Manufacturing device of mesh grid of lead-acid storage battery

A lead-acid battery and manufacturing equipment technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of low production efficiency, large equipment cost and high maintenance cost, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

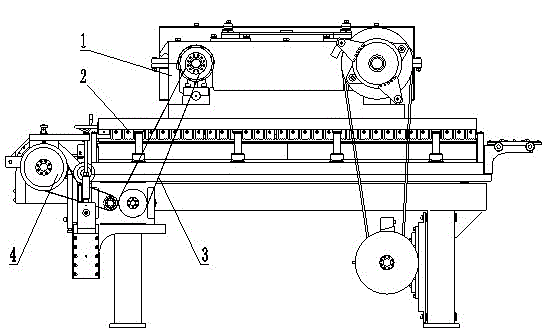

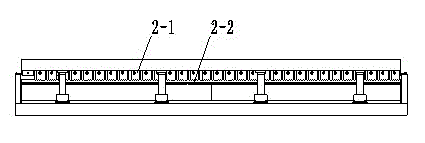

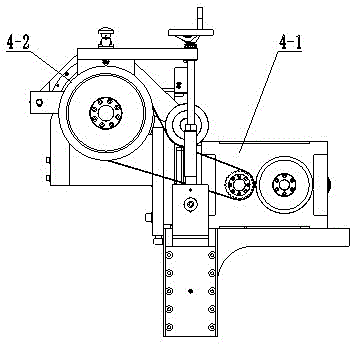

[0023] See Figure 1, figure 2 , Figure 4 , Figure 5 , the present invention comprises punching machine 1, stretching die 2 and step feeding mechanism 4, and described stretching die 2 is matched with punching machine 1, and it is made up of upper die 2-1 and lower die 2-2, and described upper die 2- 1 includes a mold base 2-1-2 and a group of punching blades 2-1-1 symmetrically arranged on both sides of the mold base, and the punching blades 2-1-1 are along the two sides of the mold base 2-1-2 Arranged in steps, each punching blade is provided with a set of punching teeth 2-1-1-1 and a correction tooth 2-1-1-2, the correction teeth 2-1-1-2 are located at the punching Front end of blade 2-1-1 feeding direction.

[0024] see figure 2 , Figure 4 , Figure 5 , the number of punching blades 2-1-1 of the present invention matches the size of the processed mesh grid 5, the number of punching teeth of each punching blade is N, and the number of adjacent punching teeth 2-1- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com