Patents

Literature

61results about How to "High punching precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

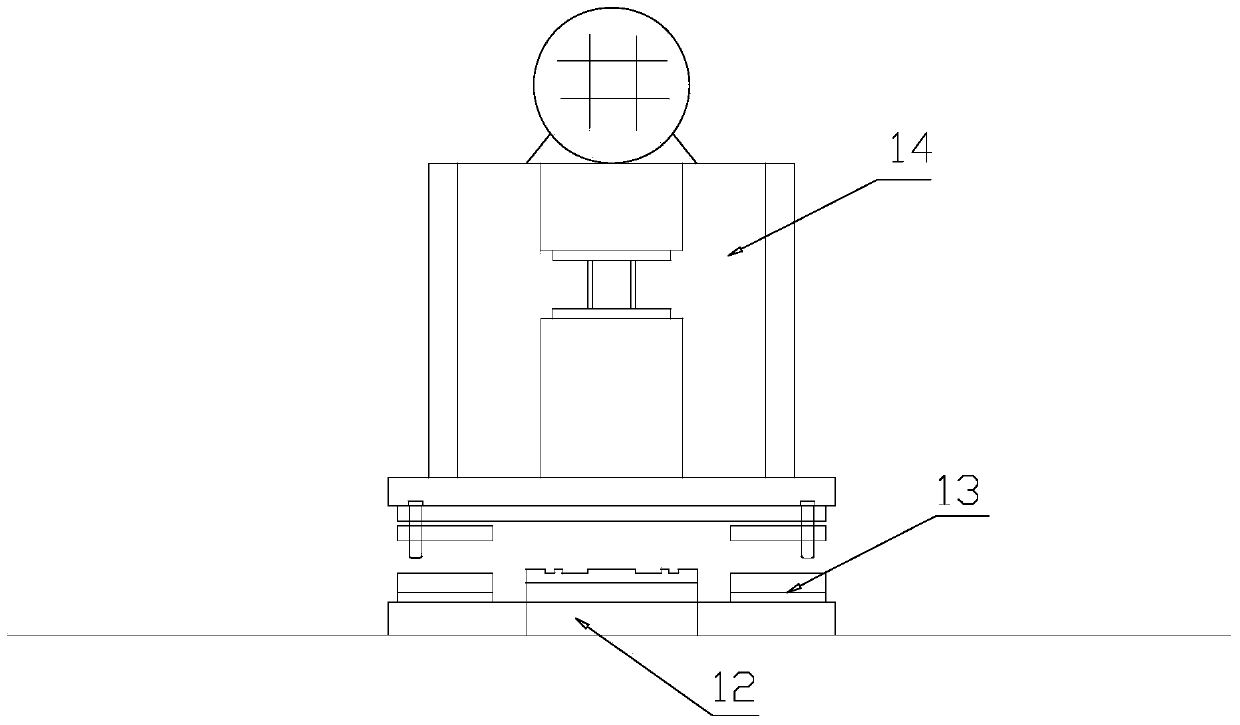

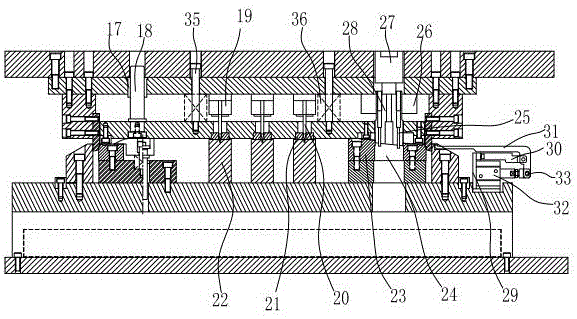

Punching machine

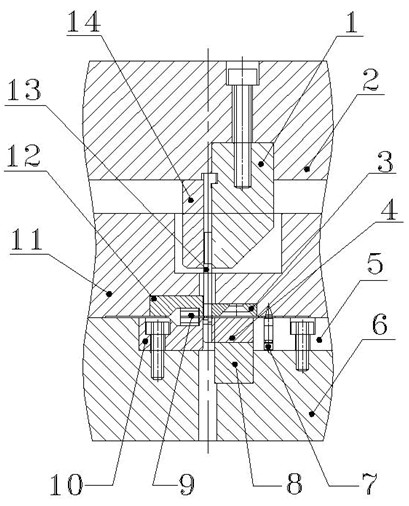

The present invention relates to the field of mechanical processing equipment, in particular to a punching machine, which includes a fuselage, a workbench, an electric control box, and an operation box. A crank-link mechanism is arranged inside the fuselage, and the crank-link mechanism includes a crankshaft and sequentially connected The flywheel on the crankshaft, the crankshaft rear seat, the connecting rod connected to the crankshaft in rotation, the crankshaft front seat, the lower end of the connecting rod is rotatably connected with a center guide post, and the bottom of the center guide post is connected with saw teeth, oil cylinder and slider in turn, and the oil cylinder It is an annular cylinder with a piston on its inner ring, an oil pipe connected to one end of the clamping pump on the oil cylinder, the other end of the clamping pump is connected to the air pump, and a hollow slide tube is connected to one end of the slider, and the hollow slide tube is set on the On the slider guide post inside the fuselage, the workbench is located on the fuselage just below the slider. The invention provides a punch press with stable operation and improved precision.

