Patents

Literature

85results about How to "Reduce the difficulty of feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

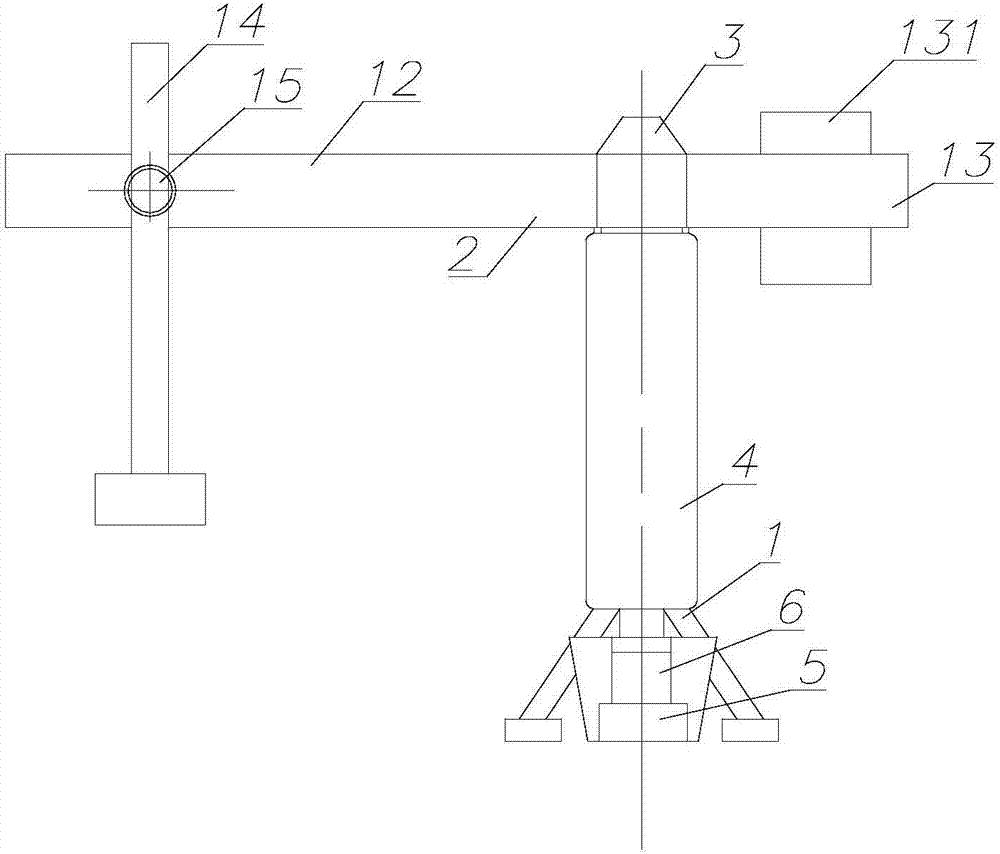

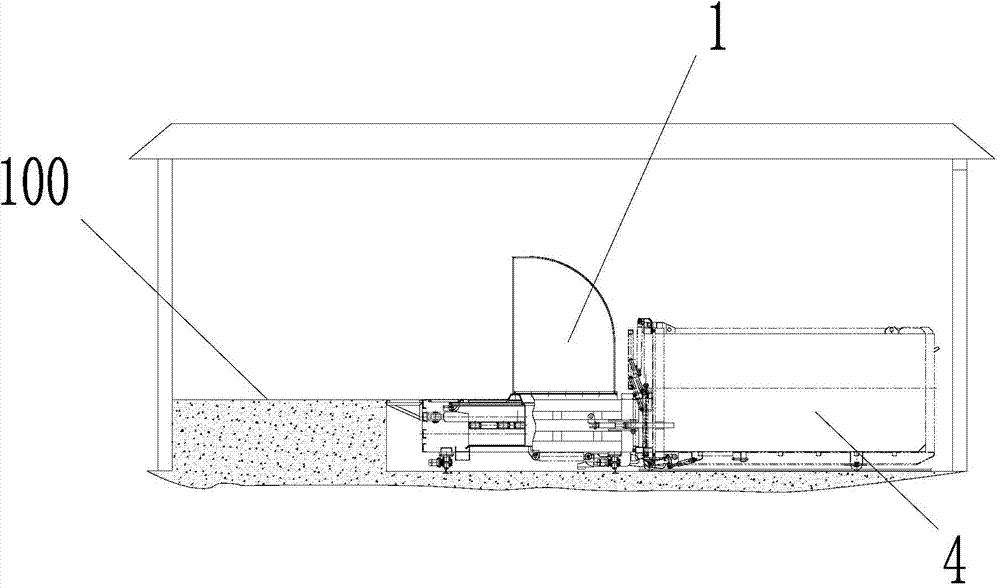

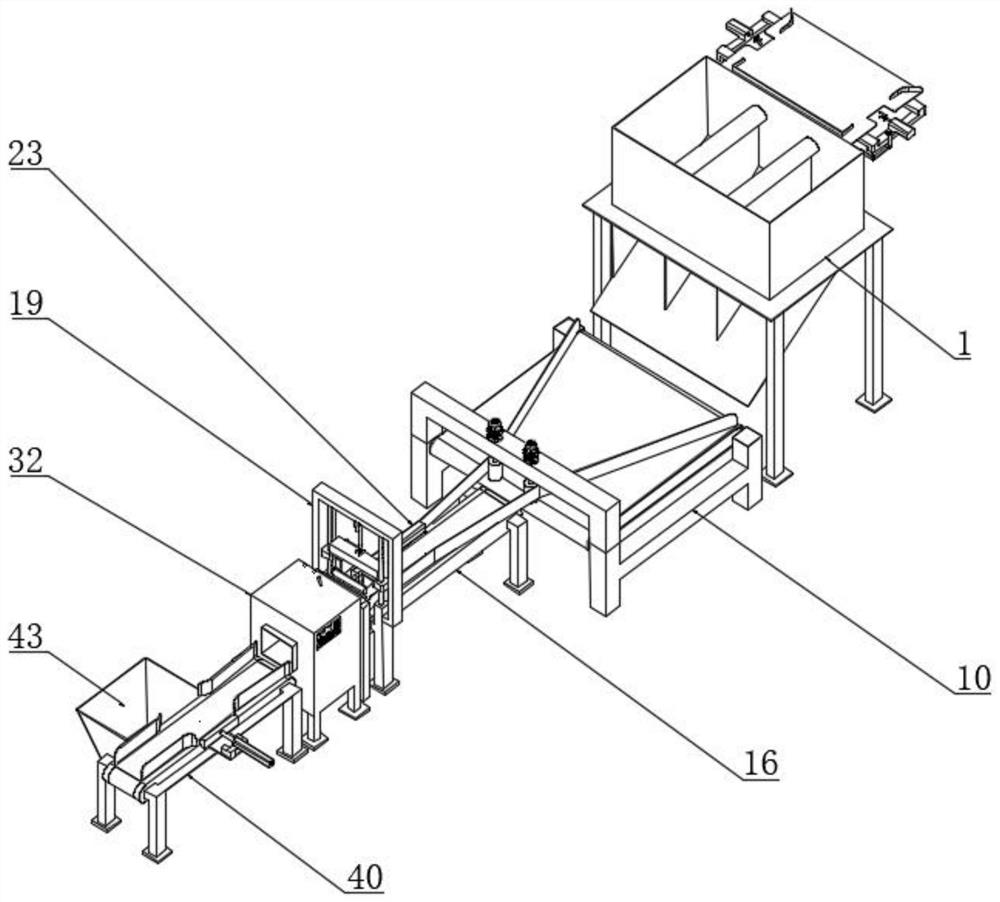

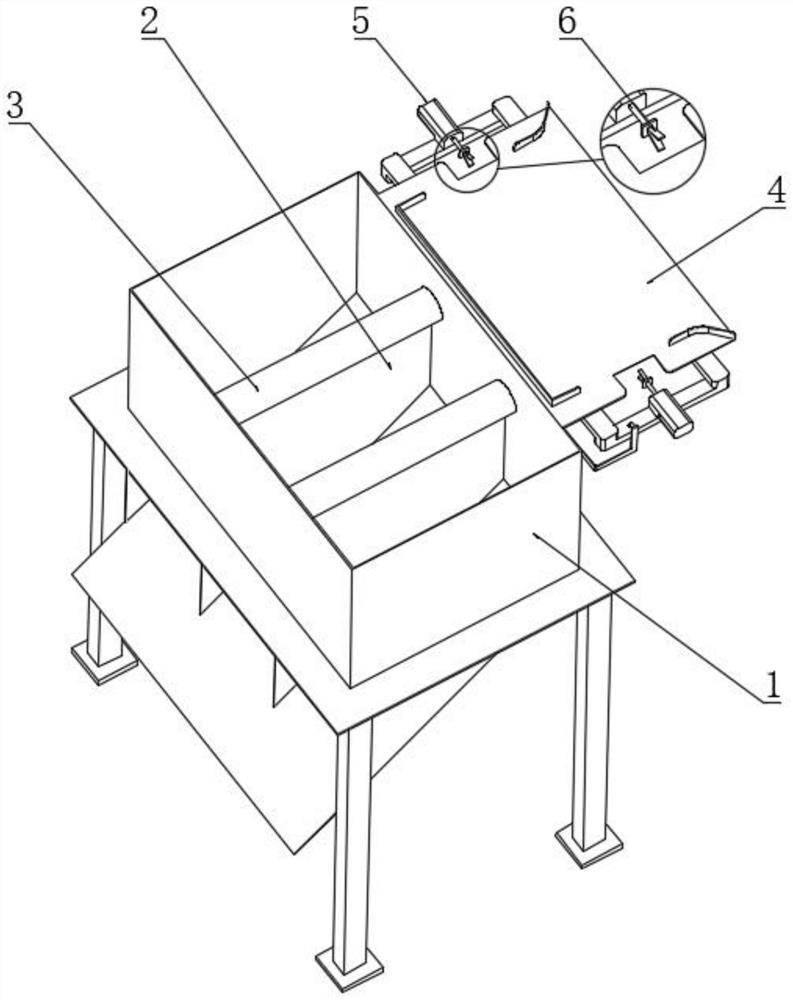

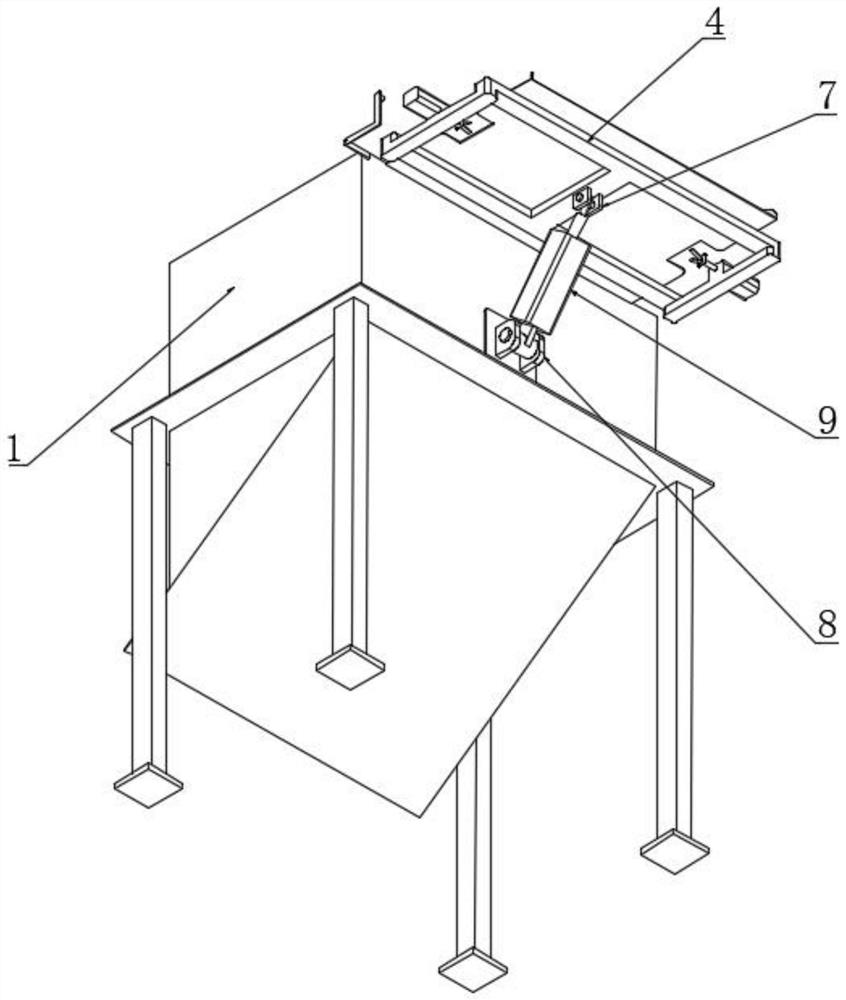

Novel wallboard gluing and composite pressure maintaining production line and polystyrene board loading device thereof

InactiveCN105905590AImprove accuracyRealize automatic grabbing and loadingConveyorsConveyor partsProduction linePolystyrene

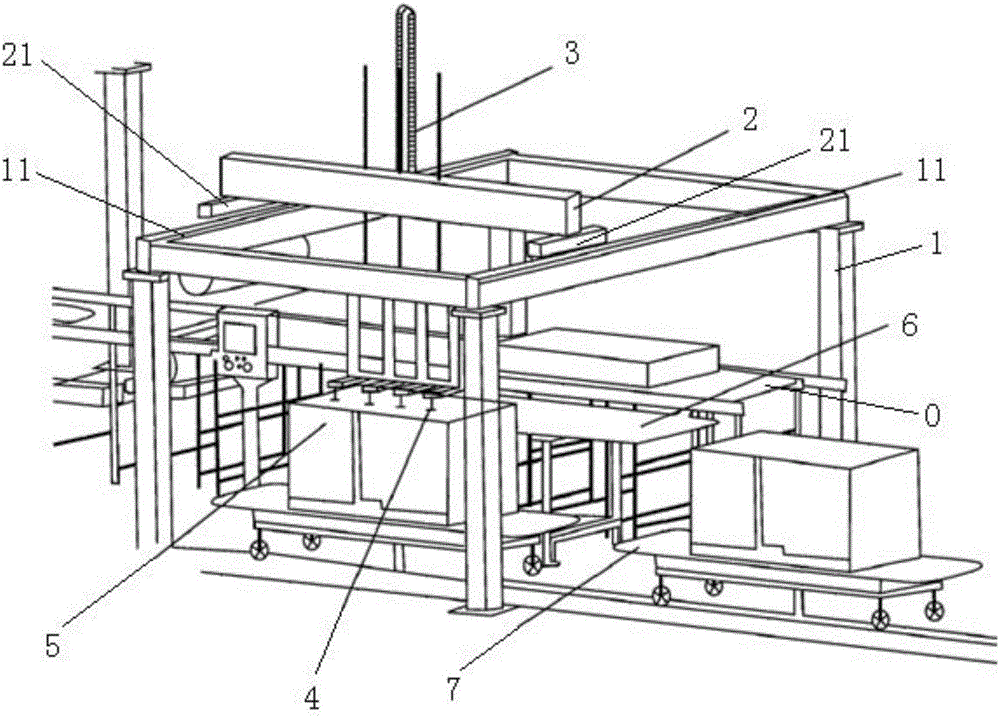

The invention discloses a novel wallboard gluing and composite pressure maintaining production line and a polystyrene board loading device thereof. The polystyrene board loading device includes a support frame crossing a line body transversely, a feeding slide table mounted on the support frame in a sliding manner and a lifting mechanism whose fixed end is mounted on the feeding slide table. A lifting end of the lifting mechanism moves up or down in the vertical direction relative to the feeding slide table and a grabbing piece is mounted at the lifting end. The grabbing piece is connected to or separate from a polystyrene board. The support frame is provided with a slide rail extending in the width direction of the line body. A slide block is mounted on the feeding slide table. The slide block is mounted on the slide rail in a sliding manner. An aligning table is also arranged between the initial position of the polystyrene board and the line body. In this way, automatic grab loading is realized, so that the loading difficulty is reduced, the processing efficiency is improved. Besides, since the aligning table is arranged, the automatic alignment of the polystyrene board during a loading process is realized and the loading position accuracy is improved.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

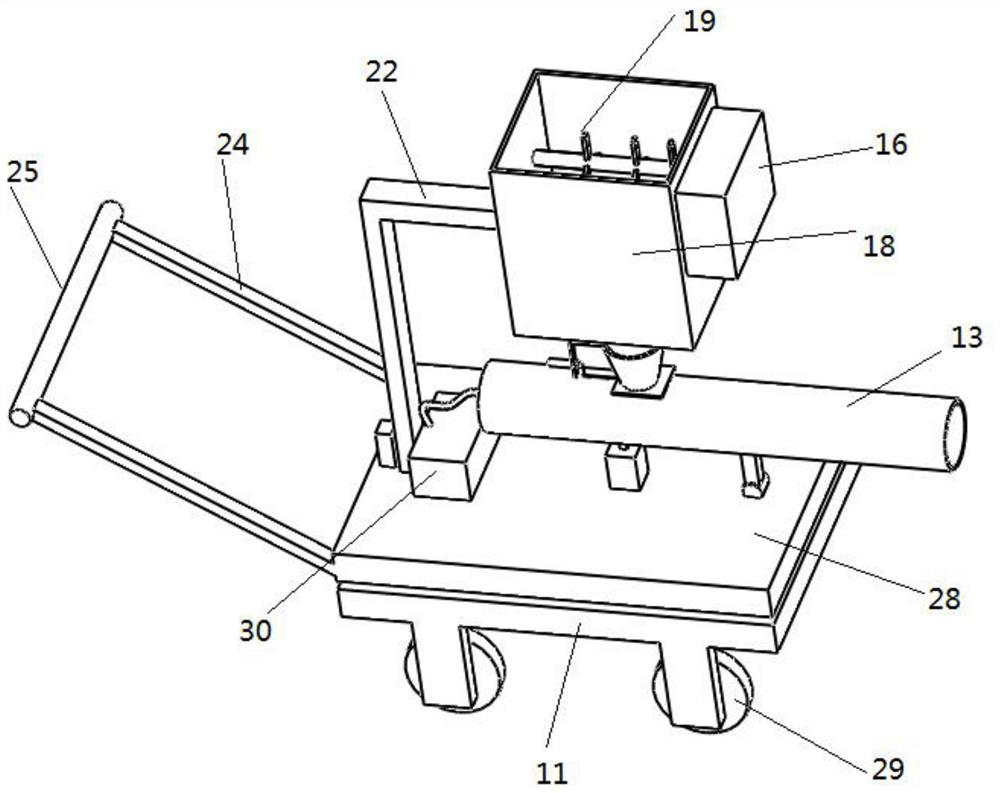

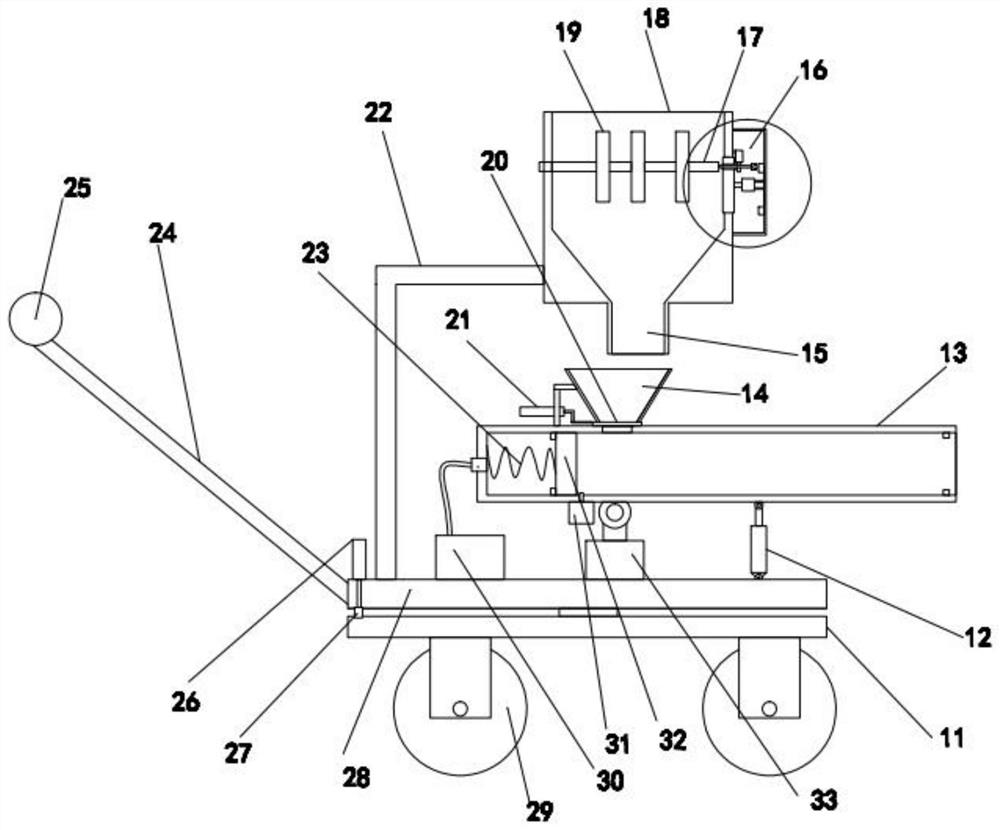

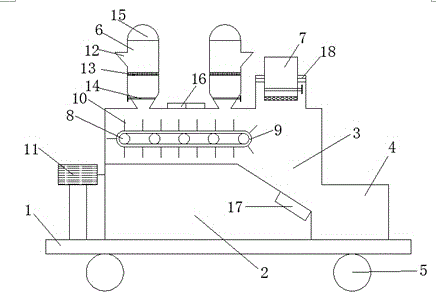

Novel electromechanical automatic feeding device

InactiveCN107738889APrevent fallingAvoid getting stuckConveyorsControl devices for conveyorsEngineering

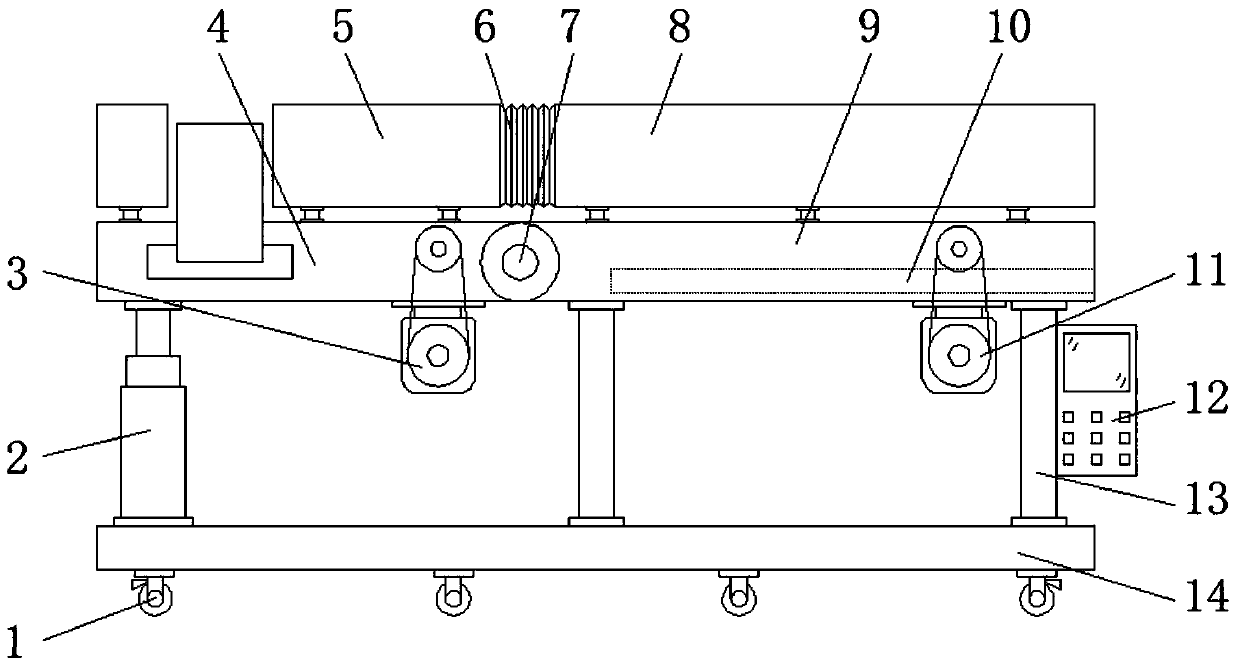

The invention discloses a novel electromechanical automatic feeding device. The novel electromechanical automatic feeding device comprises a base plate, a first feeding frame and a second feeding frame. The first feeding frame is fixedly supported at one end of the base plate through a stand column. One end of the first feeding frame is fixedly connected with the second feeding frame through a rotary shaft. A hydraulic elevator is mounted on the base plate and located below the end, away from the rotary shaft, of the second feeding frame. The output end of the hydraulic elevator is fixedly connected with the second feeding frame. Feeding conveyor belts are arranged in the first feeding frame and the second feeding frame correspondingly. A first protective baffle and a second protective baffle are fixed to the two sides of the top of the first feeding frame, and a first protective baffle and a second protective baffle are fixed to the two sides of the top of the second feeding frame. According to the novel electromechanical automatic feeding device, the hydraulic elevator is fixedly connected between the base plate and the second feeding frame so that the height of the output end ofthe second feeding frame can be adjusted, the inclination angle can be adjusted according to actual production requirements to meet actual feeding requirements, and the novel electromechanical automatic feeding device is convenient to use and has good applicability.

