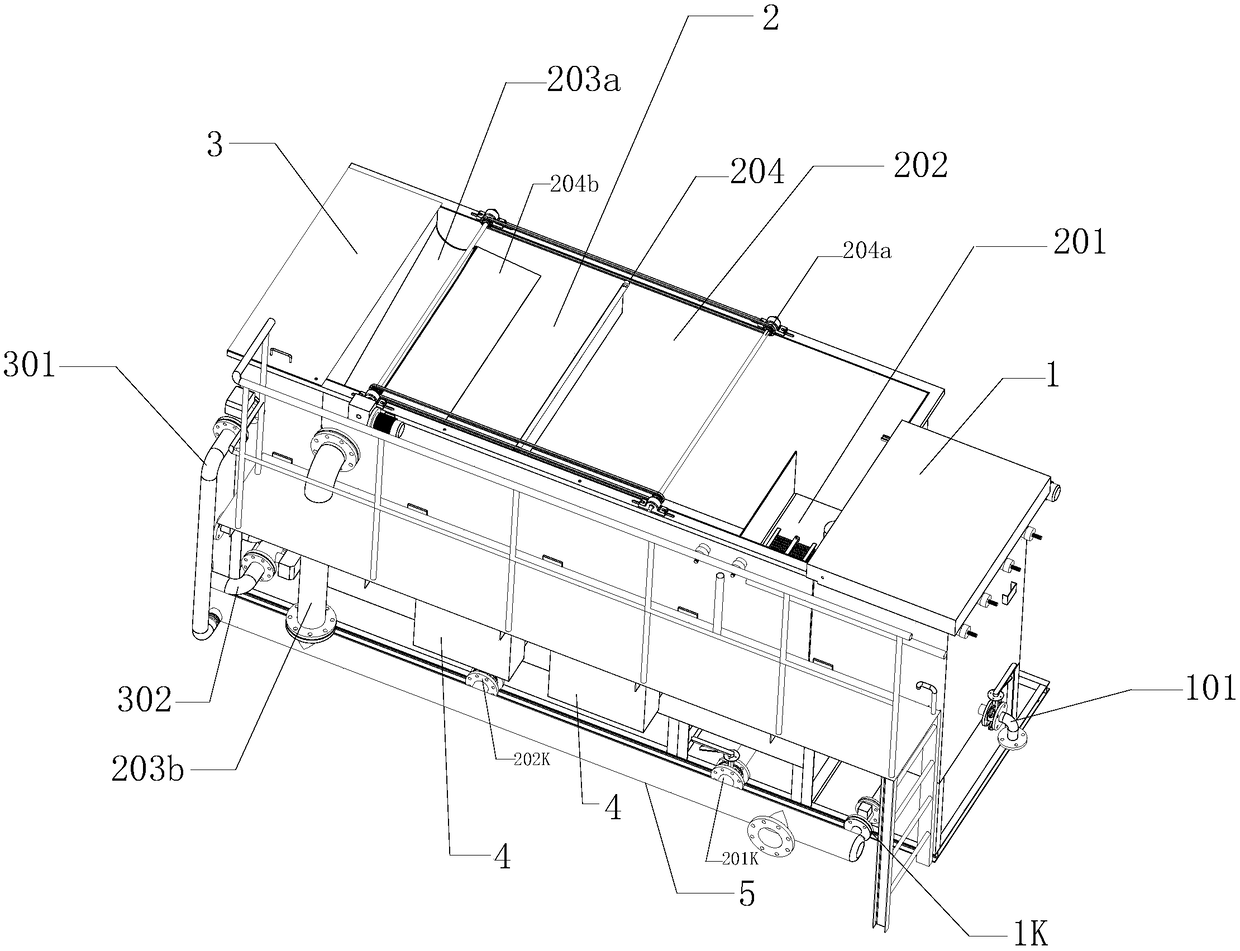

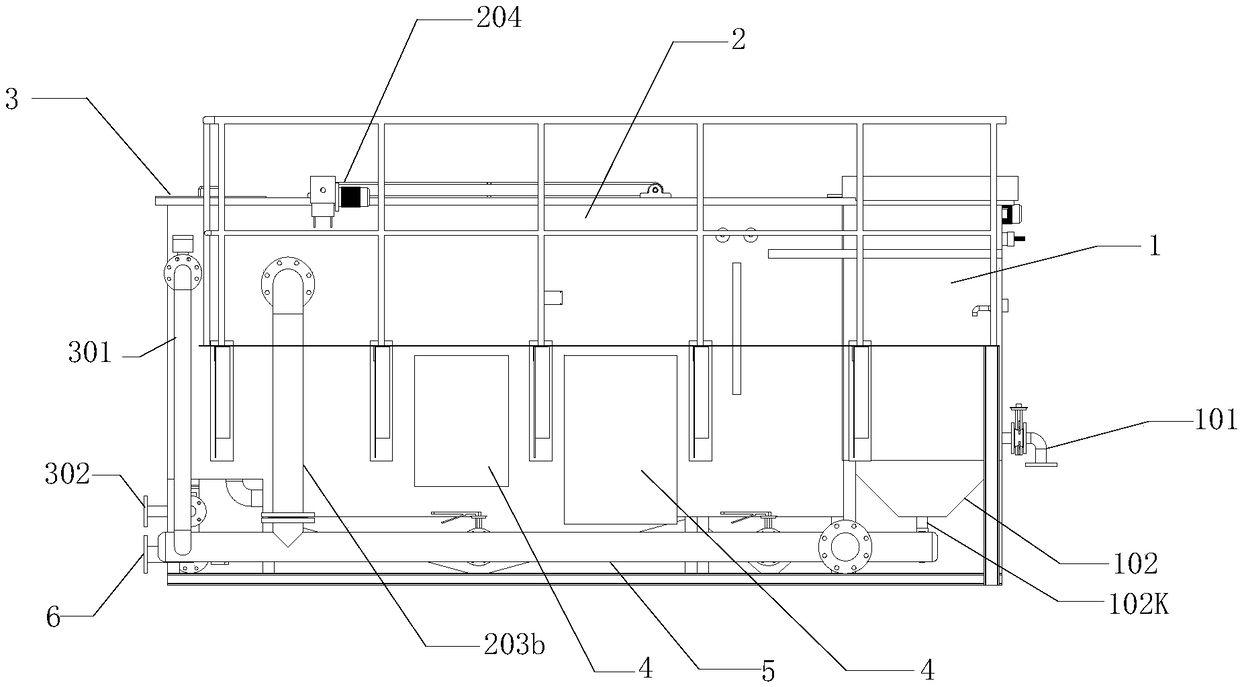

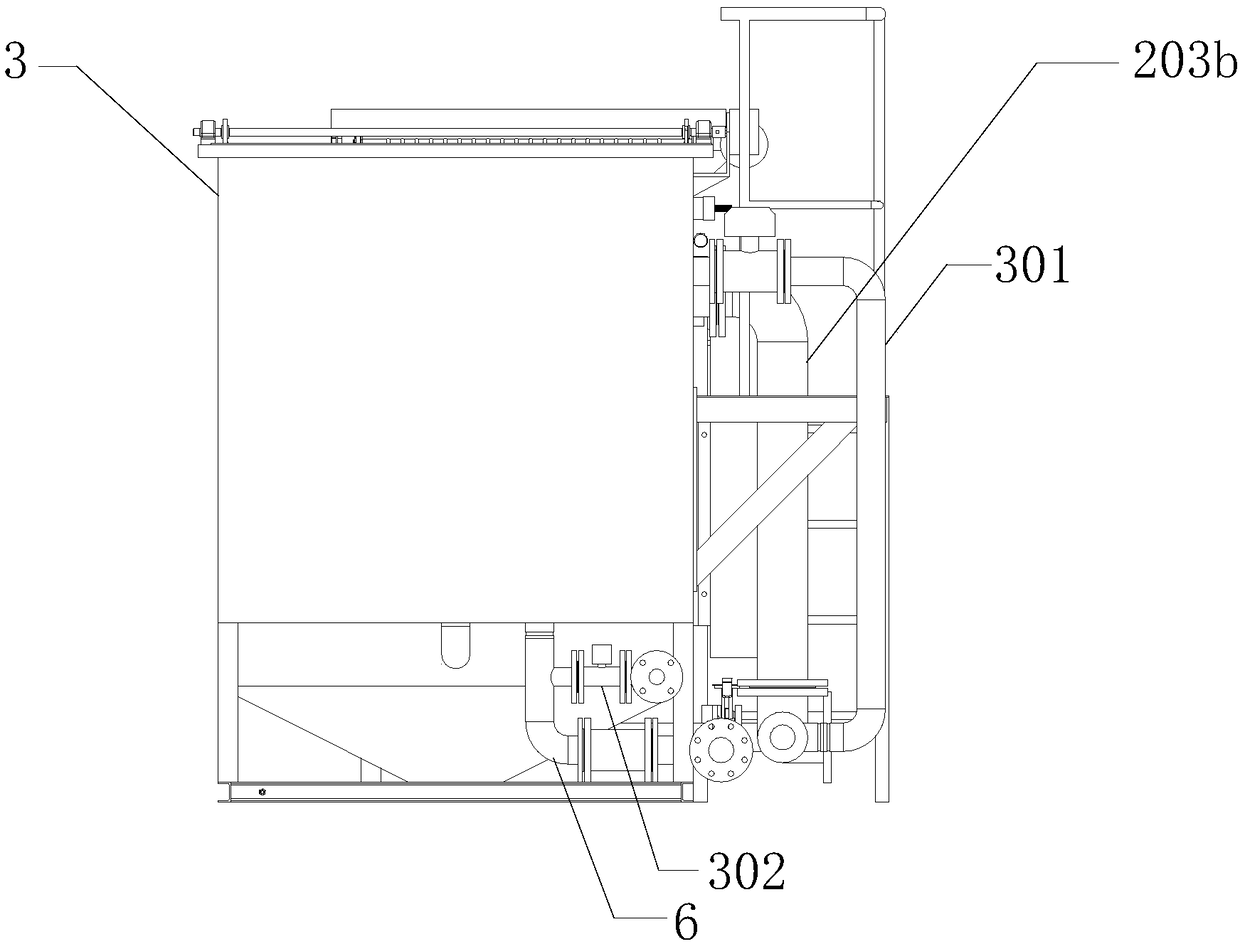

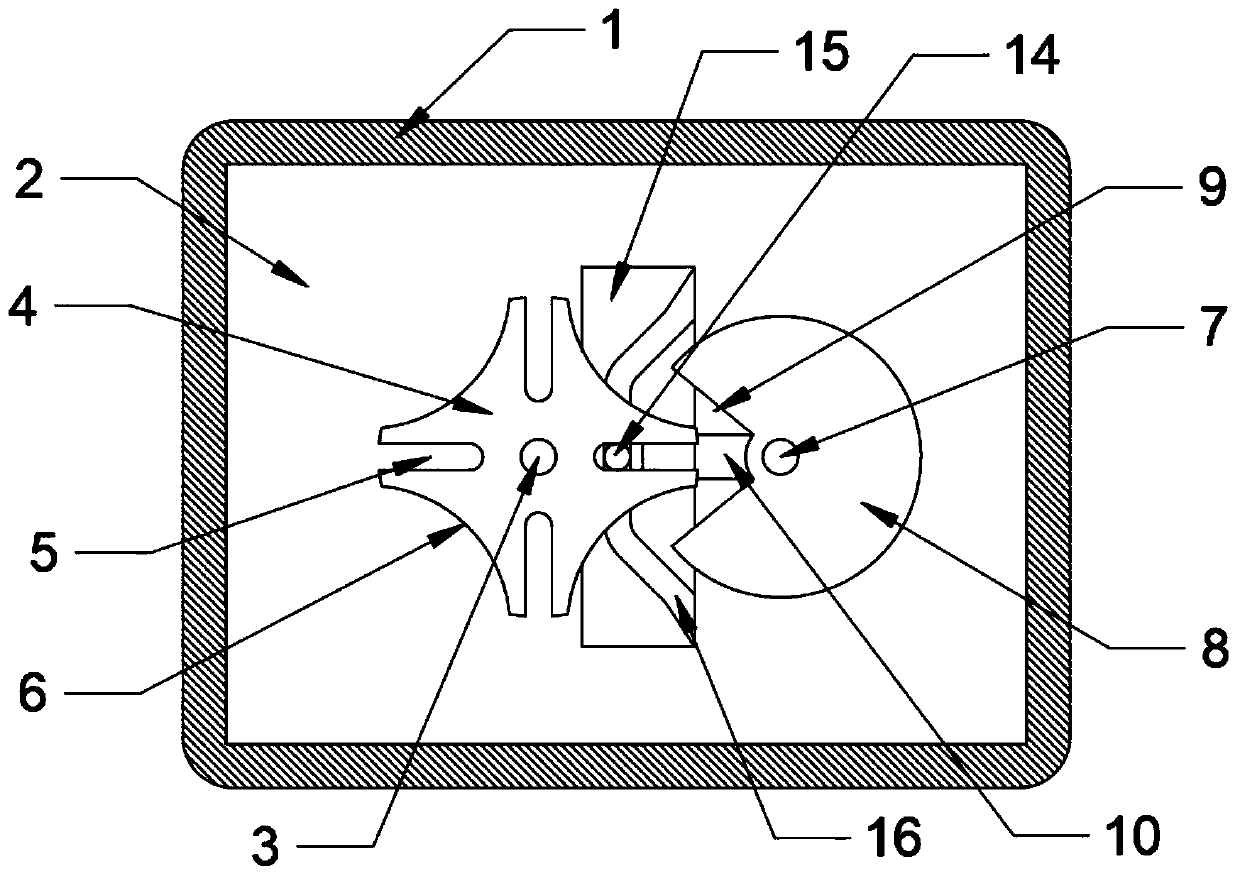

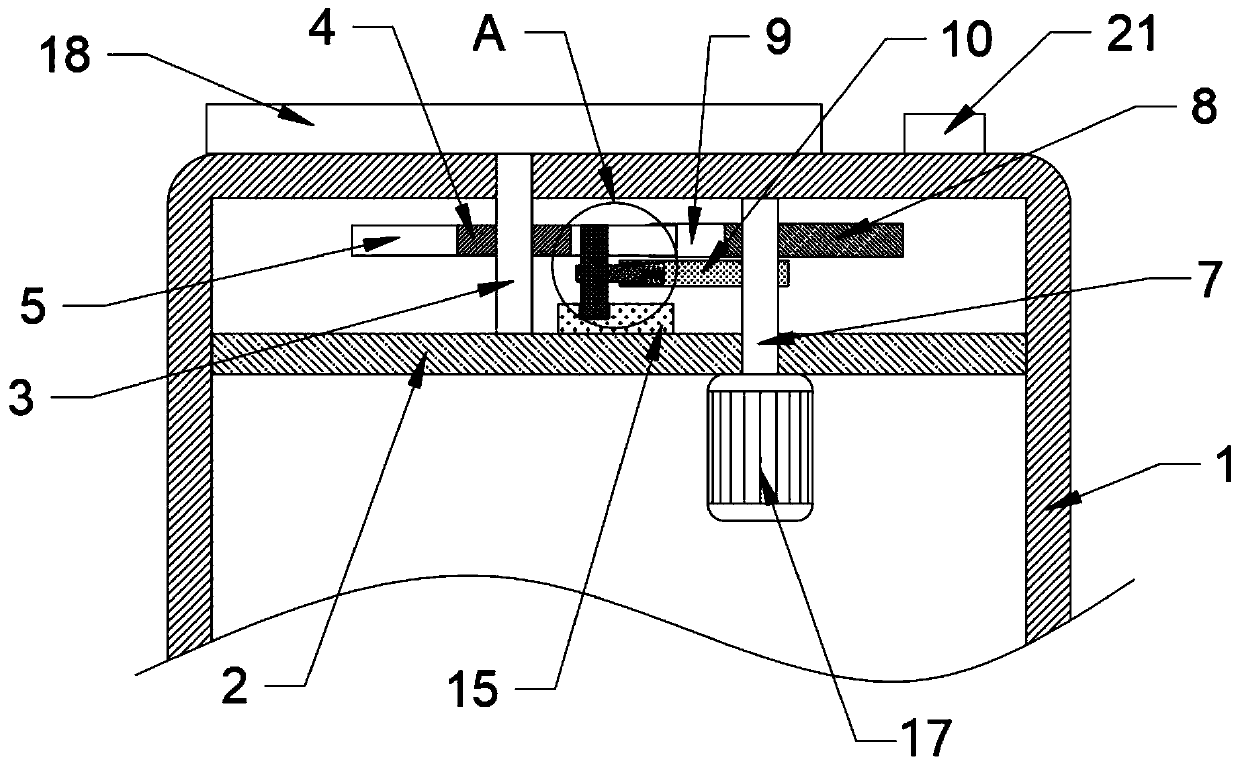

ECFF (electric-flocculation+electrolytic-flotation+filtration) type integral electric-flocculation car-washing waste water treatment device

InactiveCN109133441AReduce manufacturing costReduce floor spaceSpecific water treatment objectivesTreatment involving filtrationElectrolysisFiltration

The invention discloses an ECFF (electric-flocculation+electrolytic-flotation+filtration) type integral electric-flocculation car-washing waste water treatment device, comprising a casing, and an electric-flocculation reaction chamber, an electrolytic-flotation chamber and a filtration chamber which are communicated in sequence and arranged inside the casing. The electric-flocculation reaction chamber is arranged between a first side wall of the casing and a first partition plate, and an electric-flocculation device is arranged inside the electric-flocculation reaction chamber; the electrolytic-flotation chamber is arranged between the first partition plate and a second side wall of the casing, and an electrolytic chamber, a flotation chamber and a sewage discharging device are arranged inthe electrolytic flotation chamber; the filtration chamber is arranged between the second partition plate and the second side wall of the casing, and a filtration device is arranged in the the filtration chamber. The whole treatment device has comprehensive design of functional structure and thus its floor area and manufacturing cost can be reduced greatly; with cooperation of the electric-flocculation device, the electrolytic-flotation device and the filtration device, waste water can be sterilized, cleaned and purified once the device is connected with current, and thus, secondary pollutionis prevented effectively, treatment cost for recovery of waste water in the prior art is lowered, and car-washing waste water recovery treatment is much economical and environmentally friendly.

Owner:CHENGDU FILTRASCALE TECH

Efficient three-dimensional injection molding factory and efficient injection molding production method

The invention relates to an efficient three-dimensional injection molding factory which, from low to high, comprises no less than two work floors and a product transport elevator, wherein the product transport elevator can stop at each work floor; each work floor, from periphery to middle, is sequentially provided with an installing platform, a feeding turntable, a mold unloading platform and a workpiece taking platform; the installing platform is symmetrically provided with a plurality of injection units, each work floor is provided with multiple sets of mold unloading devices for alternately installing and removing mold units used in match with the injection units among the injection units, the mold unloading platform, the workpiece taking platform and the feeding turntable, and the workpiece taking platform is provided with a workpiece taking device. The invention also relates to an efficient injection molding production method. According to the invention, the plane occupied area of an injection molding processing factory is greatly reduced, and space resources are efficiently utilized; the important process of injection molding can be separately performed in the injection units and the mold units, and continuous processing can be performed in continuous mold taking to injection units, thereby greatly improving the production efficiency. The efficient three-dimensional injection molding factory and efficient injection molding production method disclosed by the invention can be applied to injection molding production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