Owner:东莞市岗峰精密工业有限公司

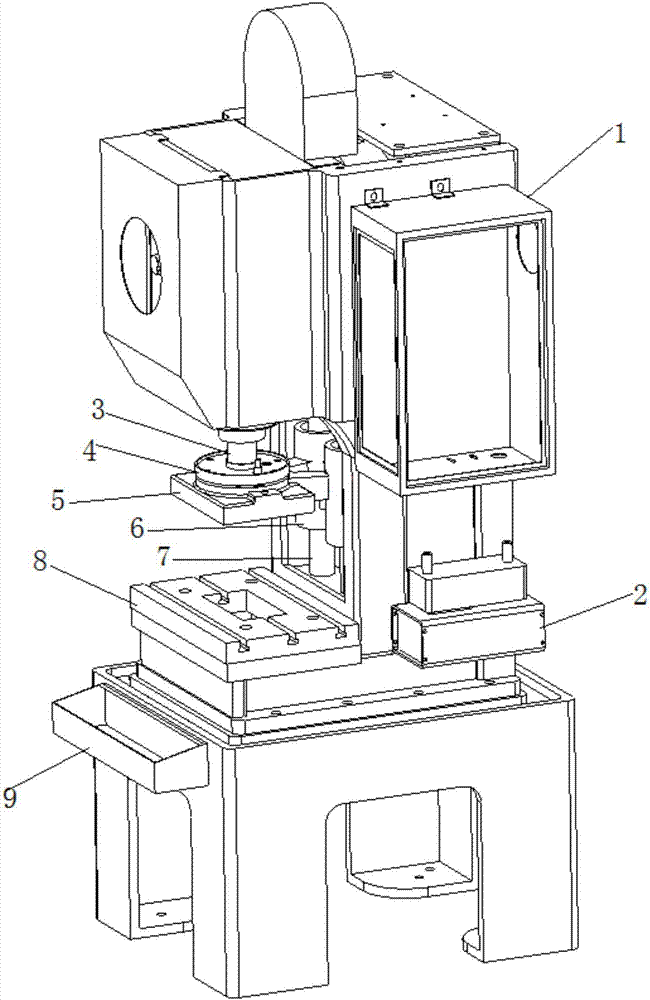

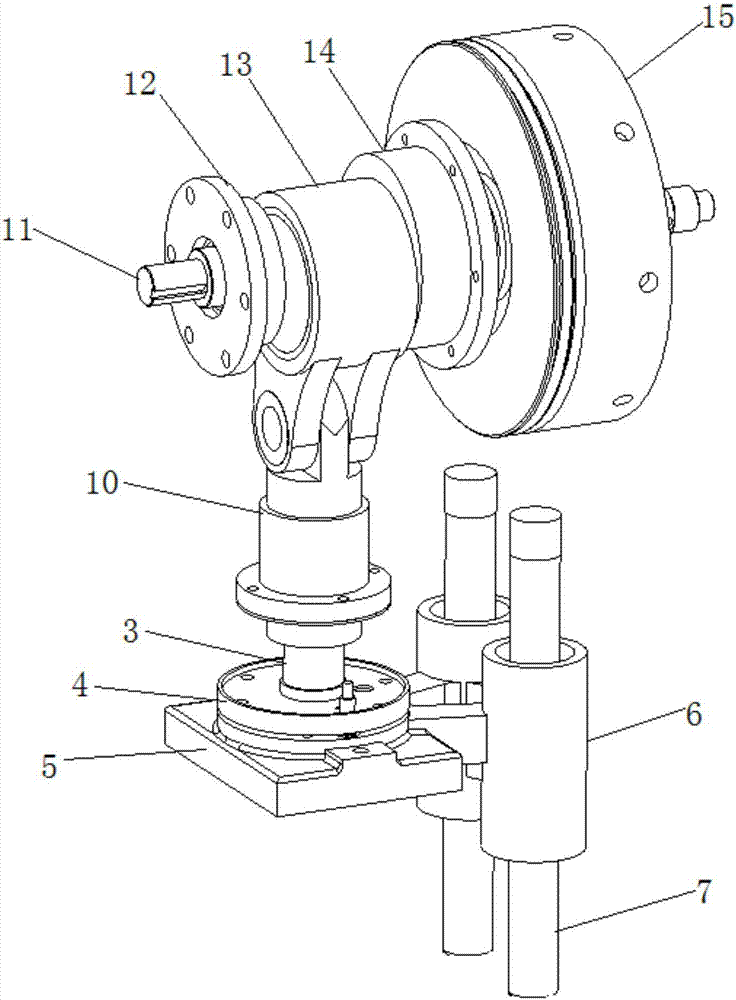

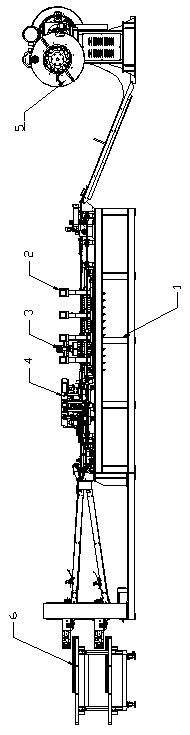

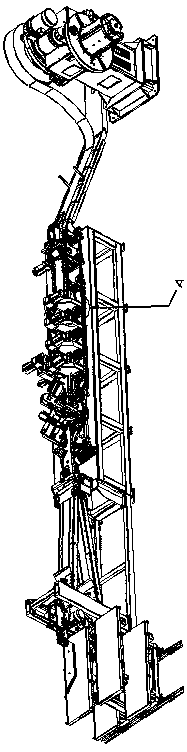

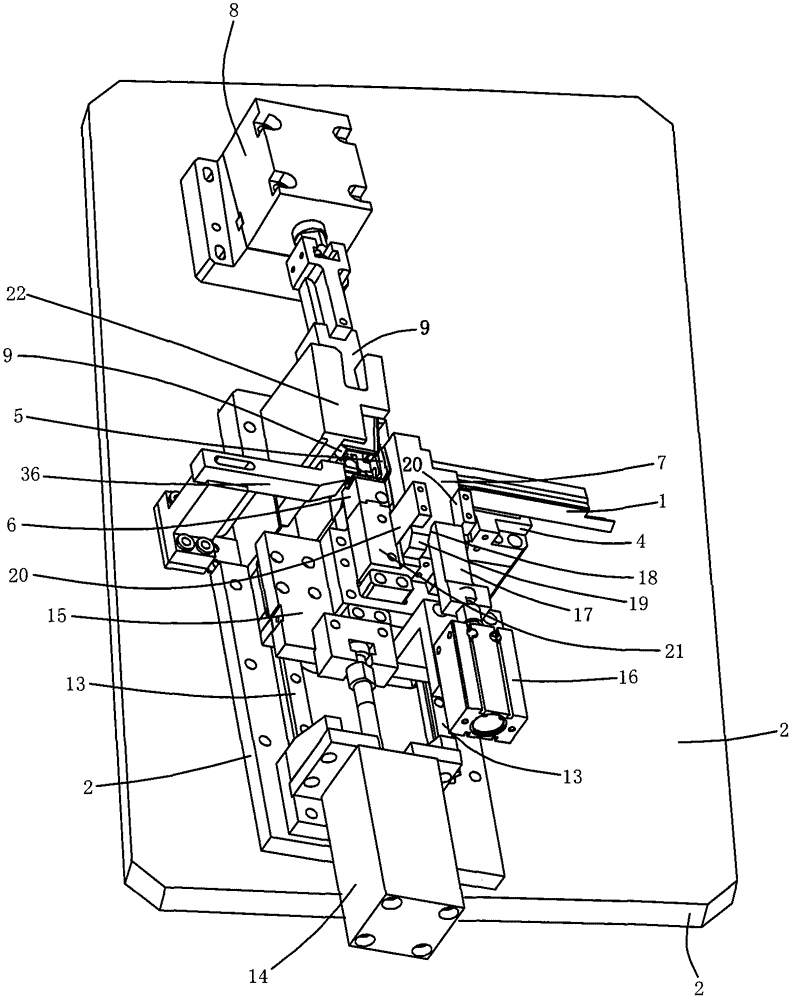

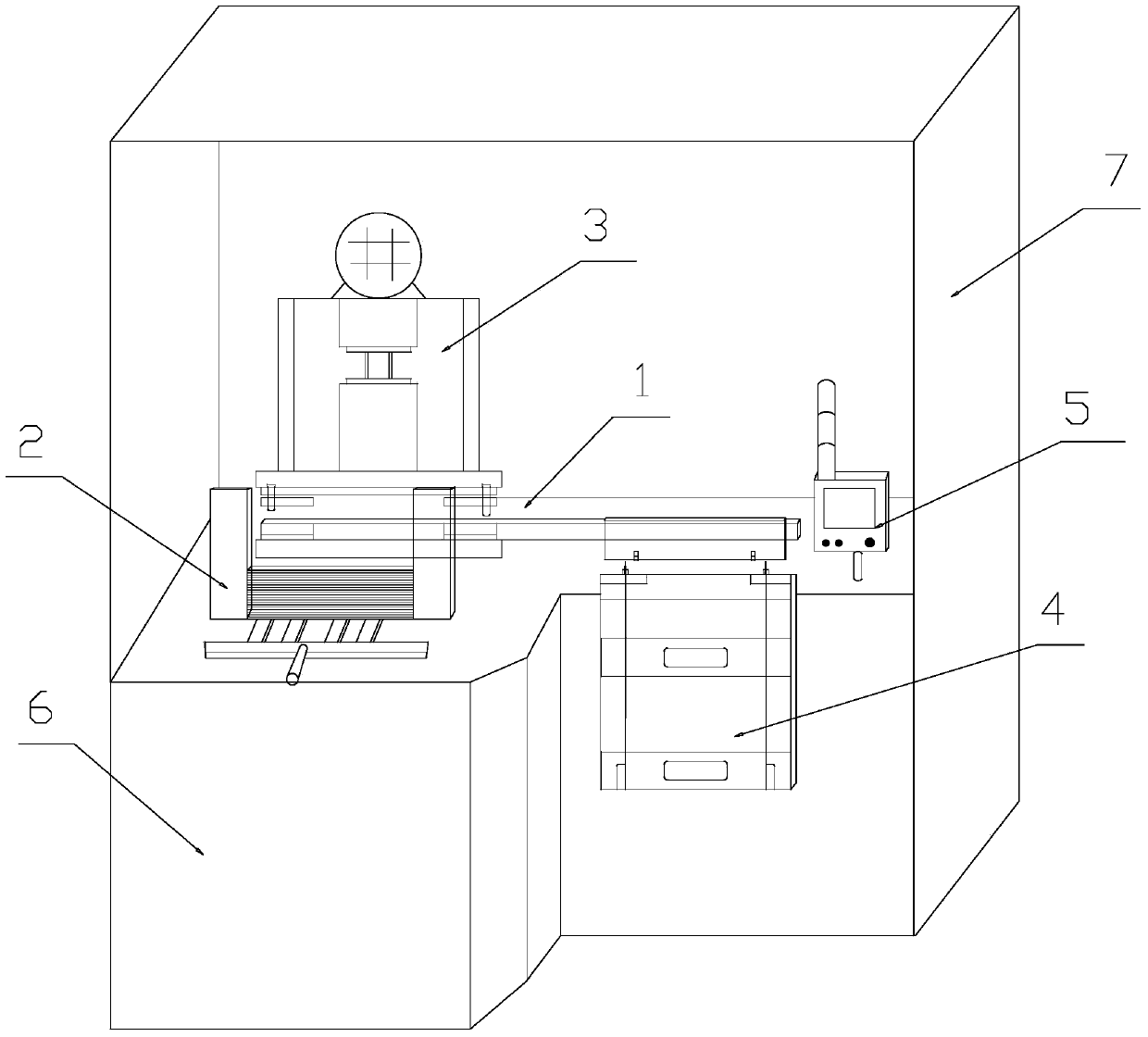

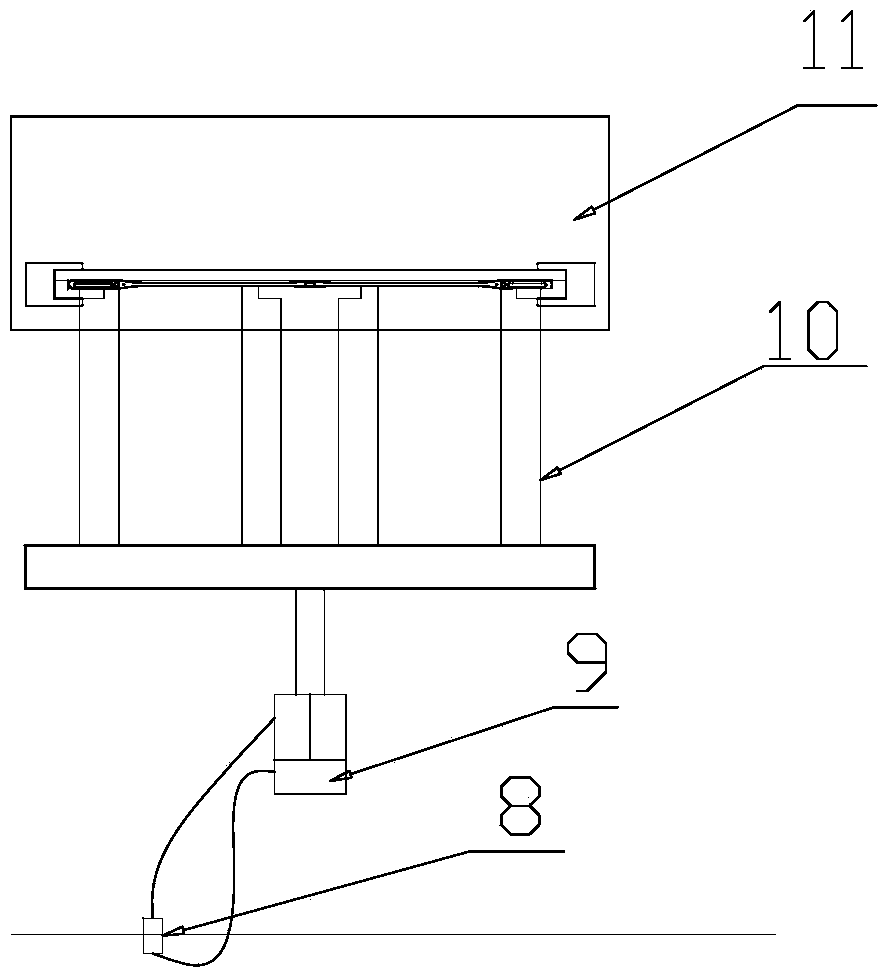

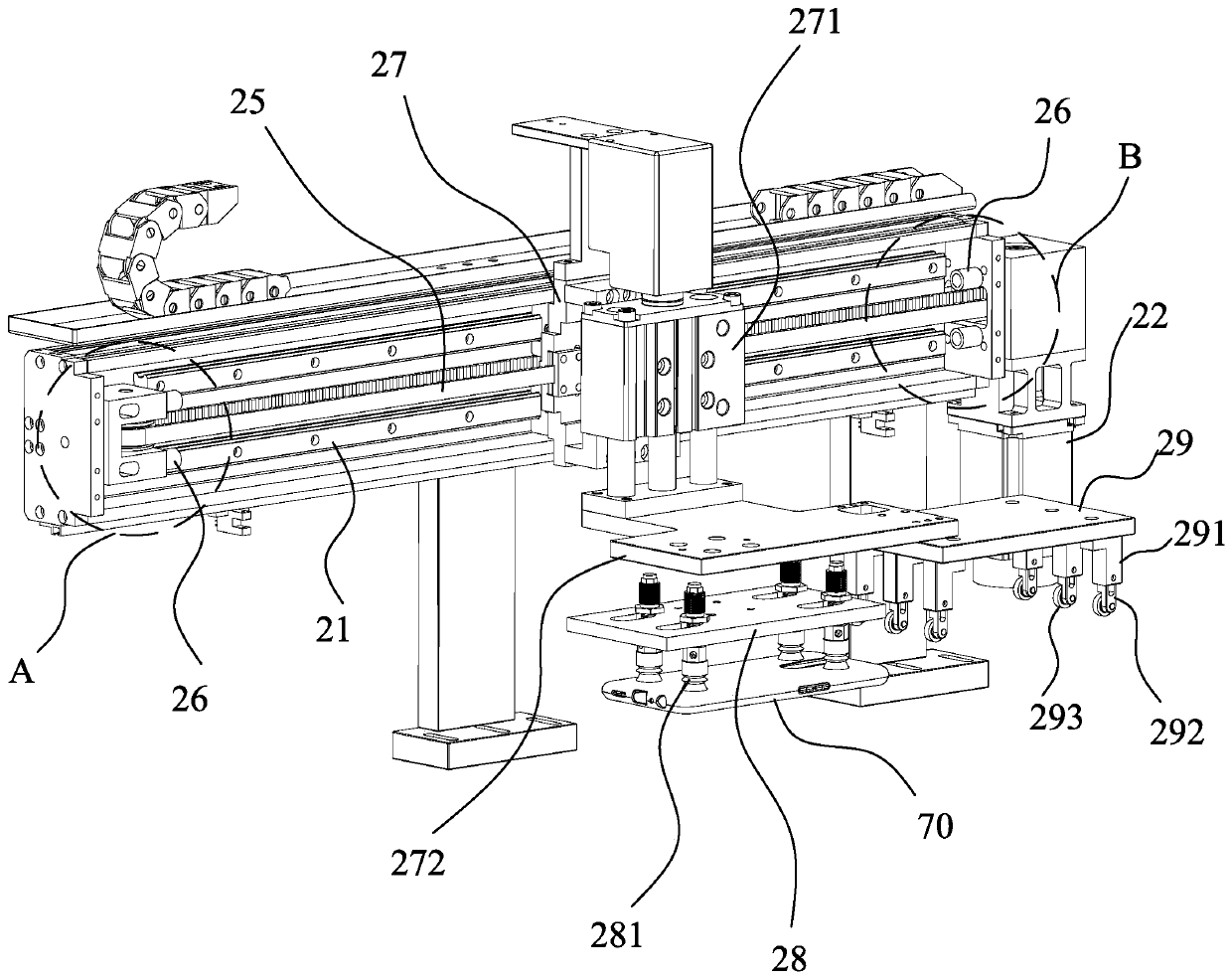

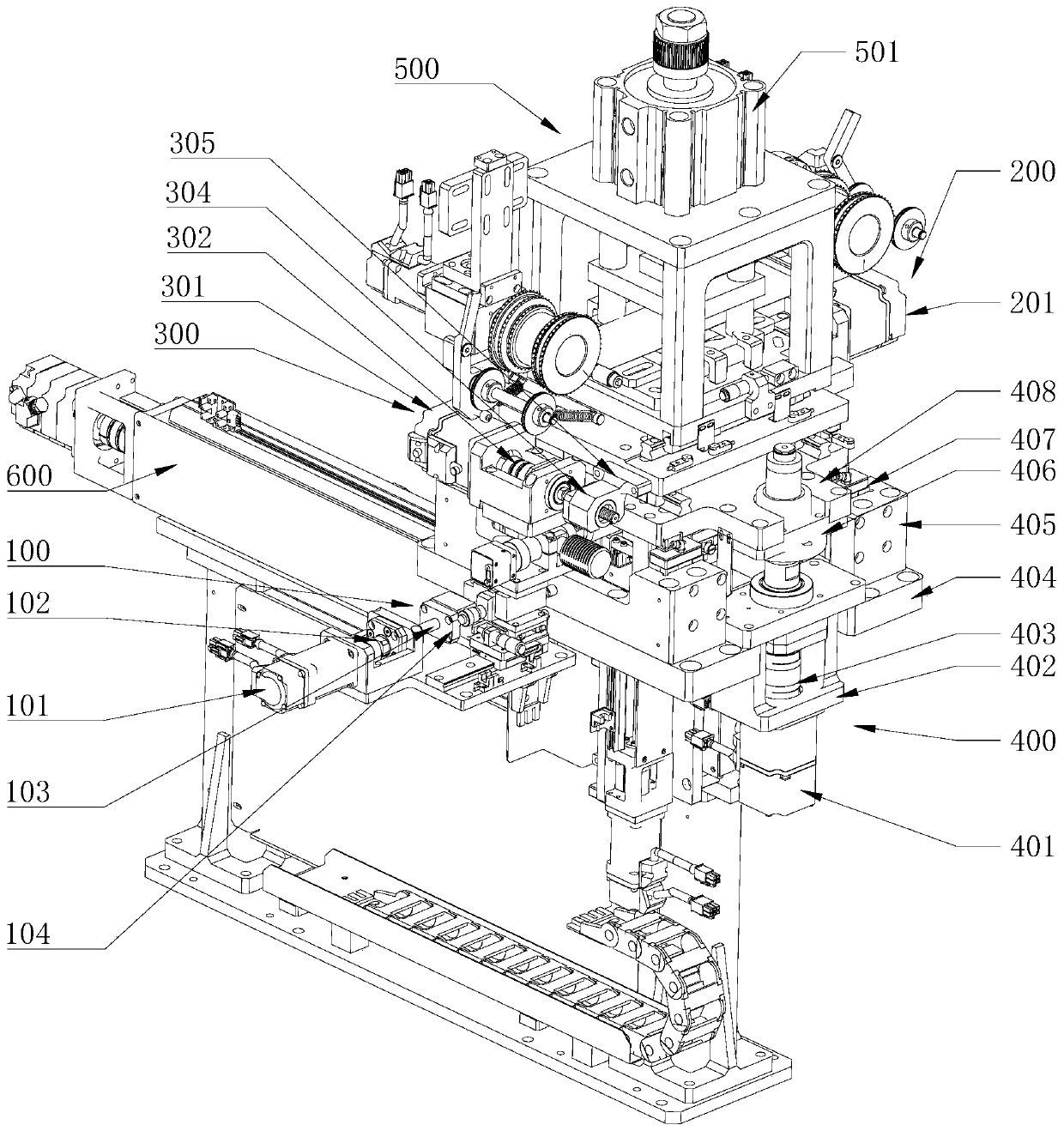

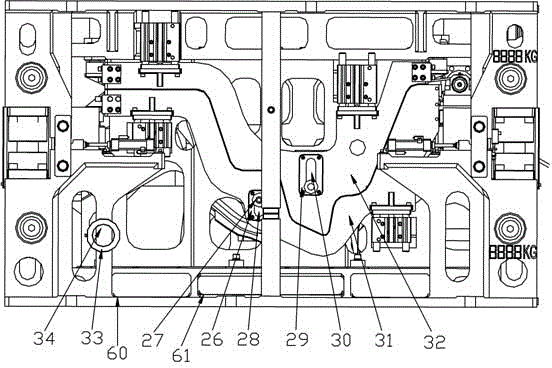

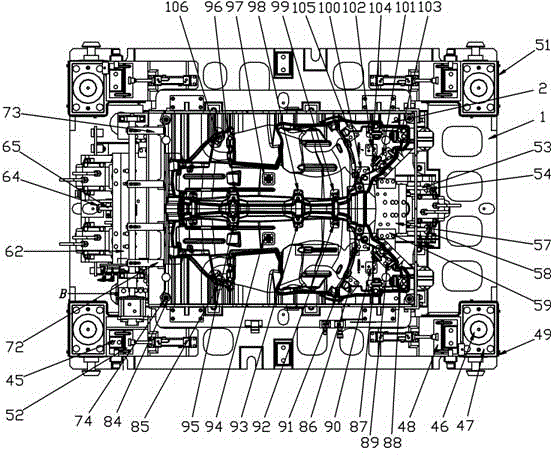