Owner:WEIHAI VOCATIONAL COLLEGE

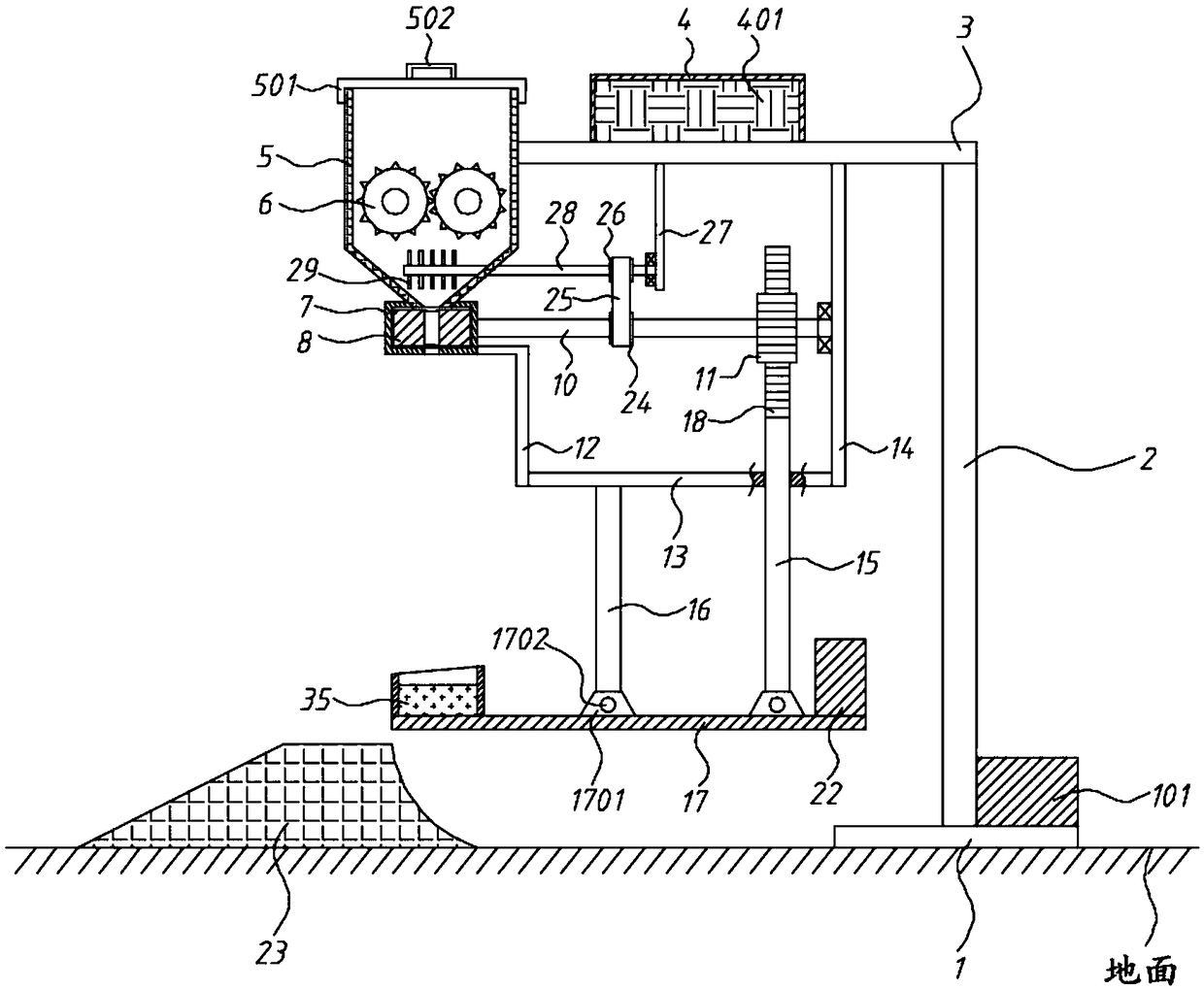

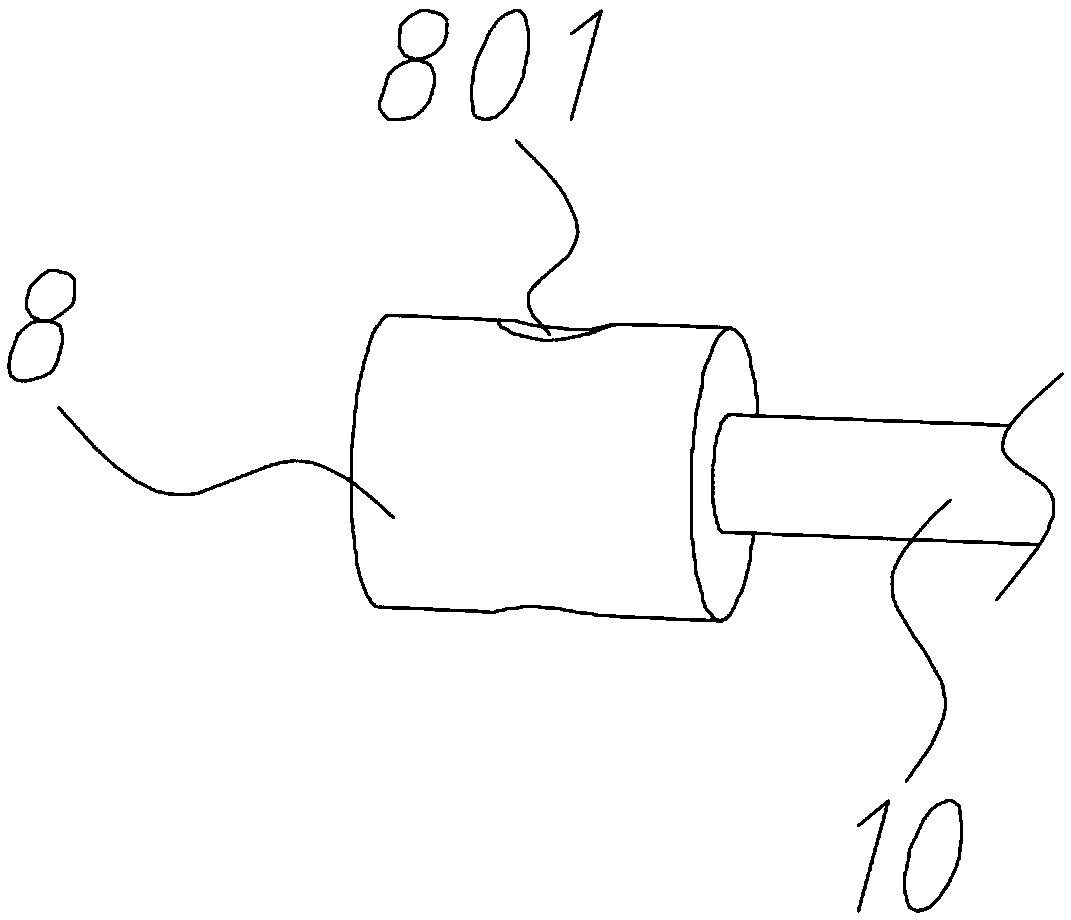

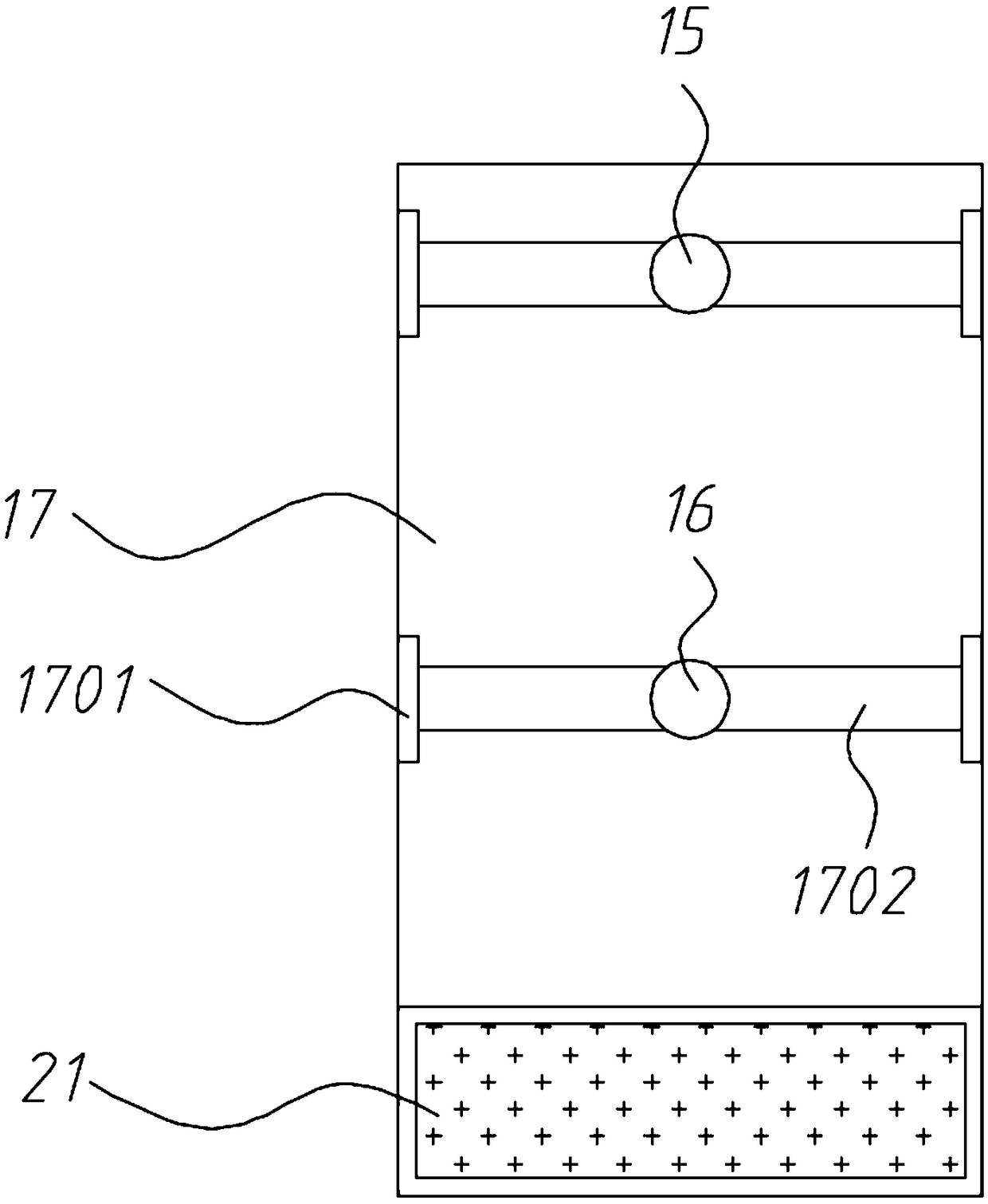

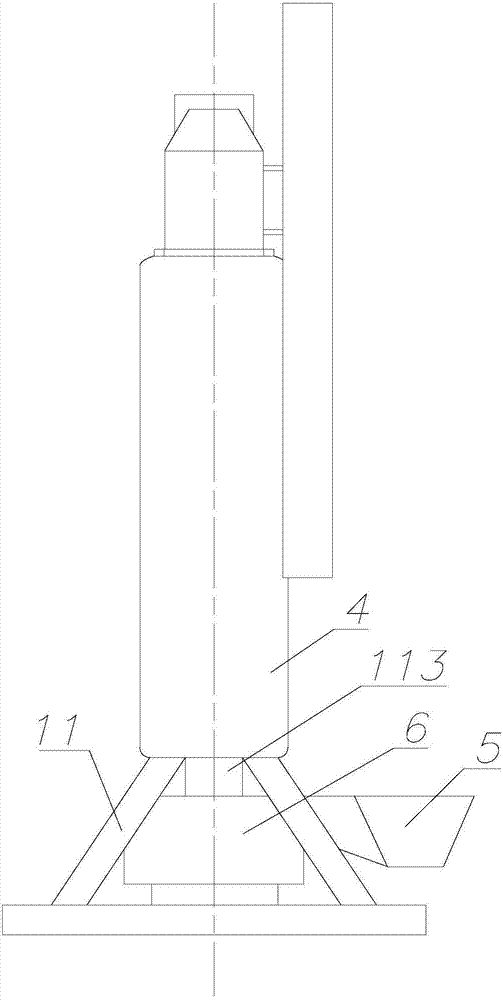

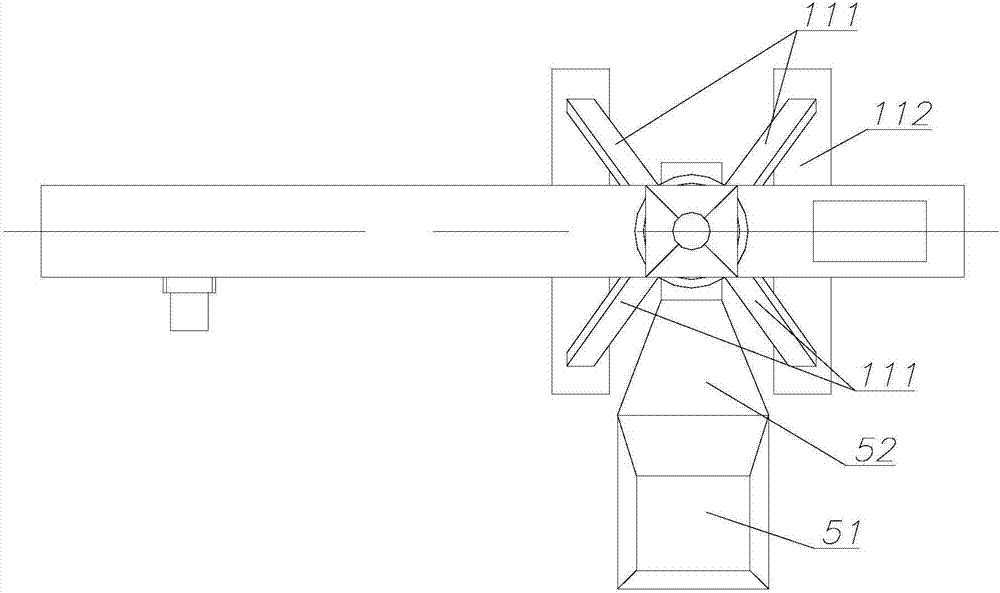

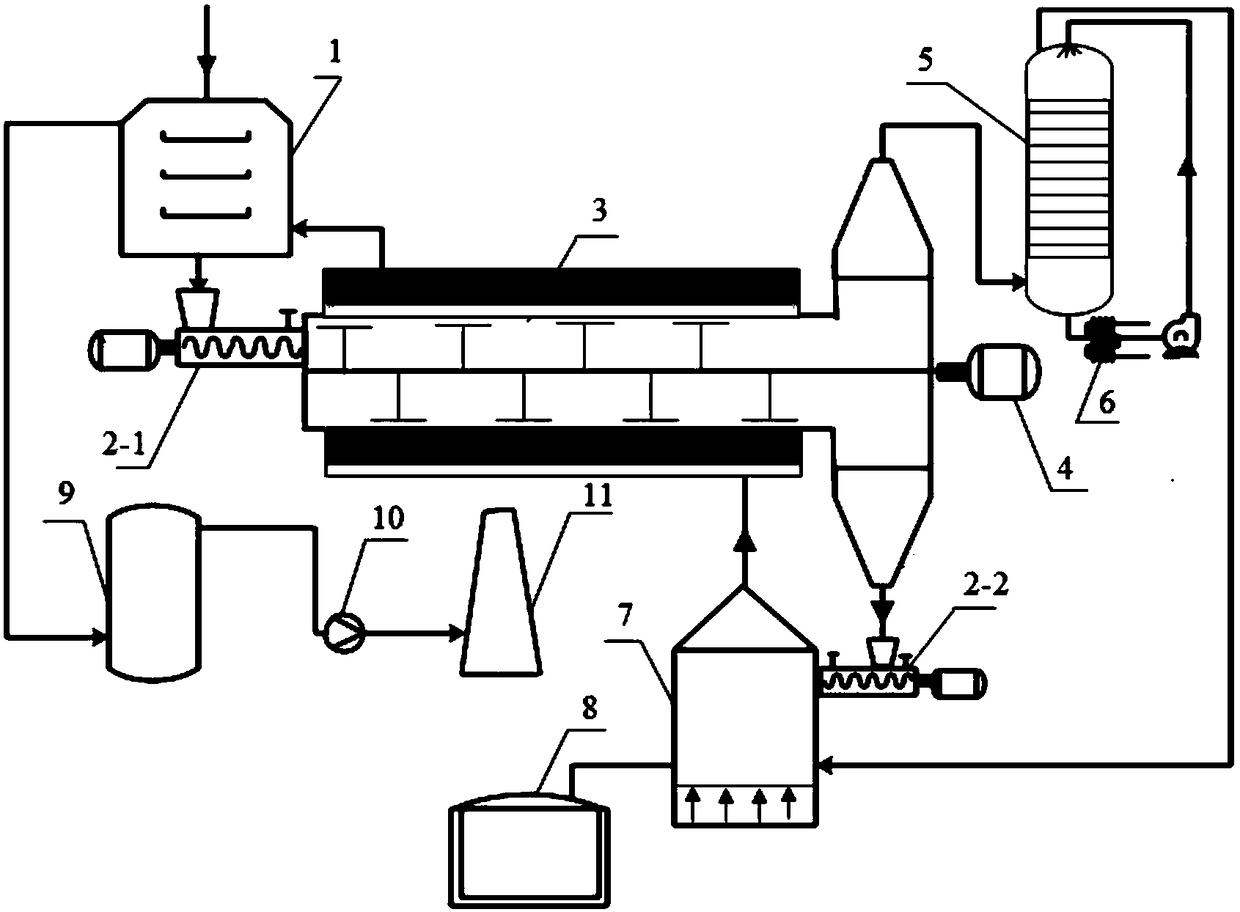

Entire-tire gasification device and method for waste tires

ActiveCN104629806ASimple equipment structureLess investmentGasification processes detailsFixed-bed gasificationWaste tiresBiomass

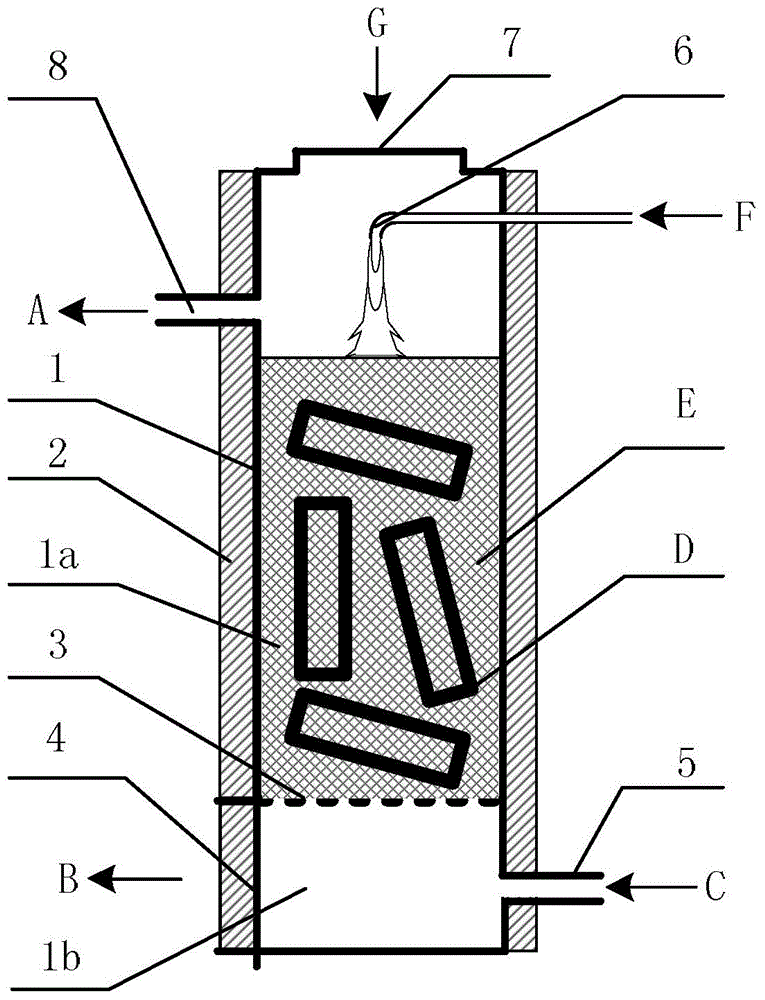

The present invention relates to an entire-tire gasification device and an entire-tire gasification method for waste tires. The device is composed of a gasification furnace body (1), a heat preservation layer (2) and a porous grate (3), wherein the porous grate (3) is arranged at the lower part of the gasification furnace body (1), and the gasification furnace body (1) is divided into an upper gasification chamber (1a) and a lower ash box (1b); an ash outlet (4) is formed in the left side of the ash box (1b), and a gasifying agent inlet (5) is formed in the lower right side of the ash box; the heat preservation layer (2) is arranged at the outside of the gasification furnace body; a plasma ignition device (6) is arranged at one side of the upper part of the gasification chamber (1a), a fuel outlet (8) is formed in the other side of the upper part of the gasification chamber, and a gasification raw material inlet (7) is formed in the top of the gasification chamber. A biomass raw material and an entire waste tire are conveyed into the gasification chamber after being mixed, a gasifying agent is filled from the lower side of the gasification device, and the fuel gas generated in the reaction is exhausted from the fuel outlet (8); solid ash and tire steel wires are discharged from the ash outlet after the gasification. The device has the advantages of simple structure, low manufacturing cost, simple operation, strong method controllability, capability of reducing tires and higher gasification efficiency.

Owner:NANJING UNIV OF TECH

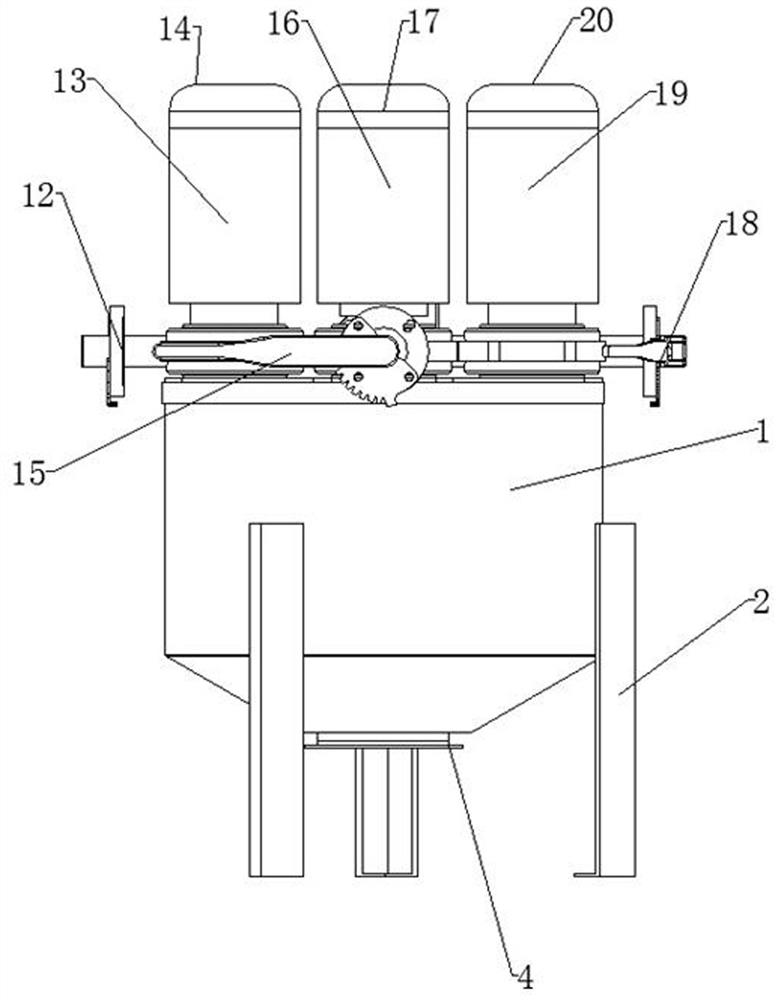

Concrete stirrer

InactiveCN112092184AReduce labor intensityImprove stirring efficiencyCement mixing apparatusSold ingredients supply apparatusSpiral bladeElectric machinery

The invention relates to the technical field of stirring of concrete and particularly relates to a concrete stirrer. The concrete stirrer comprises a stirring cylinder, wherein a feeding structure isarranged on the outer side of the stirring cylinder; the feeding structure comprises a first feeding pipe and a second feeding pipe which are obliquely arranged; feeding shafts are rotatably mounted in the first feeding pipe and the second feeding pipe; first spiral blades are fixedly mounted on the outer sides of the feeding shafts; the bottom ends of two feeding shafts penetrate through the first feeding pipe and the second feeding pipe which are adjacent to each other; a driven belt wheel and a driving belt wheel are mounted at the ends of the two feeding shafts; the driven belt wheel and the driving belt wheel are connected with each other through a belt; a second motor is fixedly mounted at the end, away from a feeding shaft at one end of the second feeding pipe, of the driving belt wheel; and hoppers are vertically mounted at the upper parts of the bottoms of the first feeding pipe and the second feeding pipe in a communication manner. Compared with the prior art, the stirring effect is better; meanwhile, the feeding difficulty is reduced; and the labor intensity of workers is relieved.

Owner:张继密

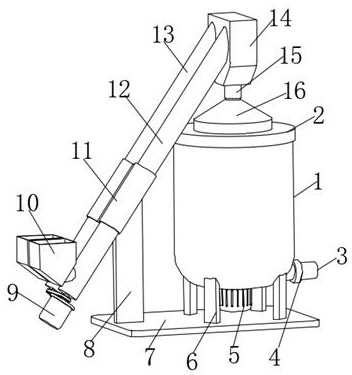

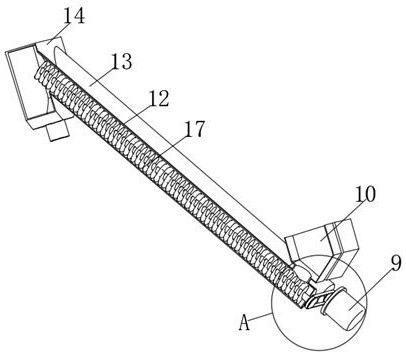

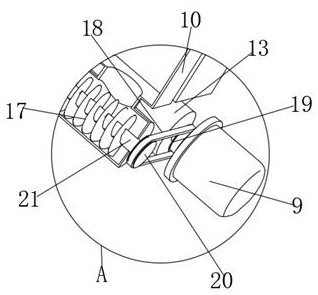

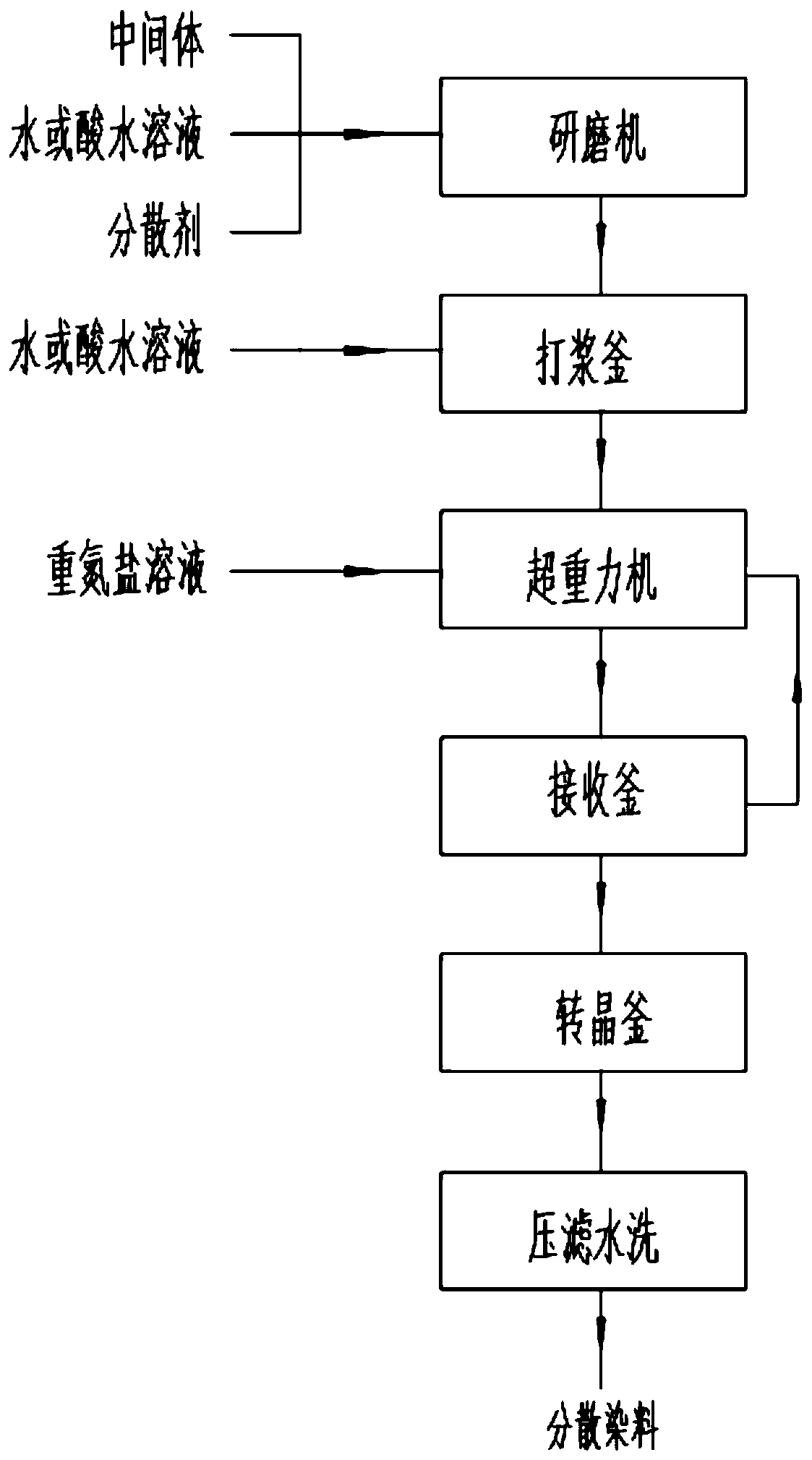

Continuous production method and system of heterogeneous system azo disperse dye

The invention provides a continuous production method and system of a heterogeneous system azo disperse dye, and the method comprises the following steps: grinding and pulping a coupling intermediateinsoluble in water or an acid aqueous solution, a dispersing agent, and the water or the acid aqueous solution to obtain a coupling pulping solution, continuously pumping the coupling pulping solutionand a diazonium salt solution into a supergravity machine for coupling reaction, enabling a reaction material to flow into a receiving kettle, forming a circulating system by the receiving kettle, aheat exchanger and the supergravity machine, controlling the liquid level or weight of the receiving kettle, continuously extracting the reaction material into a crystal transformation kettle, and carrying out heating crystal transformation, filter pressing and washing to obtain the azo disperse dye. According to the method, through combination of intermediate grinding, dispersant adding and supergravity machine enhanced reaction, sulfuric acid or hydrochloric acid needing to be added during pulping in a traditional process is reduced or even eliminated, the wastewater amount can be effectively reduced, the reaction efficiency is improved, and the method has obvious advantages in the aspects of reaction retention time, product purity and yield.

