Building outline forming machine

A technology for building outlines and forming machines, which is used in construction, building construction, and processing of building materials, etc., can solve problems such as work quality and efficiency limitations, low equipment integration, and long assembly cycle, so as to avoid clogging of feeding materials. The effect of reducing the use of land and improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

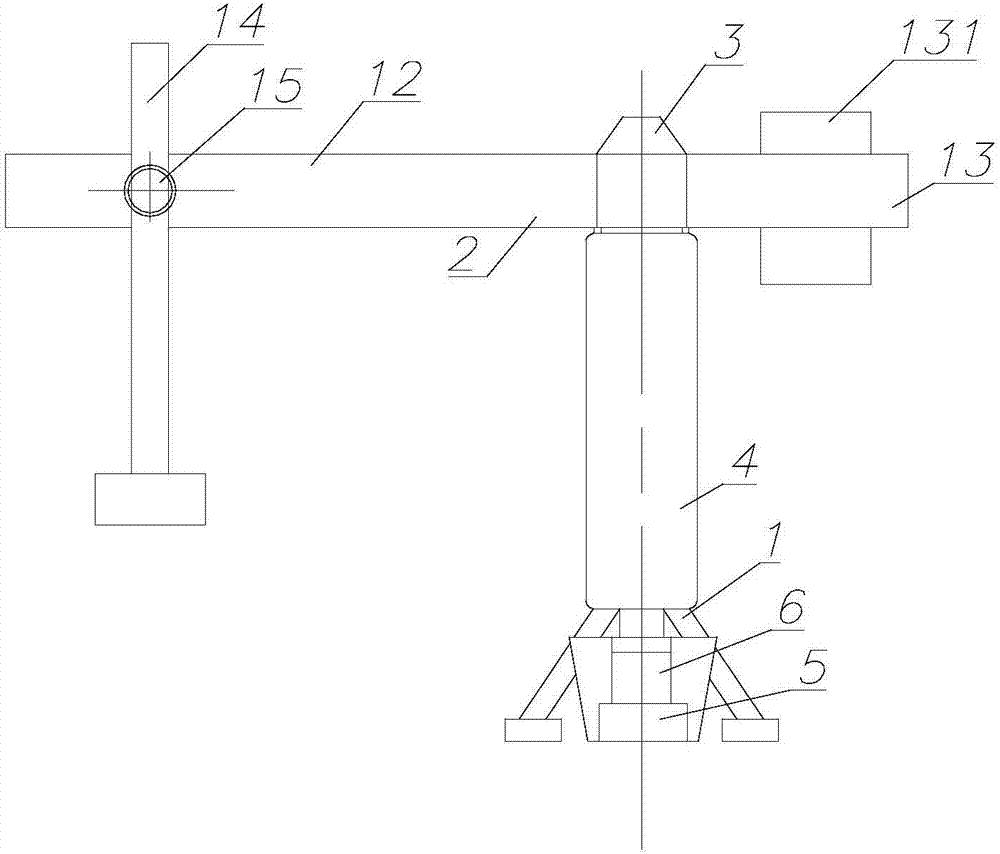

Embodiment 1

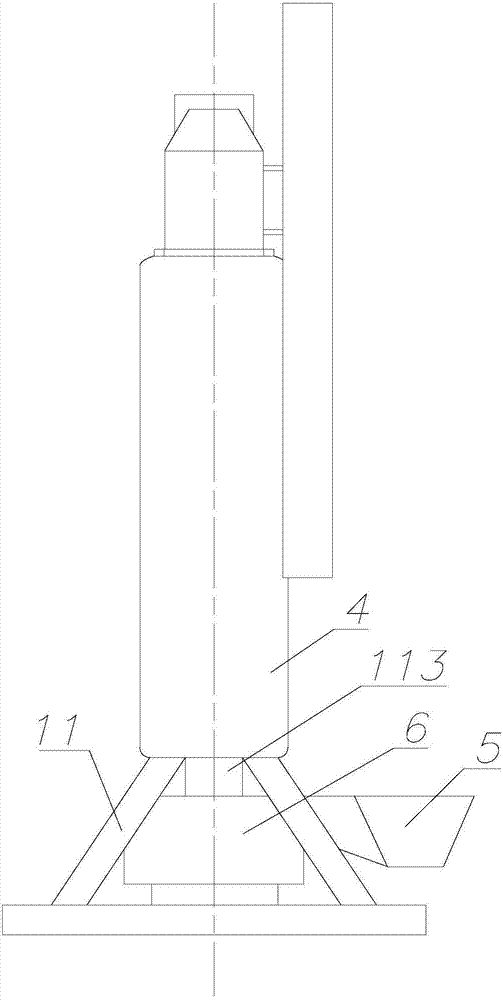

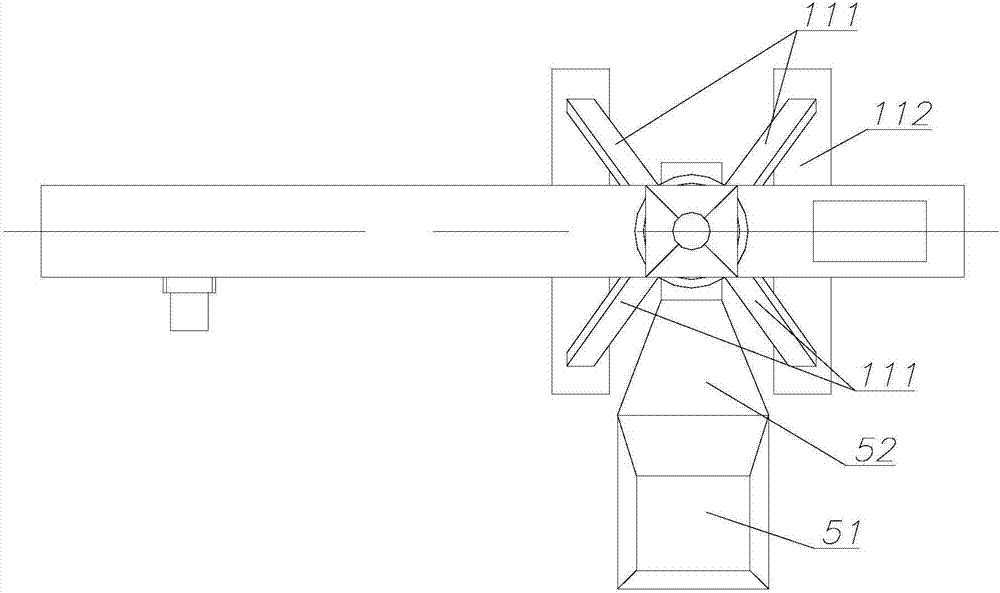

[0034] The silo 4 includes a plurality of sub-silos for storing raw materials of different types or particle sizes. A stirring mechanism 6 and a conveying mechanism 5 are arranged at the bottom of the silo 4. The conveying mechanism 5 is connected to the discharge port of the stirring mechanism 6. Each sub-silo can store raw materials such as sand and cement, and additives such as wet agent, quick-drying agent, and thickener according to the design requirements. The stirring mechanism 6 sends the raw materials to the material output unit 100 through the conveying mechanism 5 after stirring. Preferably, an electromagnetic switch is provided at the outlet of the sub-bins, and the control unit controls the electromagnetic switches to add the raw materials in each sub-bin to the stirring mechanism 6 in proportion, and then send them to the conveying mechanism 5 after mixing.

[0035] like figure 2As shown, the stirring mechanism 6 is arranged in the bottom frame 11 of the base 1 ...

Embodiment 2

[0039] like Figure 4 As shown, the base 1 is provided with a pneumatic conveyor 500 that cooperates with the silo 4, and a stirring mechanism 6 is arranged above the silo 4. The silo 4 is used to store dry materials such as dry powder mortar. The raw materials are transported to the stirring mechanism 6 to stir the dry powder mortar, and then the stirred dry powder mortar is sent to the material output unit 100 .

[0040] The powder is transported by the pneumatic conveyor 500, and the dry powder mortar is pneumatically conveyed, which can effectively reduce the difficulty of feeding and avoid clogging of the feeding pipe, especially for operations on high floors. Mechanism 6, the powder is stirred by the stirring mechanism 6 and then fed to the material output unit 100 horizontally along the rotary platform, so that the stirred material is not easy to block the pipe, and the feeding is more stable, improving the working quality. Of course, the pneumatic conveyor 500 can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com