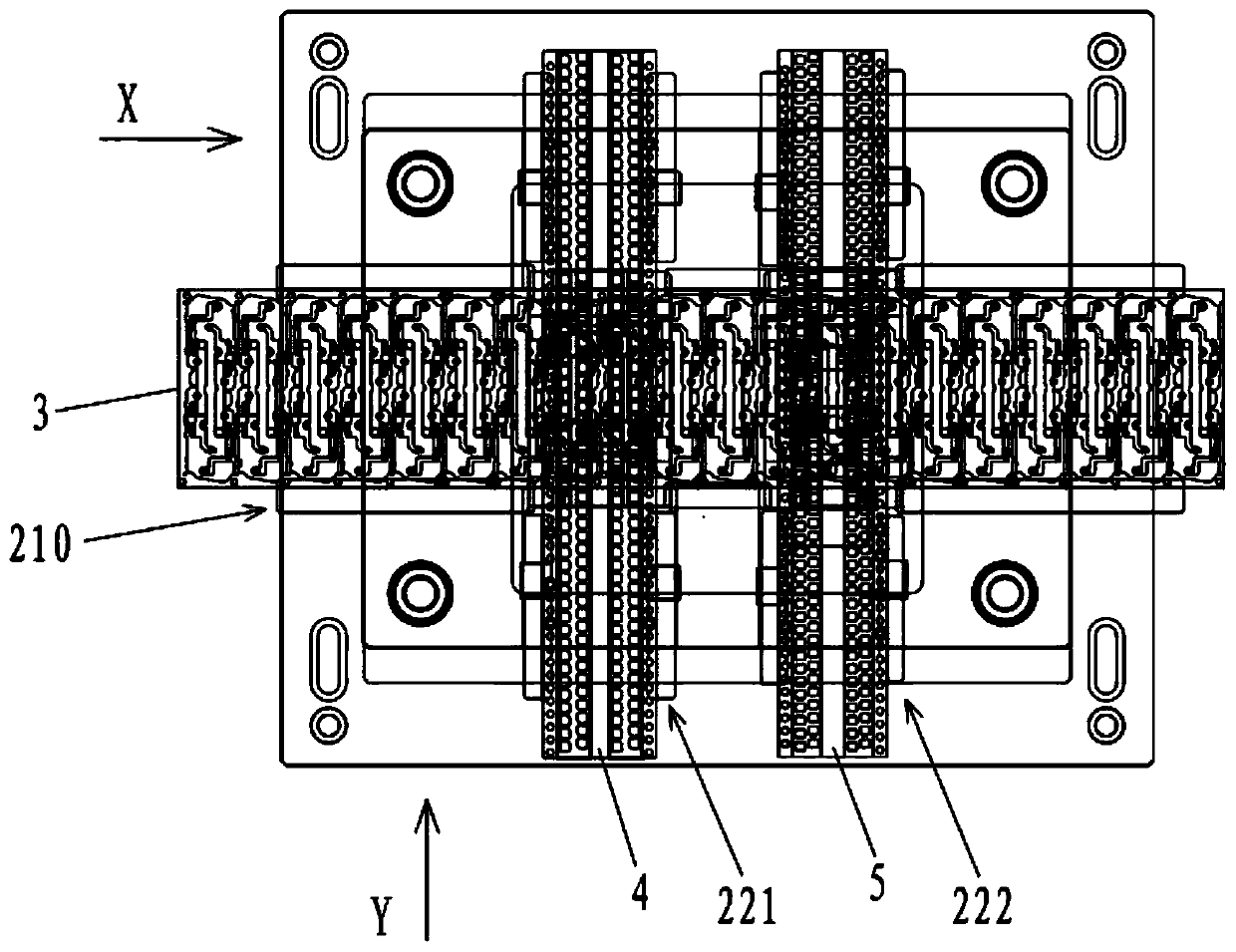

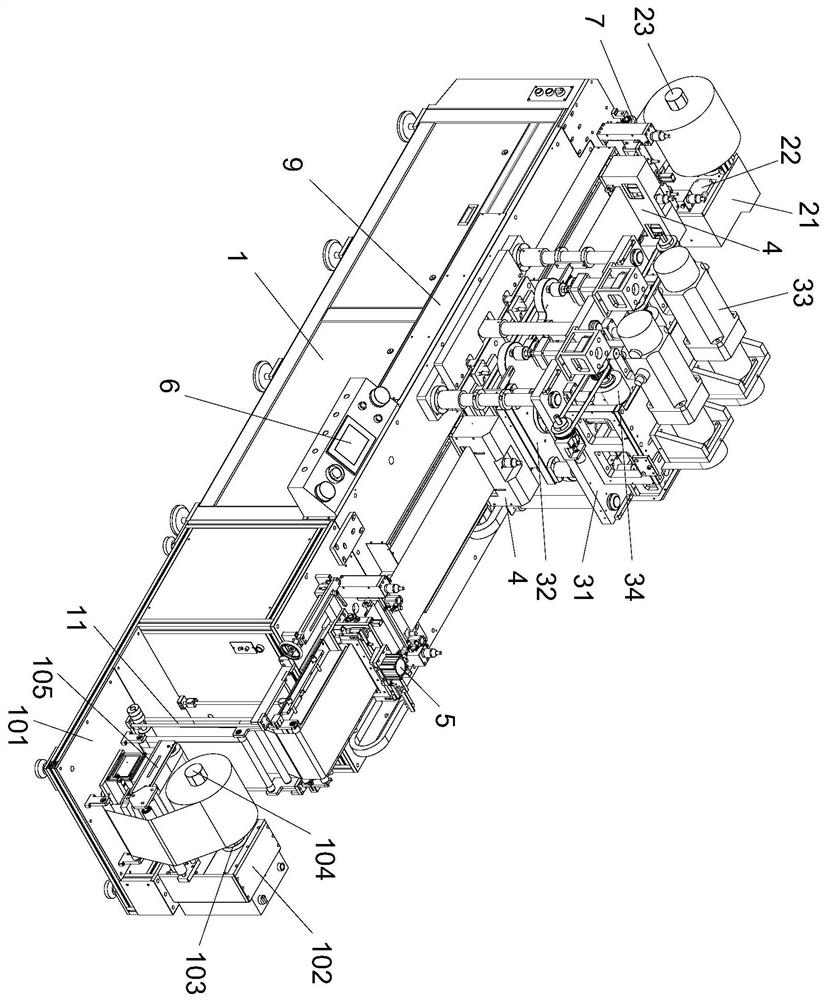

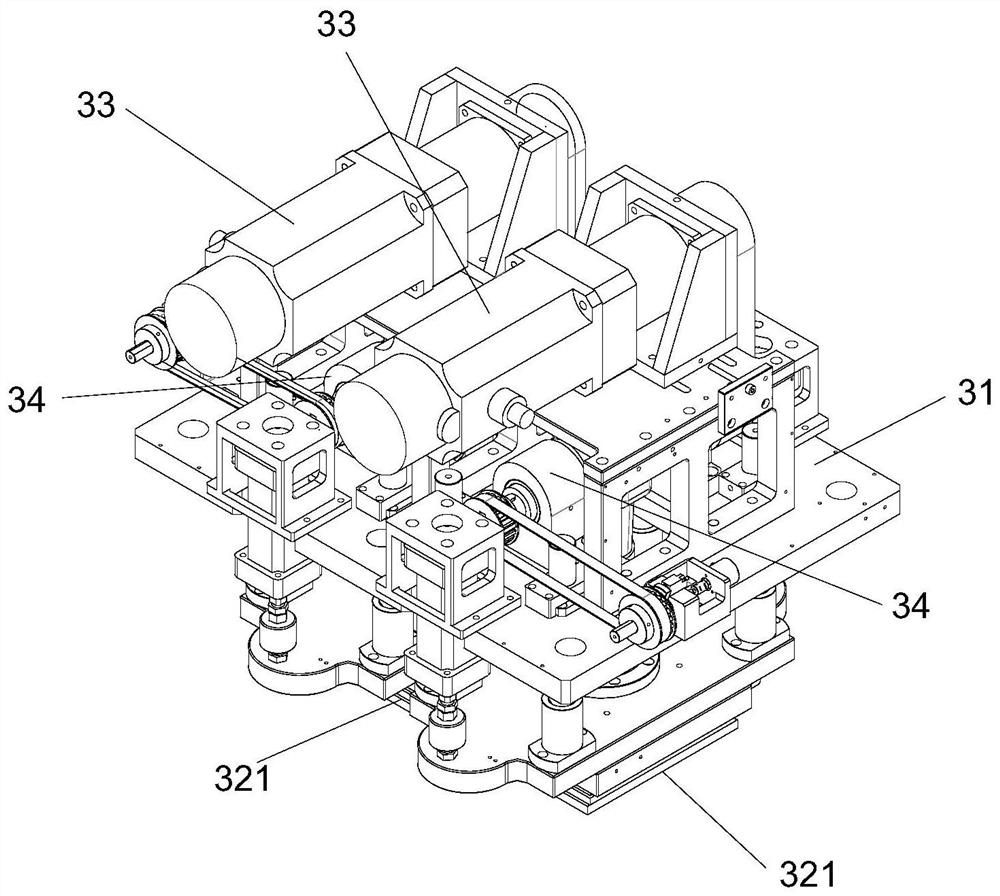

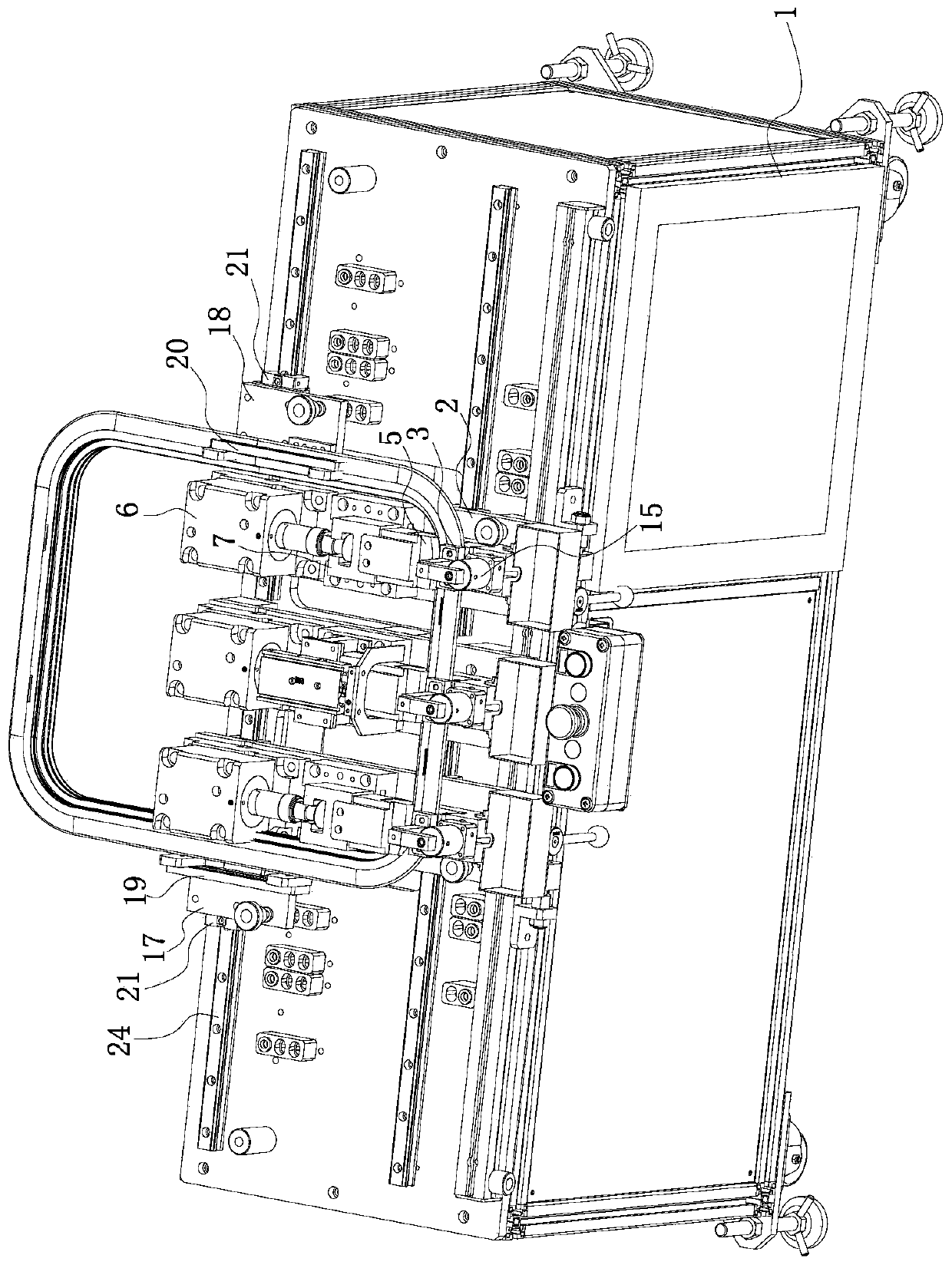

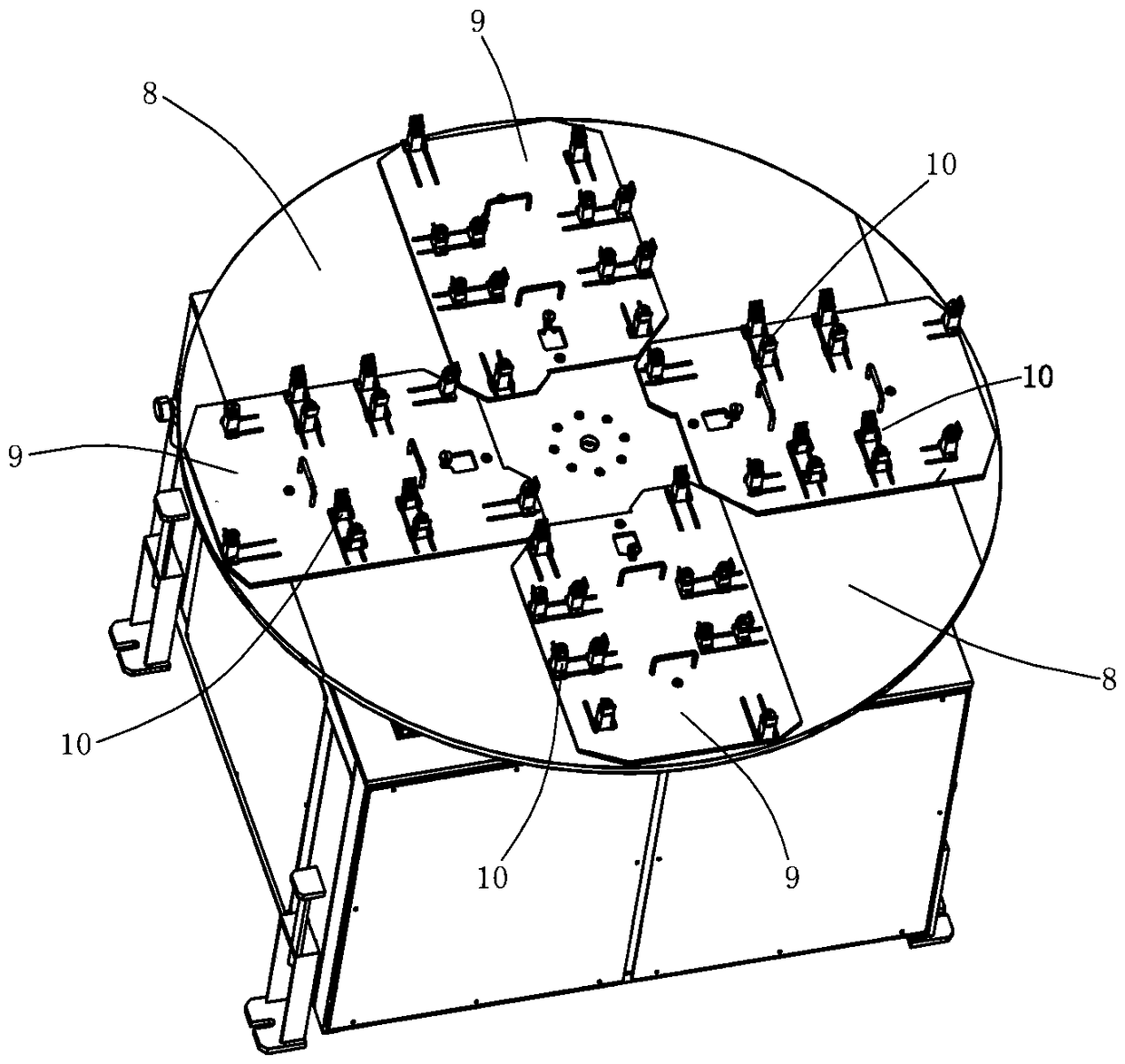

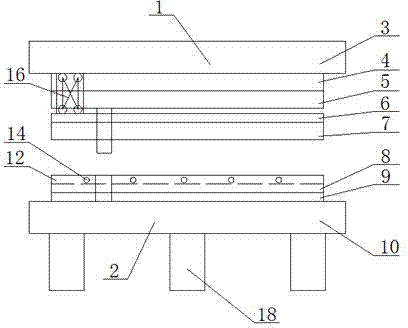

Punching line of automobile door pillar and panel workpieces and mechanical arms for punching line

ActiveCN104259295AHigh degree of automationImprove efficiencyMetal-working feeding devicesPositioning devicesProduction linePunching