Owner:ZHEJIANG DIBANG CHEM +1

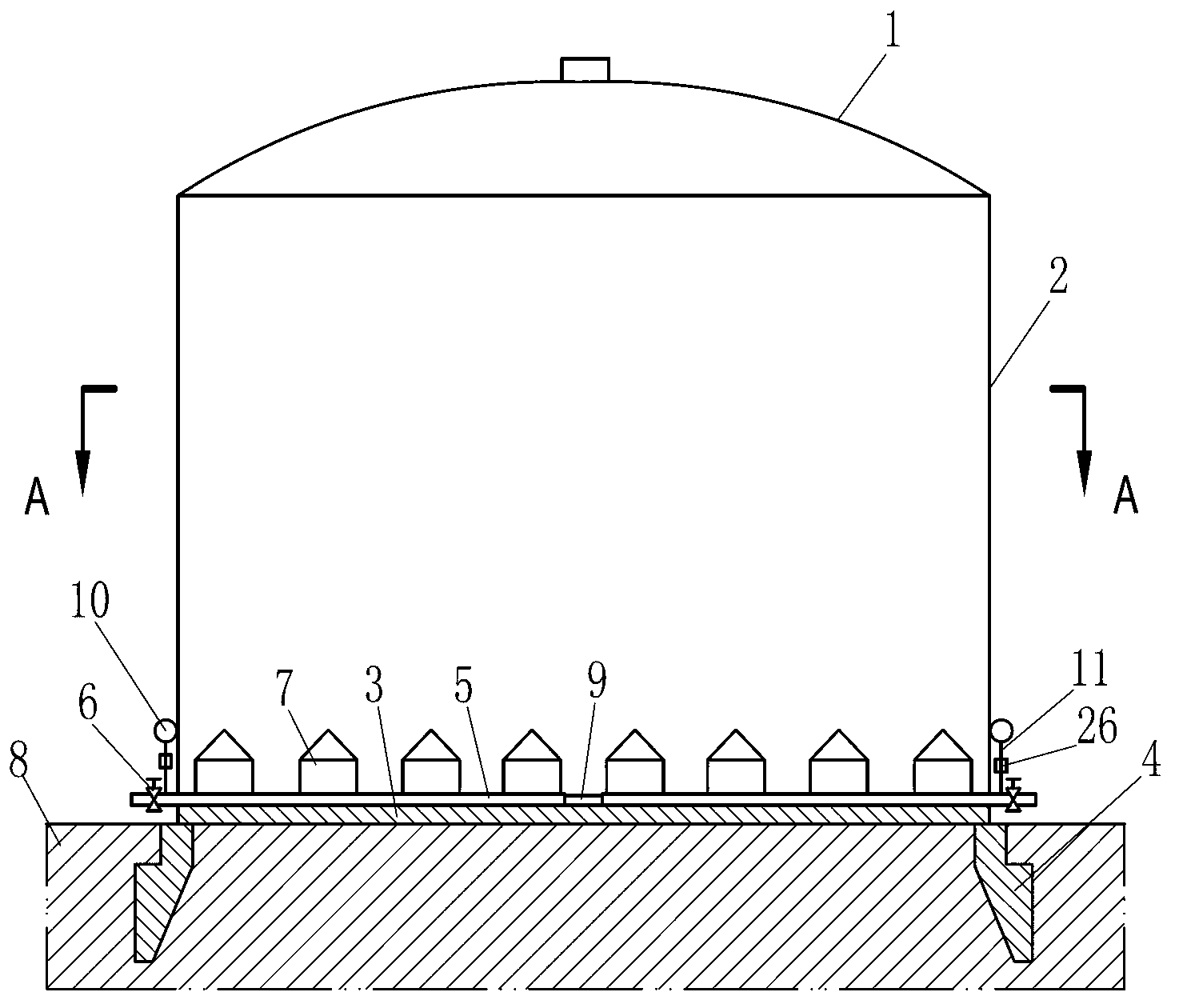

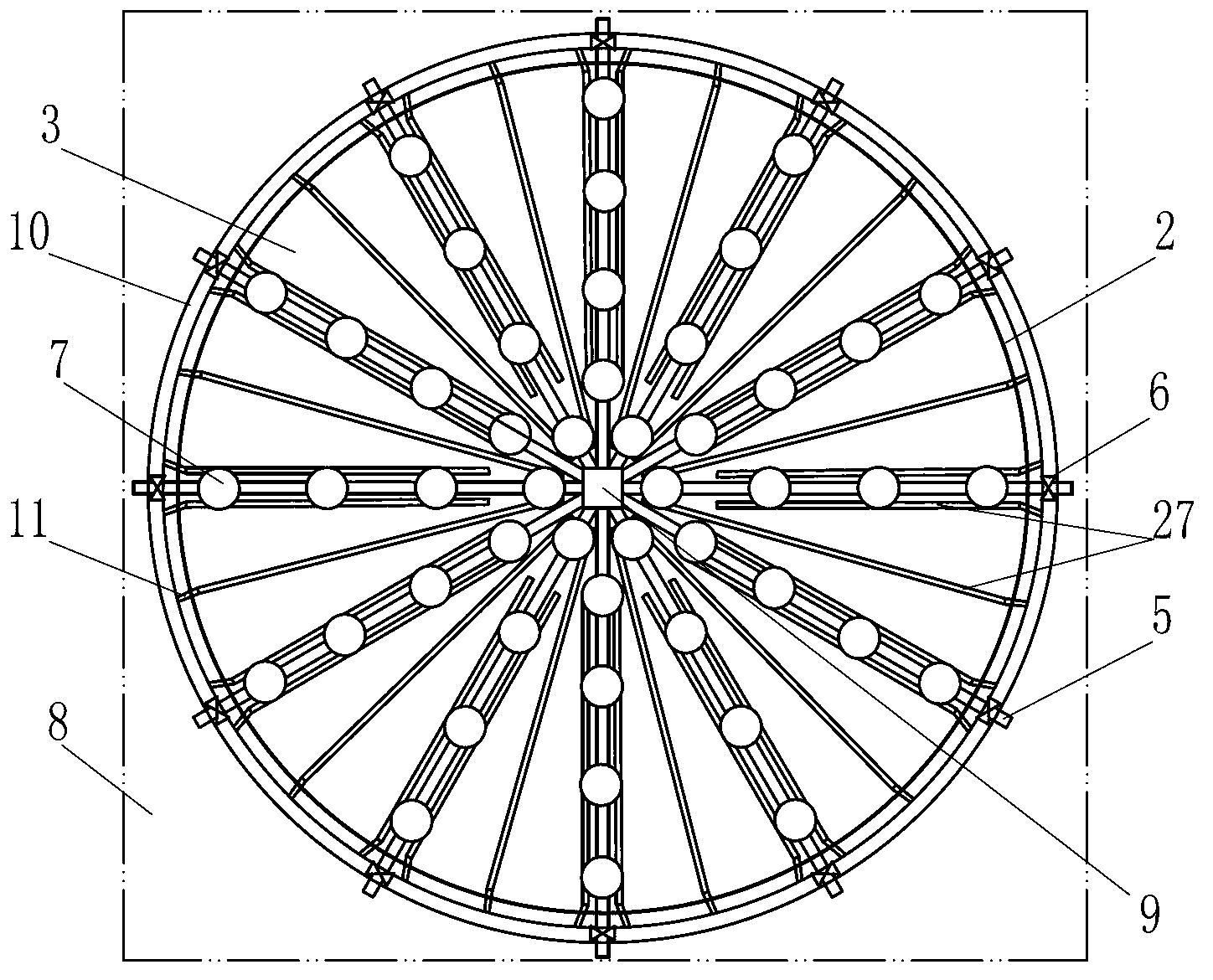

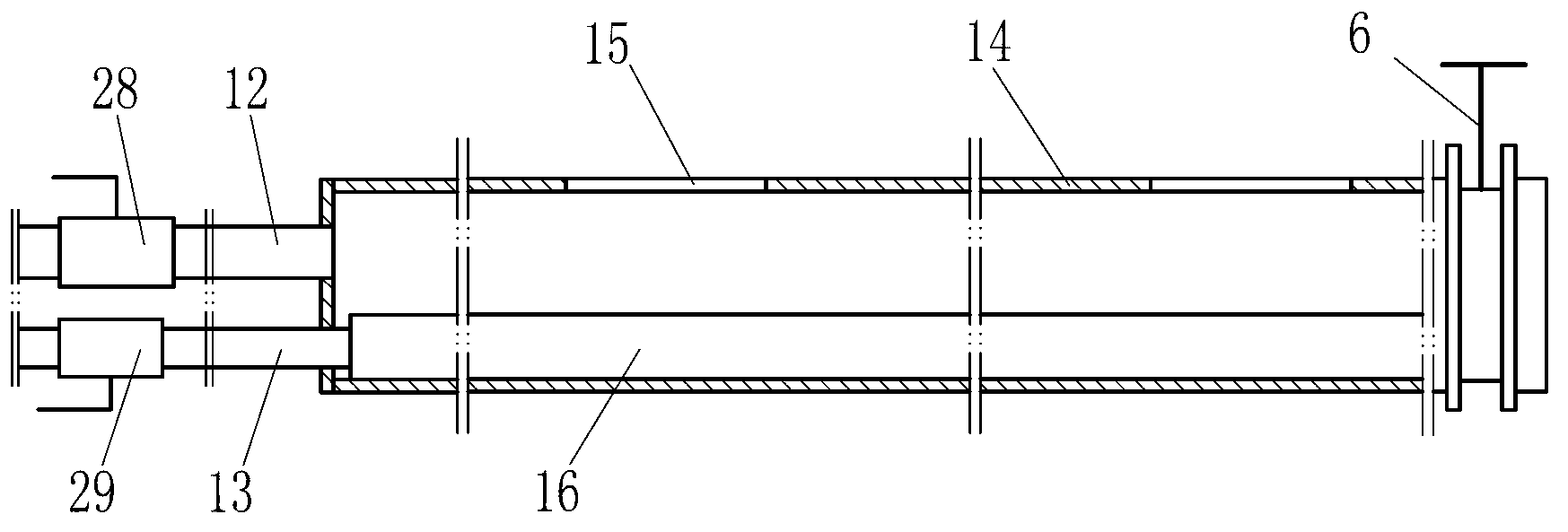

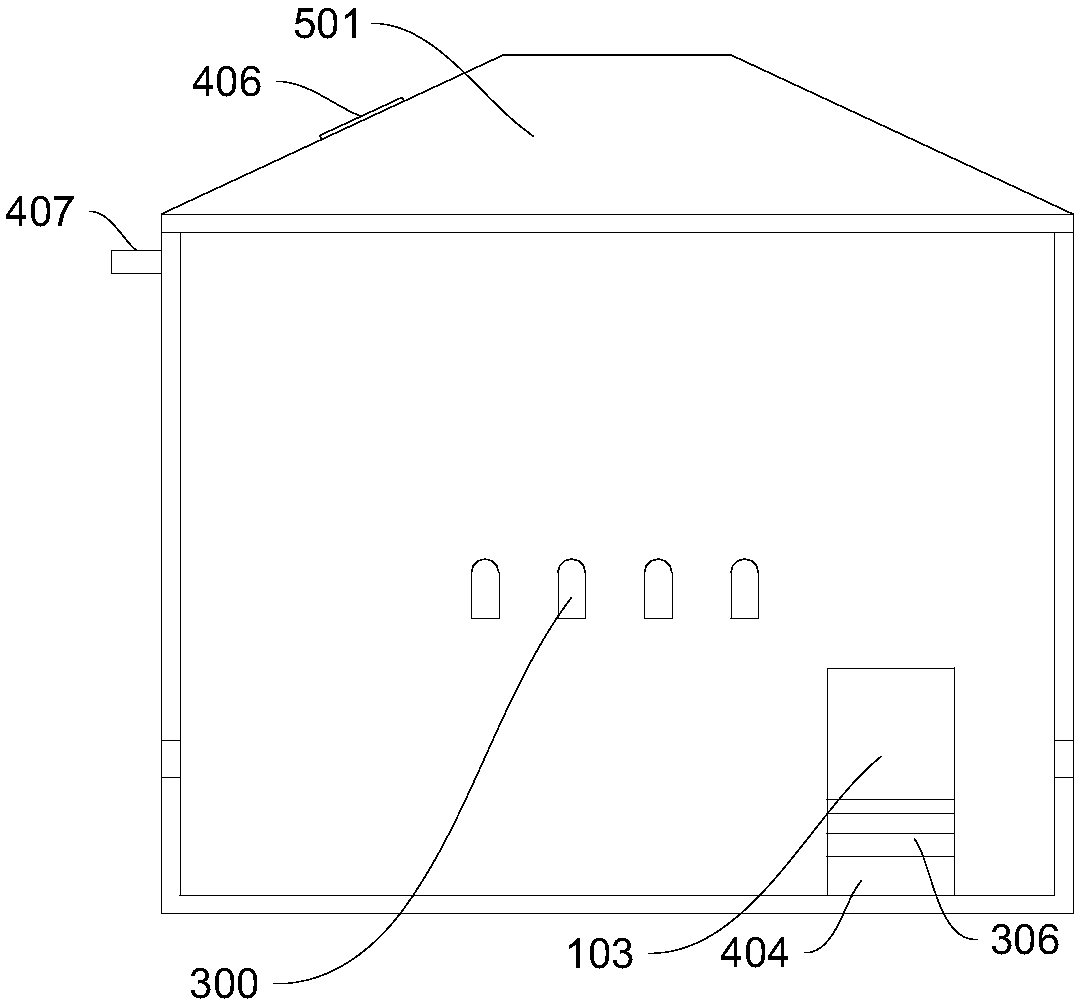

Floor type powdery material storehouse

ActiveCN103287858AImprove space utilizationLess investmentBulk conveyorsBulk storage containerEngineeringMechanical engineering

The invention relates to a floor type powdery material storehouse which comprises a storehouse top, storehouse walls, a storehouse bottom and a storehouse foundation, wherein material flowing assisting devices are arranged on the storehouse bottom and are composed of pneumatic fluidization rods which are connected with air supply pipelines, material falling openings are formed in material conveying pipes, a decompression cabin is arranged on each material falling opening of the material conveying pipes, the side wall of each decompression cabin is provided with a feeding notch, the pneumatic fluidization rods are arranged in the material conveying pipes, the material conveying pipes are horizontally arranged on the surface of the storehouse bottom and penetrate through the bottoms of the storehouse walls and extend out of the storehouse, a material flow control device is arranged at a discharge end, located outside each storehouse wall, of each material conveying pipe, the other end, located inside the storehouse, of each material conveying pipe is an air supply end, and the air supply end of each material conveying pipe is connected with an air supply pipeline. In addition, barriers can be arranged on the periphery of each material falling opening of the material conveying pipes. The floor type powdery material storehouse is simple in structure and good in economy and safety performance, and can be widely applied to storage of powdery materials such as coal ash and cement.