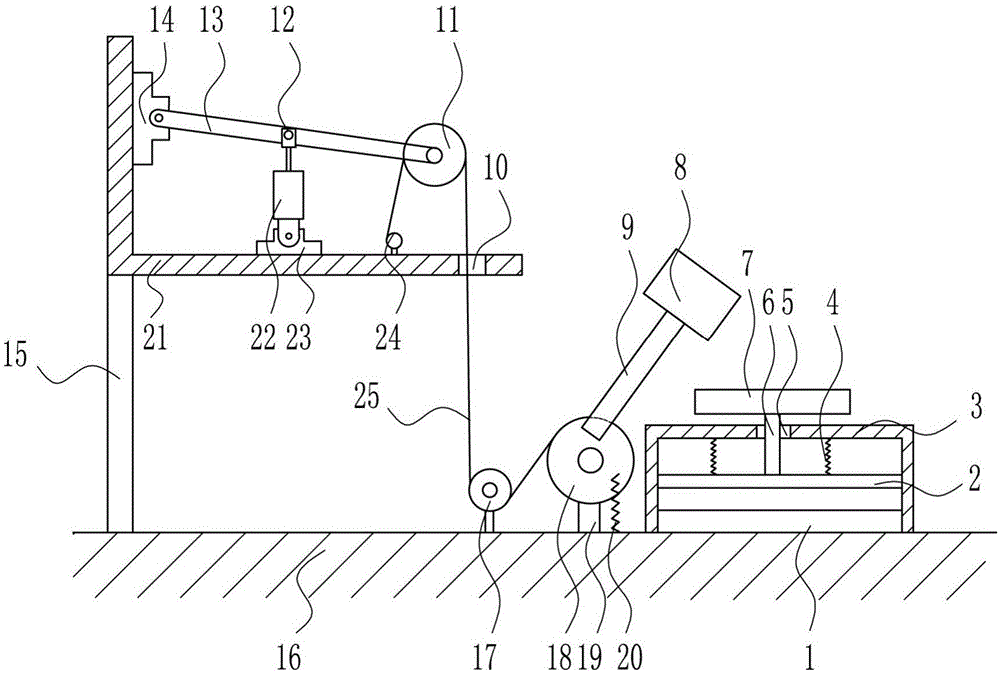

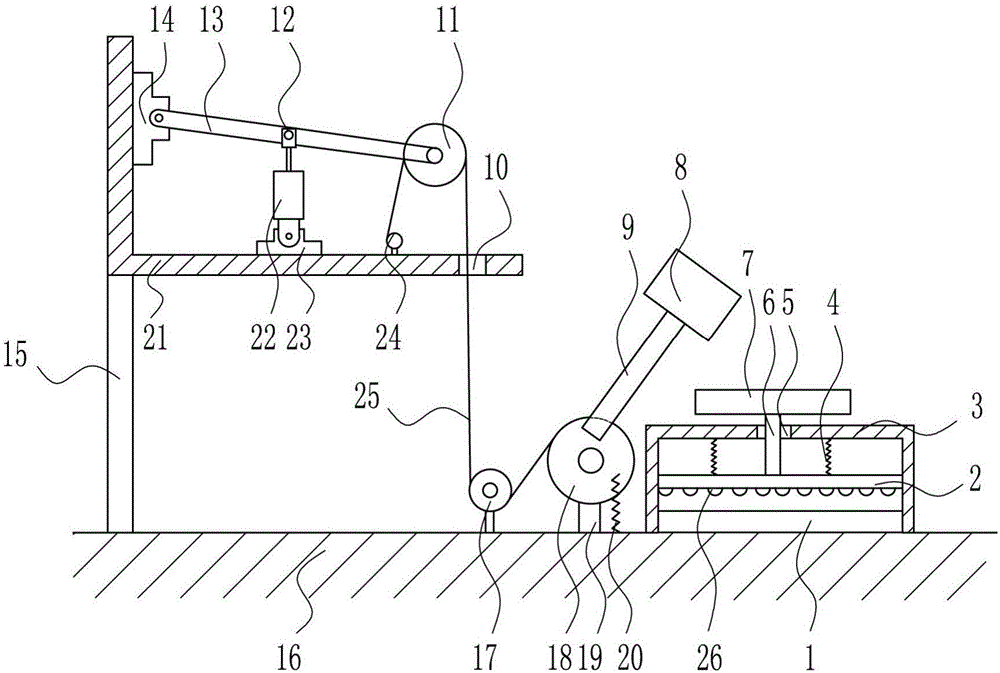

Alloy steel plate stamping device for manufacturing hardware

The invention relates to a stamping device, in particular to an alloy steel plate stamping device for manufacturing hardware. Good stamping forming effects can be realized by the alloy steel plate stamping device for manufacturing the hardware. The alloy steel plate stamping device for manufacturing the hardware comprises a die, a stamping case, second springs, a connecting bar, a pressure block, a hammer, a second swing bar, a first fixed pulley, a connecting block, a first swing bar, a first swing seat, a first fulcrum bar, a second fixed pulley, a disc, a second fulcrum bar, a first spring, a lifting frame, a cylinder, a second swing seat, a fixing ring and a stay wire. The first fulcrum bar, the second fixed pulley, the second fulcrum bar and the stamping case are sequentially arranged on the ground from the left to the right. The alloy steel plate stamping device for manufacturing the hardware has the advantages that the good stamping forming effects can be realized by the alloy steel plate stamping device, and the alloy steel plate stamping device is simple in arrangement and convenient to manually operate and is comprehensible.

Owner:深圳市鸿鸣通科技有限公司

Photovoltaic power generation transformer

InactiveCN103258625AEliminate seam lossFully balanced no-load currentTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresThree-phaseHigh pressure

The invention relates to a photovoltaic power generation transformer which is characterized by comprising a three-phase iron core arranged in a triangular mode. Each phase of the iron core is formed by coiling silicon steel sheets continuously, and a low-voltage coil and a high-voltage coil are respectively wound around the exterior of each phase of the iron core so that a three-phase coil arranged in the mode shaped like a Chinese character 'pin' can be formed. The low-voltage coil and the high-voltage coil of each phase are divided in the axial direction and are separated through a silicon pad and a divided magnetic circuit. Two ends of a vertically-pulling screw are respectively connected with one installing support. A locating structure locates the three-phase coil between the two installing supports, and leading-out bars connected with the three-phase coil are fixed on the installing supports. The photovoltaic power generation transformer is high in impedance, low in energy consumption and efficient.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

