Punching equipment used for ground flat tube

A punching and equipment technology, which is applied in the direction of metal processing equipment, punching tools, feeding devices, etc., can solve the problems of low automation, low punching efficiency, and low punching quality, so as to achieve reasonable operation, improve efficiency, and improve The effect of punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

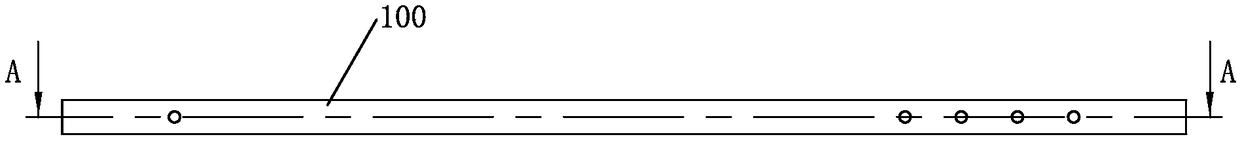

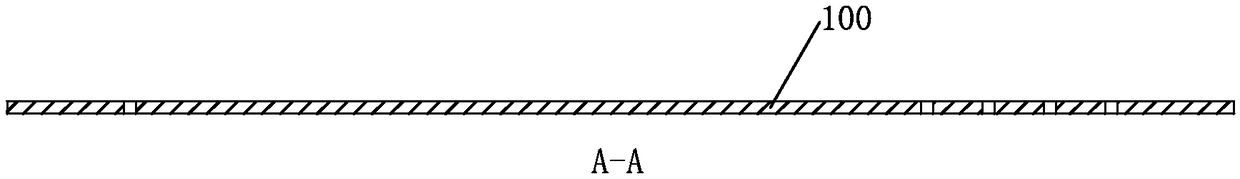

[0030] The first embodiment of the present invention provides a punching device for a grounded flat tube, which is used to punch a long conductive workpiece to obtain figure 1 , figure 2 The grounded flat tube 100 is shown.

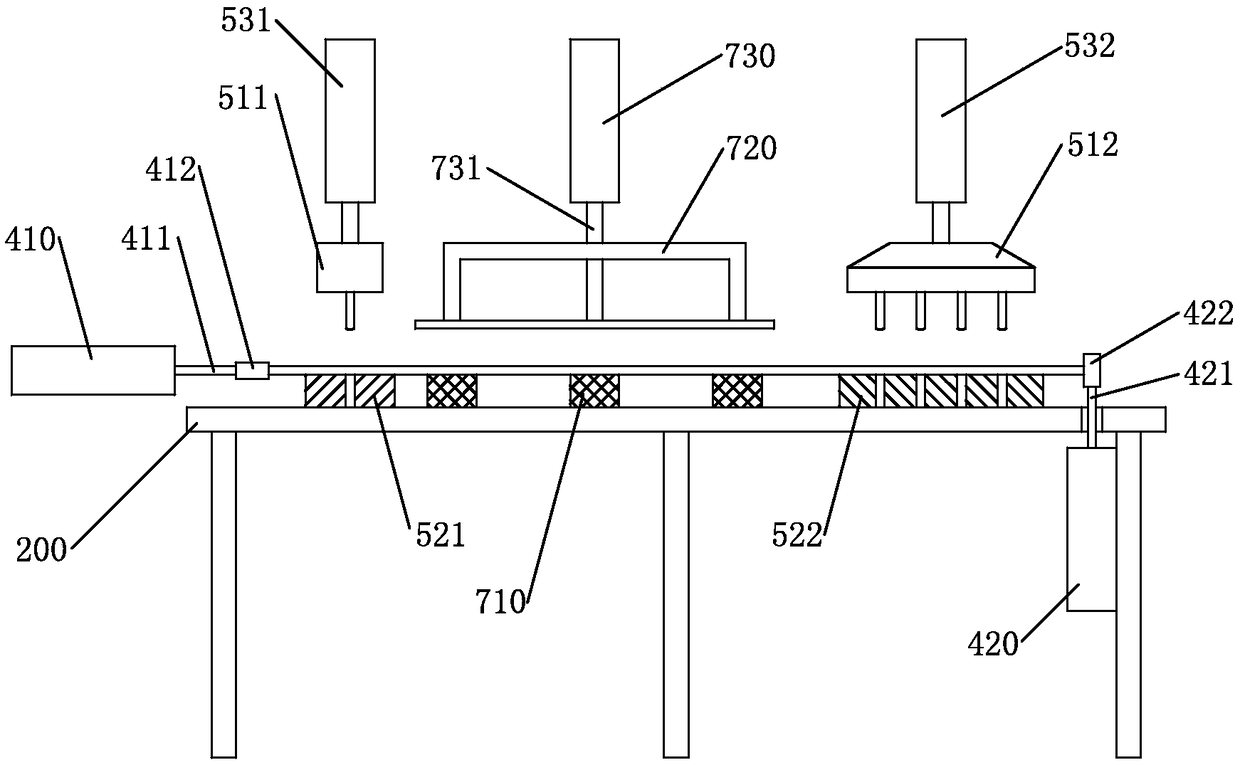

[0031] Such as image 3 , Figure 4 , Figure 5 , Image 6 As shown, the punching device for grounding flat tubes provided in this embodiment includes a workbench 200 on which a feeding mechanism, a positioning mechanism, and a punching mechanism are provided. The feeding mechanism includes a hopper 310, a conveyor belt 320, and a feeding cylinder 330. The positioning mechanism includes a left positioning cylinder 410, a right positioning cylinder 420, a positioning stop rod 430, and a transmission rod 440 for driving the positioning stop rod 430 to swing back and forth. The rod 430 is connected to the transmission rod 440, and the punching mechanism includes an upper mold base 510, a lower mold base 520 and a punching cylinder 530. The upper mold base 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com