Owner:赵世青

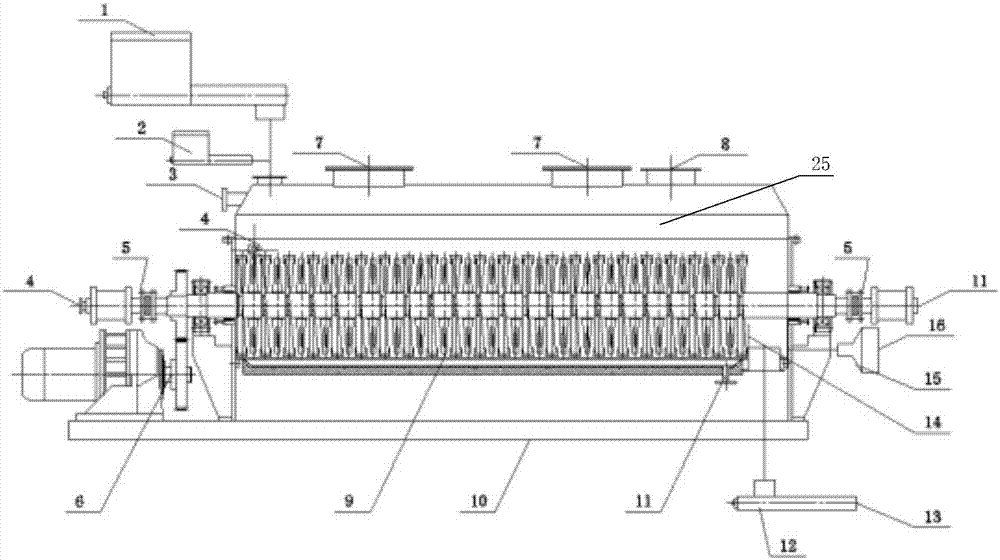

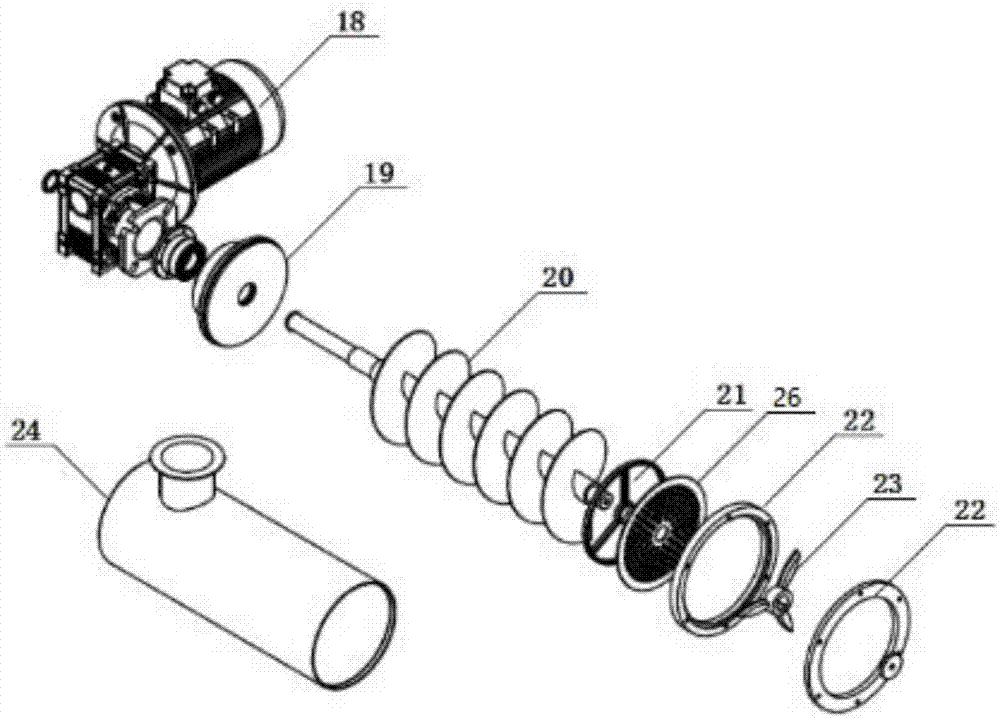

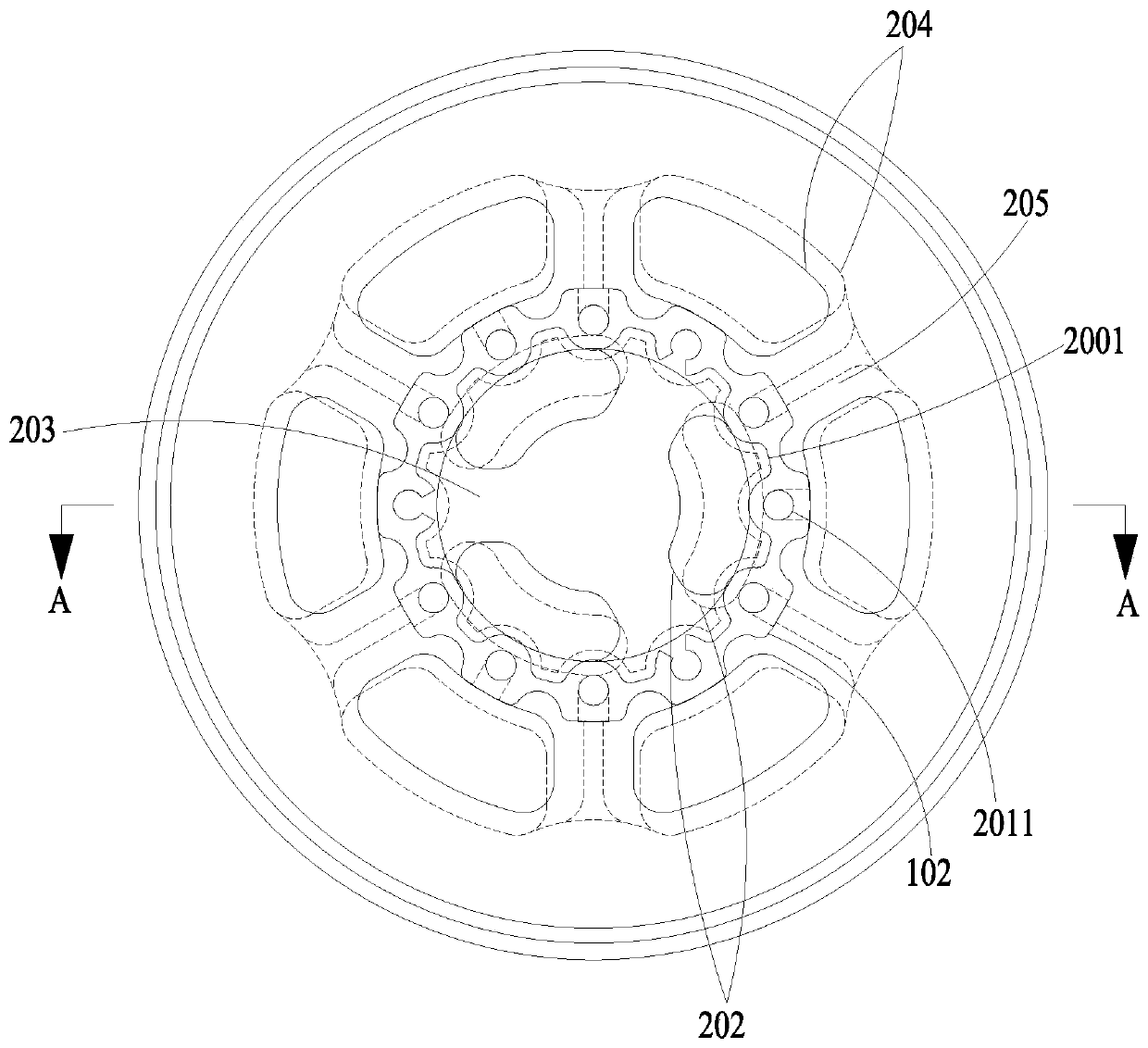

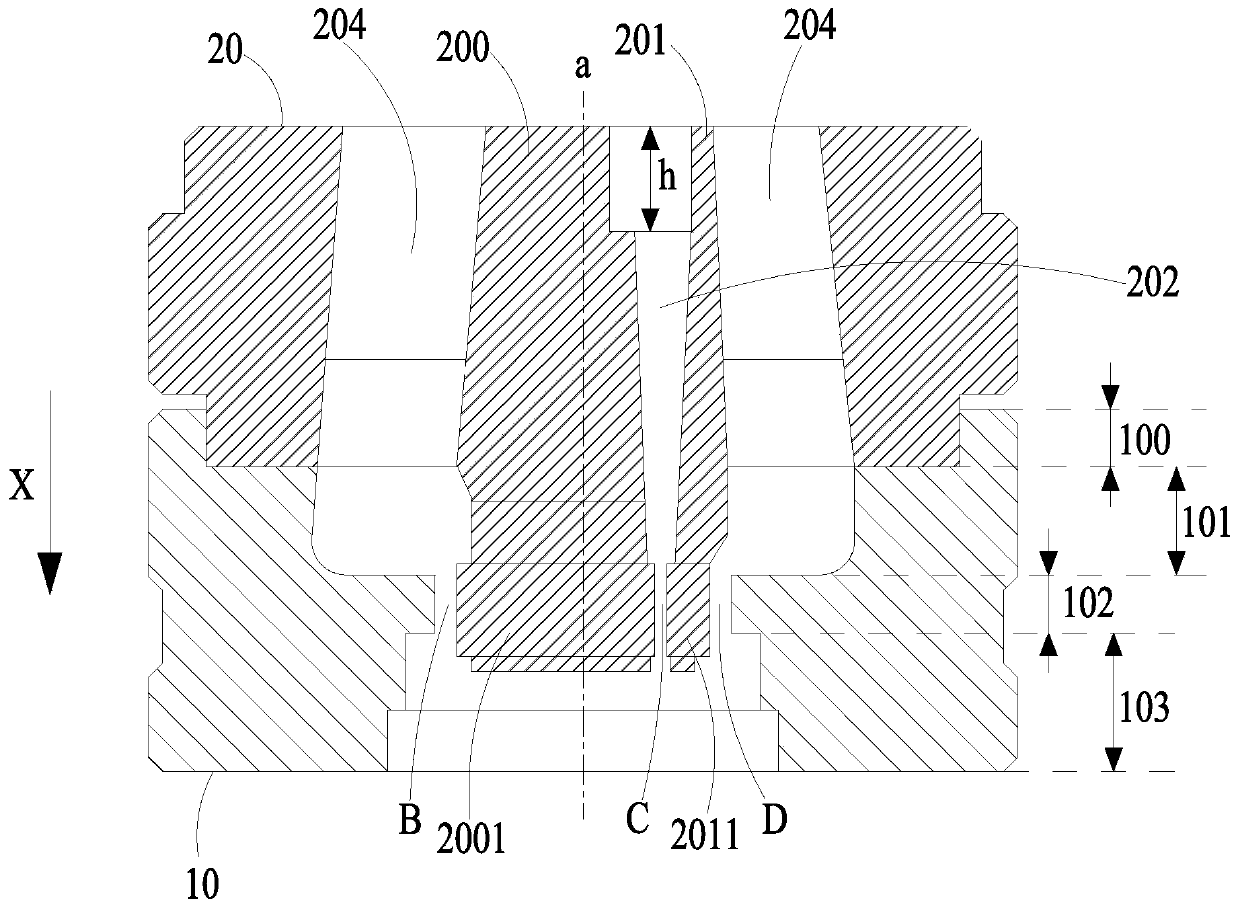

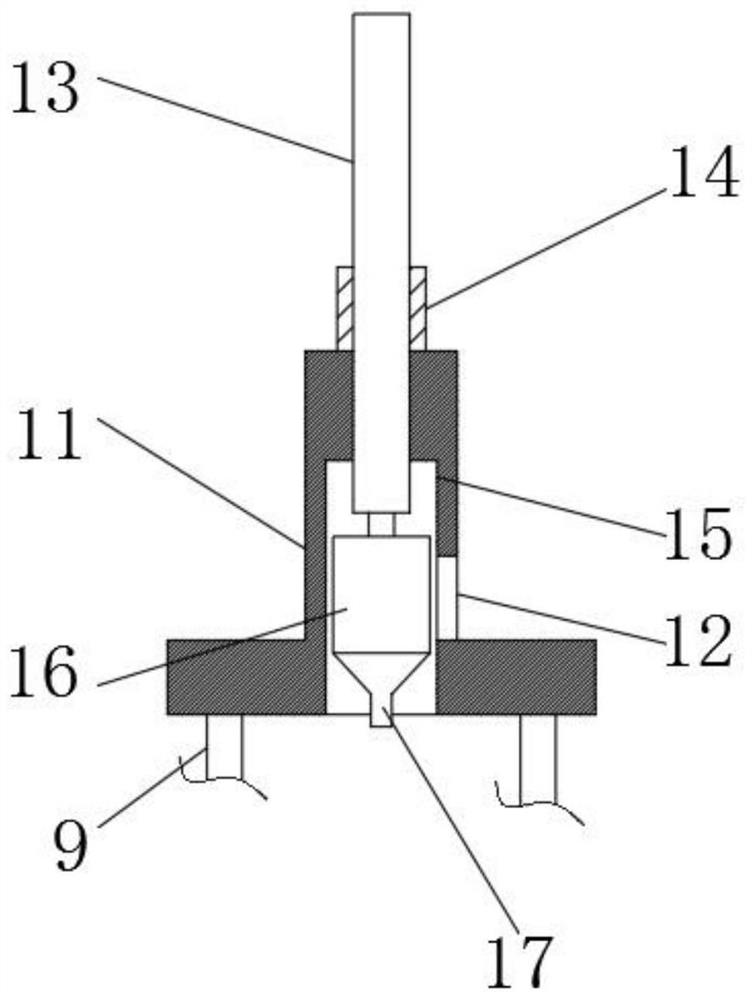

Domestic sludge and pulverized coal drying and forming device

PendingCN107954585AControl shapeReduce sizeSludge treatment by de-watering/drying/thickeningGranulation by material expressionPulp and paper industryVacuum pump

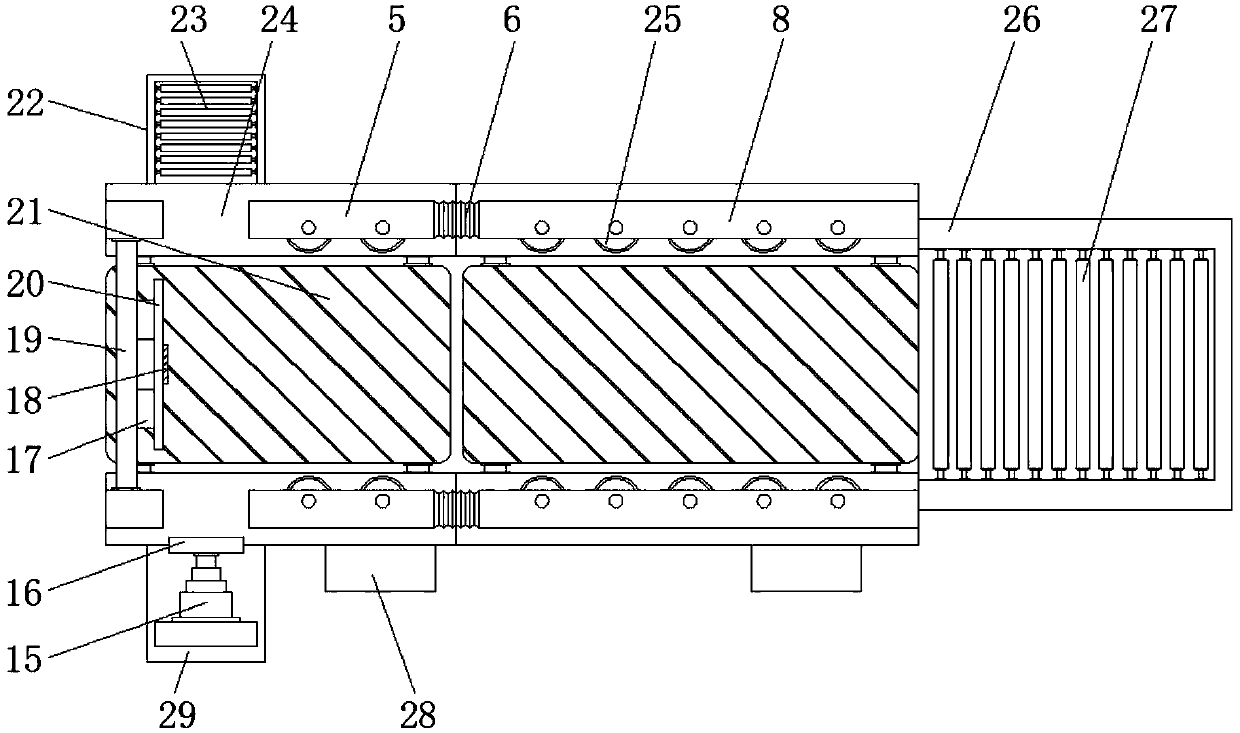

The invention provides a domestic sludge and pulverized coal drying and forming device which comprises a sludge double-spiral charging device, a pulverized coal spiral charging metering device, a vacuum pump interface, a steam interface, a rotary joint, a transmission system, a single-spiral discharging device, a sludge outlet forming control device and a dryer main body device. The device provided by the invention has the advantages that the transmission speed can be changed according to the treatment capacity; the ratio of sludge to pulverized coal can be controlled by adjusting the rotationspeed of the sludge double-spiral charging device and the rotation speed of the pulverized coal spiral charging device; the particle size of sludge formed particles can be controlled by end plates with different hole sizes, and the length of the sludge formed particles can be controlled by the rotation speed of a revolving scraper; and the shapes and sizes of dried products can be controlled, thecharging difficulty in an incineration process can be reduced, the fuel required for sludge incineration treatment is less, and the sludge can be incinerated more thoroughly.

Owner:JIANGSU UNIV OF TECH

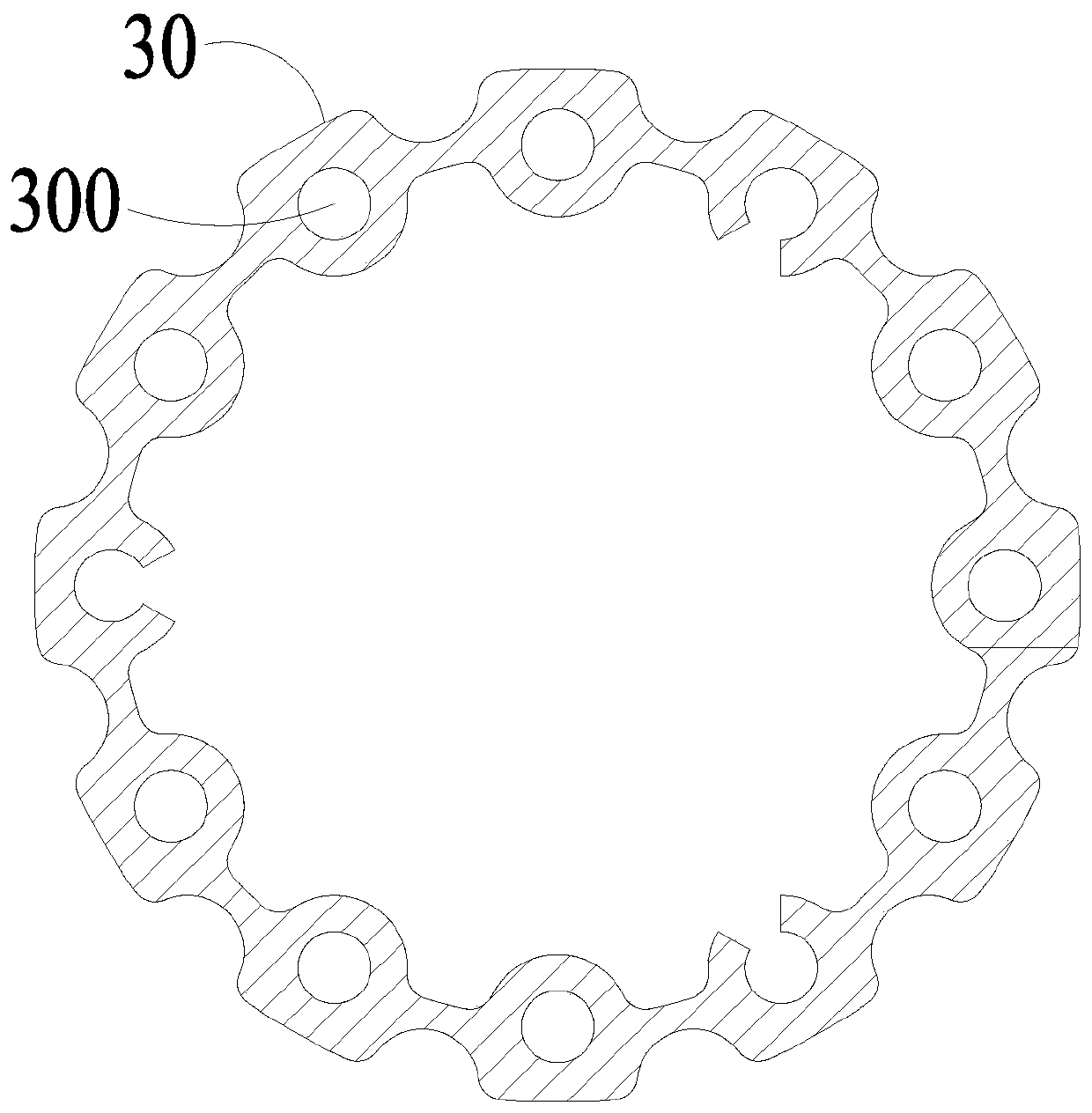

Multi-die-core complex profile hot extrusion die

PendingCN111215469AReduce the difficulty of feedingConsistent molding speedExtrusion diesEngineeringMechanical engineering

The invention relates to a multi-die-core complex profile hot extrusion die. The multi-die-core complex profile hot extrusion die comprises a female die and a main die, wherein the female die is provided with a welding cavity, a forming cavity and a discharge cavity which are sequentially arranged and communicate with one another in the extrusion direction; the male die is provided with a main diecore, a plurality of auxiliary die cores distributed at intervals along the periphery of the main die core, a plurality of inner shunting holes distributed at intervals along the circumference and aplurality of outer shunting holes distributed at intervals along the circumference; a first forming area is formed between the forming end of the main die core and the forming cavity, a second formingarea is formed between the forming ends of the auxiliary die cores and the forming end of the main die core, a third forming area is formed between the forming ends of the auxiliary die cores and theforming cavity, and the first forming area, the second forming area and the third forming area communicate with one another; and the inner shunting holes are formed in one sides, close to the centerline of the male die, of the auxiliary die cores and communicate with the welding cavity, the outer shunting holes are formed in one sides, far away from the center line of the male die, of the auxiliary die cores and communicate with the welding cavity, and the area sum of the plurality of inner shunting holes is smaller than the area sum of the plurality of outer shunting holes. According to thescheme, the yield can be improved.

Owner:福建省东硕模具制造有限公司

Lever principle-based livestock farming automatic feeding device

ActiveCN109349152AAvoid cloggingGuaranteed crushing effectAnimal feeding devicesAvicultureTransmission beltGear wheel

The invention relates to the technical field of livestock feeding, particularly to a lever principle-based livestock farming automatic feeding device. The lever principle-based livestock farming automatic feeding device is designed on the basis of the lever principle; a bottom plate serves as the main body of a lever, and a feeding trough and a second balance weight provide stress at both ends ofthe main body. When livestock eats feed inside the feeding trough, stress at the left end can be reduced, the right end lowers down to drive a second rod to move down, and a rack drives a first rotating shaft tube to rotate through gears; one the one hand , a blanking end rotates along, a through chute is aligned to a blanking port at the bottom of a feeding hopper and a discharging port at the bottom of a loading cavity, feed fed into the feeding hopper can fall into the feeding trough to increase the weight of the feeding trough and to drive the lever to work reversely to stop feed feeding,on the other hand, a second rotating shaft is driven by a transmission wheel and a transmission belt to rotate along and further drives a mixing bar to mix at a reducing section to avoid blocking.

Owner:唐山宝树泉科技有限公司

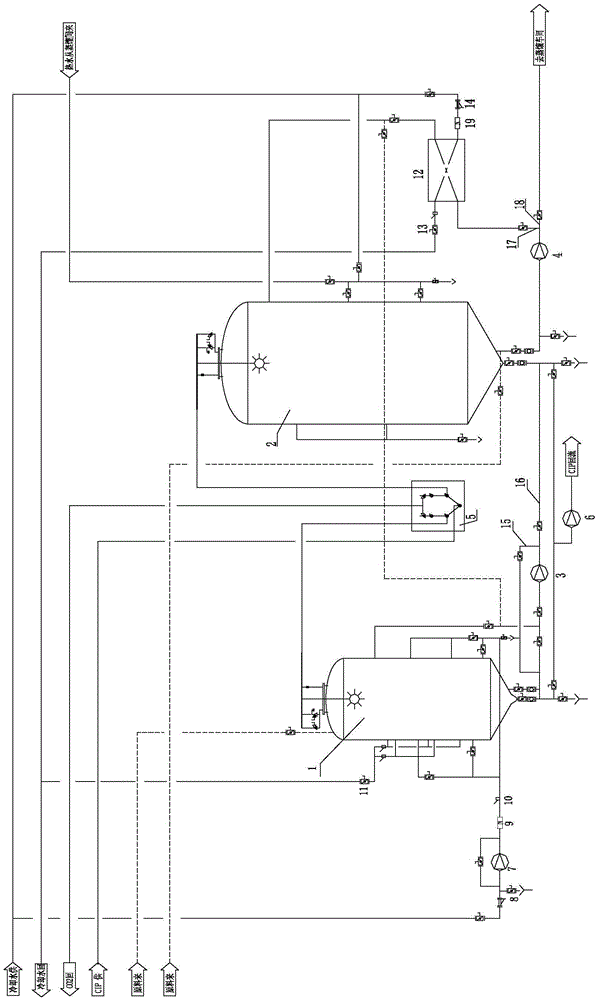

Integrated plant and method for rice wine semi-solid fermentation

ActiveCN105586212AIncrease fermentationGood liquidityAlcoholic beverage preparationAgricultural engineeringSemi solid

The invention discloses an integrated plant for rice wine semi-solid fermentation. The integrated plant comprises a prior-fermentation tank set and a later-fermentation tank set. The prior-fermentation tank set comprises at least one main fermentation tank, a cooling coiler arranged in the main fermentation tank and a circulation feeding pump arranged outside the main fermentation tank. A raw material feed port is formed in the top of the main fermentation tank, a main fermentation circulation discharging pipe is arranged on the upper portion of a body of the main fermentation tank, and a main fermentation tank returning / discharging pipe is arranged on the bottom of the body of the main fermentation tank. The later-fermentation tank set comprises at least one later-fermentation tank, a cooling heat exchanging device arranged outside the later-fermentation tank and a later-fermentation tank mash pump. Rice wine fermentation is divided into a prior fermentation period and a later fermentation period, the problem of semi-solid fermentation is solved through the prior-fermentation tank, the volume of the prior-fermentation tank is about one fourth that of the total fermentation volume, the later-fermentation tank is simplified, the volume of the later-fermentation tank is about three fourths that of the total fermentation volume, the prior-fermentation tank needing cooling for temperature reducing and the later-fermentation tank needing temperature keeping are arranged in a separated mode, the feeding difficulty of semi-solid materials is lowered, the equipment investment and the workshop investment are reduced, the temperature controlling effect is improved, and the energy consumption is reduced.

Owner:CHINA GDE ENG

High-precision production injection molding process and injection molding machine

The invention belongs to the technical field of data joint injection production, and aims to provide a high-precision production injection molding process and an injection molding machine. According to the technical scheme, the injection molding machine comprises a rack, wherein a workbench is arranged on the rack; a first oil cylinder is arranged at the lower end of the rack; a driving plate is slidably connected to the output end of the first oil cylinder; a driving rod is fixedly connected to the upper end of the driving plate; the upper end of the driving rod is fixedly connected with a fixing plate; the upper end of the workbench is provided with a lower die; the lower end of the fixing plate is provided with an upper die; the upper end of the fixing plate is fixedly connected with aguiding column; one side of the rack is provided with an extension platform; a feeding mechanism is arranged on the extension platform; and a cooling circulation system is arranged in the lower die and the upper die. According to the high-precision production injection molding process and the injection molding machine, the cooling circulation system is additionally arranged to the injection molding machine, so that a molten plastic in a die cavity is cooled by the cooling circulation system after the molten plastic is injected into the die cavity, the cooling effect is good, the molding speedis high, and the working efficiency is improved.

Owner:深圳市宏科电子有限公司

Biomass pretreatment method

PendingCN109135860AUniform length distributionImprove plasticityBiofuelsSolid fuelsFiberPretreatment method

The invention relates to the technical field of production of biomass fuels, in particular to a biomass pretreatment method. The biomass pretreatment method comprises the following steps: (1) cuttingoff or breaking biomass raw materials to obtain chippings with the particle size range being 10-60 mm; (2) carrying out cyclone separation and pulse dust removal treatment on the obtained chippings; (3) washing the chippings with circulating water, and adjusting the water content of the chippings to be 10-30%; (4) carrying out supercritical CO2 explosion treatment on the obtained wet chippings; (5) carrying out microwave drying treatment on the wet chippings until the water content of the chippings is less than or equal to 10%; and (6) crushing the chippings until the meshes of the chippings are 100. By hydro-thermal treatment and supercritical explosion treatment, impurities are removed, the content of an alkali metal element is reduced, wood fibers are softened, thus, slag-bonding is relieved, and feeding is facilitated.

Owner:芜湖聚焰生物质能源科技有限公司

Push-pull feeding device

ActiveCN106312667AReduce the difficulty of feedingIncrease productivityMetal working apparatusPush pullSlide plate

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Building outline forming machine

ActiveCN106907006AReduce floor spaceAvoid cloggingBuilding material handlingMolding machineEngineering

A building outline forming machine comprises a rotating platform and a base used for supporting the rotating platform. The rotating platform is mounted on the base through a rotary table and comprises a swing arm and a balance arm which are connected and separately arranged on the two sides of the rotary table. The balance arm is provided with a counterweight unit. The swing arm is provided with a cantilever which is connected with the swing arm through a mobile mechanism. The mobile mechanism drives the cantilever to horizontally move on the swing arm. The cantilever is provided with a 3D printing module. The rotating platform and the 3D printing module are supported aloft for operation through the base and the ground, the occupied using area of the whole machine can be effectively decreased, mounting of the building outline forming machine at a construction site is not limited by site factors, and the 3D printing module is driven to rotate around the base through the rotating platform so that a large operation range can be covered while the size of the whole machine is decreased, and the mounting position of the outline forming machine can be flexibly selected.

Owner:BUILDERA CONSTR TECH SHANGHAI CO LTD

Bait feeding device and method for polyculture of shrimps and crabs

ActiveCN112471032AReduce the difficulty of feedingPracticalTransportation and packagingRotary stirring mixersPolycultureShrimp

The invention discloses a bait feeding device and method for polyculture of shrimps and crabs. The bait feeding device comprises a base, supporting legs are symmetrically arranged on the two sides ofthe lower end of the base, idler wheels used for walking are arranged at the lower ends of the supporting legs, a movable base is rotationally arranged at the upper end of the base, a push rod is arranged on the left side of the movable base, and a handrail convenient to hold is arranged at the left end of the push rod; and a storage barrel used for containing two kinds of bait is arranged above the movable base, the left side of the storage barrel is fixedly connected with the surface of the movable base through a supporting clamp, at least one rotating shaft is horizontally arranged in the storage barrel, and a plurality of cutters used for cutting and stirring materials are symmetrically arranged on the upper side and the lower side of the rotating shaft. The bait feeding device is designed according to existing requirements, a mechanism capable of quickly mixing the two kinds of bait is provided, the spraying direction and distance can be adjusted according to the requirement for the bait throwing position after mixing, then bait throwing operation is conducted, the feeding difficulty is lowered, and practicability is high.