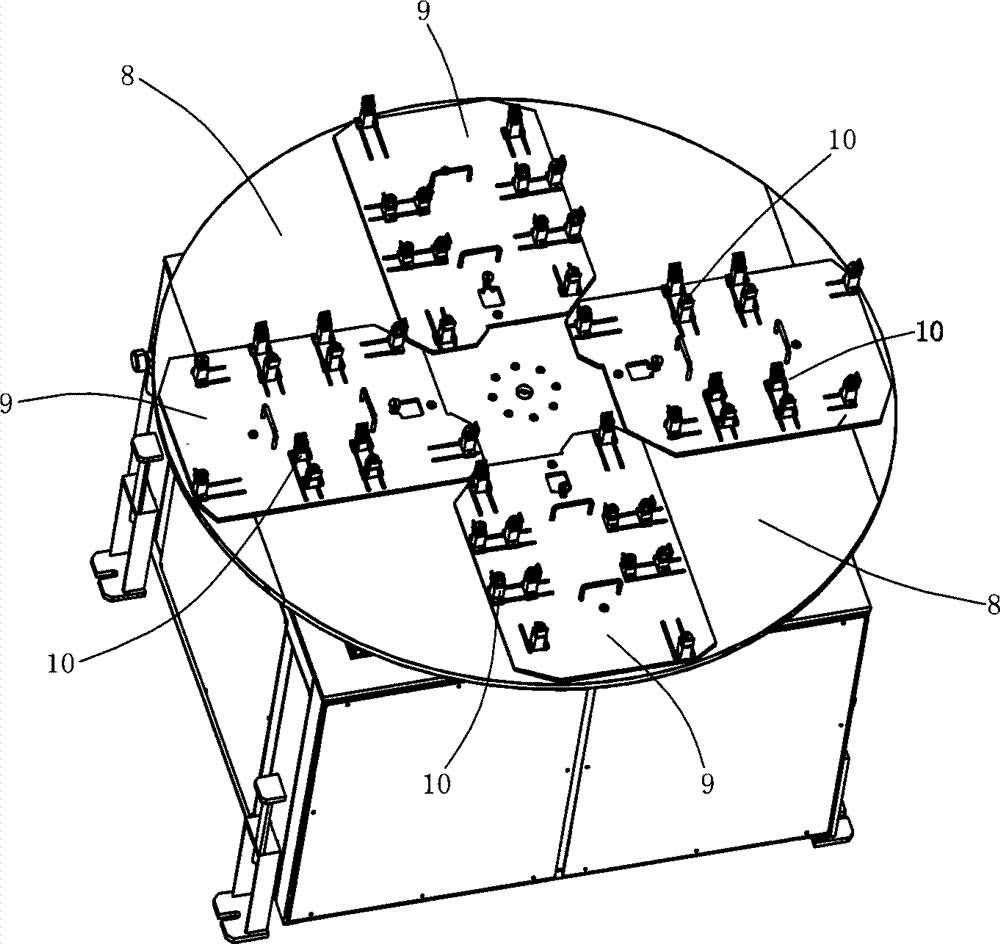

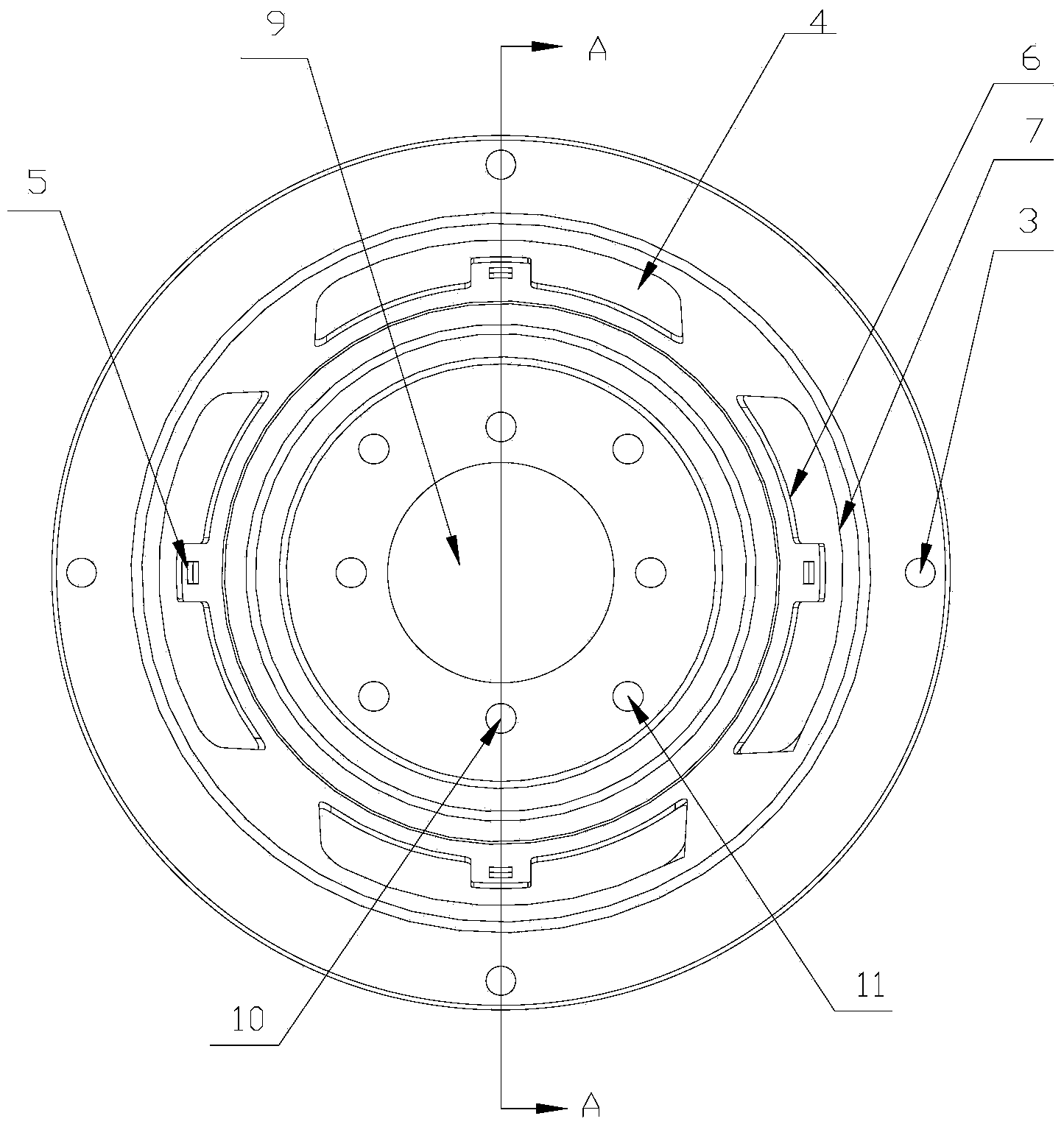

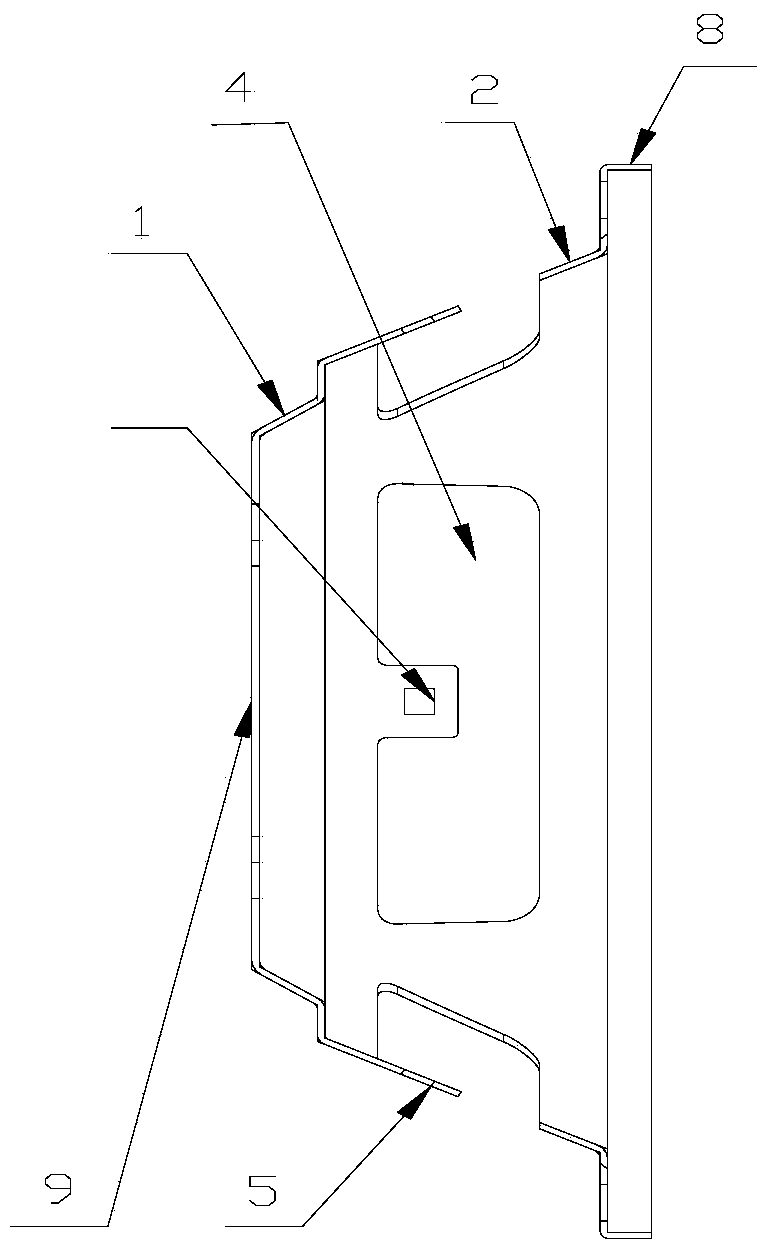

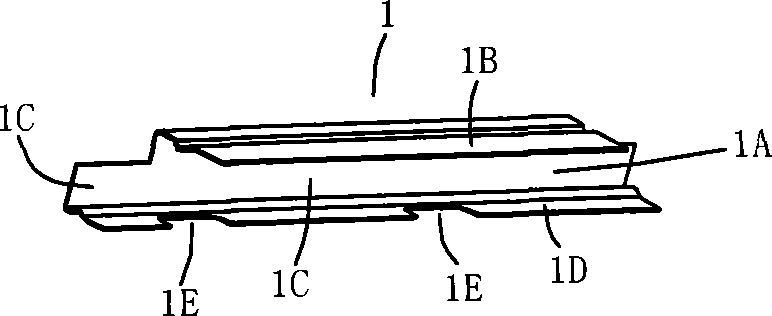

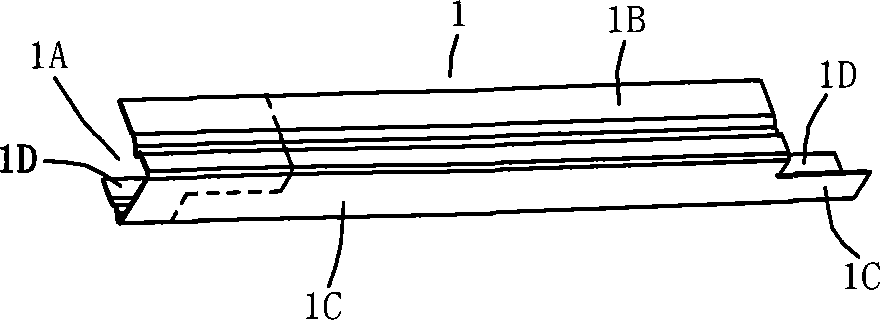

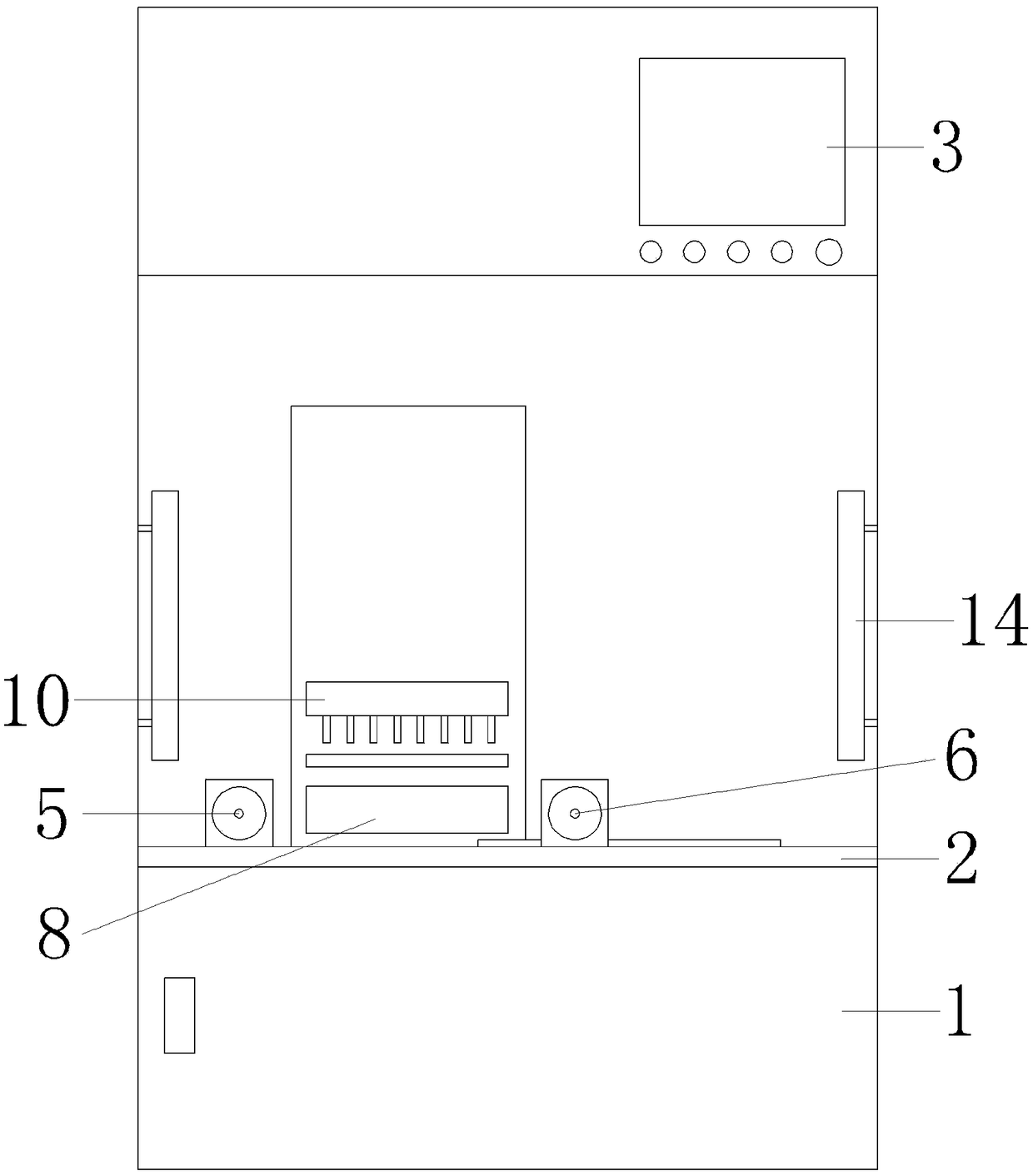

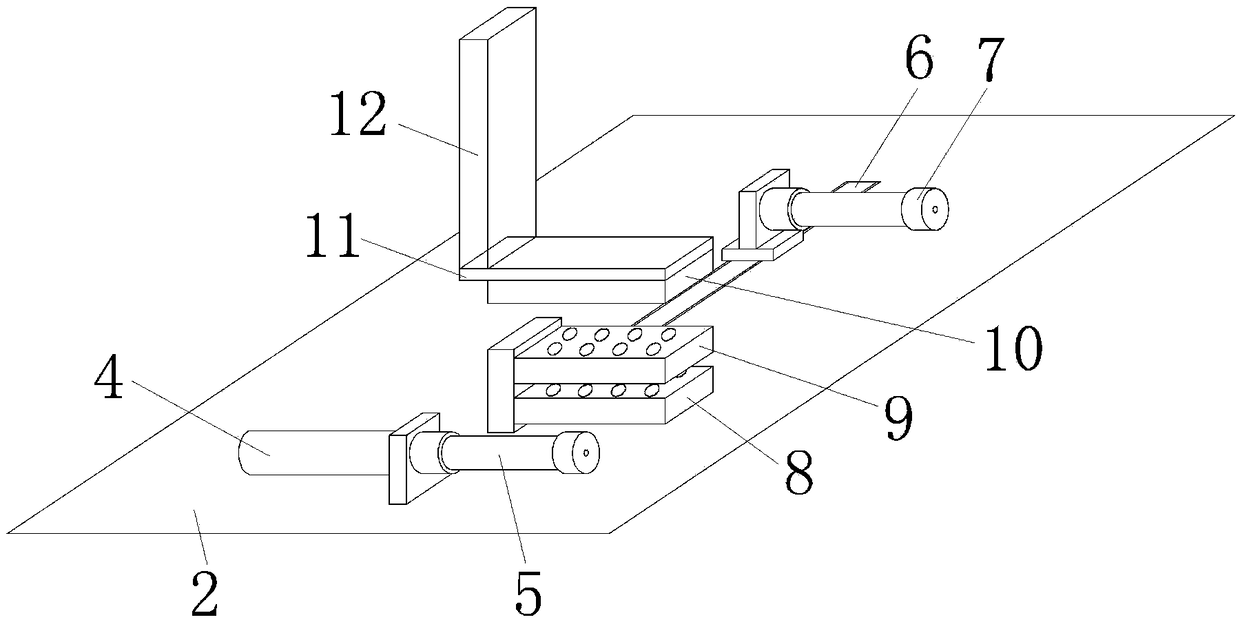

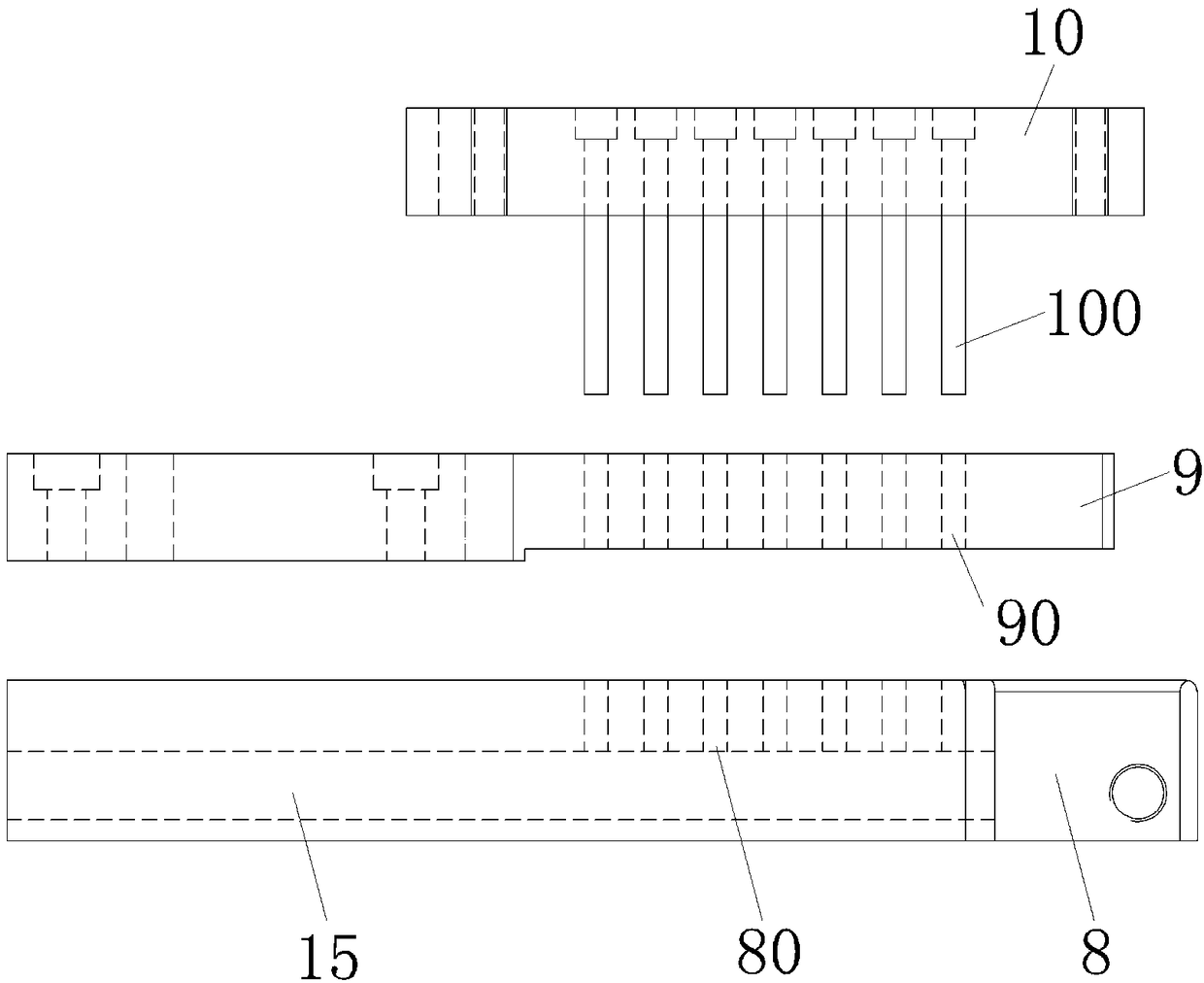

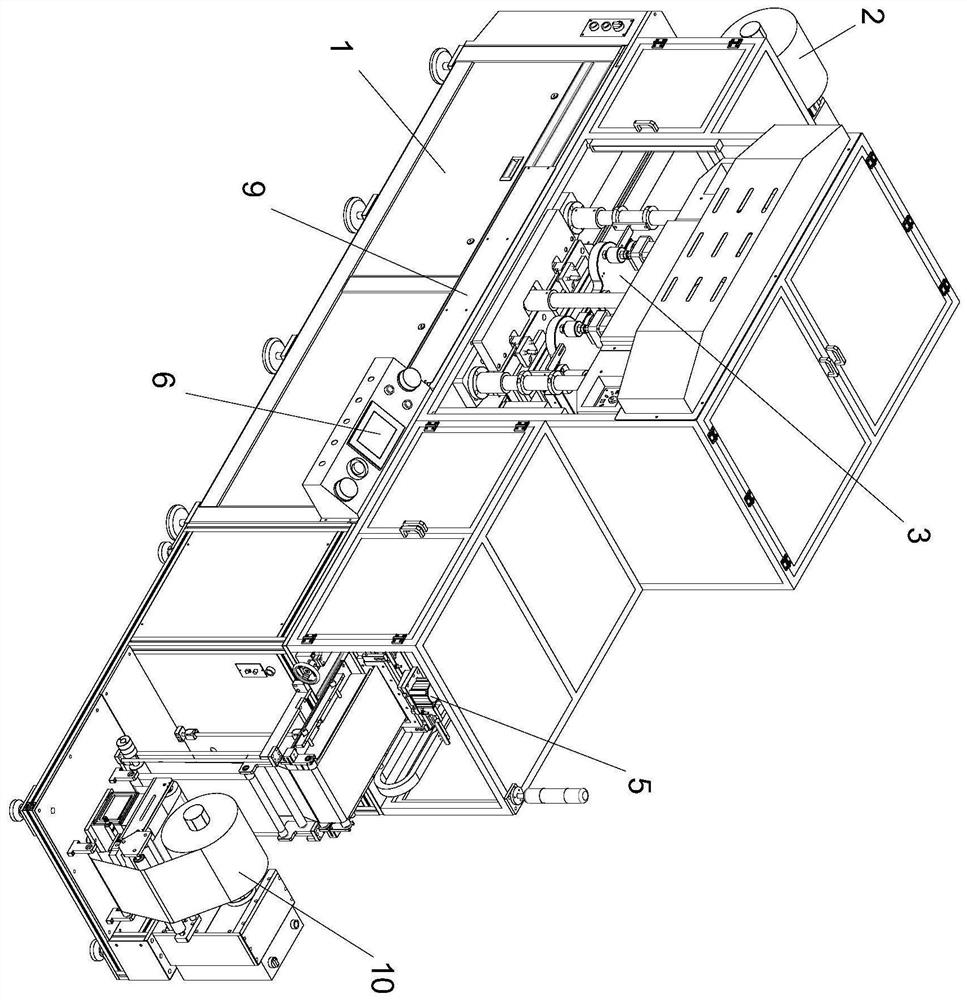

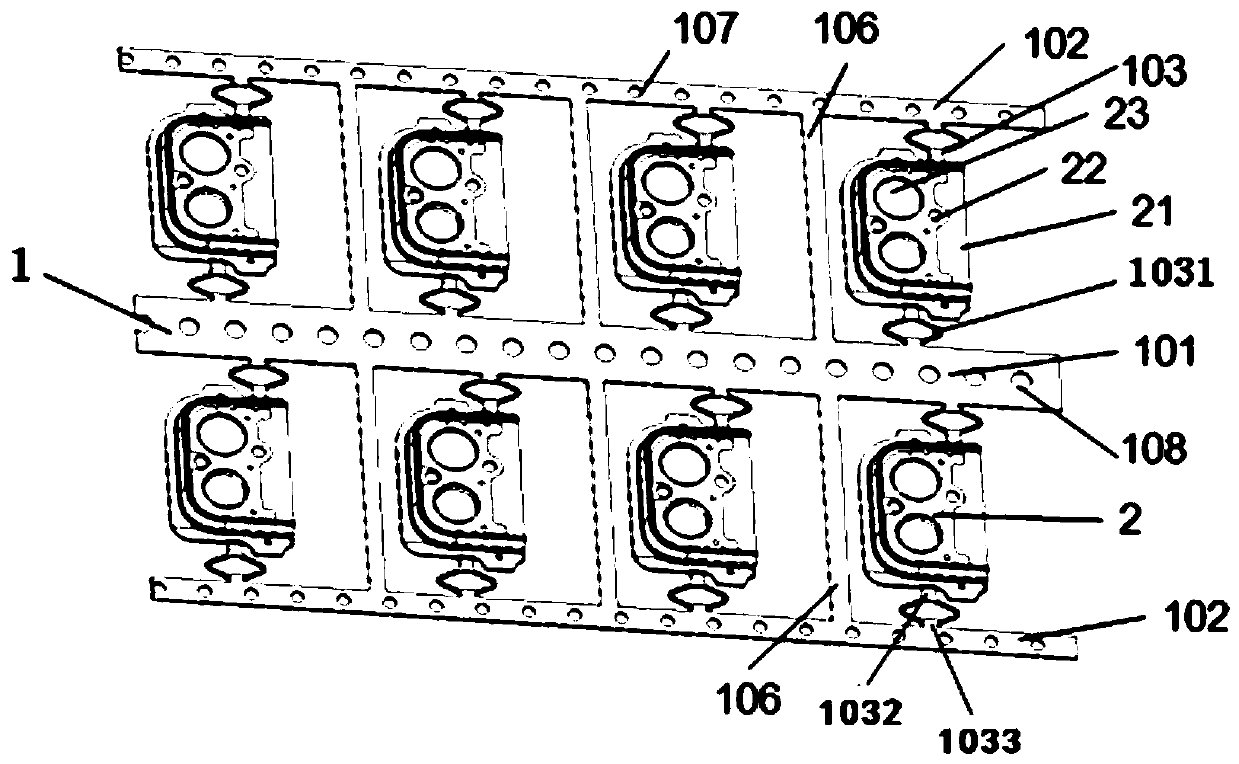

Disclosed are a punching line of automobile door pillar and panel workpieces and mechanical arms for the punching line. A plurality of presses (2) are linearly arranged at equal intervals. Each punching die assembly (3) is provided with an outer plate cavity and an inner plate cavity; a transverse rod (4) crosses the whole punching line; the transverse rod (4) can be driven to move up and down by a vertical drive mechanism; the transverse rod (4) is sleeved with a sliding sleeve (5); the sliding sleeve (5) can be driven to move side to side along the transverse rod (4) by a transverse drive mechanism; the sliding sleeve (5) is provided with the mechanical arms (6) on the left and right sides of each press (2); the mechanical arms are used for gripping and moving automobile door pillar and panel outer plates and inner plates (1) at respective positions; a turnplate (8) on which a plurality of bed plates (9) are evenly arranged is disposed at the left end; an inner plates and outer plates holder (10) is disposed on each bed plate (9). The punching line and the mechanical arms have the advantages that automatic punching level of automobile door pillars and panels is increased greatly, and punching efficiency of the automobile door pillars and panels is greatly improved.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