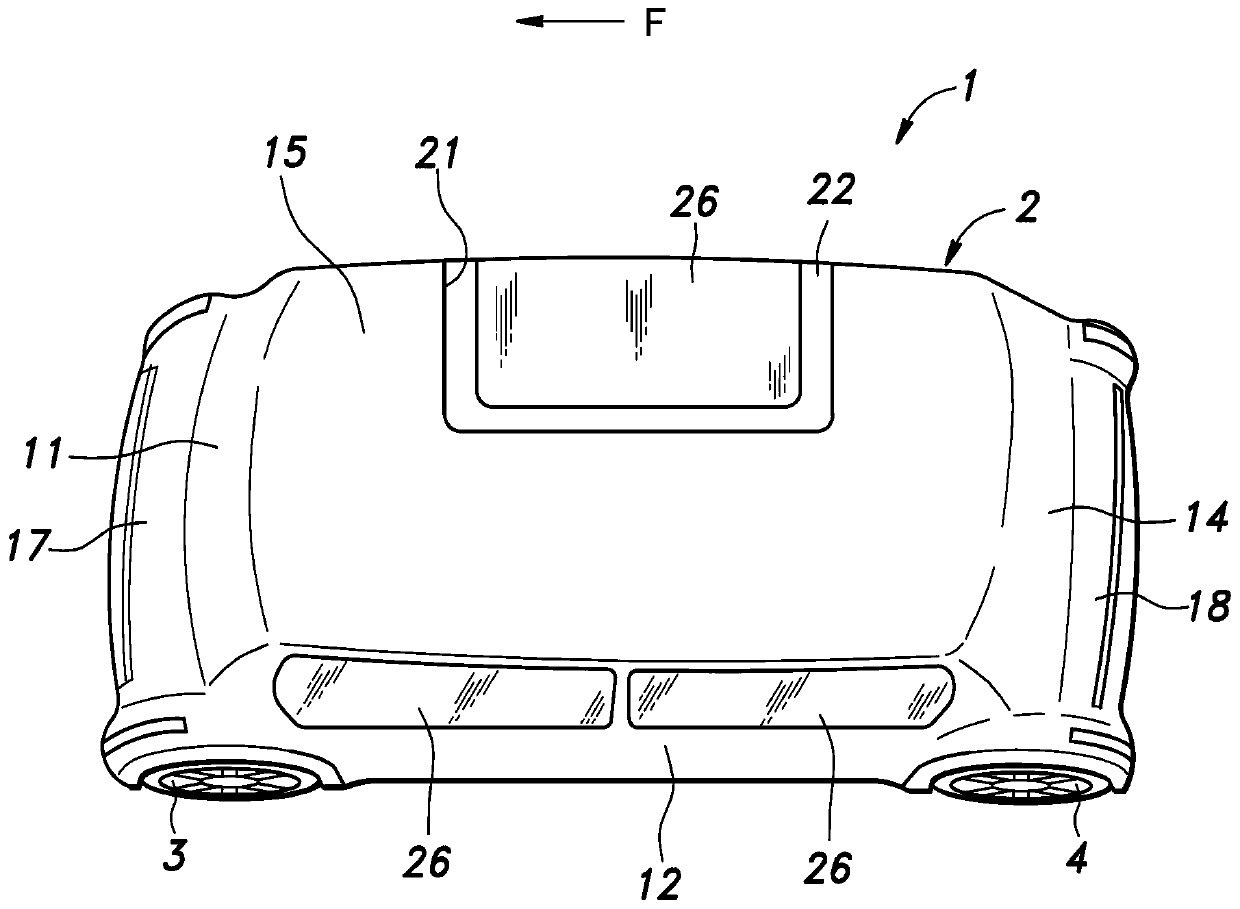

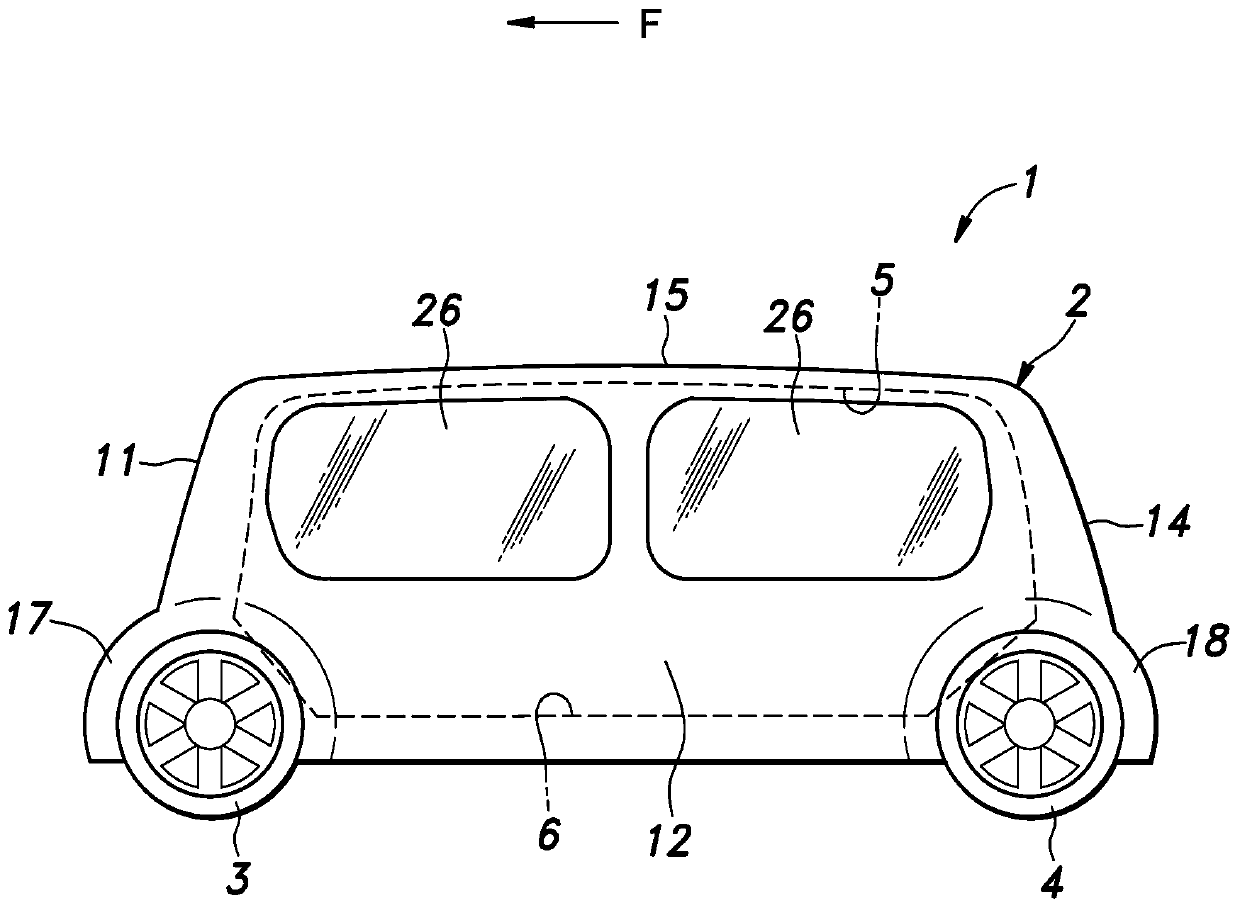

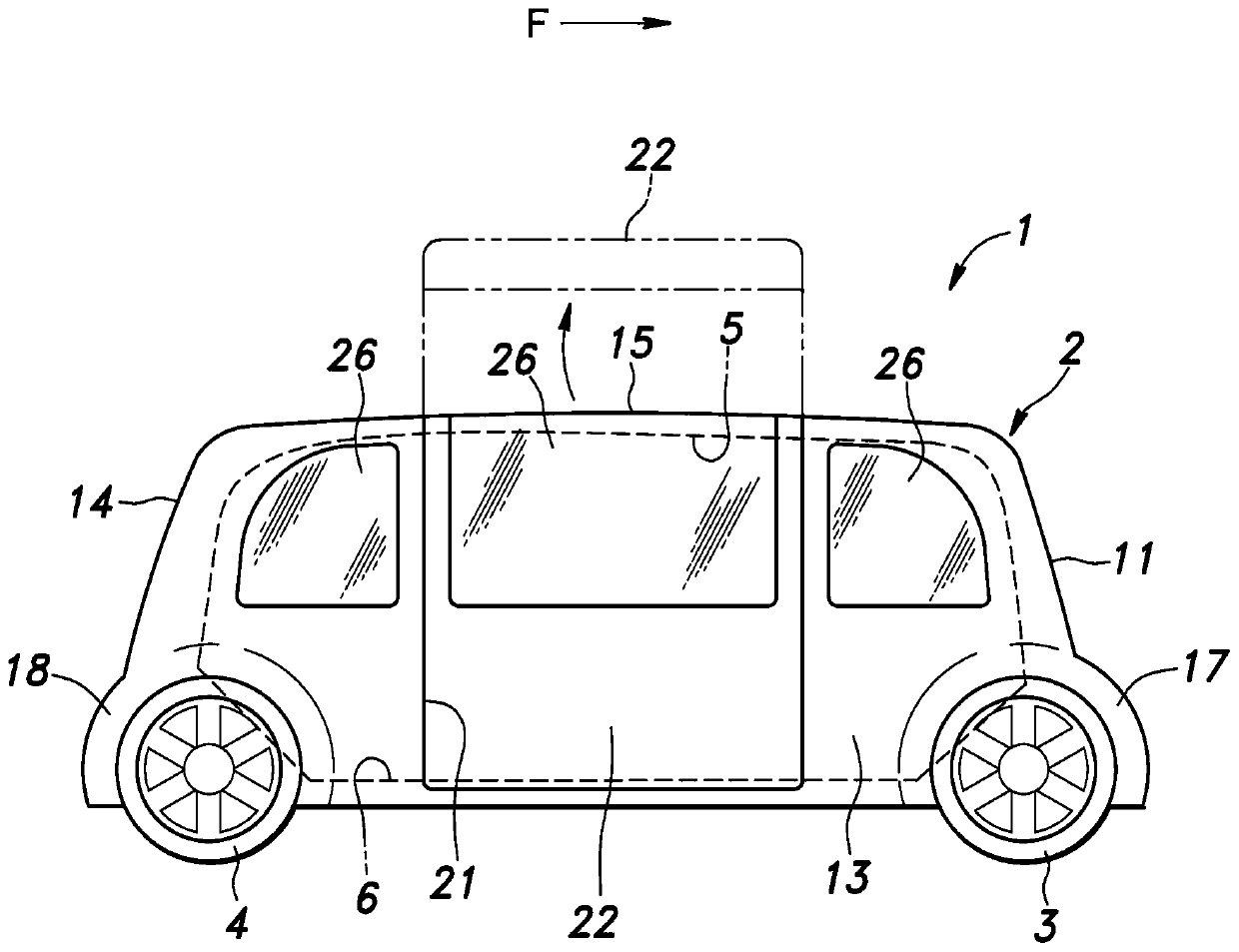

Vehicle

PendingCN110803077AReduce floor spaceImprove ride comfortArm restsMovable seatsAutomotive engineeringRotational axis

A vehicle provides a comfortable space for a wide range of passengers. The vehicle (1) includes a plurality of seats (31) arranged in a fore and aft direction in a cabin (5) of the vehicle, each seatbeing supported in the cabin so as to be rotatable around a vertically extending rotational axis. Preferably, at least one of the seats includes a support column (32) extending vertically from a floor(6) of the cabin, and a seat cushion (33) supported at an upper end of the support column so as to be rotatable around the vertically extending rotational axis.