Owner:营口市农业农村综合发展服务中心

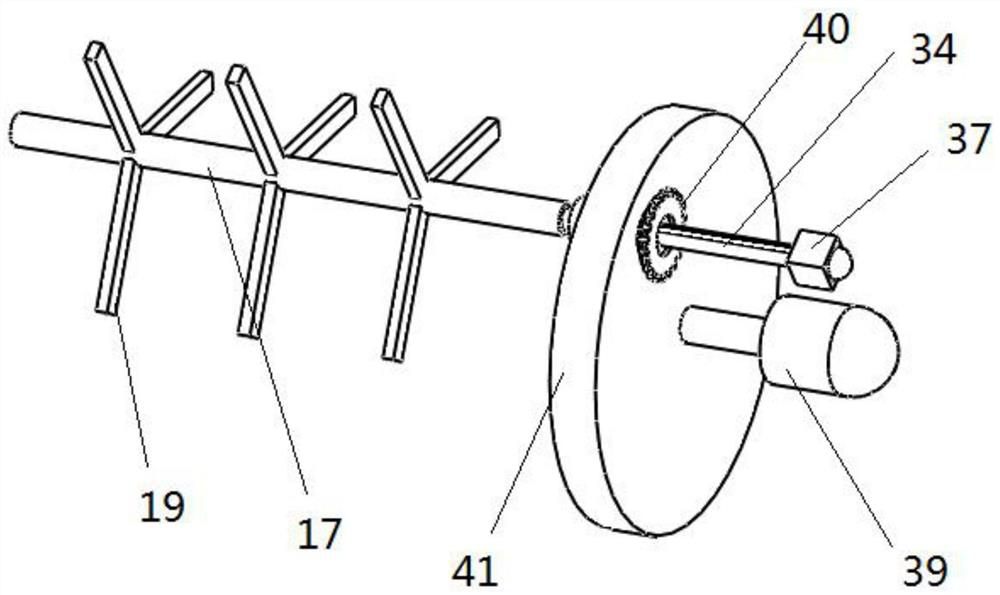

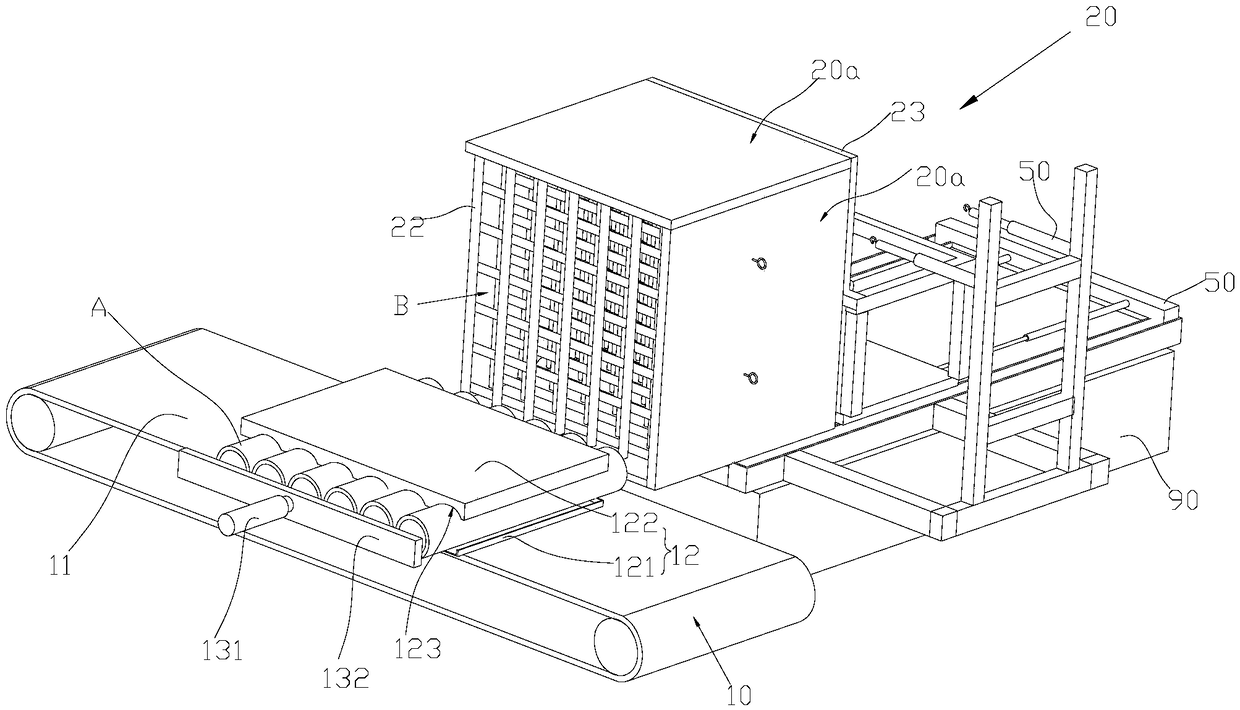

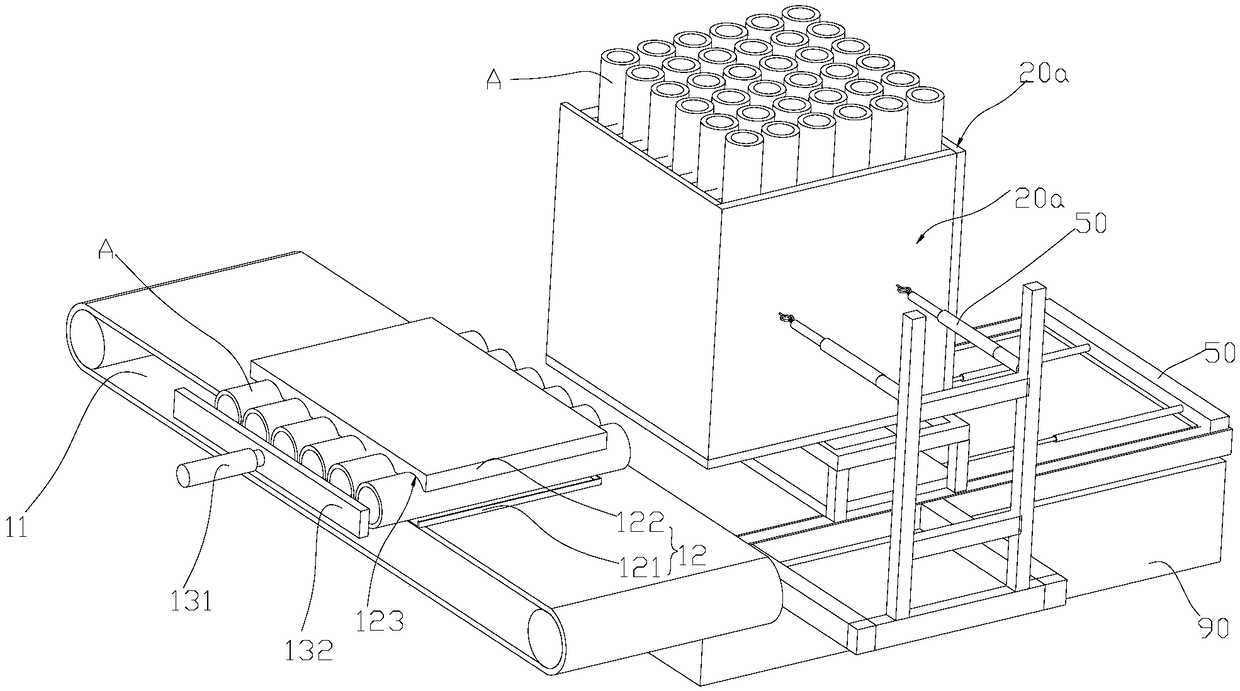

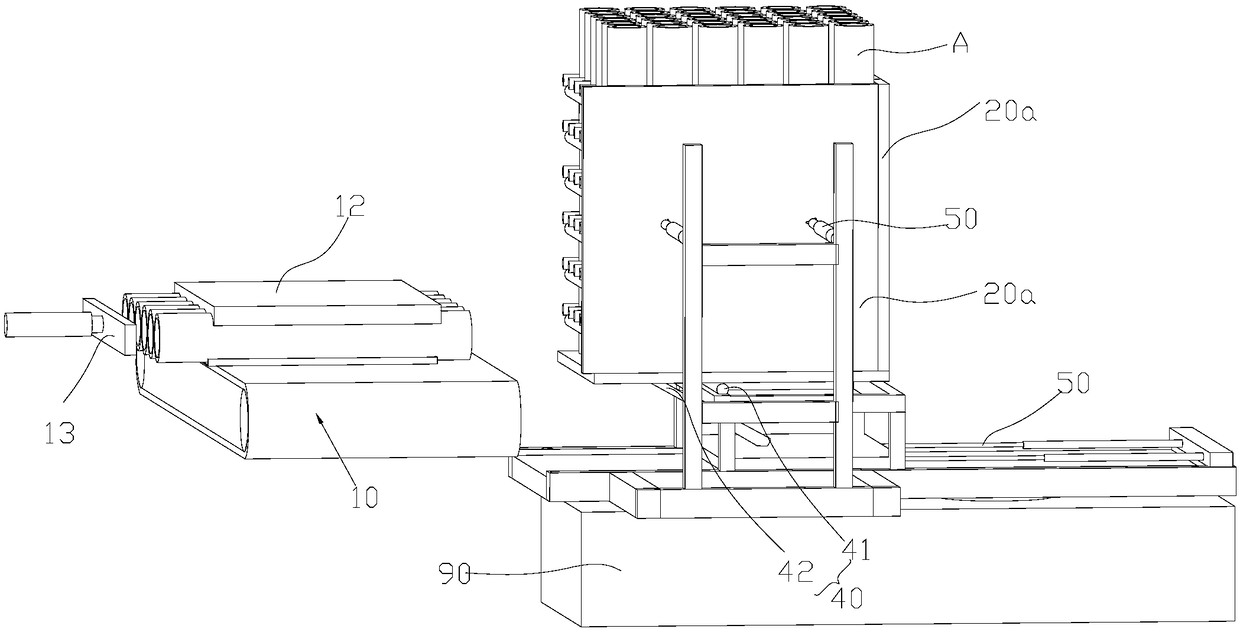

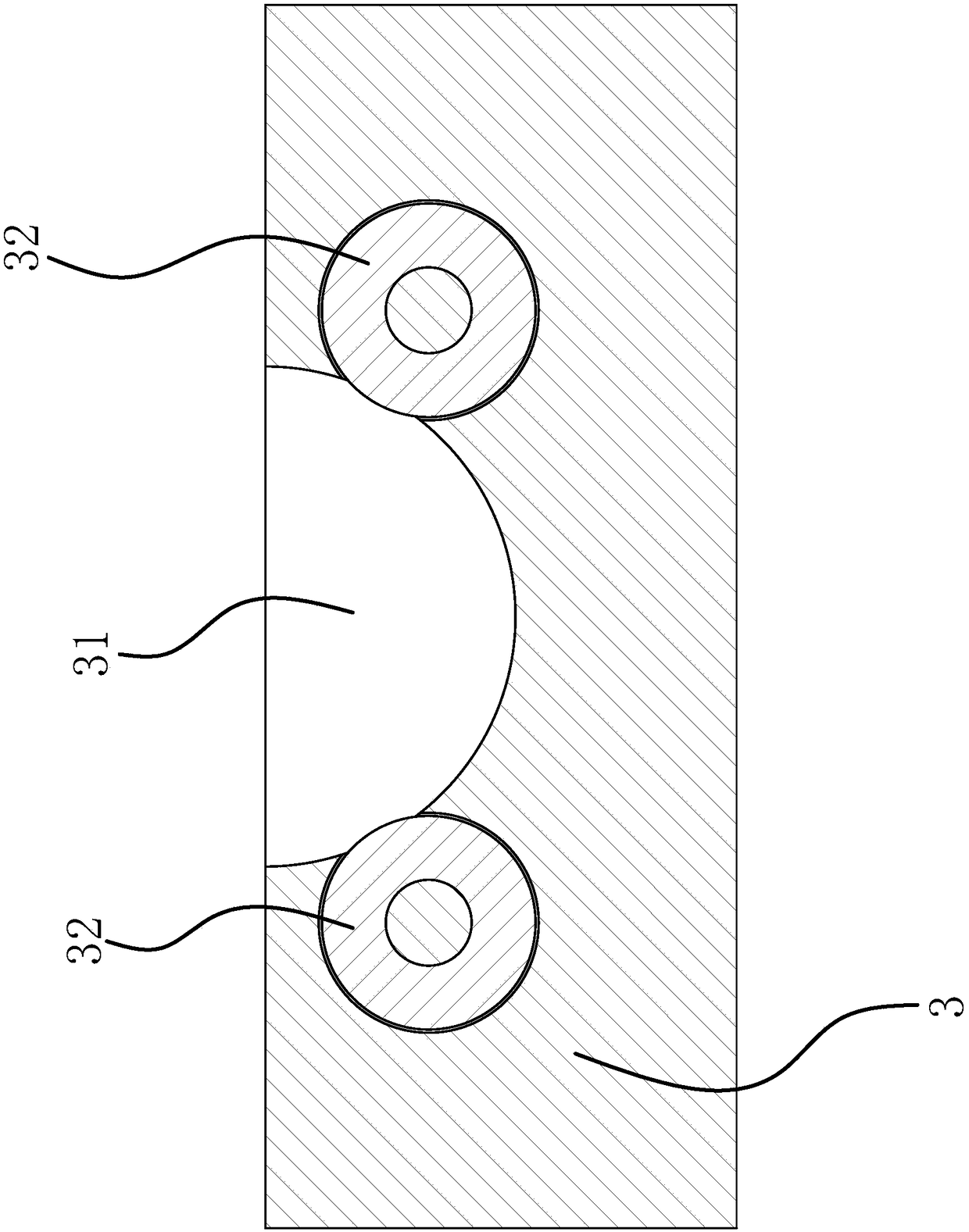

Transfer mechanism

ActiveCN108820853AEasy to insertPrecise positioningConveyorsConveyor partsEngineeringTransfer mechanism

The invention relates to the field of pipe surface treatment, in particular to a transfer mechanism. The transfer mechanism is provided with a plurality of round or rectangular tubular regions B usedfor containing to-be-treated tubes A, one end of each tubular region B is open, and the other end of each tubular region B is closed; the section size of the tubular regions B is slightly larger thanthe outer diameter of the to-be-treated tubes A, and the tubular regions B form a square shape; the section size of the tubular regions B is adjustable, and the minimum value of the section size is slightly larger than the outer diameter of the to-be-treated tubes A. During feeding of the transfer mechanism, the section size of the tubular regions B is adjusted to the maximum value, the tubes canbe inserted into the tubular regions B very easily, the feeding difficulty is reduced, and the feeding efficiency is improved. After tube feeding is finished, the section size of the tubular regions Bis adjusted, so that the tubes are firmly locked in the tubular regions B. According to the structure that the section size of the tubular regions B is adjustable, the requirement for quick feeding can be met, the tubes can also be positioned, and thereof the transfer mechanism can be widely applied to the fields such as feeding and transferring of the tubes.

Owner:ANHUI XUANTONG IND DESIGN CO LTD

Oil sludge and sludge synergistic treatment device and method

PendingCN108840539AImplement co-processingReduce the difficulty of feedingWaste water treatment from quariesSludge treatment by pyrolysisOil sludgeCo-processing

The invention provides an oil sludge and sludge synergistic treatment device and method. The treatment device comprises a pyrolysis device, an oil-gas separation device and a gas-solid combustion device, wherein an oil gas discharging port of the pyrolysis device is connected with a feeding port of the oil-gas separation device, a solid discharging port of the pyrolysis device is connected with afeeding port of the gas-solid combustion device, a gas outlet of the oil-gas separation device is connected with a gas inlet of the gas-solid combustion device, and a gas outlet of the gas-solid combustion device is connected with a heat source inlet of the pyrolysis device. An oil sludge and sludge mixture is sequentially subjected to pyrolysis, oil-gas separation and gas-solid combustion, synergistic treatment of oil sludge and sludge is realized, the pyrolysis efficiency is high, and combustion treatment is thorough. Heat produced in the combustion process can be sufficiently used for pyrolysis and drying processes, the energy utilization rate is high, additional energy supplement is not required, and the treatment cost is low.

Owner:ZKCH

Feed processing and producing feeding device

The invention provides a feed processing and producing feeding device. The feed processing and producing feeding device is mainly used for the field of feed processing and producing. The feed processing and producing feeding device comprises a base plate, a support, a conveying pipe, feeding buckets, a mixing bucket and universal wheels. The support is arranged on the upper surface of the base plate, the conveying pipe is arranged in the support, the three feeding buckets are arranged on the upper surface of the support and include two large-material buckets and one small-material bucket, a conveying device is arranged inside the conveying pipe, the tail end of the conveying pipe is bent downwards and connected with the mixing bucket, and the lockable universal wheels are arranged on the lower surface of the base plate. According to the feed processing and producing feeding device, multiple materials can be fed at the same time; in addition, it can be avoided that in the feeding process, dust in smashed materials floats around, and the environment is polluted, and the body health of an operator cannot be affected; as a mesh screen is additionally arranged in the device, large-particle substances which do not meet requirements can be removed; after a vibration exciter is additionally arranged, the pipe can be prevented from being blocked in the conveying process; as the small-material bucket is arranged, small materials can be added while large materials are added, feeding time is saved, and feeding difficulty is lowered.

Owner:TIANJIN MUJIA FEED CO LTD

Intermediate frequency furnace with automatic feeding function

The invention discloses an intermediate frequency furnace with an automatic feeding function, which comprises a base, a waste groove, a machining table, a locking block and a limiting block, wherein the waste groove is formed in the base, the machining table is installed on the base, a turnover mechanism is arranged on the machining table, a supporting plate is connected to the turnover mechanism, a smelting furnace is installed on the supporting plate, a casting opening is formed in the smelting furnace, a smelting cavity is formed in the smelting furnace, and a first supporting column is installed on the base. According to the intermediate frequency furnace with the automatic feeding function, the lifting box capable of ascending and descending is arranged, when secondary feeding is conducted on the smelting cavity, the lifting box conveys raw materials to the position right above the smelting cavity through ascending and descending, a first overturning plate and a second overturning plate are opened through rotation of a winding roller, the raw materials fall into a feeding hopper from a storage box, and the materials are accurately added into the smelting cavity through the feeding hopper, so that the feeding process is automatically completed, the feeding convenience is improved, and the danger is reduced.

Owner:丹阳市建晟精密机械科技有限公司

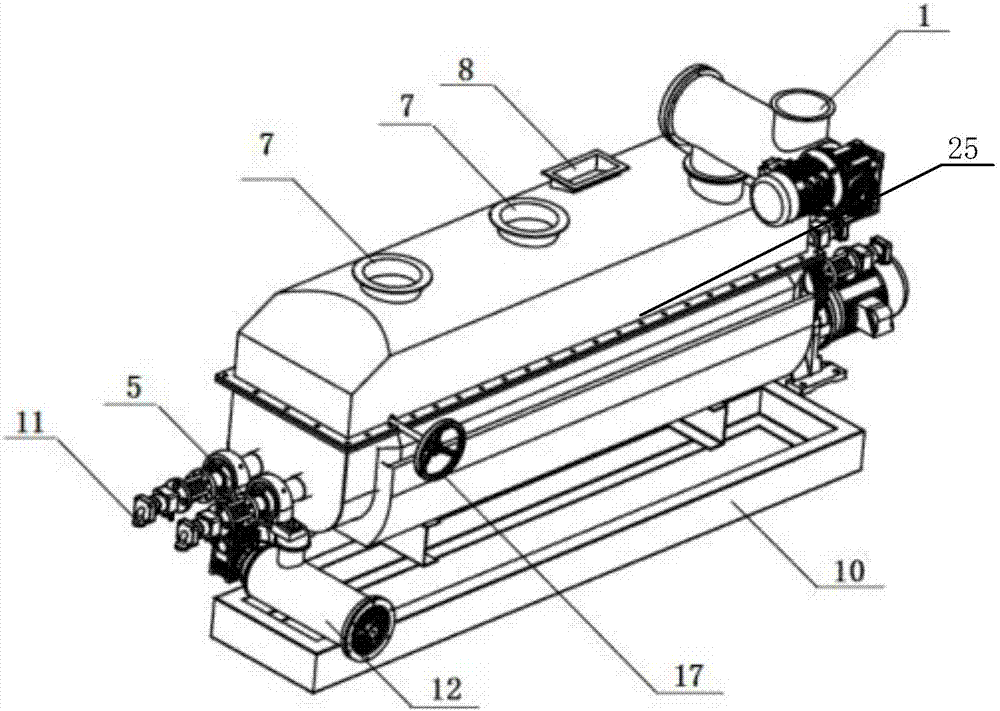

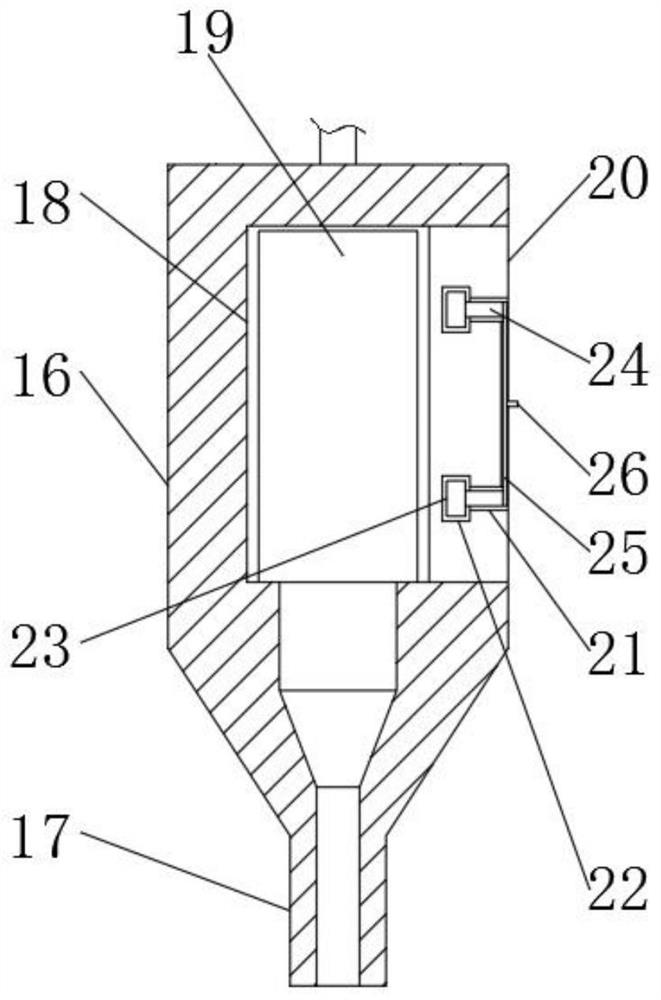

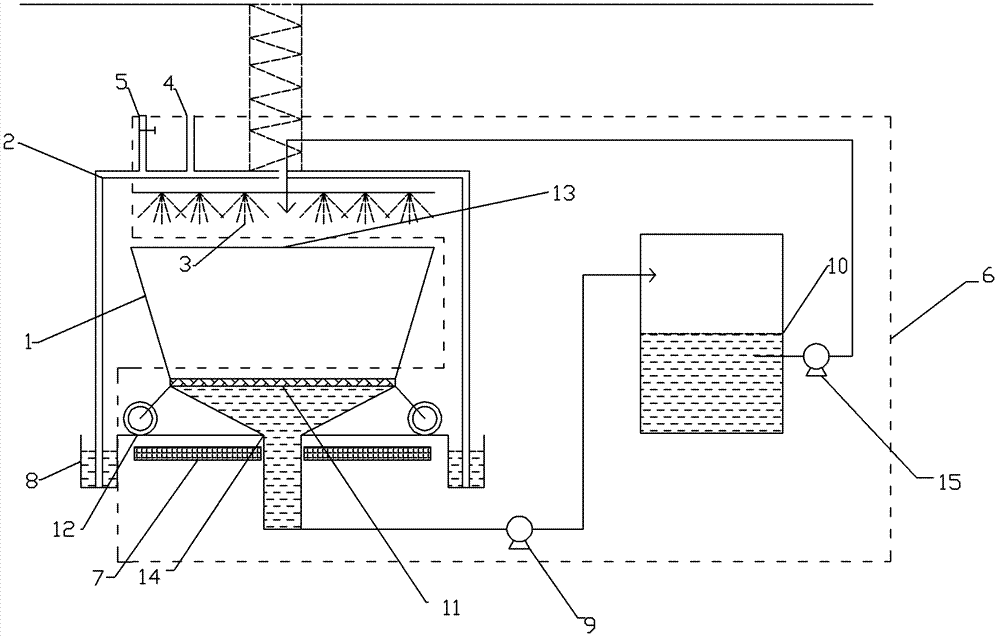

Container type dry fermentation system

InactiveCN102533523BReduce the difficulty of uninstallationReduce the difficulty of feedingBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlSpray nozzle

The invention belongs to the technical field of garbage recycling and the development and the utilization of biological energy sources and especially relates to a container type dry fermentation system. The convenience in charging and discharging is achieved through a manner that a stainless steel cover is matched with a wheeled movable dry fermentation device, and an opening of the movable dry fermentation device is used for charging and the discharging is carried out by directly withdrawing a bottom perforated baffle, wherein the stainless steel cover can vertically stretch out and draw back and is fixedly arranged on the ceiling of a fermentation room; the temperature control in a dry fermentation process is achieved through a temperature-controlling device built in the ground surface,meanwhile, a foam plastic board heat-insulating material is applied to the cover body, therefore, the temperature of the dry fermentation process is maintained; water grooves are paved on the ground surface along the bottom contour of the stainless steel cover, so that an anaerobic environment is guaranteed by using a water seal manner; and the leachate circulation is achieved through a leachate circulation system, i.e. a leachate collecting tank, pumps and spraying nozzles. According to container type dry fermentation system, the difficulty in the charging / discharging of dry fermentation canbe solved, meanwhile, the environmental conditions required for the dry fermentation process can be controlled, so that the efficiency of the dry fermentation is increased, and meanwhile, the transportation cost and the energy consumption are reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

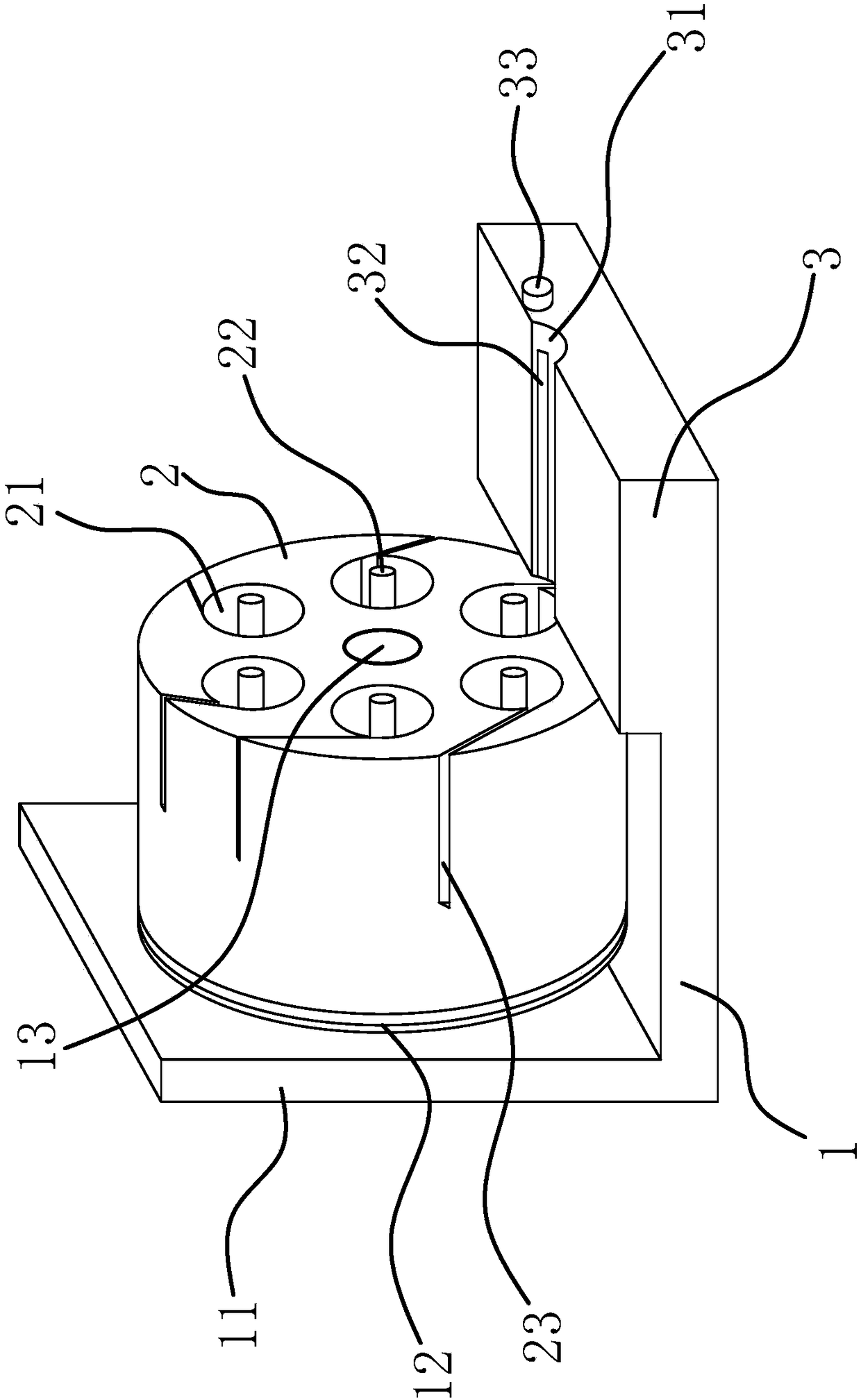

Metal coiled material feeding device and metal coiled material feeding method

ActiveCN108526244AReduce labor intensityReduce the difficulty of feedingHollow articlesEngineeringMetal

The invention provides a metal coiled material feeding device and a metal coiled material feeding method. The metal coiled material feeding device comprises a frame, a roller is rotatably connected onthe frame, a plurality of material chambers are uniformly formed in the upper periphery of the roller, an opening is formed in one end of each material chamber, a positioning shaft fixed onto the roller is arranged at an axis in each material chamber, a feeding device is arranged on the frame and positioned on the opening side of the material chambers, metal coiled materials can be fed into the material chambers by the feeding device, and material feeding grooves in one-to-one correspondence to the material chambers are formed in the roller and tangent to the inner walls of the material chambers and penetrate inner cavities of the material chambers and the outer wall of the roller. The device has the advantages of high efficiency and safety and the like.