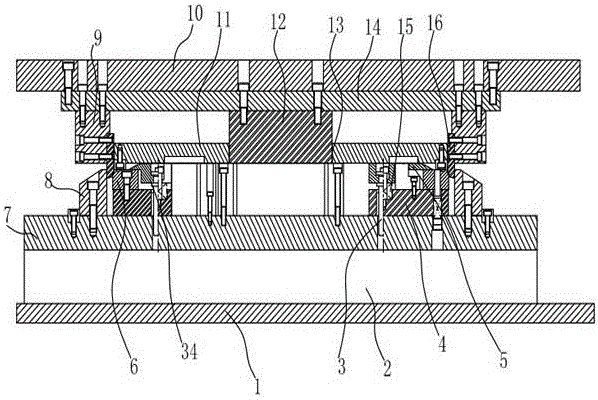

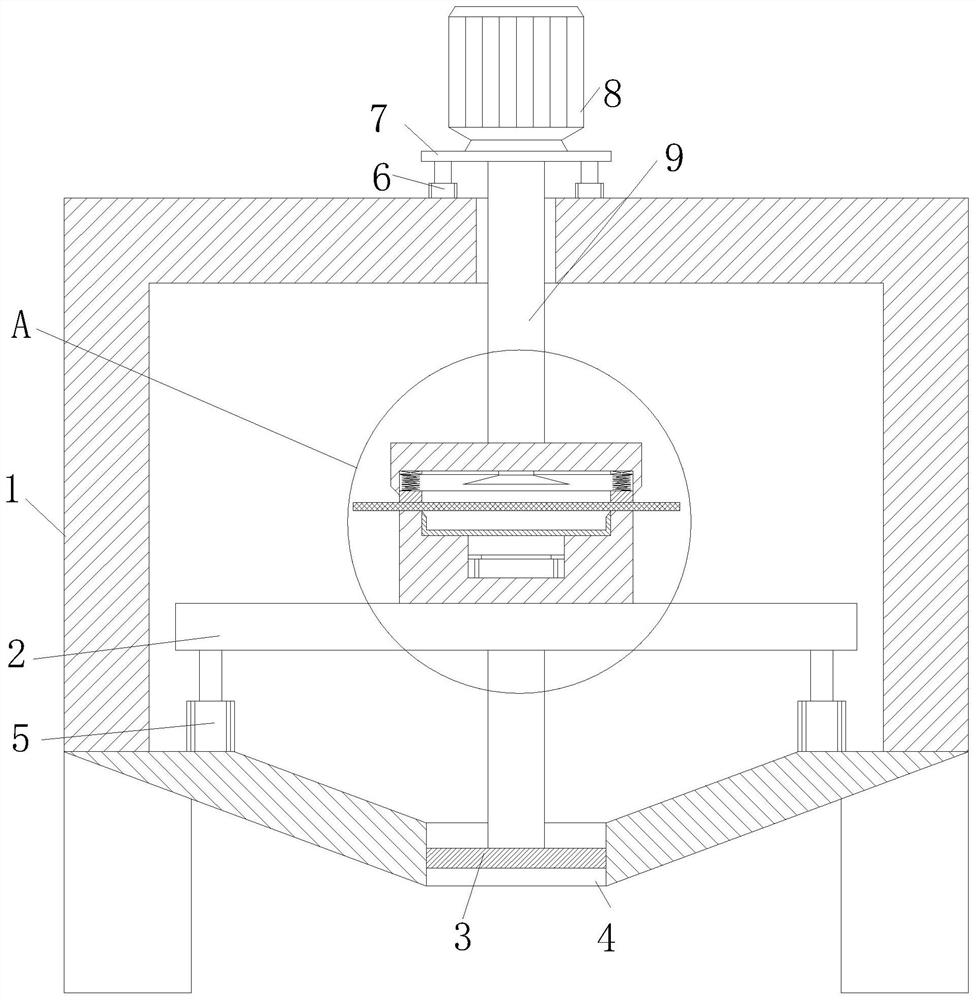

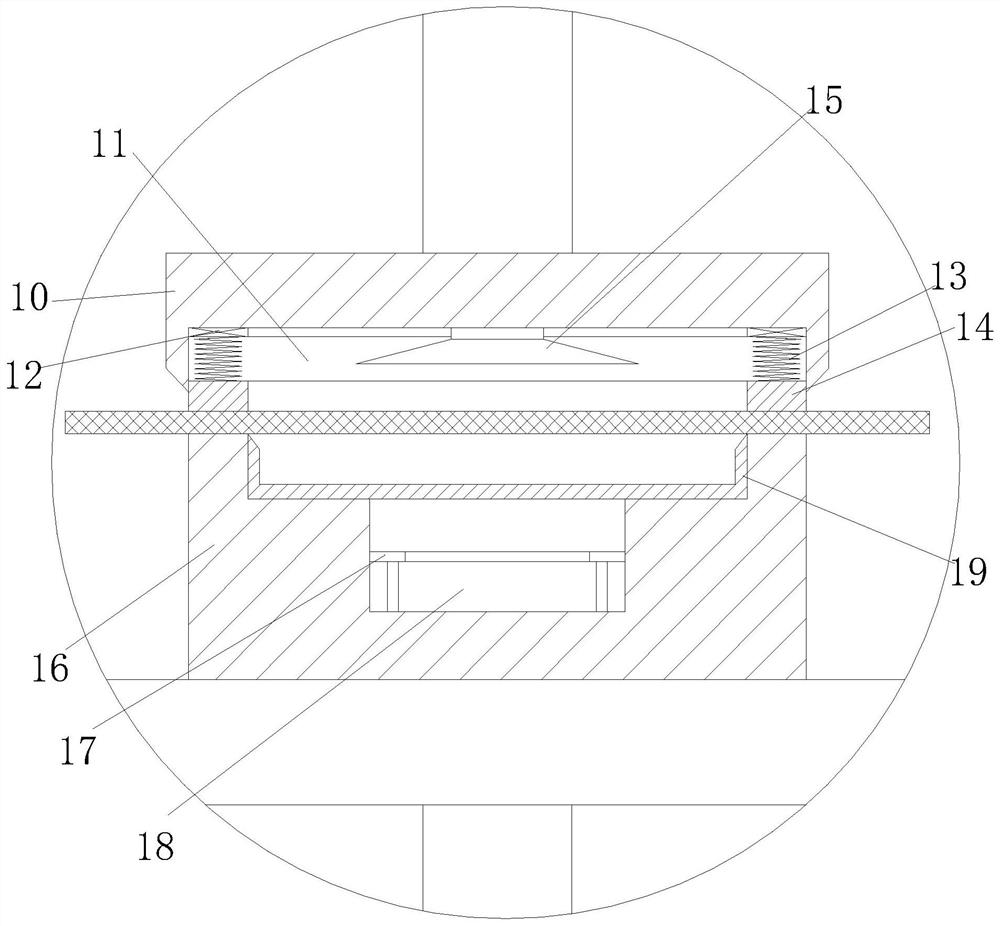

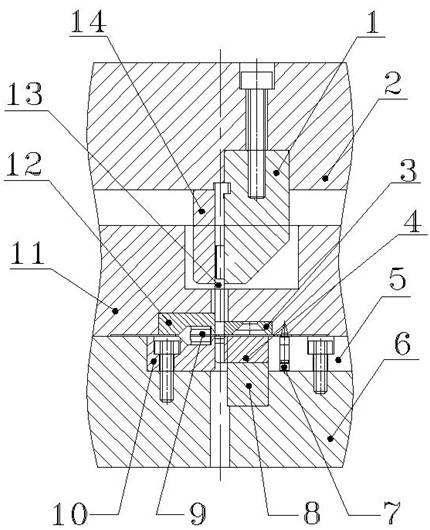

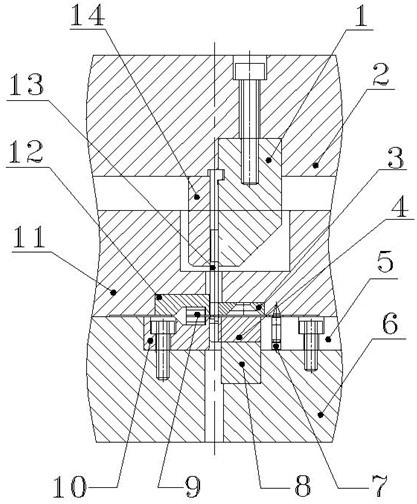

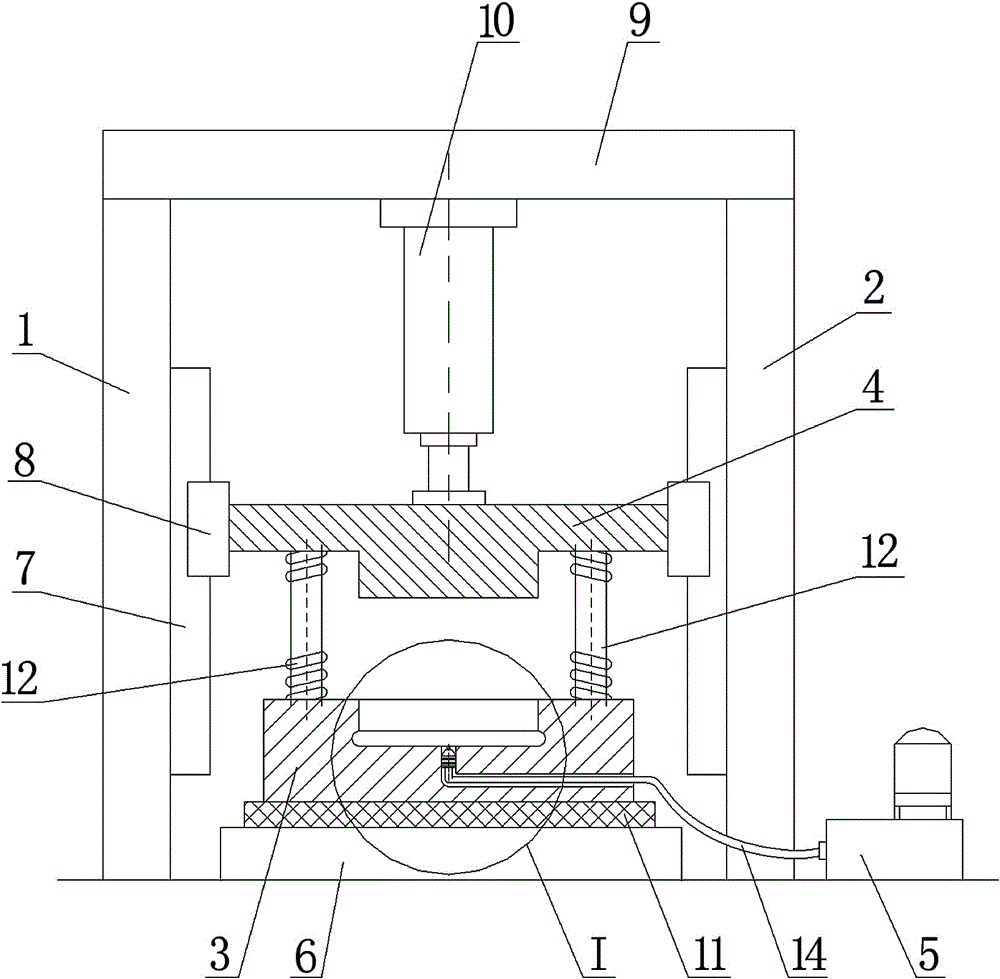

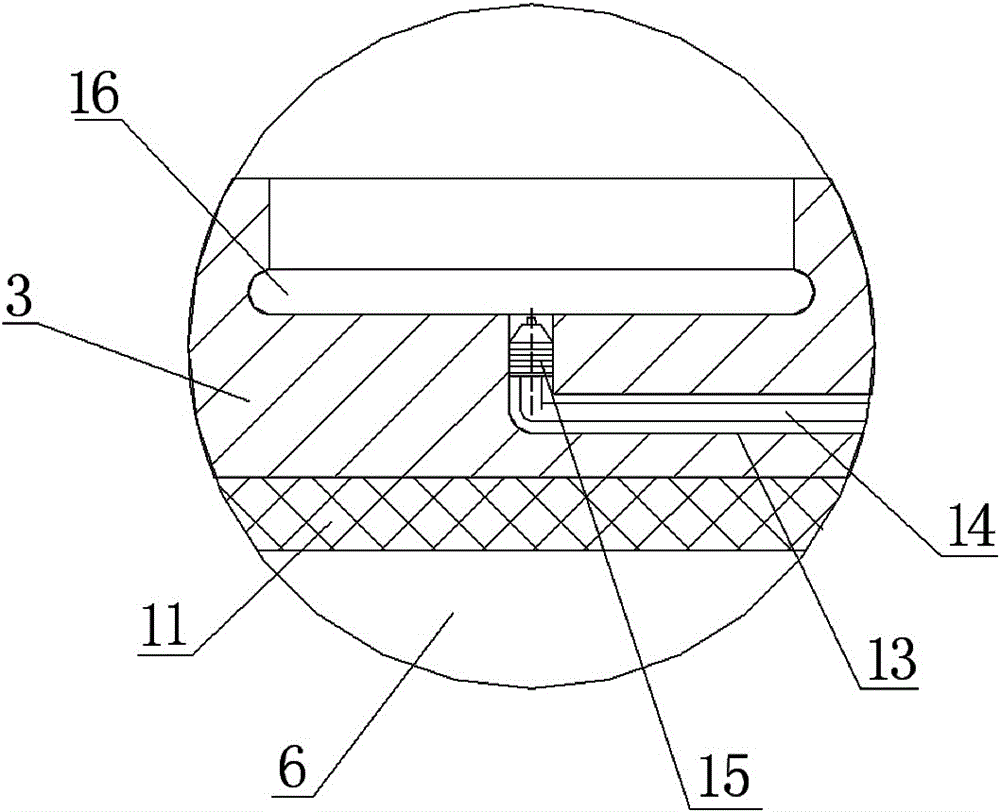

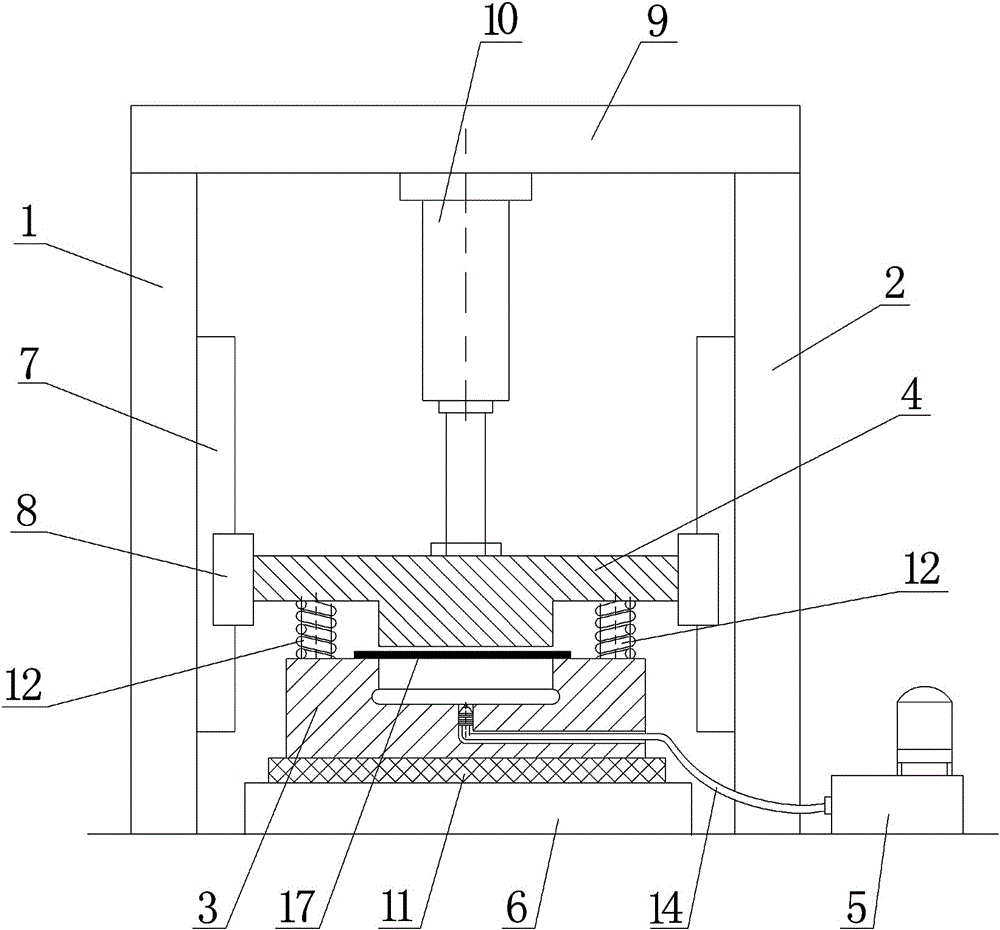

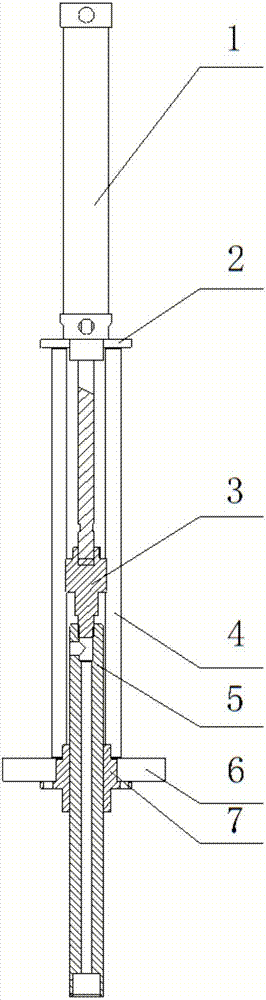

Novel punching die for easy-to-tear films on polypropylene infusion bags

ActiveCN105171844ACompact structureHigh punching precisionMetal working apparatusPunchingPolypropylene