Owner:HONDA MOTOR CO LTD

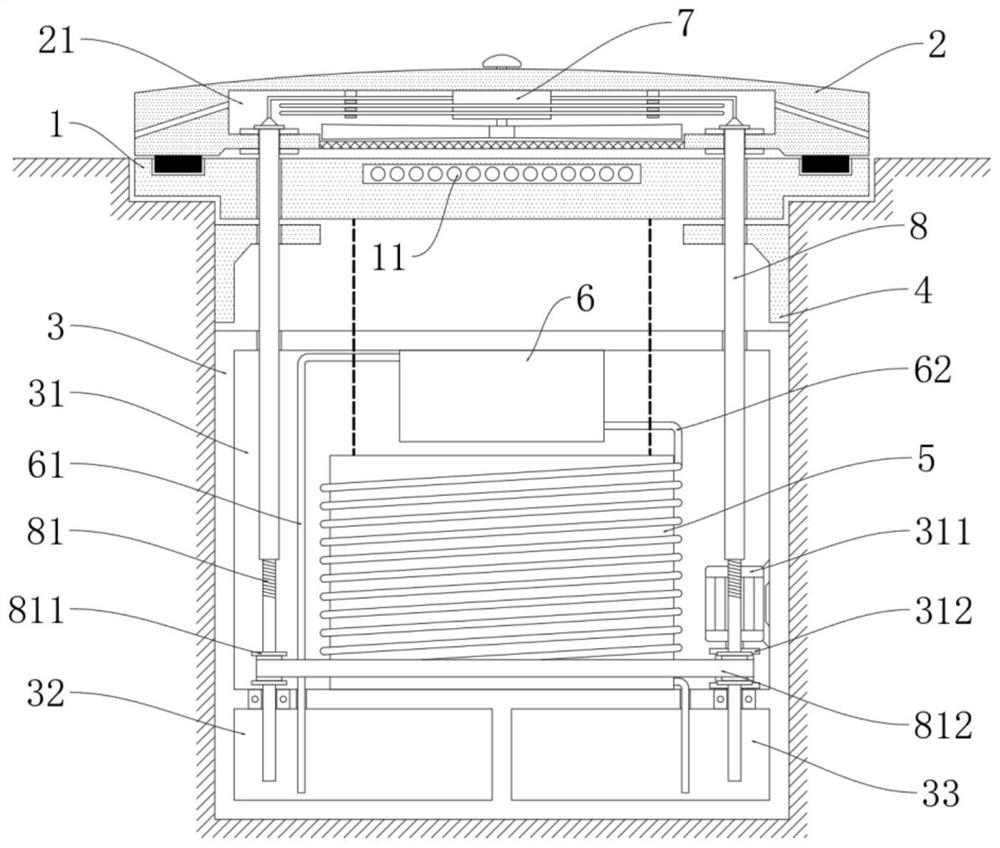

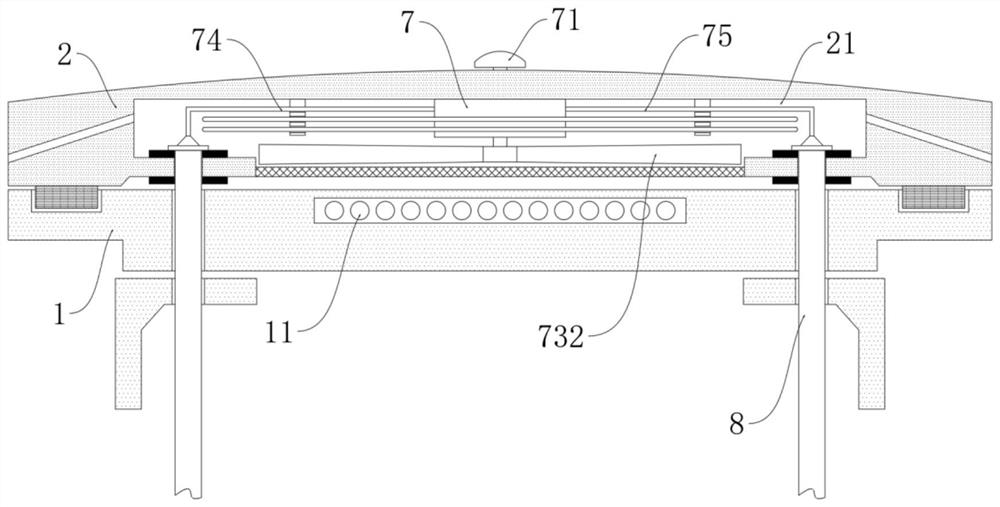

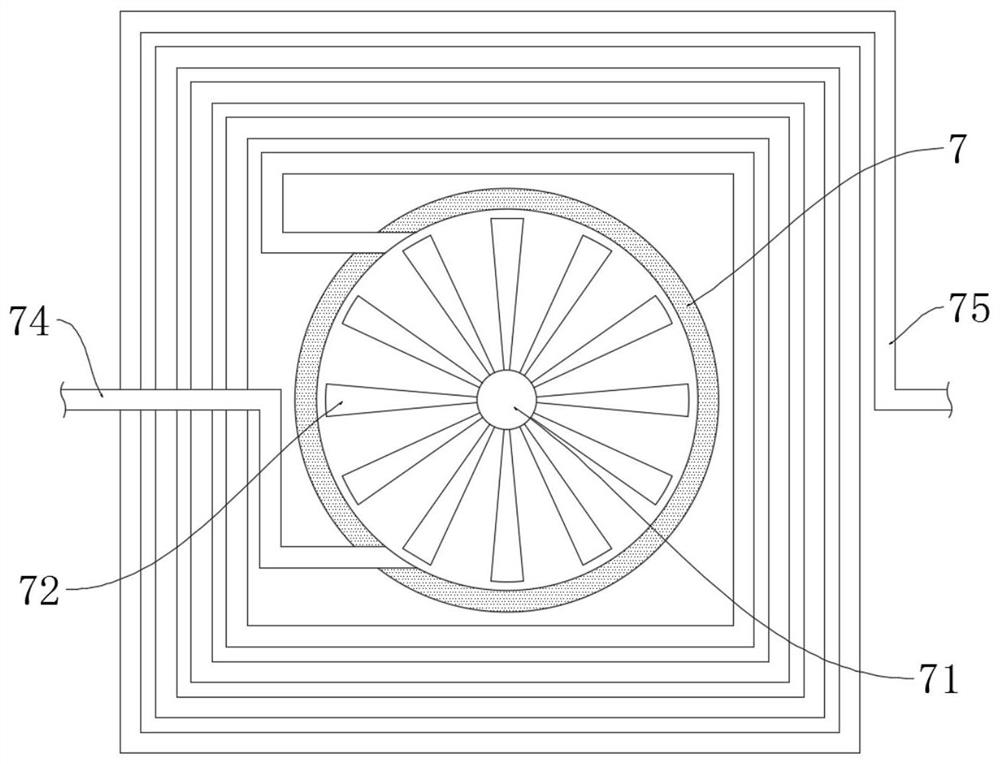

Buried wireless charging pile for new energy automobile

ActiveCN111959303AReduce floor spaceAvoid charging efficiency dropCharging stationsElectric vehicle charging technologyElectric energyInductive charging

The invention discloses a buried wireless charging pile for a new energy automobile, which comprises a sun shield, and a sealing cover plate, a plurality of right-angle supporting plates and a charging box, wherein the sealing cover plate, the right-angle supporting plates and the charging box are sequentially installed in a concrete embedded pit from bottom to top; the sealing cover plate coversa pit opening of the embedded pit; the upper surfaces of the right-angle supporting plates make contact with and are fixed to the lower surface of the sealing cover plate; and a wireless charging discis embedded in the upper surface of the sealing cover plate. The charging box is buried and installed, so that the occupied space of the ground is reduced; the influence of the distance on the charging efficiency is reduced through fixed-distance charging of the sealing cover plate and the automobile chassis; the temperature of the charging pump is reduced through water-cooling heat exchange of the liquid inlet pipe, so that the influence of overheat charging on the efficiency is reduced, the ambient temperature of the automobile is reduced through air cooling of the sun shield, high-temperature charging spontaneous combustion is avoided, the charging safety is improved, air-cooling automatic regulation and control are achieved through the temperature sensing pipe, and electric energy loss is reduced.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY

Linear cleaning peristaltic metering pump

PendingUS20220003228A1Simple and compact structureGood synchronizationPositive displacement pump componentsFlexible member pumpsReciprocating motionEngineering

A linear cleaning peristaltic metering pump includes a pump body, a hose fixing accessory and an anti-backflow accessory. The hose fixing accessory is configured for arranging a working hose. The anti-backflow accessory is configured for clamping and loosening the working hose. The pump body is configured for performing reciprocating motion to clamp or loosen the working hose, thereby realizing a pumping effect by metering pump. The anti-backflow accessory is in cooperation with the pump body. The pump body comprises a roller lifting assembly, a roller hose-pressing assembly, a pump body outer cover assembly and a power transmission part. The power transmission part is configured for driving the roller lifting assembly to perform lifting linear motion, thereby driving the roller hose-pressing assembly to move and to clamp or loosen the working hose.