Owner:华源包装(咸宁)有限公司

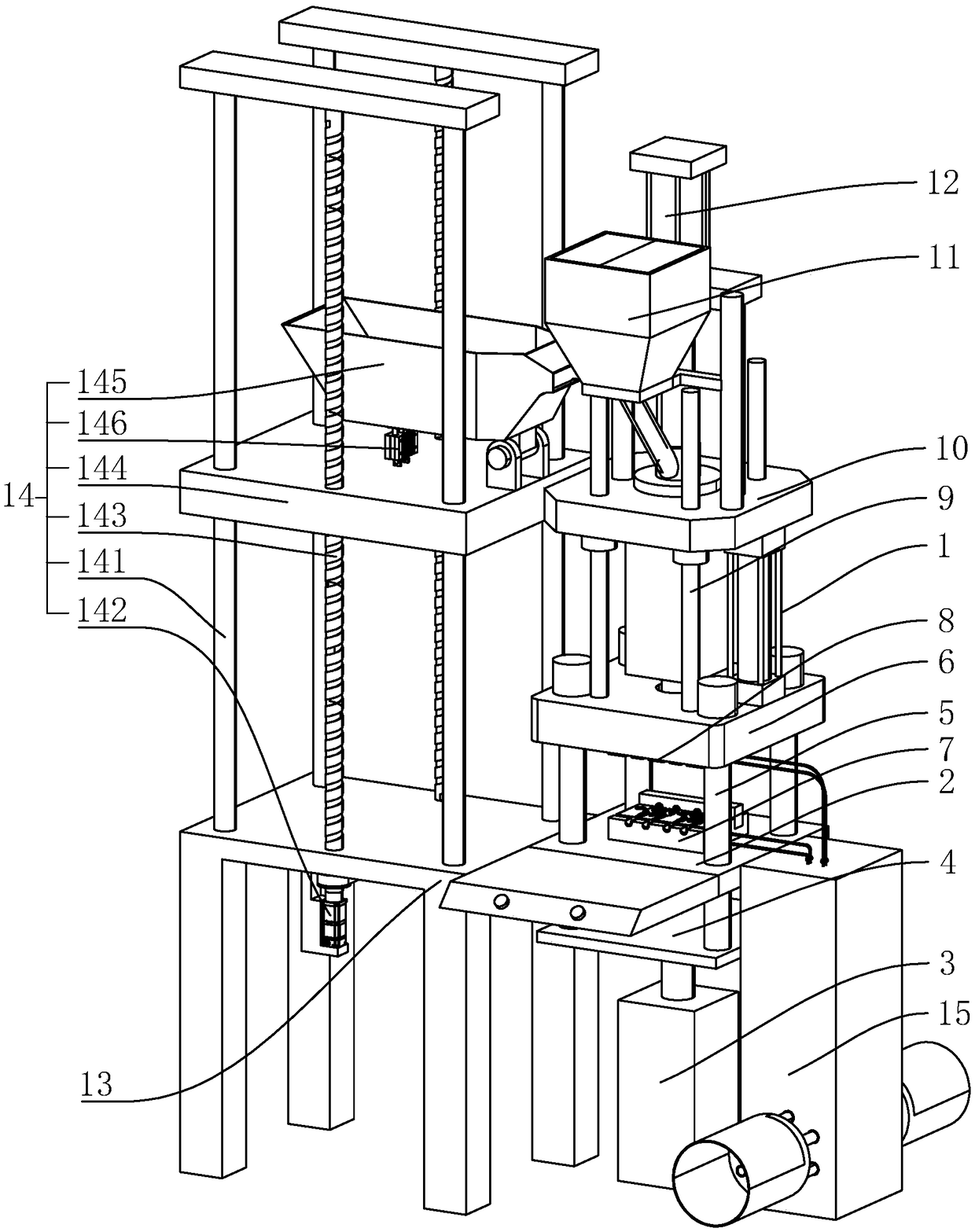

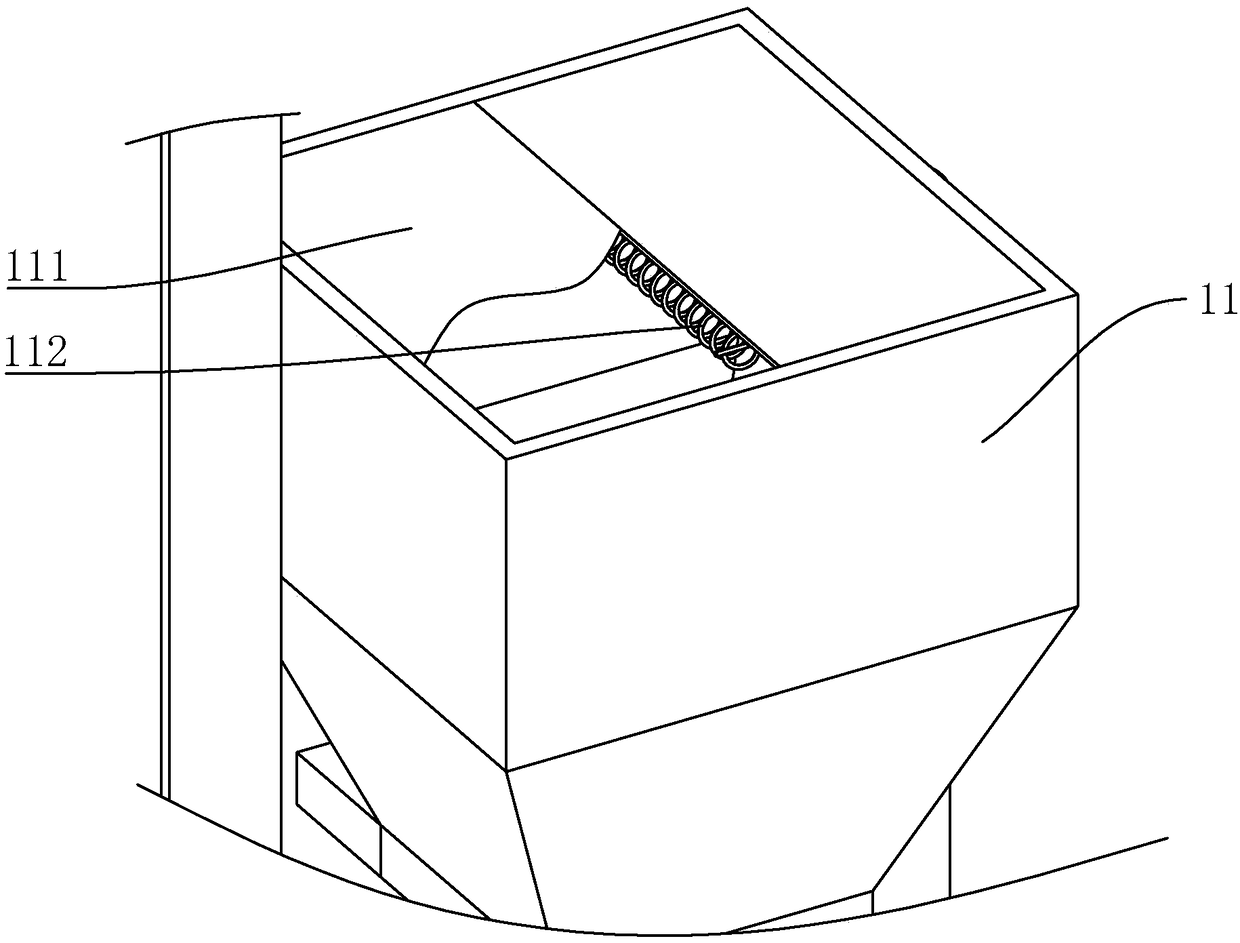

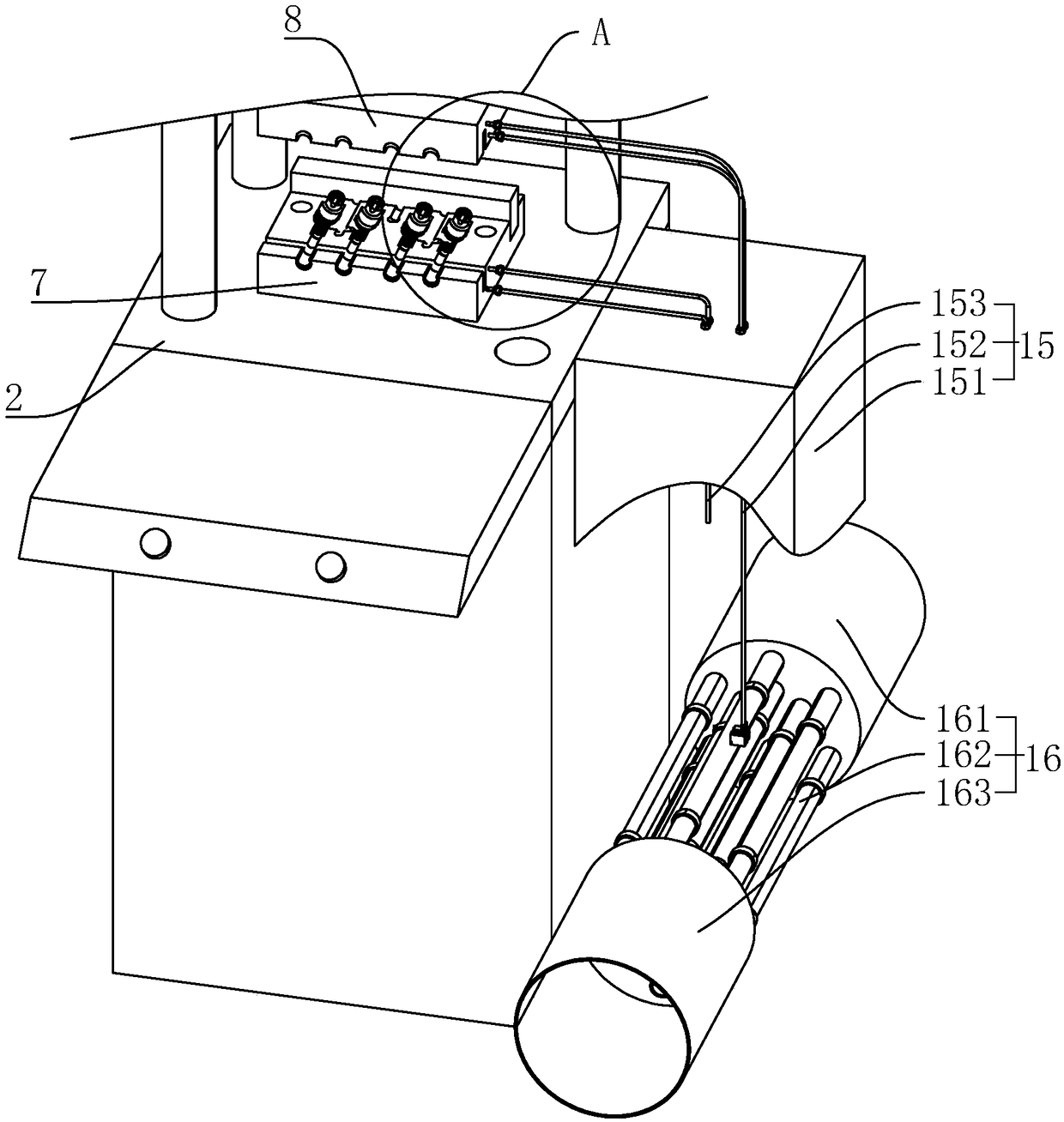

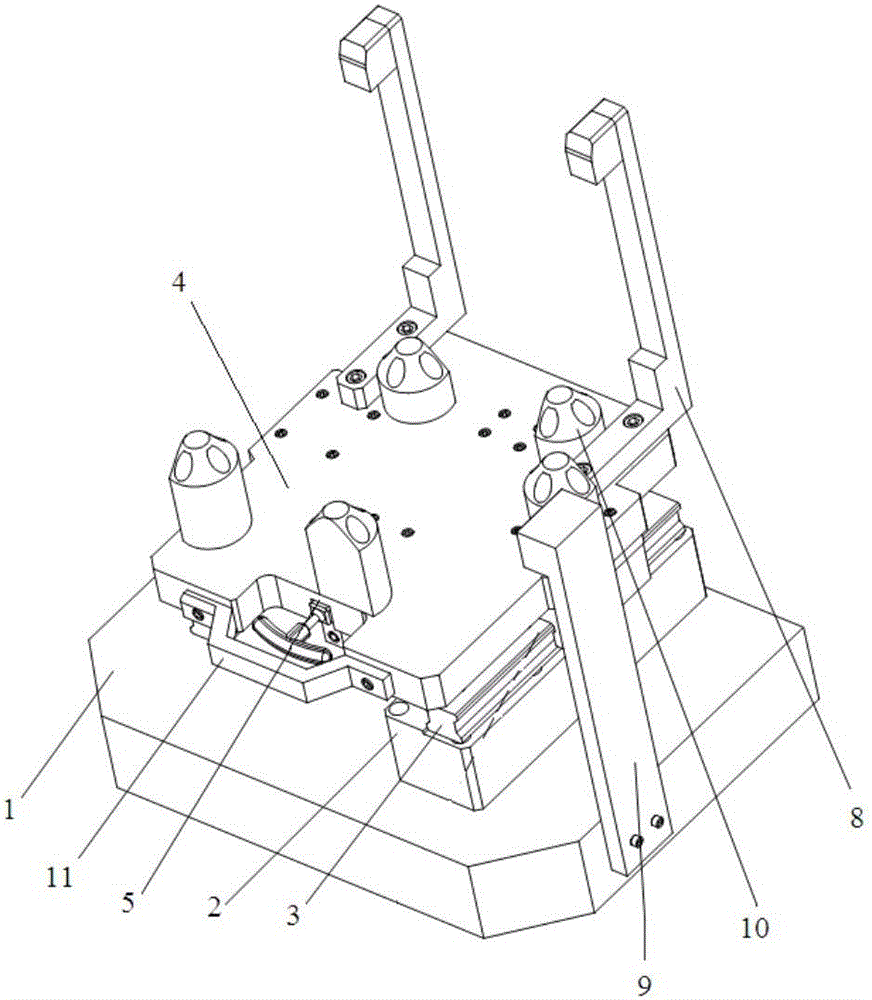

Automatic production device for relay armature

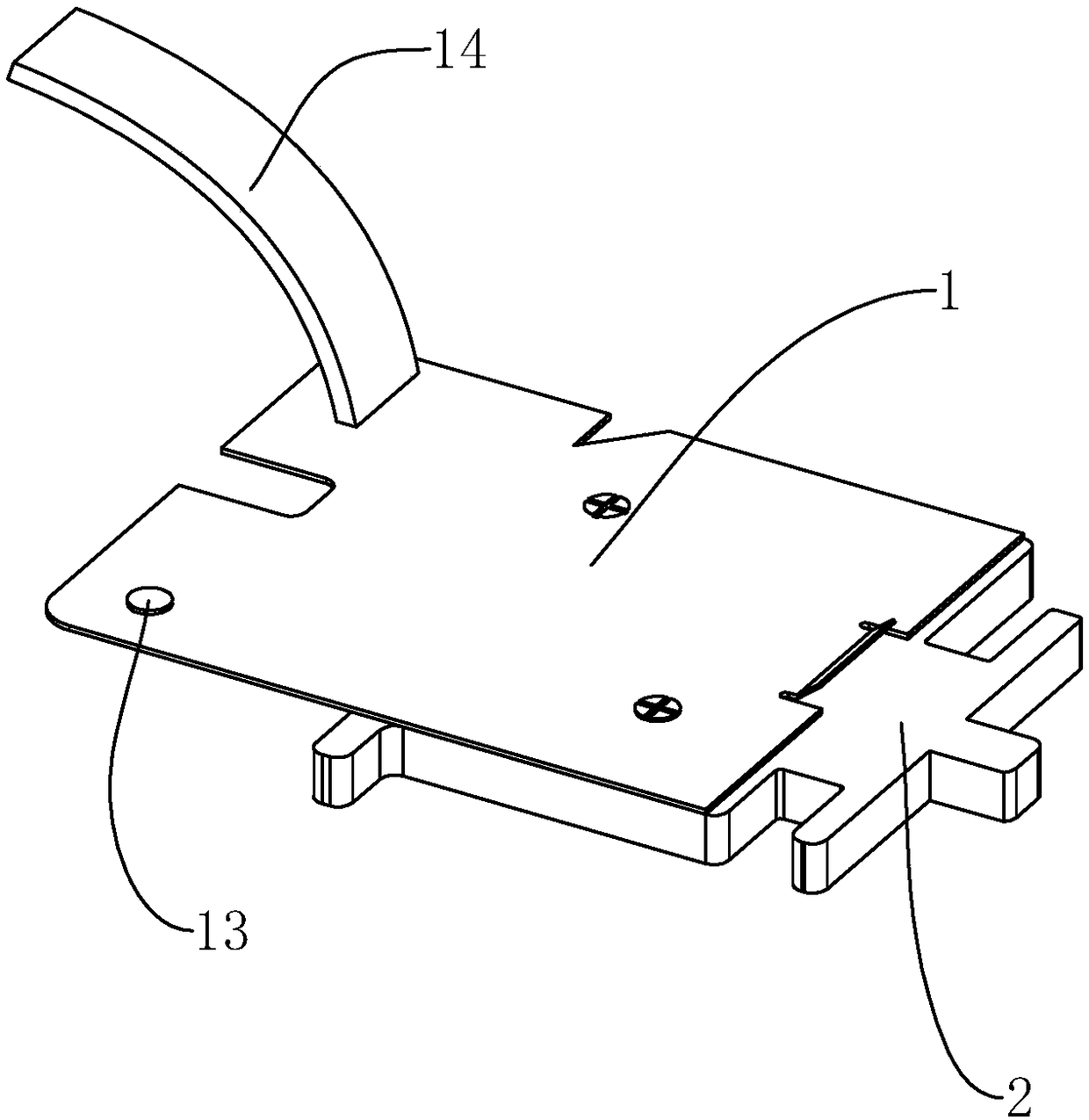

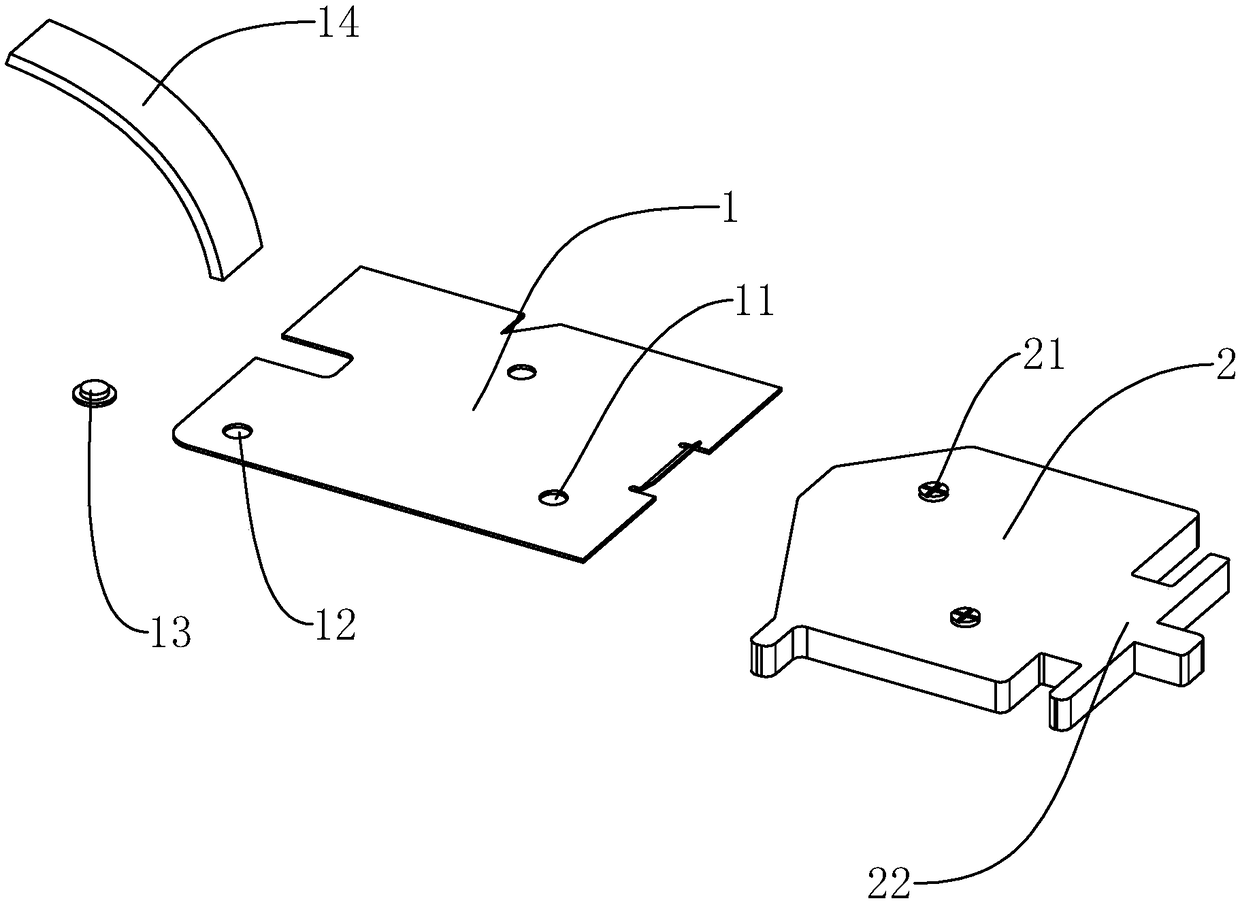

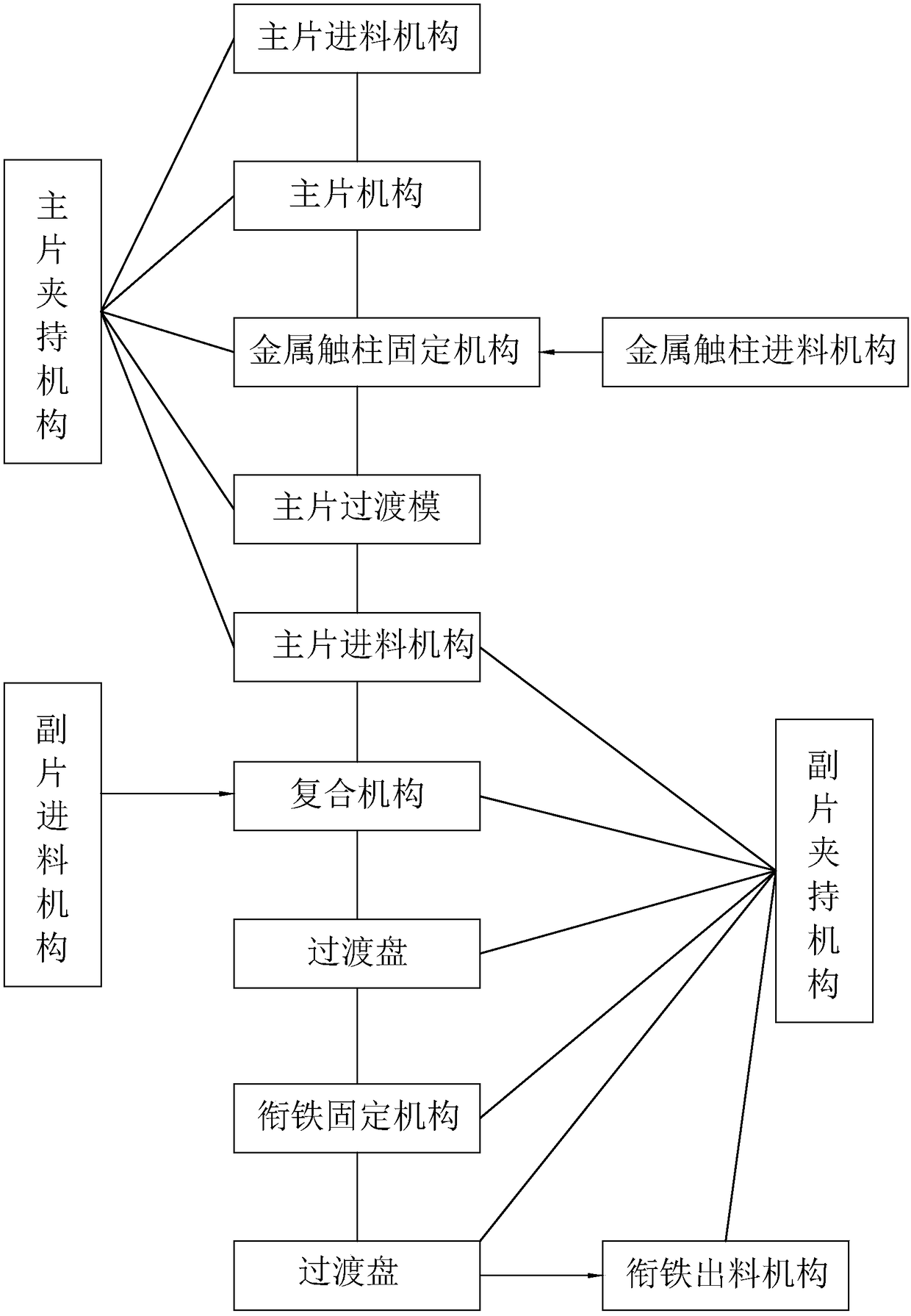

ActiveCN108364832AReduce fixed difficultyImprove automation production efficiencyRelaysEngineeringMechanical engineering

The invention discloses an automatic production device for a relay armature. According to the main points of the technical scheme, the automatic production device comprises a machine, a main sheet processing device and an auxiliary sheet processing device, wherein the main sheet processing device and the auxiliary sheet processing device are arranged on the machine; the main sheet processing device comprises a main sheet feeding mechanism, a metal touch column loading mechanism for loading contact insert columns, a metal touch column fixing mechanism and a main sheet transporting mechanism which are sequentially arranged; the metal touch column fixing mechanism is used for making the contact insert columns pass through corresponding main sheets and fixing the contact insert columns on thecorresponding main sheets; the main sheet transporting mechanism is used for transporting the main sheets into the auxiliary sheet processing device; the machine is provided with a main sheet clampingmechanism for transferring the main sheets; the auxiliary sheet processing device comprises an auxiliary sheet feeding mechanism, a compounding mechanism, an armature fixing mechanism and an armaturedischarge mechanism which are sequentially arranged; the armature fixing mechanism is used for connecting the main sheets and corresponding auxiliary sheets into a whole; and the machine is providedwith an auxiliary sheet clamping mechanism which is used for clamping the main sheets into the compounding mechanism from the main sheet transporting mechanism and transferring the compounded main sheets and auxiliary sheets. The automatic production device has the effect that the automatic production efficiency for the relay armature is significantly improved.