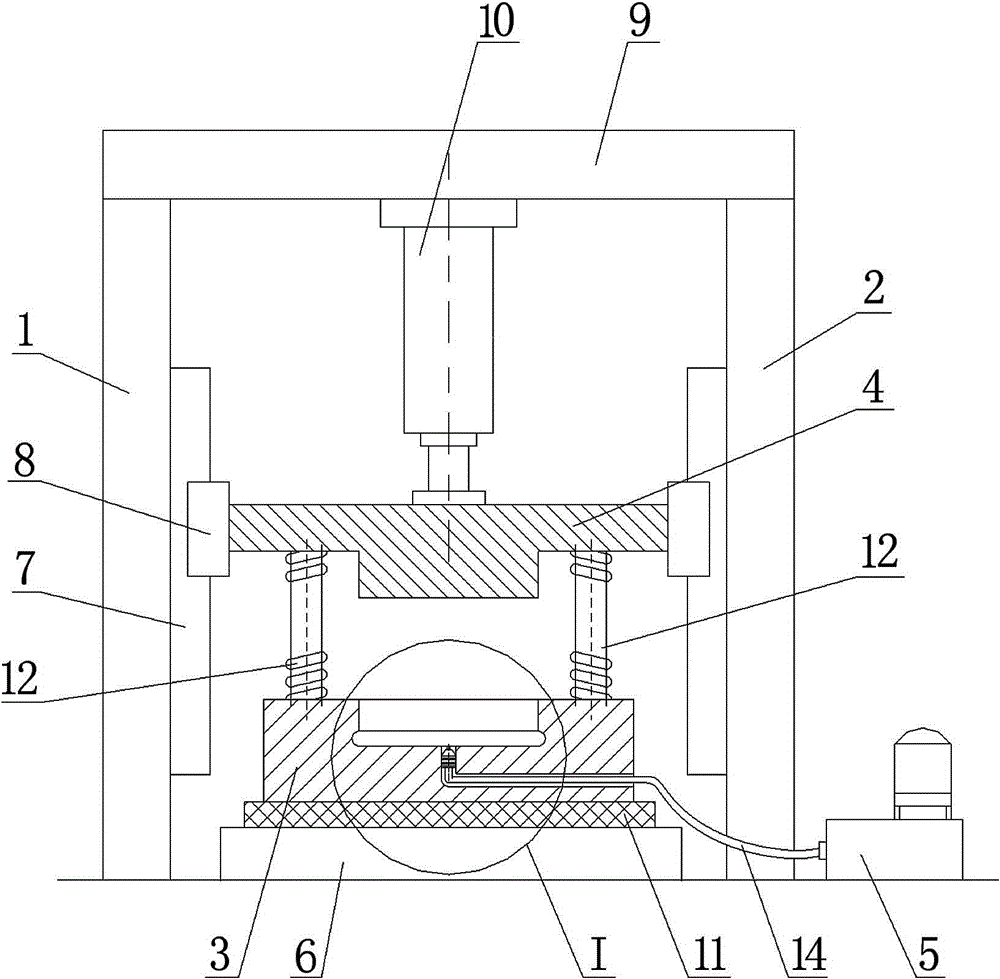

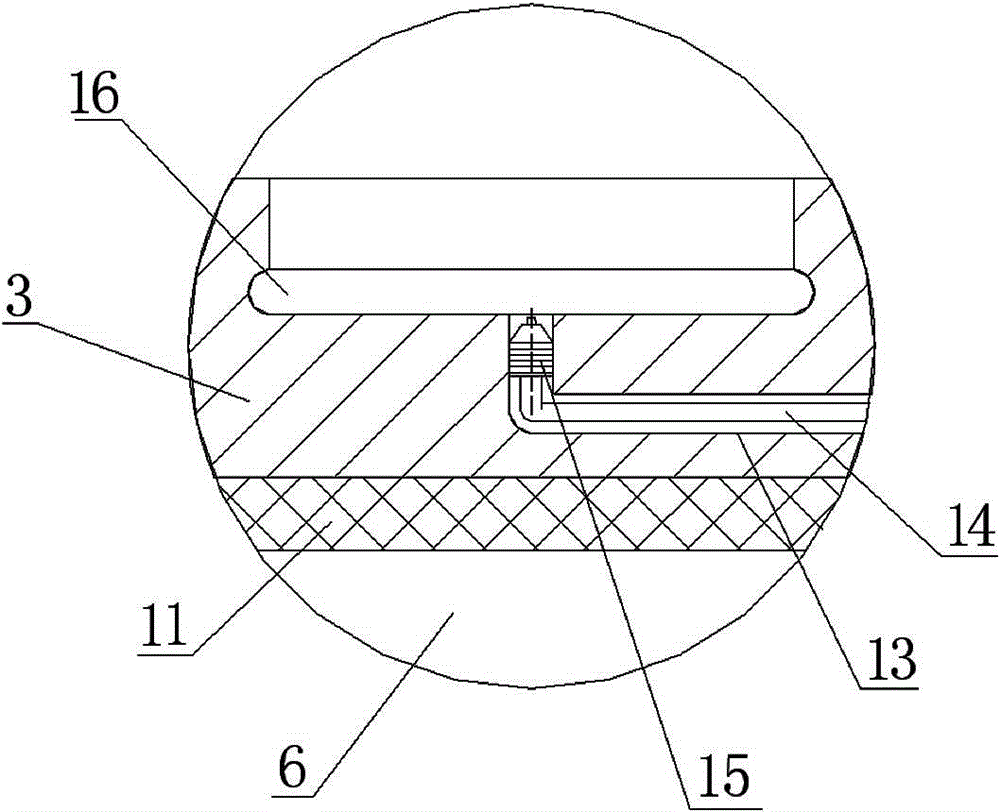

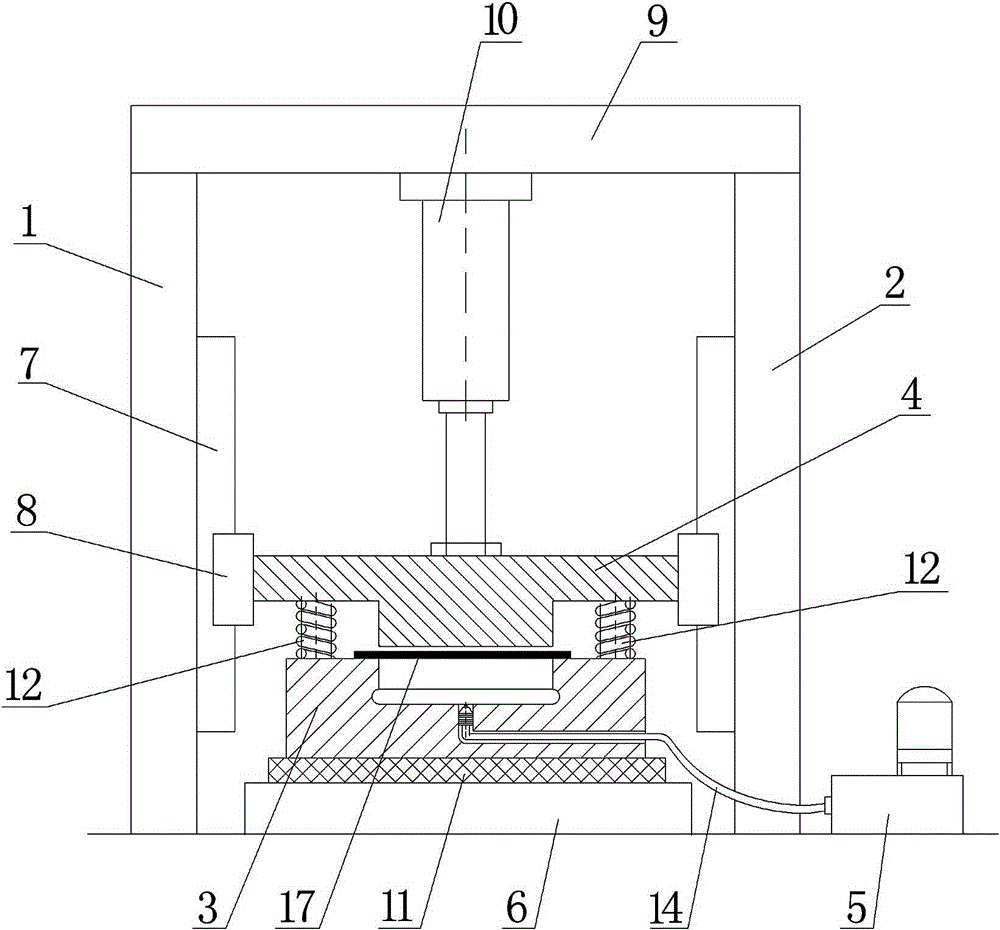

The invention discloses a novel punching die for easy-to-tear films on polypropylene infusion bags. The punching die comprises a vertical column I (1), a vertical column II (2), a female die (3), a male die (4), a constant-pressure air source (5), and a workbench (6) arranged between the vertical column I (1) and the vertical column II (2). An air cylinder (10) is fixedly installed on the bottom surface of a supporting beam (9). The action end of a piston rod of the air cylinder (10) is provided with the male die (4). The left end and the right end of the male die (4) are fixed to two sliding blocks (8) respectively. An air inflow pipe (14) and an air nozzle (15) are arranged in an L-shaped channel (13). One end of the air inflow pipe (14) is connected with the air nozzle (15). The other end of the air inflow pipe (14) is connected with the output end of the constant-pressure air source (5). An annular groove (16) for collecting powdered scraps of the easy-to-tear films is formed in the inner wall of a groove of the female die (3). The punching die has the beneficial effects that punching accuracy is high, safety and reliability are achieved, the easy-to-tear films are convenient to take out, and punching efficiency is improved.

Owner:SICHUAN KELUN PHARMA CO LTD

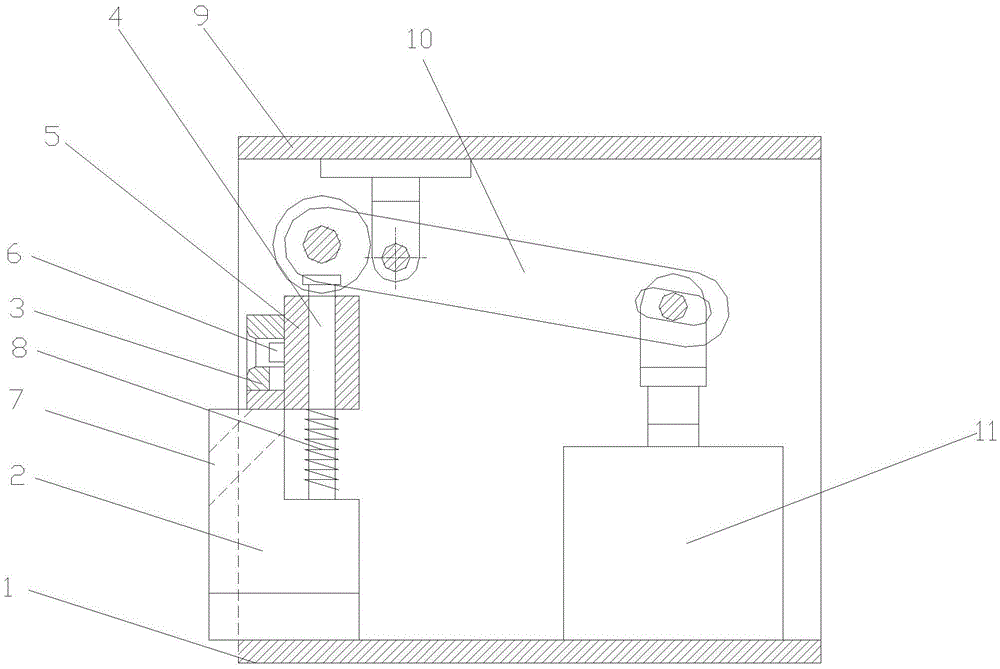

Punching device

InactiveCN105522033AImprove securityImprove efficiencyShaping safety devicesPressesPunchingEngineering

The invention discloses a punching device. The punching device comprises a substrate. An installation base is arranged on the substrate. A material containing die is arranged on the installation base. A punching die capable of moving up and down is arranged on the installation base. A plunger chip is arranged on the punching die. A plurality of reset springs used for ejecting the punching die upwards to reset are arranged between the installation base and the punching die. A floor stand is arranged on the substrate. A lever used for pressing down the punching die is hinged to the lower surface of the floor stand. One end of the lever is located above the punching die, and the other end of the lever is hinged to a piston rod of an air cylinder which is arranged on the floor stand or the substrate and used for driving the lever. The punching device is simple in structure and convenient to use.

Owner:ZHANGJIAGANG XUJUN MACHINERY PARTS CO LTD

High-speed cut-to-length line for transformer silicon steel sheet machining

PendingCN109352345AImprove shear efficiencyEasy to moveOther manufacturing equipments/toolsPunchingTransformer

The invention relates to a high-speed cut-to-length line for transformer silicon steel sheet machining. The high-speed cut-to-length line for transformer silicon steel sheet machining comprises a cut-to-length bracket; the cut-to-length bracket is provided with a feeding channel; the feeding channel is provided with at least one punching device, a V scissoring device and a pair of cut-to-length devices; each punching device is driven to transversely move through an independent punching transverse moving mechanism; the V scissoring device is driven to transversely move by a V scissoring transverse moving mechanism; the punching devices, the V scissoring device and any one cut-to-length device are respectively driven to synchronously perform the punching work; and an emptying device and a collecting device are arranged at two ends of the feeding channel. The high-speed cut-to-length line has the following advantages: through arrangement of the transverse moving mechanisms, gaps among thepunching devices, the V scissoring device and the cut-to-length devices can be transversely adjusted, so that the punching devices, the V scissoring device and any one cut-to-length device can synchronously perform the punching work, and the shearing efficiency is greatly improved.