Owner:CHANGSHA ZENITHSUN INTELLIGENCE QUANTITATIVE TECH CO LTD

A rotary guide table for outpatient clinics

InactiveCN110030472BReduce floor spaceEasy to useStands/trestlesIdentification meansEngineeringMechanical engineering

The embodiment of the invention discloses a rotary type guiding table for outpatient service. The rotary type guiding table includes a mounting box, a mounting plate, a driven rotating shaft, a firstrotary disc, a driving rotating shaft, a second rotary disc, a fixing rod, a sliding rod, a spring, a pulling column, a limiting plate, a servo motor, a rotary disc, a rotary box, a display panel anda control panel, wherein the mounting plate is fixed to the upper end of the inner wall of the mounting box, the upper surface of the mounting plate is rotatably connected with the driven rotating shaft through a bearing, the first rotary disc is fixed to the middle of the driven rotating shaft, drive grooves and limiting grooves are formed in the side wall of the first rotary disc at intervals, the end, away from the driven rotating shaft, of the upper surface of the mounting plate is connected with the driving rotating shaft through a bearing, the second rotary disc is fixed to the end, close to the first rotary disc, of the driving rotating shaft and slidably connected with the limiting grooves, and a fan-shaped groove is formed in the outer side of the rotary disc. According to the rotary type guiding table for outpatient service, through the rotary display panel, the occupied area can be greatly reduced under the situation that the display area is not reduced, operation is stable,and the rotary type guiding table is convenient for people to use.