Owner:鼎捷自动化科技有限公司

Punching equipment used for ground flat tube

InactiveCN109201850AImprove punching efficiencyRun reasonablyPerforating toolsMetal-working feeding devicesPunchingMachining

The invention discloses punching equipment used for a ground flat tube and belongs to the field of electric power accessory machining equipment. The equipment comprises a workbench. A feeding mechanism, a positioning mechanism and a punching mechanism are arranged on the workbench. The feeding mechanism comprises a material containing hopper, a conveying belt and a feeding air cylinder. The positioning mechanism comprises a left positioning air cylinder, a right positioning air cylinder, a positioning stop lever and a transmission rod. The punching mechanism comprises an upper die base, a lower die base and a punching air cylinder. When the feeding air cylinder performs feeding, the ground flat tube is pushed to the lower die base, the transmission rod drives the positioning stop lever tooscillate upwards so as to position the feeding position during feeding, after punching is completed, the feeding air cylinder pushes the ground flat tube to move away from the lower die base so as toachieve discharging, and the transmission rod drives the positioning stop lever to oscillate downwards so as to avoid intervening during discharging. Through combination of the feeding mechanism, thepositioning mechanism and the punching mechanism, automatic feeding, punching and discharging can be achieved, the punching efficiency of the ground flat tube is effectively improved, and accordingly, the power distribution network engineering construction efficiency can be improved easily.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

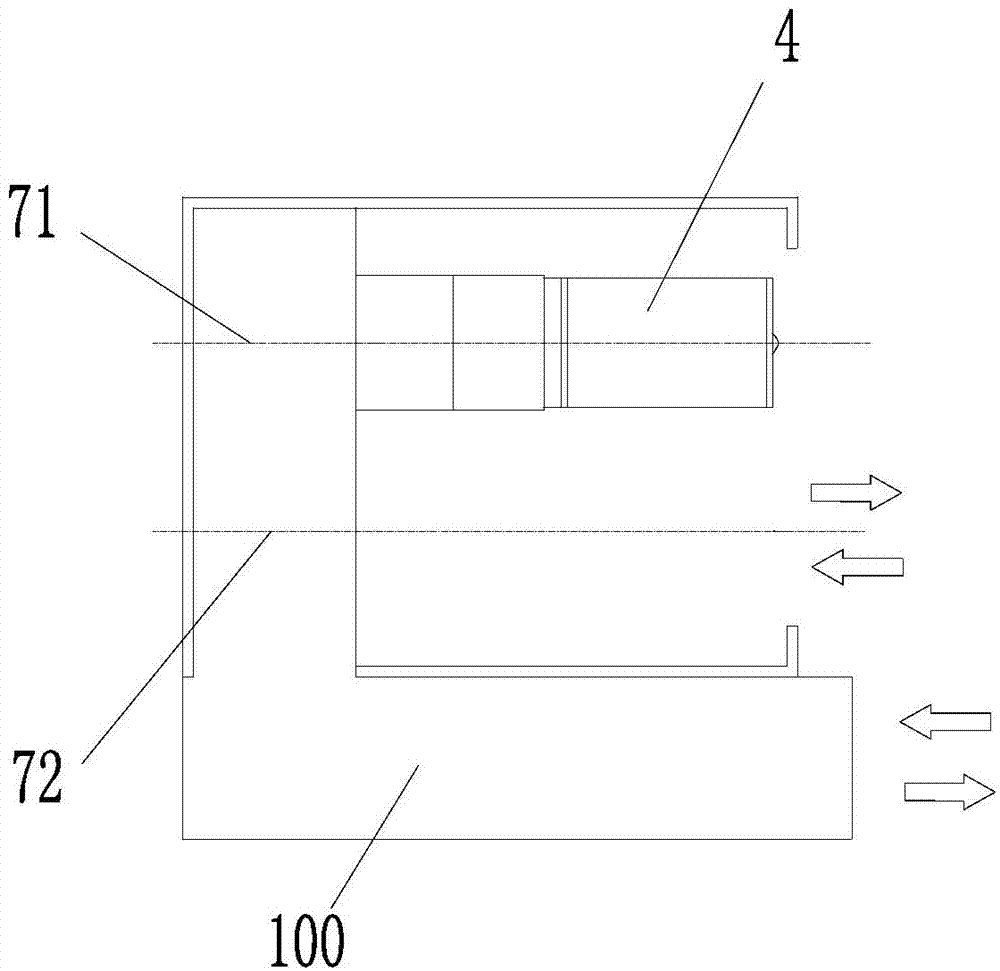

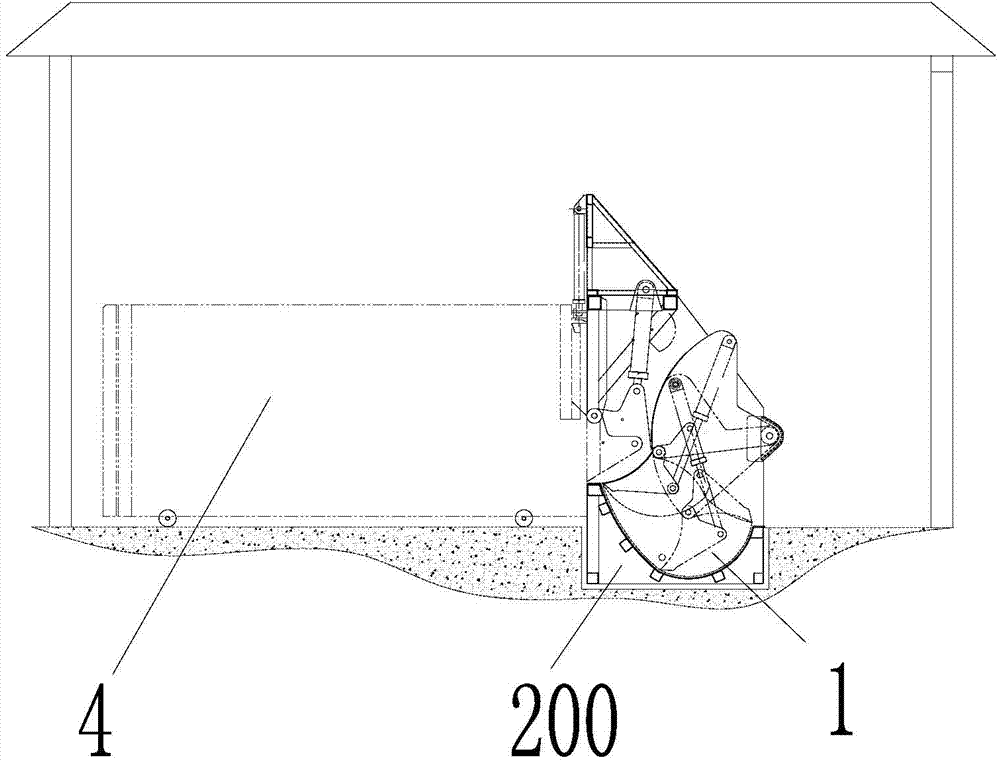

Garbage compressor and garbage compacting station

ActiveCN103692678AReduce the difficulty of feedingEfficient compressionPressesWaste managementGas compressor

The invention discloses a garbage compressor, comprising a padding bin (1), a loading scraper (21), a feeding channel (3) and a pushing head (5), wherein the padding bin (1) is used for containing garbage unloaded from a garbage collecting vehicle; the upper scraper is used for scraping garbage in the padding bin from an inlet in a low position of the padding bin to an outlet in a high position of the padding bin; the feeding channel is arranged below the outlet of the padding bin and is used for communicating the outlet of the padding bin with an inlet of a garbage bin (4); the push head is arranged in the feeding channel and is used for pushing and compacting the garbage, which is sent to the feeding channel from the padding bin, into the garbage bin (4). The invention also provides a garbage compacting station with the garbage compressor. By using the garbage compressor and the garbage compacting station, the performance of the garbage compacting station is improved, and the garbage compacting station is smaller in floor space.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Agricultural fertilizer efficient stirring device

InactiveCN112844118AAdd accurateReduce the difficulty of feedingTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural machinery, in particular to an agricultural fertilizer efficient stirring device which comprises a stirring tank, supporting frames are evenly welded to the side face of the stirring tank, a discharging port is fixedly formed in the bottom of the stirring tank, and the top of the stirring tank is in threaded connection with a stirring tank cover. A motor mounting frame is fixedly mounted in the center of the end face of the stirring tank cover, a motor is fixedly mounted on the upper side of the motor mounting frame, and the driving end of the motor sequentially penetrates through the motor mounting frame and the stirring tank cover from top to bottom and extends into the stirring tank to be fixedly provided with a rotating rod; a stirring rod is connected to the position, located in the stirring tank, of the rotating rod, a first opening and closing butterfly valve is fixedly installed on the upper left side of the motor, the upper end of the first opening and closing butterfly valve is in threaded connection with a material storage tank body, and the upper end of the first material storage tank body is in threaded connection with a first material storage tank cover. The effects of accurate feeding and uniform stirring can be achieved through design, and no air pollution is caused.

Owner:张家界金土地众辉农业开发股份有限公司

Feed bulk raw material packaging bag damage detection device

PendingCN112722688AReduce the difficulty of unloadingReduce the difficulty of feedingConveyorsSortingManufacturing engineeringDamage detection

The invention discloses a feed bulk raw material packaging bag damage detection device which comprises a hopper. A first conveying frame is installed at the bottom of one side of the hopper, a second conveying frame is installed on one side of the first conveying frame, a feeding frame is installed on one side of the second conveying frame, and a detection box is installed on one side of the feeding frame. A third conveying frame is installed at the bottom of one side of the detection box, material distribution baffles are welded to the two sides of the inner wall of the hopper, semicircular stop blocks are welded to the top ends of the material distribution baffles, a material bearing table is hinged to one side of the top end of the hopper, clamping air cylinders are installed on the two side edges of the top end of the material bearing table, and clamping jaws are installed at the push rod ends of the clamping air cylinders. During operation, manual operation is not needed, the automation degree is high, the detection difficulty of the bagged raw materials can be reduced, the detection efficiency of the bagged raw materials is improved, the bagged raw materials can be rapidly unloaded and stored, and the cost of detection and warehousing of the bagged raw materials can be reduced.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

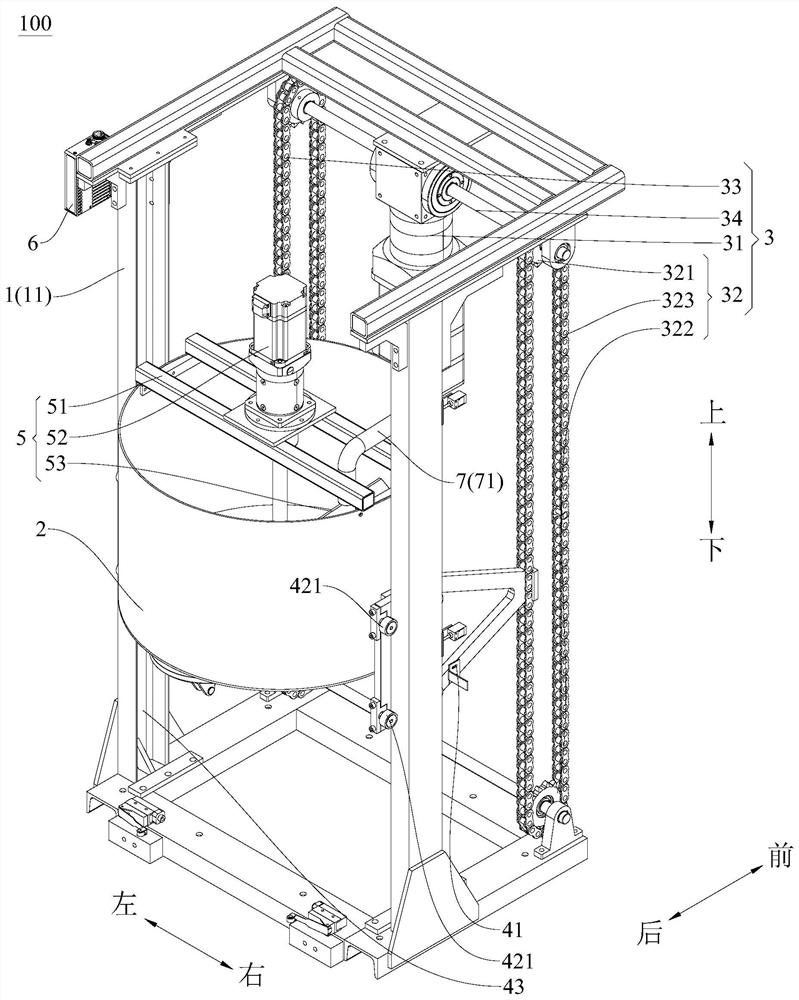

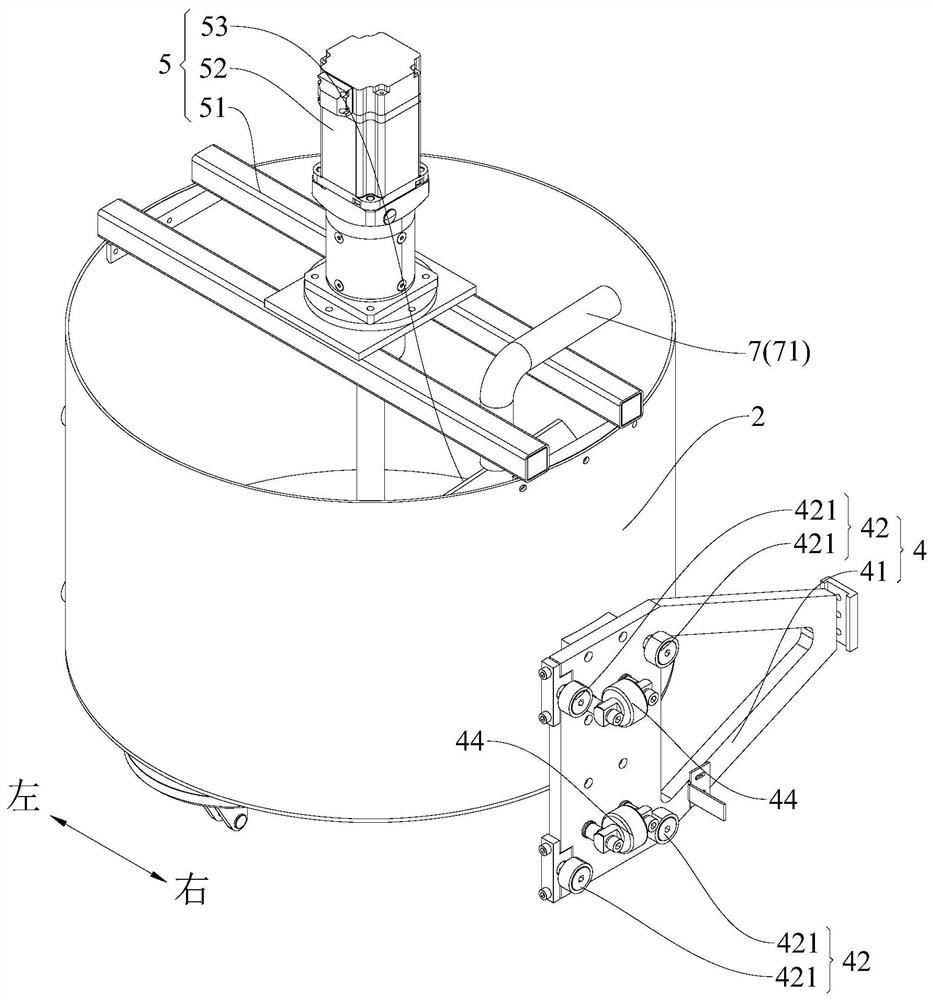

Lifting feeding device

The invention provides a lifting feeding device. The lifting feeding device comprises a supporting frame, a hopper, a lifting device and guide mechanisms, wherein the supporting frame comprises a guide rod extending in the vertical direction, the hopper is arranged on the supporting frame in a lifting mode along the guide rod, the lifting device is arranged on the supporting frame so as to drive the hopper to move, each guide mechanism comprises a connecting frame and guide wheel sets, the guide wheel sets are connected to the connecting frame, the guide wheel sets are arranged by holding theguide rod and are in rolling fit with the guide rod, one end of the connecting frame is connected with the hopper, and the other end of the connecting frame is connected with the lifting device. According to the lifting feeding device provided by the embodiment of the invention, the feeding difficulty can be reduced, the structure is simple, and time and labor are saved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Pig herd breeding method and system thereof

ActiveCN105955331AIncrease feed intakeReduce breastfeedingMechanical power/torque controlAnimal watering devicesTemperature controlHerd

The invention provides a pig herd breeding method and system thereof, and belongs to the field of breeding. Water is injected into a water level adjusting box, and the water level adjusting box supplies water to a constant temperature water supply tank when the water level in the constant temperature water supply tank is lower than a second preset water level; water in the constant temperature water supply tank is heated by utilizing a second heating mechanism; a second temperature adjusting instrument is adjusted to a second preset temperature value; temperature of water in the constant temperature water supply tank is detected by utilizing a water temperature sensor, and the water temperature sensor transmits a second temperature measurement value to the second temperature adjusting instrument; when the second temperature measurement value is less than the second preset temperature value, the second temperature adjusting instrument transmits a heating signal to a second temperature control mechanism, and the second temperature control mechanism controls the second heating mechanism to heat water in the constant temperature water supply tank; and the constant temperature water supply tank is provided with drink mouths used for pigs, and the pig herd drinks the heated water through the drink mouths used for the pigs. According to the technical scheme, constant temperature material supply can be realized, and the type of material supply is various, so that the health growth of the pig herd is facilitated and the breeding difficulty of the pig herd is reduced.

Owner:王碧洪

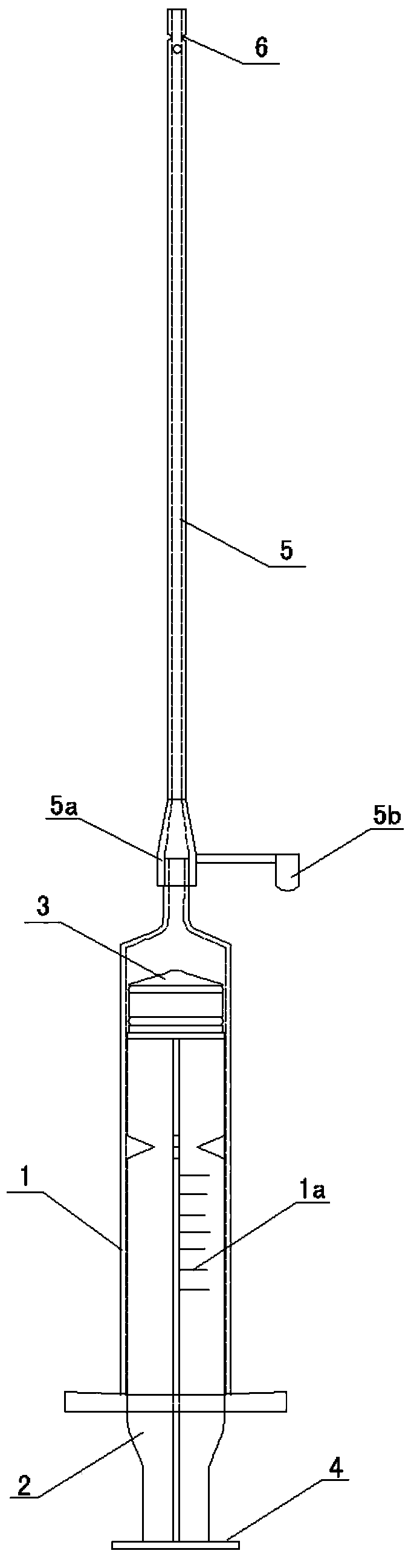

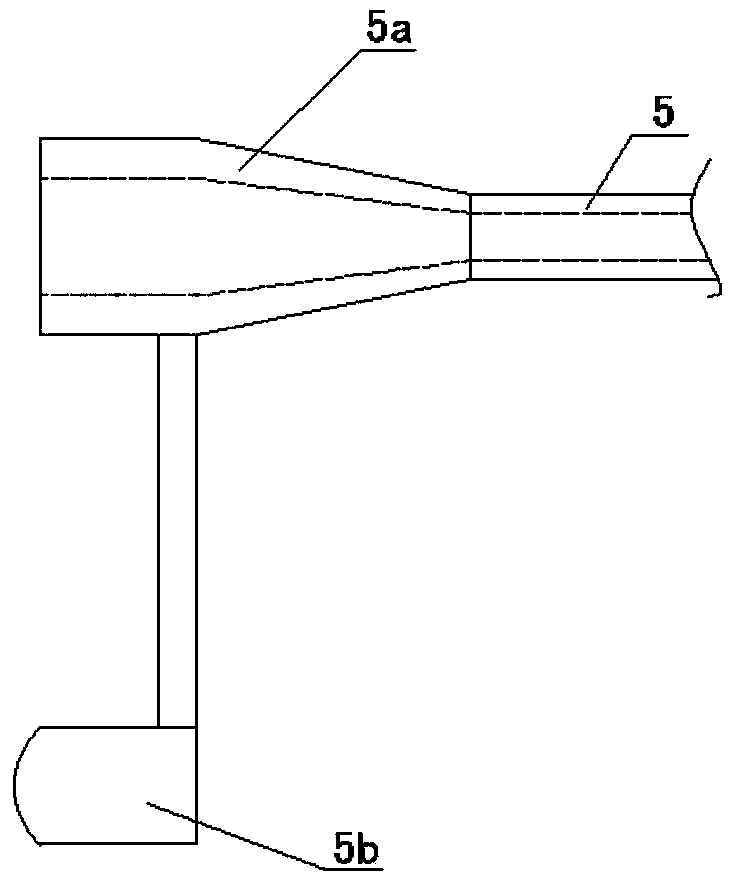

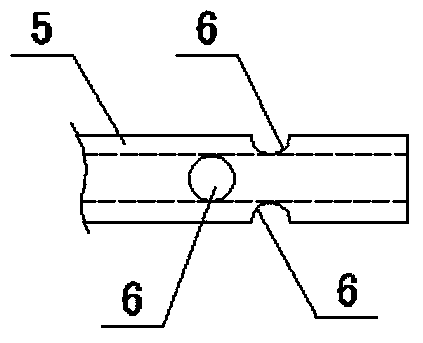

Simple medicine feeder

InactiveCN104095755AReduce sensitivityReduce the difficulty of feedingOral administration deviceEngineeringCross infection

The invention discloses a simple medicine feeder. The simple medicine feeder is characterized in that a transparent cylinder with scales is provided with a teat canal at the front end of the transparent cylinder, a piston head is arranged in the cylinder in a matching way, the tail part of the piston head is connected with the piston rod to form a quantitative liquid pusher, a section of hose sleeves the teat canal of the cylinder, and the length of the hose is based on that the front tip of the hose inserted in the oral cavity of a sick child can reach a part nearby the pharyngeal at the rear part of the tongue of the sick child. According to the simple medicine feeder, the condition that an infant patient is difficult to feed can be changed thoroughly by a simple way; furthermore, the medicine feeder is convenient, clean and sanitary to use, and the cross infection can be effectively prevented when the medicine feeder is used in medical locations.

