Novel pneumatic punching machine

A new type of pneumatic punching technology, which is applied in the field of pneumatic punching machines and new pneumatic punching machines, can solve the problems of low efficiency, low productivity, hidden safety hazards, etc., and achieve the effect of high punching efficiency and fast action speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

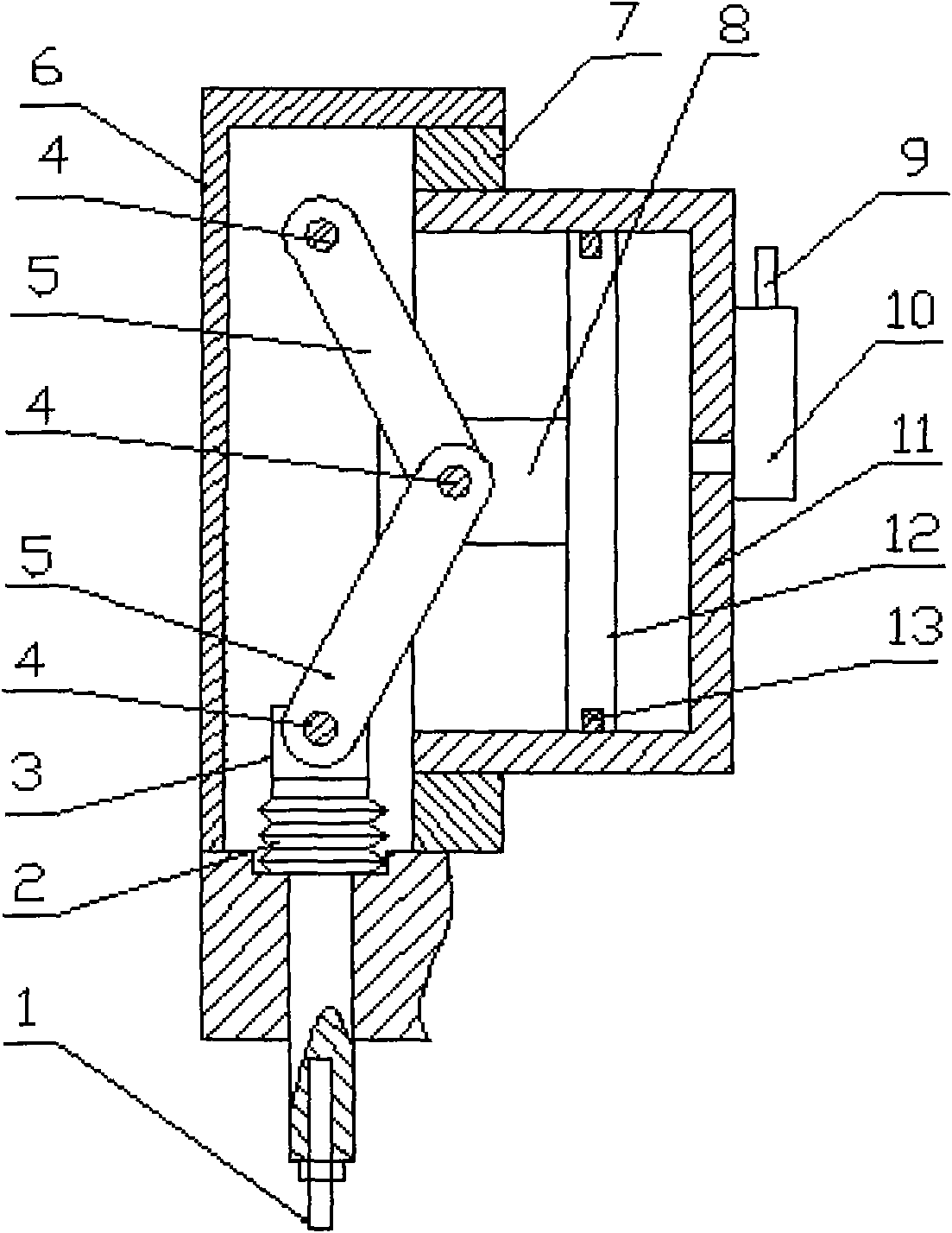

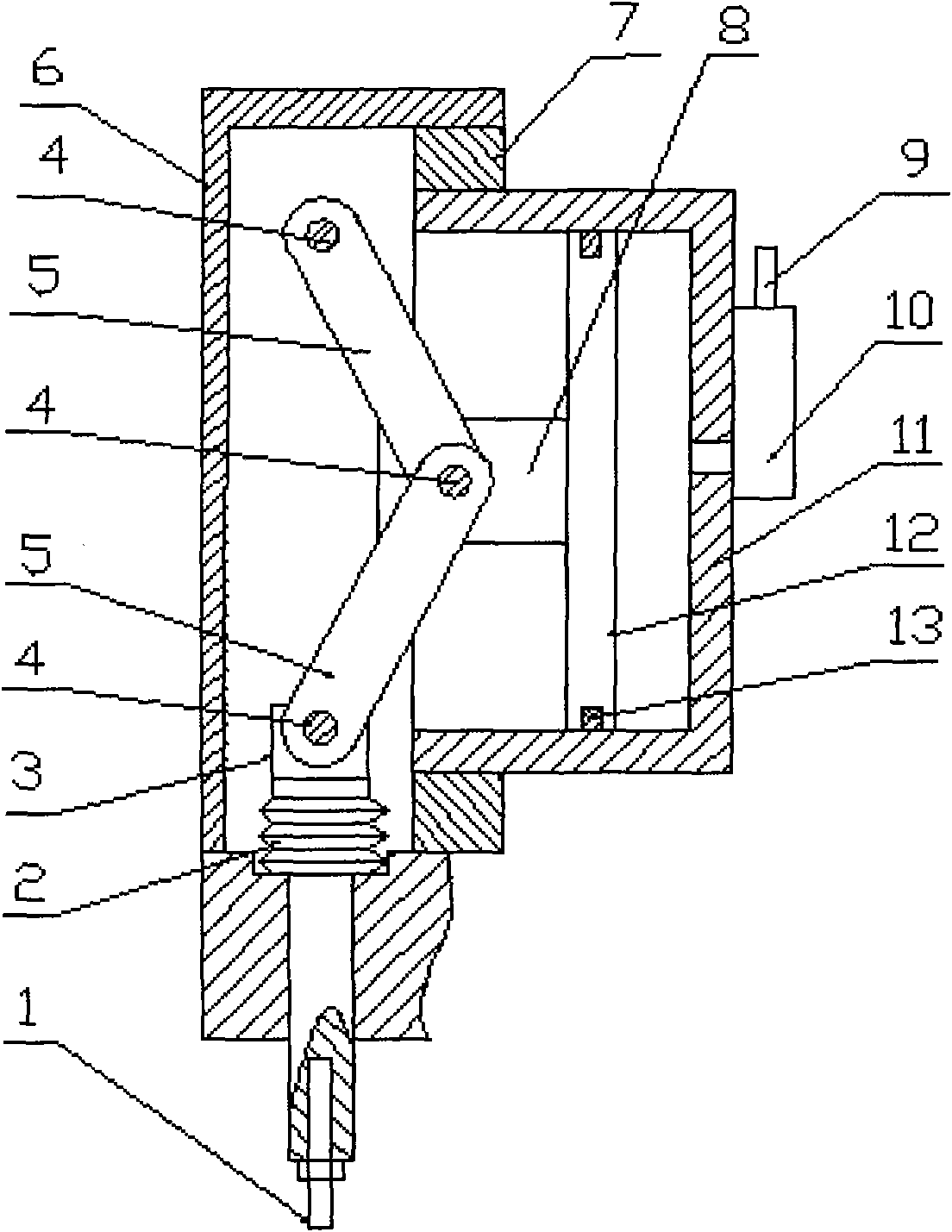

[0008] After installing the belleville springs (2) of appropriate quantity and specification on the punch (3), install the punch (3) on the bracket (6) correctly, and connect the two connecting rods (5) with the pin shaft (4 ) are correctly hinged with the bracket (6) and the punch (3) respectively. Install the flange sleeve (7) on the bracket (6), and install the cylinder assembly consisting of the piston rod (8), piston (12), cylinder (11) and sealing ring (13) on the flange sleeve (7). ) above. Use the pin shaft (4) to correctly hinge the two-section connecting rod (5) and the piston rod (8), install the quick air release valve (10) on the cylinder body of the cylinder or other appropriate positions, and place the quick air release valve ( 10) Install the air inlet joint (9) on the top, and install the drill bit (1) on the top of the punch (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com