Owner:JILIN UNIV

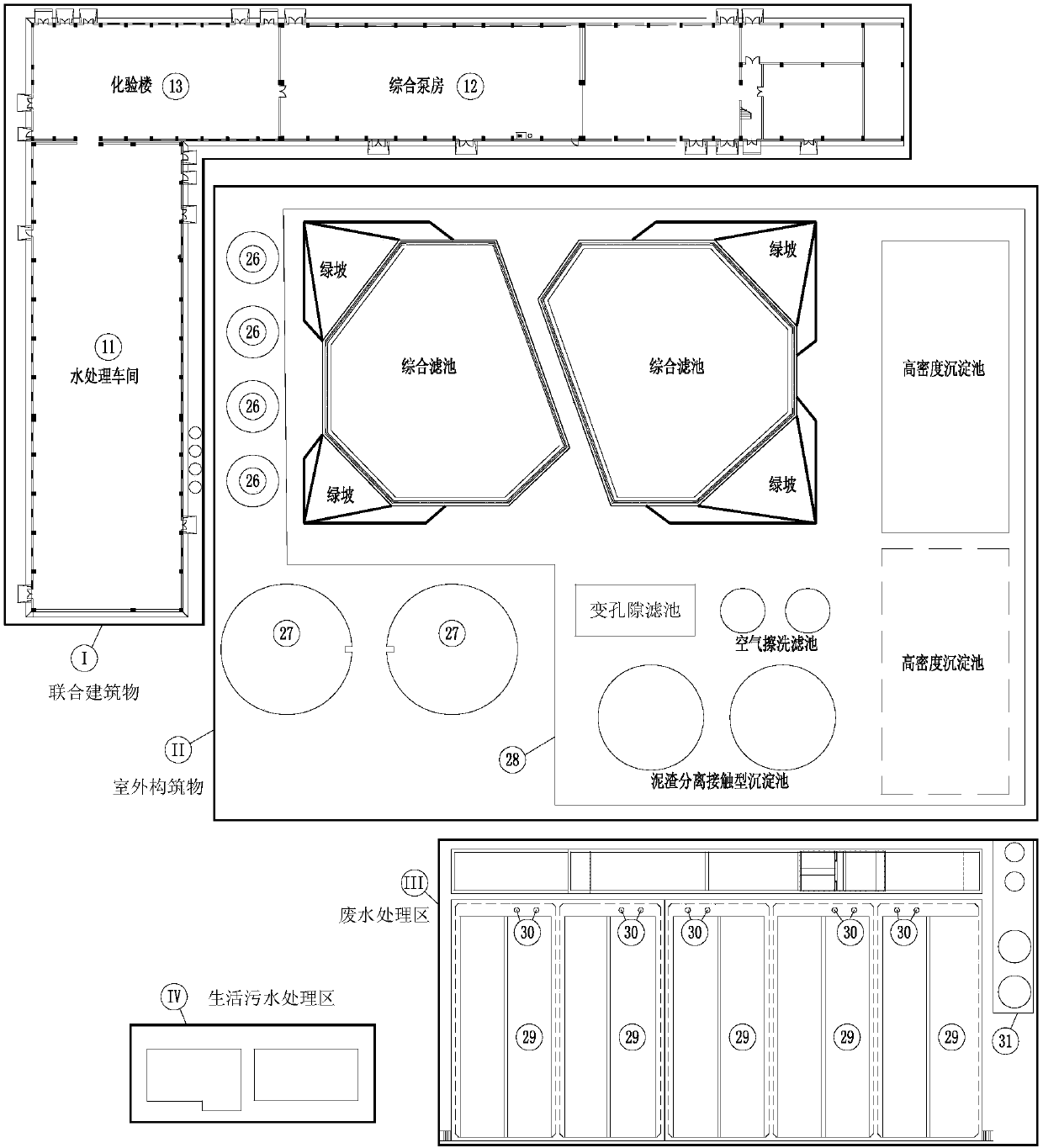

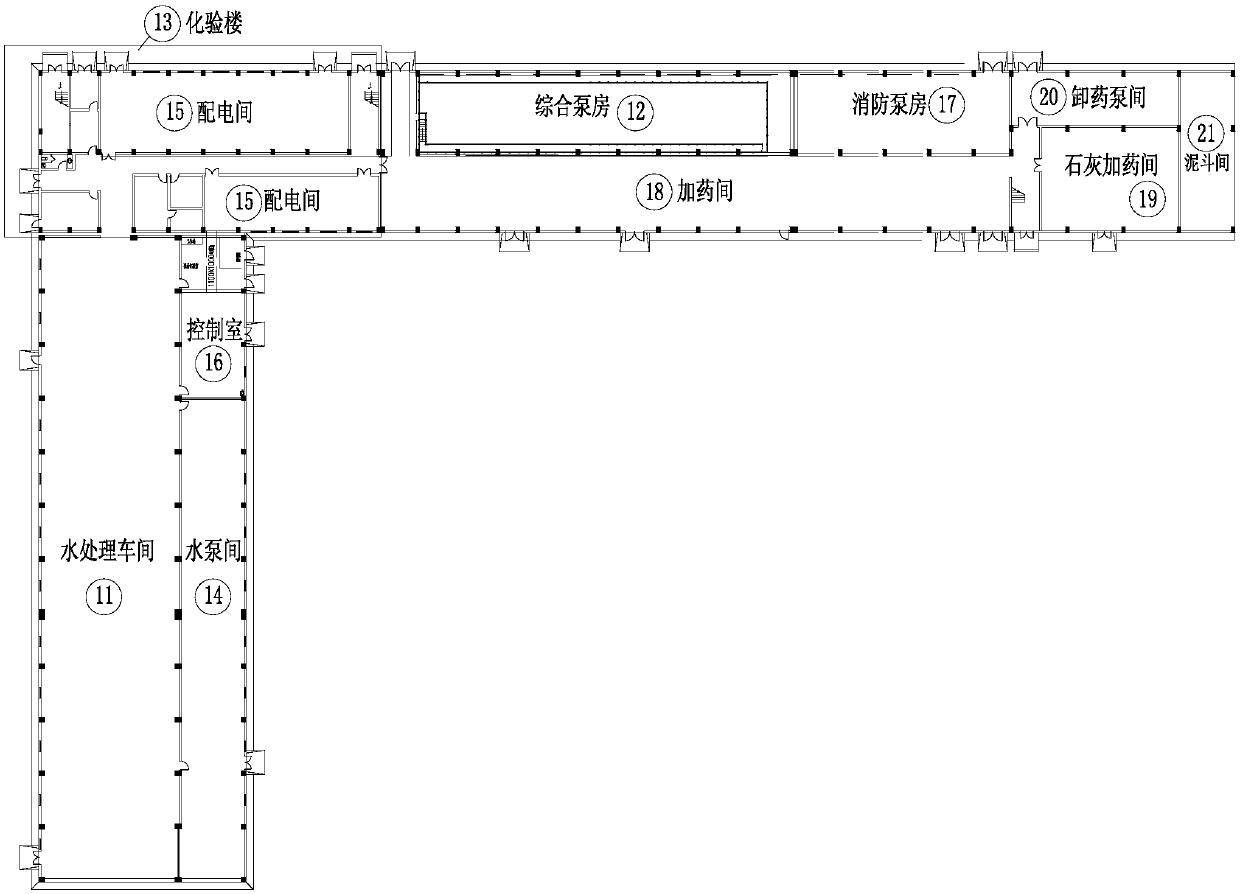

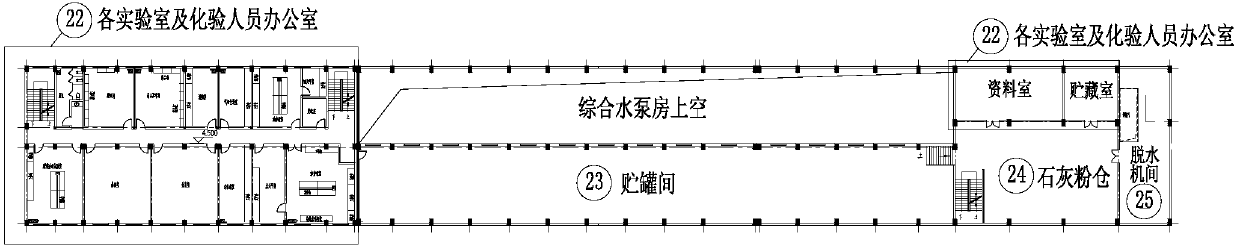

Intensive layout structure of large-scale thermal power plant water center

PendingCN107939096ATake advantage ofReduce floor spaceGeneral water supply conservationTreatment involving filtrationPower stationWastewater

Provided is an intensive layout structure of a large-scale thermal power plant water center. The large-scale thermal power plant water center includes a joint building, an outdoor structure and a wastewater treating area; a ground floor of the joint building includes a water treating workshop, a comprehensive pump house, a laboratory building, a pump compartment, a power distribution room, a control room, a fire-pump room and a dosing room, wherein a second floor is arranged above the comprehensive pump room and the laboratory building, and all laboratories, experimenter offices, a storage room, a lime powder bin and a dehydrator room are arranged on the second floor; the outdoor structure includes water tanks at all levels, desalting water tanks and various pools; a wastewater treating pool of the wastewater treating area is arranged beside the outdoor structure, the top of the wastewater treating pool is provided with a wastewater pump, and a series of wastewater treating devices arearranged beside the wastewater treating pool; the joint building is an L-shaped building composed of a horizontally arranged main building and an annex building which is vertically connected with themain building, wherein the ground floor of the main building mainly includes the laboratory building and the comprehensive pump room, and the annex building mainly includes the water treating workshop.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