Owner:THE FIRST AFFILIATED HOSPITAL OF ANHUI MEDICAL UNIV

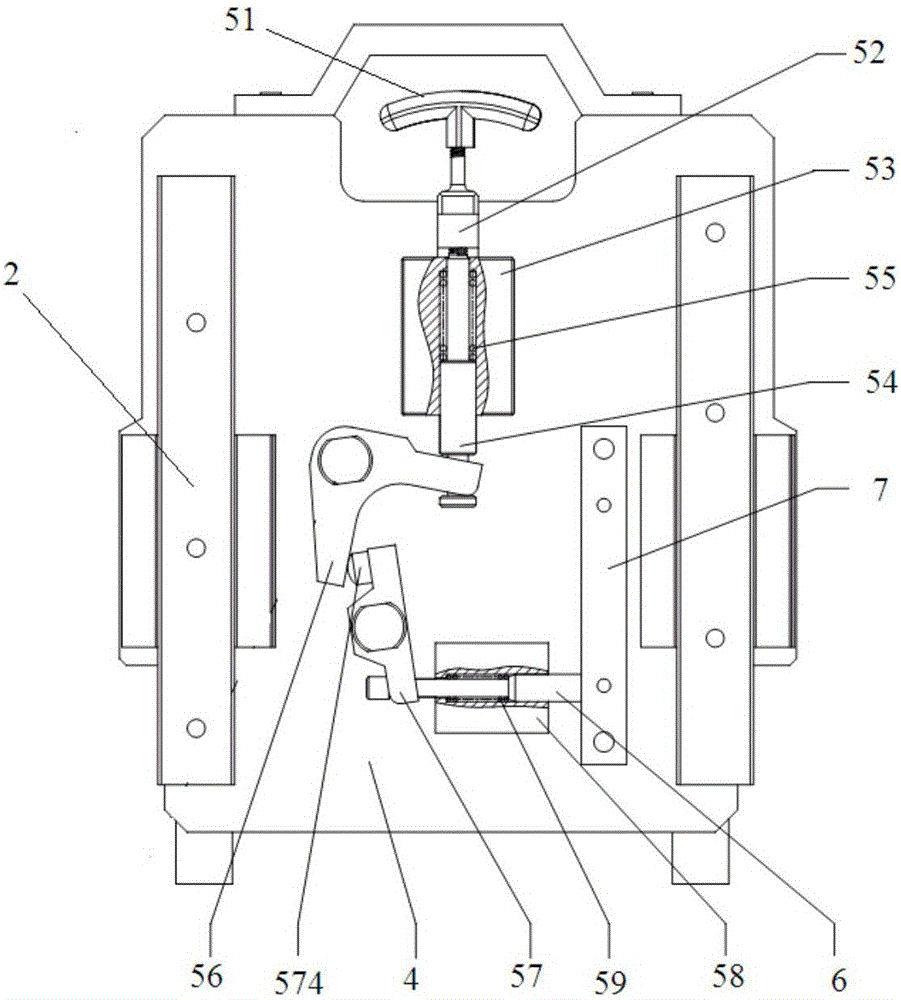

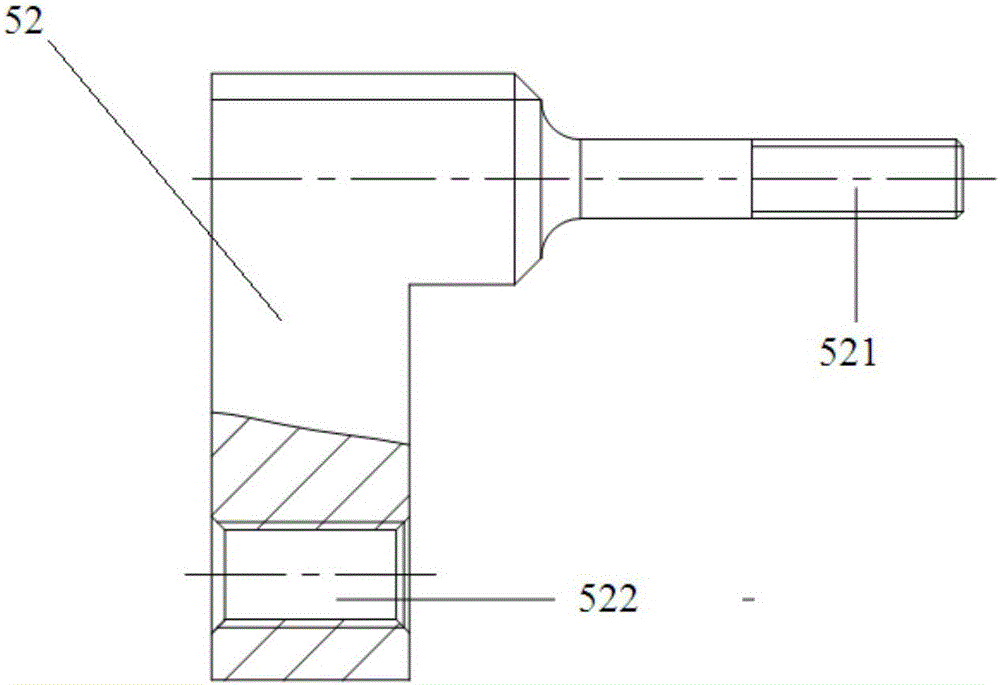

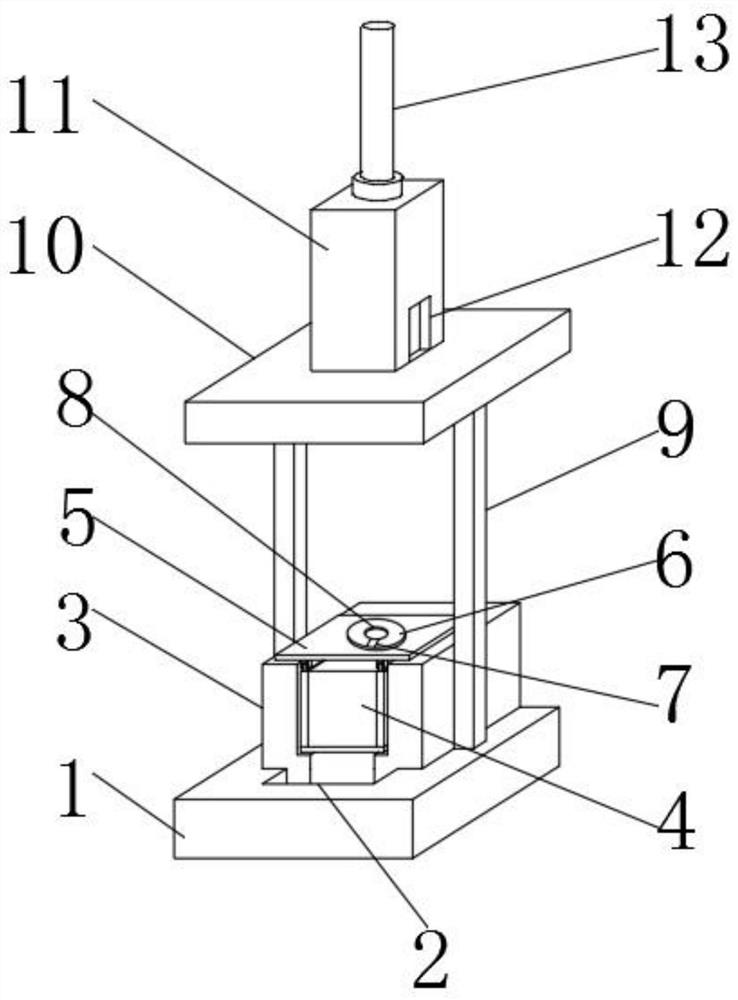

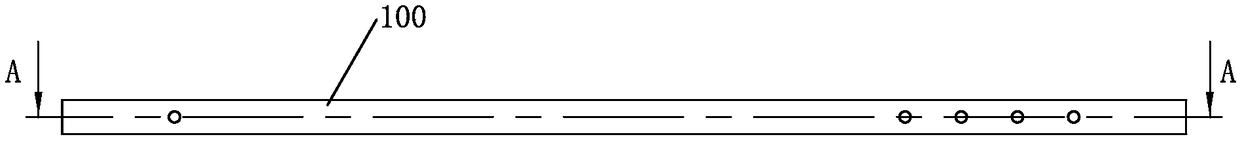

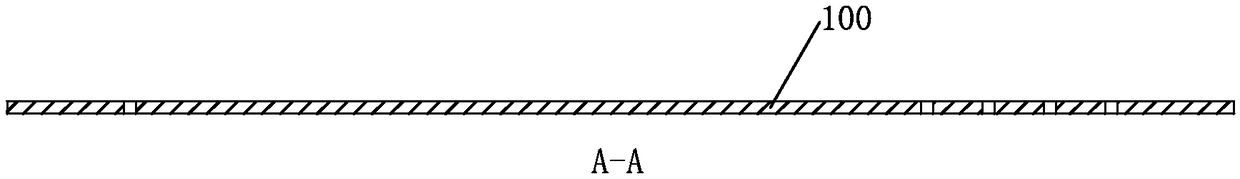

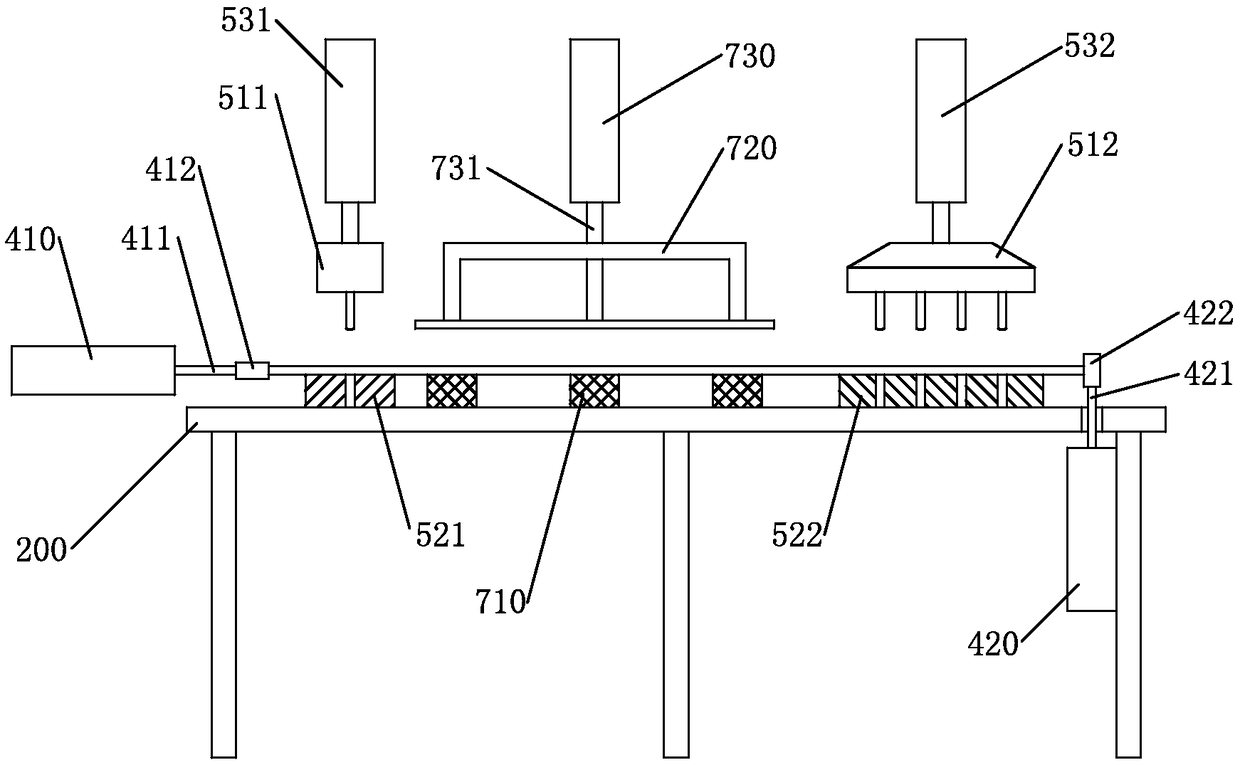

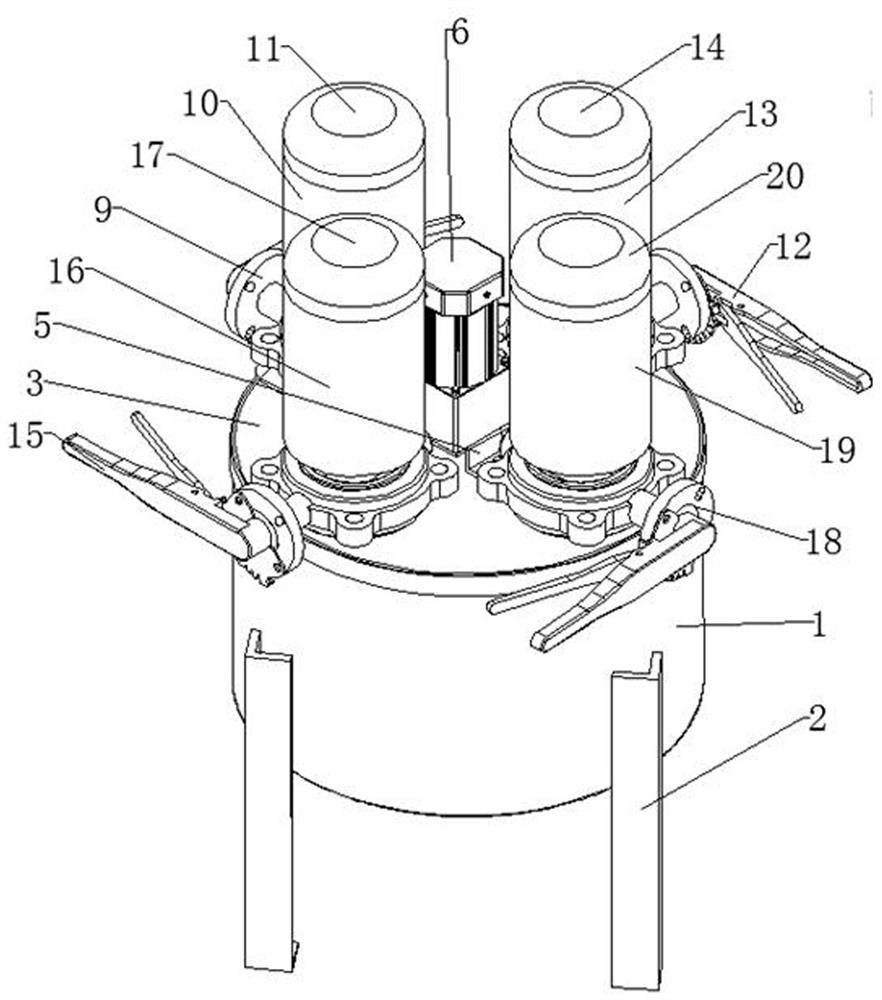

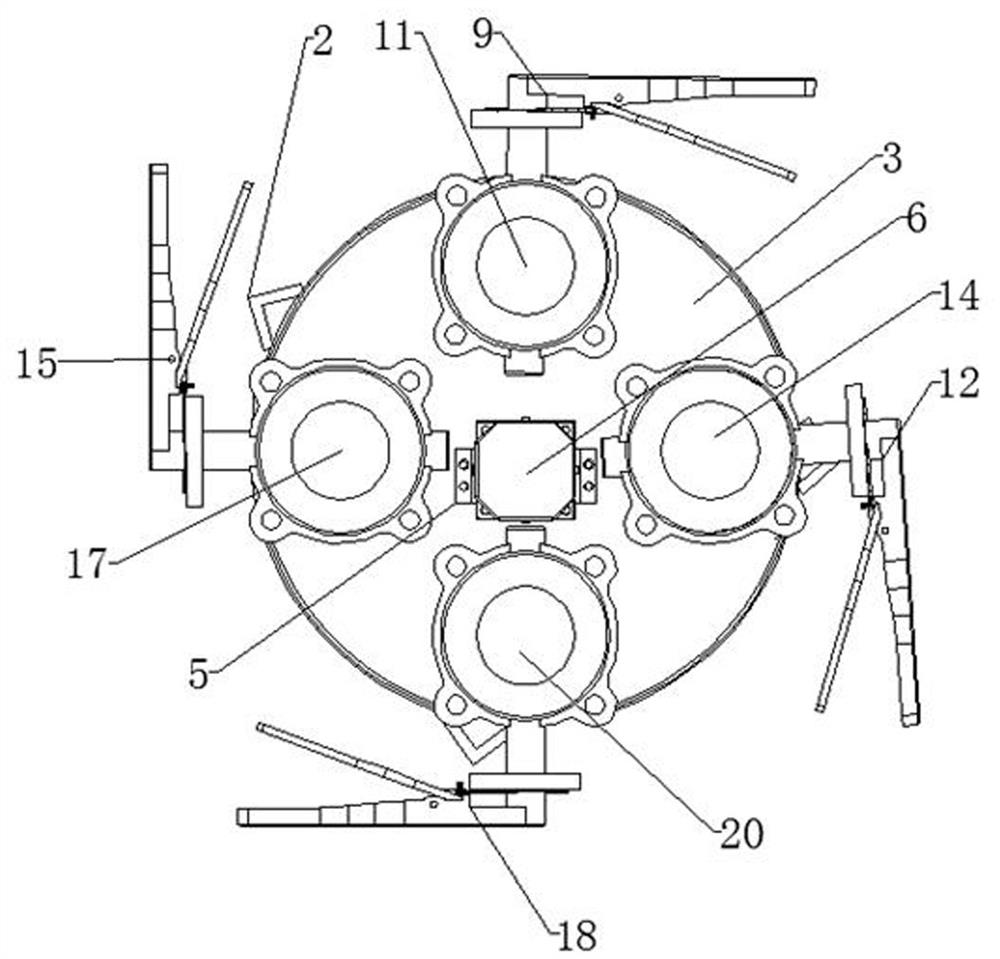

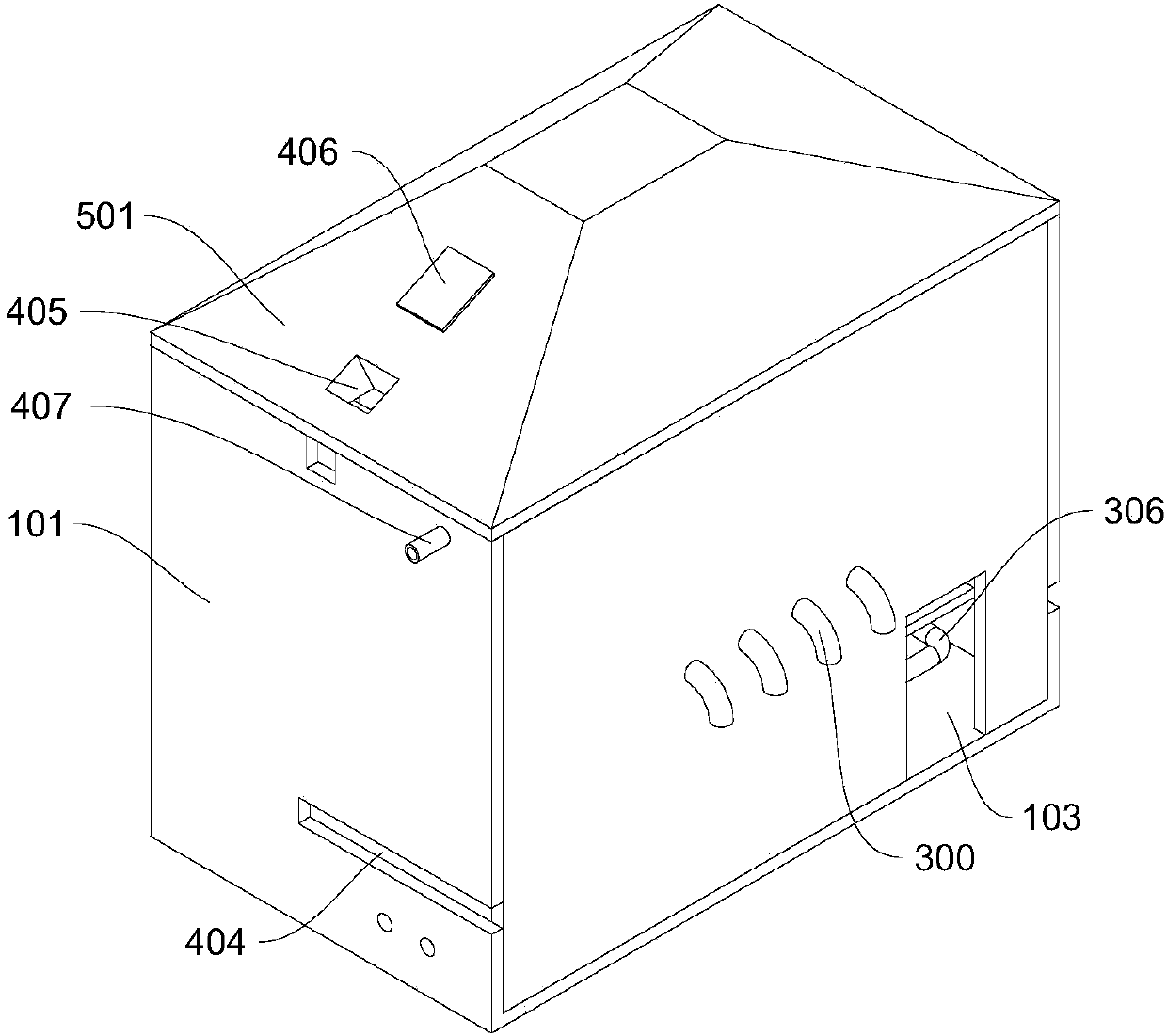

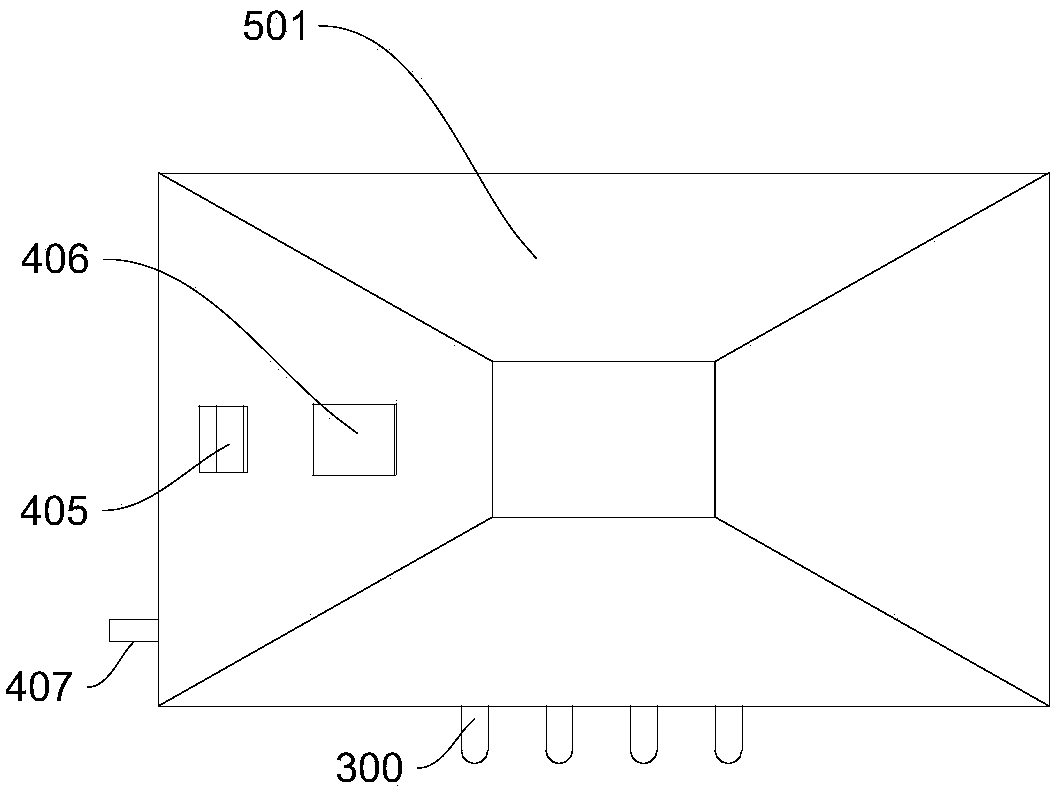

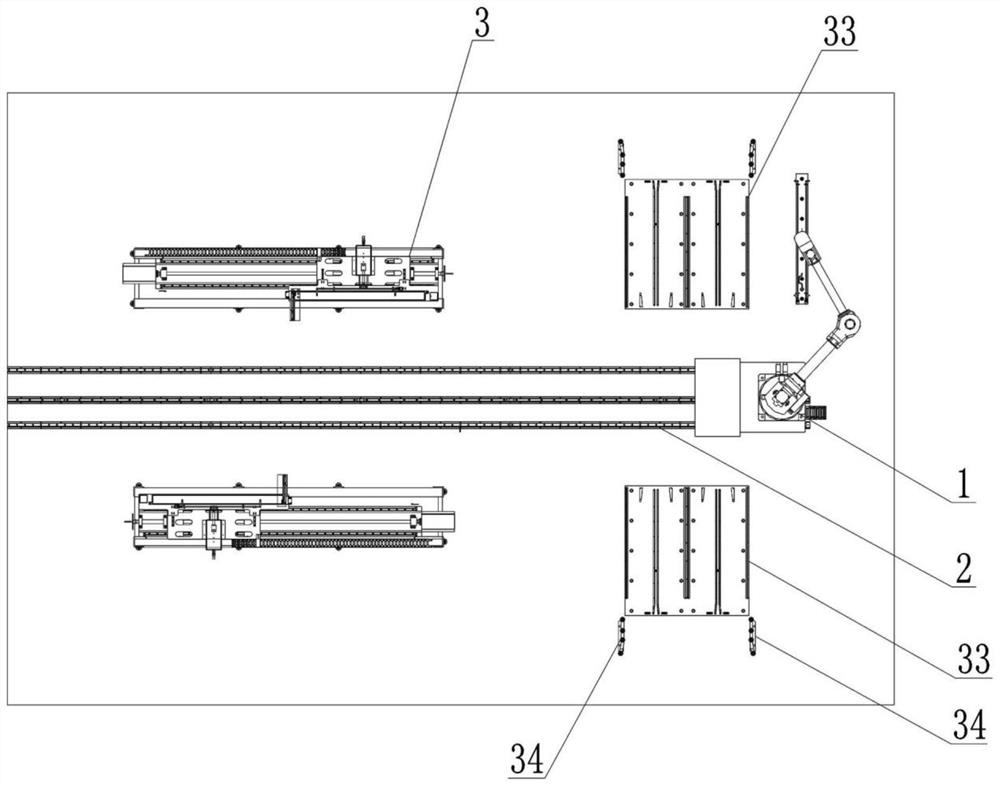

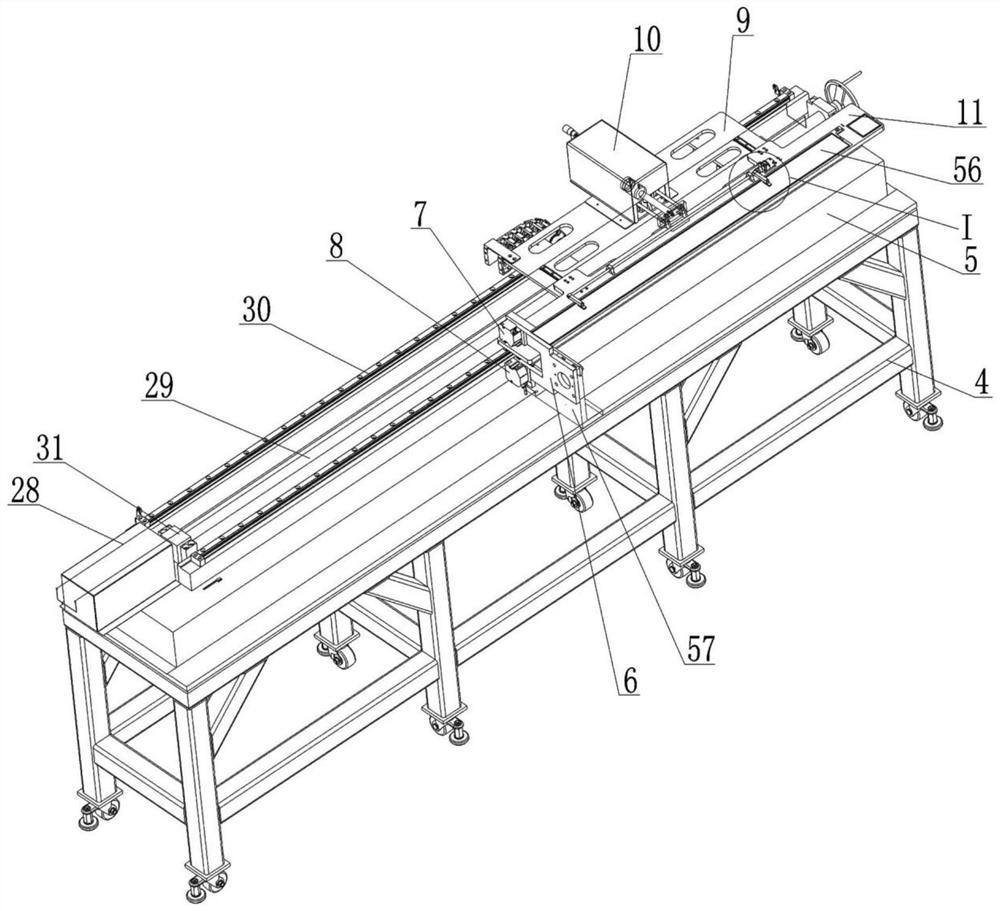

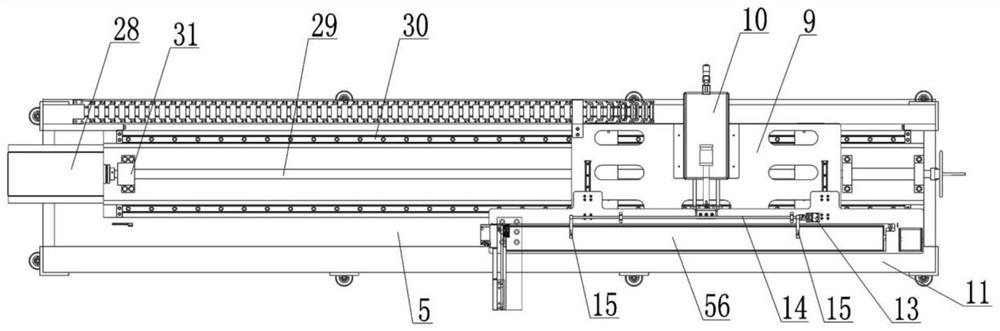

Device for automatically measuring thickness of nuclear fuel plate

PendingCN112833800AImprove detection efficiencyImprove thickness detection accuracyUsing optical meansMechanical engineeringNuclear fuel

The invention discloses a device for automatically measuring the thickness of a nuclear fuel plate. The device comprises a robot grabbing system (1) and a robot track (2); the front and rear sides of the robot track (2) are respectively provided with plate thickness detection devices (3); the robot grabbing system (1) is arranged on the robot track (2) and can move along the robot track (2); a grabbing device is arranged on an output shaft of the robot grabbing system (1); each plate thickness detection device (3) comprises a bottom frame (4) and a platform (5), wherein the platform (5) is fixedly arranged on the top surface of the bottom frame (4) and fixedly provided with a supporting seat (57); a support (6) with an opening is fixedly arranged on each supporting seat (57); and an upper laser displacement sensor (7) and a lower laser displacement sensor (8) are arranged on each support (6). The device is compact in structure, can improve nuclear fuel plate detection efficiency, improve nuclear fuel plate thickness detection accuracy, and reduce nuclear fuel plate feeding difficulty.

Owner:四川同人精工科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com