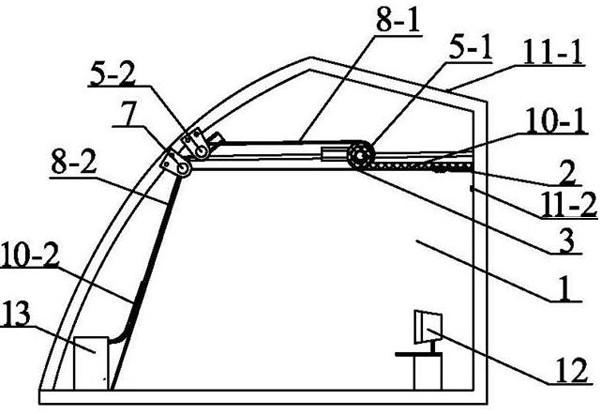

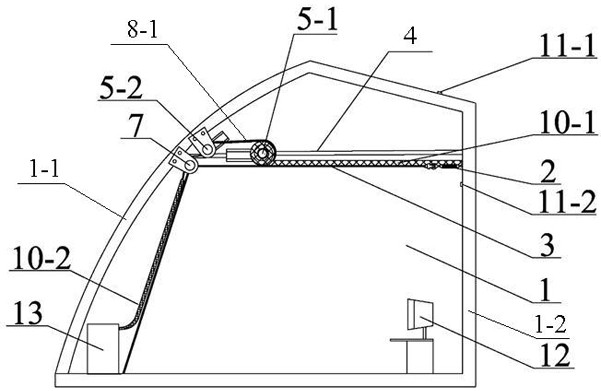

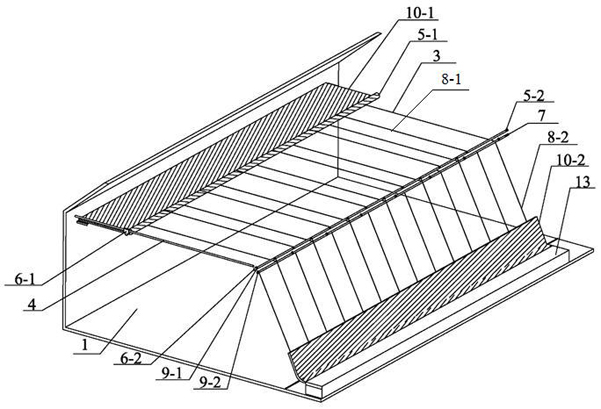

Novel solar greenhouse internal heat preservation device

PendingCN113575213AGuaranteed to workSimplify workClimate change adaptationGreenhouse cultivationElectric machineControl system

The invention relates to a novel solar greenhouse internal heat preservation device which comprises a greenhouse, a horizontal heat preservation quilt, a side heat preservation quilt, a plurality of heat preservation quilt supporting devices and a driving device, wherein each heat preservation quilt supporting device comprises a cableway fixing device, a heat preservation quilt supporting cableway and a driven shaft; the driving device comprises a horizontal heat preservation quilt driving shaft, a horizontal heat preservation quilt driving motor, a side heat preservation quilt driving shaft, a side heat preservation quilt driving motor and a motor sliding way; and the solar greenhouse inner heat preservation device is further provided with a control system. According to the device, two sets of heat preservation quilts are synchronously retracted, released and stretched through winding of different combinations of multiple steel wire ropes and different winding directions of the steel wire ropes on different transmission shafts. During working, the motors are controlled to rotate cooperatively through buttons, a power shaft achieves the heat preservation function in the sunlight greenhouse through rolling of a reel, the whole working process is efficient and simple, and operation by people is facilitated.

Owner:SHENYANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com