Owner:NANTONG SIRUI ENG

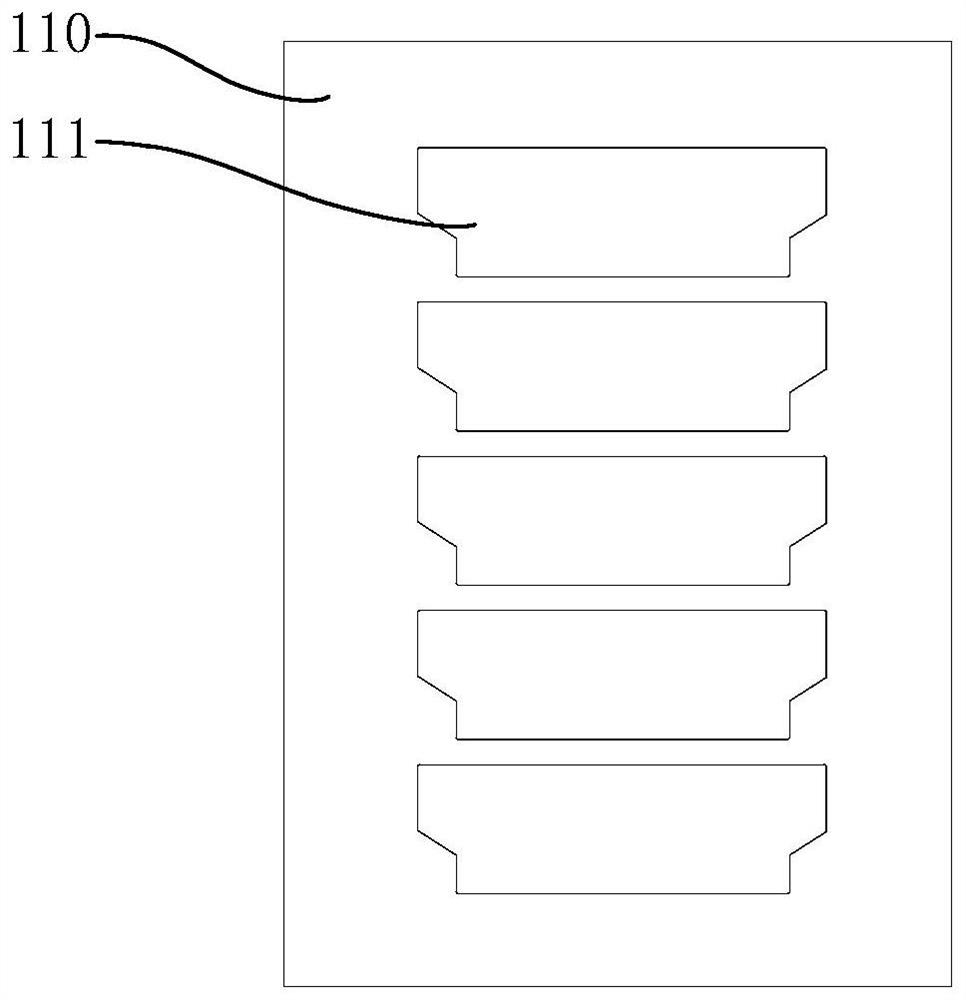

Speaker frame machining process performed by sequentially punching ear flowers and center hole

The invention discloses a speaker frame machining process performed by sequentially punching ear flowers and a center hole. The speaker frame machining process performed by sequentially punching the ear flowers and the center hole includes a series of steps of rough shape cutting, blanking, location hole punching, deep drawing, hole punching and edge trimming, ear flower punching, flanging and hole punching. The speaker frame machining process performed by sequentially punching the ear flowers and the center hole is suitable for accurately punching the ear flowers and the ear hole.

Owner:WUZHOU HENGSHENG ELECTRONICS

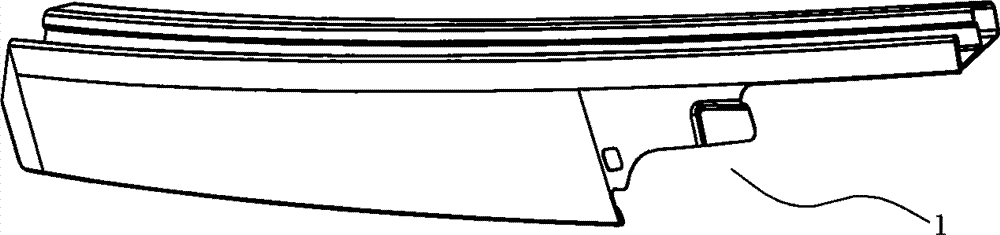

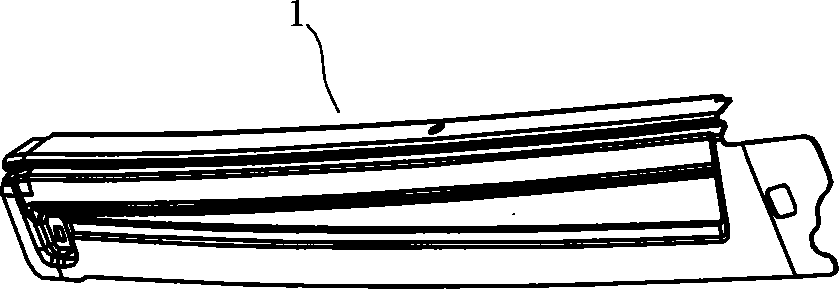

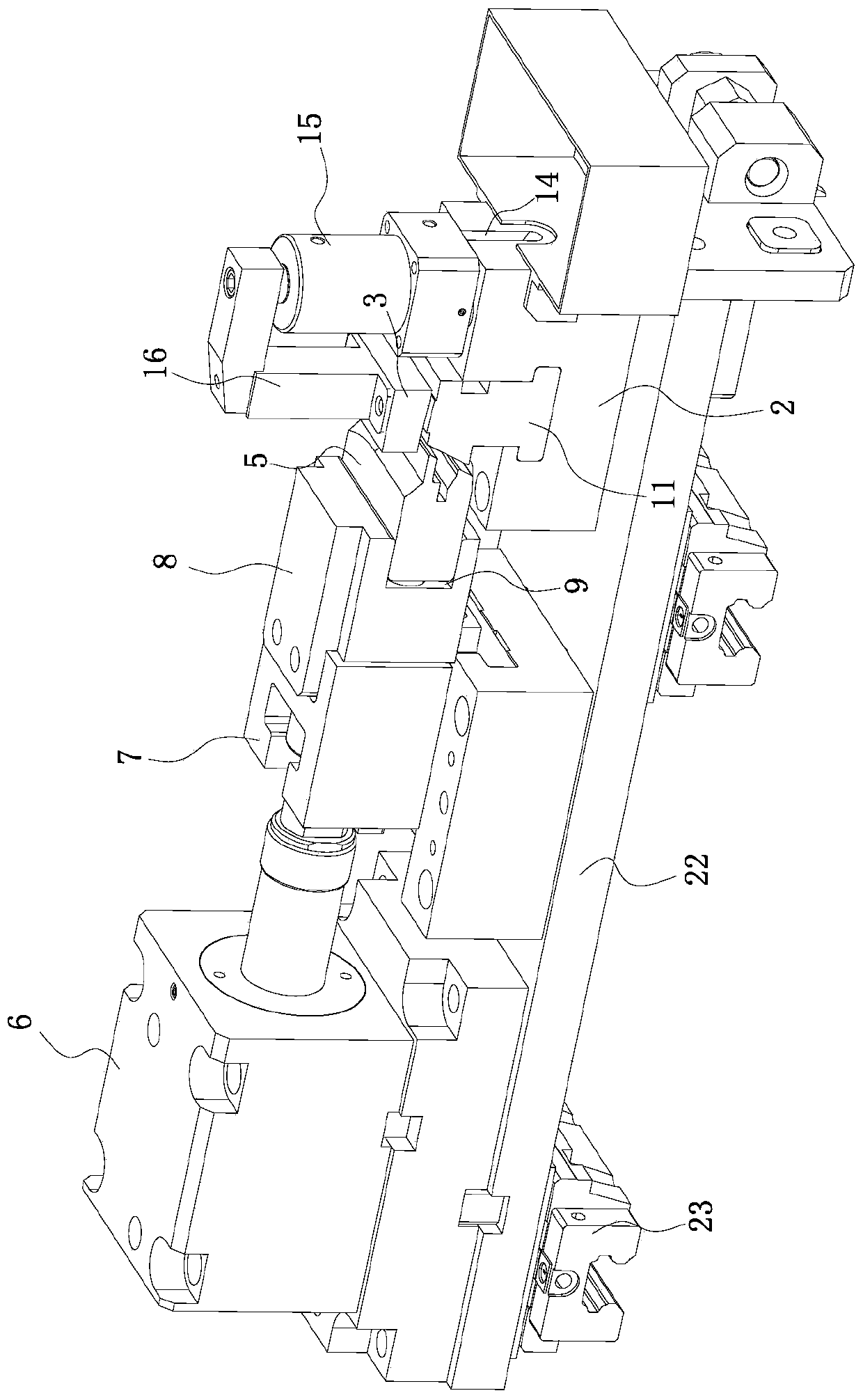

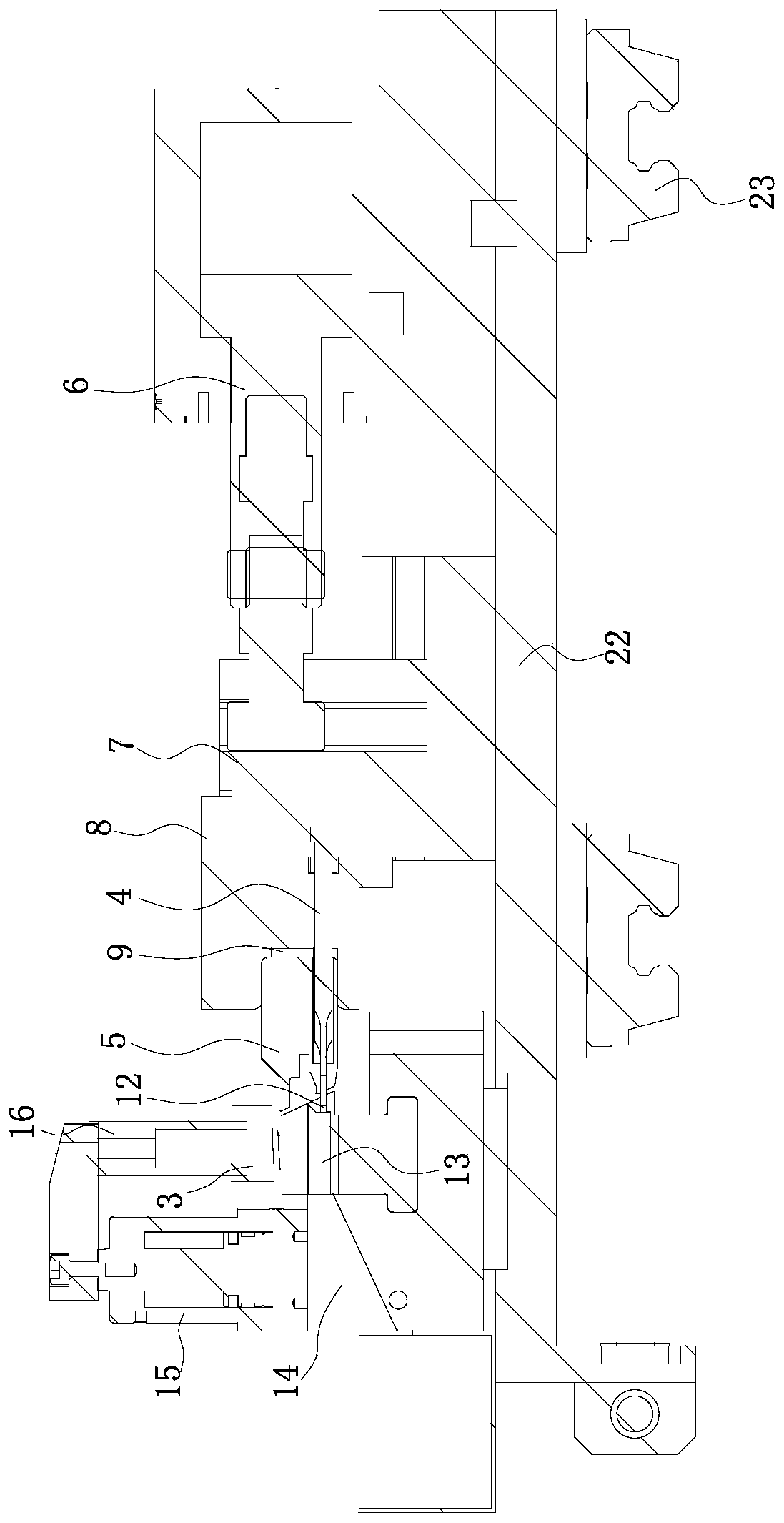

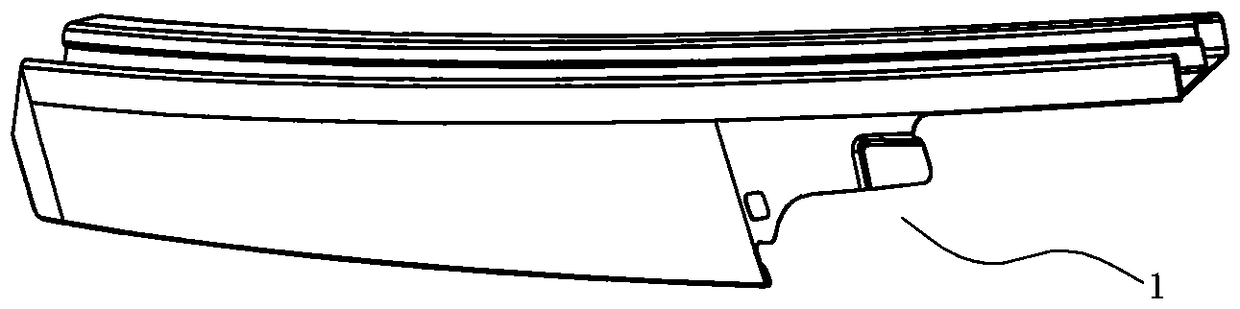

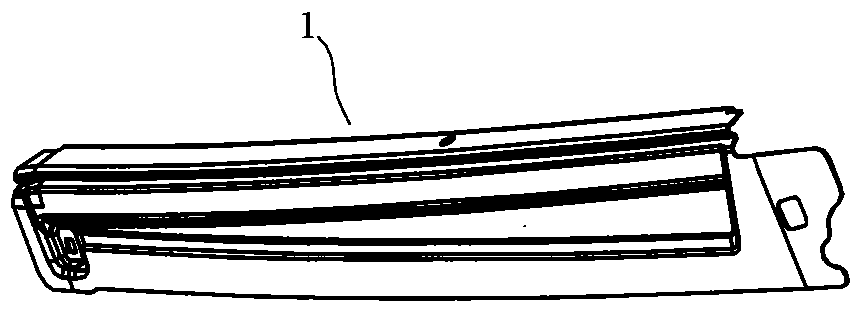

Die-cutting device special for groove strips such as guide grooves in car door and die-cutting blade of device

Disclosed is a die-cutting device for groove strips. A workpiece holding block (4), an inner workpiece stopper (5) and a workpiece clamping mechanism which are used for clamping a sideways upright groove strip workpiece (1) is arranged on the upper side of a bottom plate (2), and the workpiece clamping mechanism comprises an outer workpiece clamping block (6) and a top workpiece pressing block (7). An end die-cutting mechanism comprises a first oil cylinder (8) fixed on the rear side of the bottom plate (2), and a die-cutting blade (9) driven by the first oil cylinder (8) to perform die cutting from back to front. The shape and the size of the end portion of the outer workpiece clamping block (6) as well as the shape and the size of a notch of the die-cutting blade (9) are equal to those of a portion, needed to be reserved, of the die-cut end portion of the groove strip workpiece (1). The die-cutting blade (9) is a geometric body with the section in the shape of an angle rule. The shape and the size of an angle-rule-shaped notch (G) of the die-cutting blade (9) are also equal to those of the portion, needed to be reserved, of the die-cut end portion of the groove strip workpiece (1). The invention further provides a die-cutting device which is used for performing die-cutting on the end portions and lateral pieces of the groove strips at the same time, and particularly suitable for die-cutting of guide grooves in a car door.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

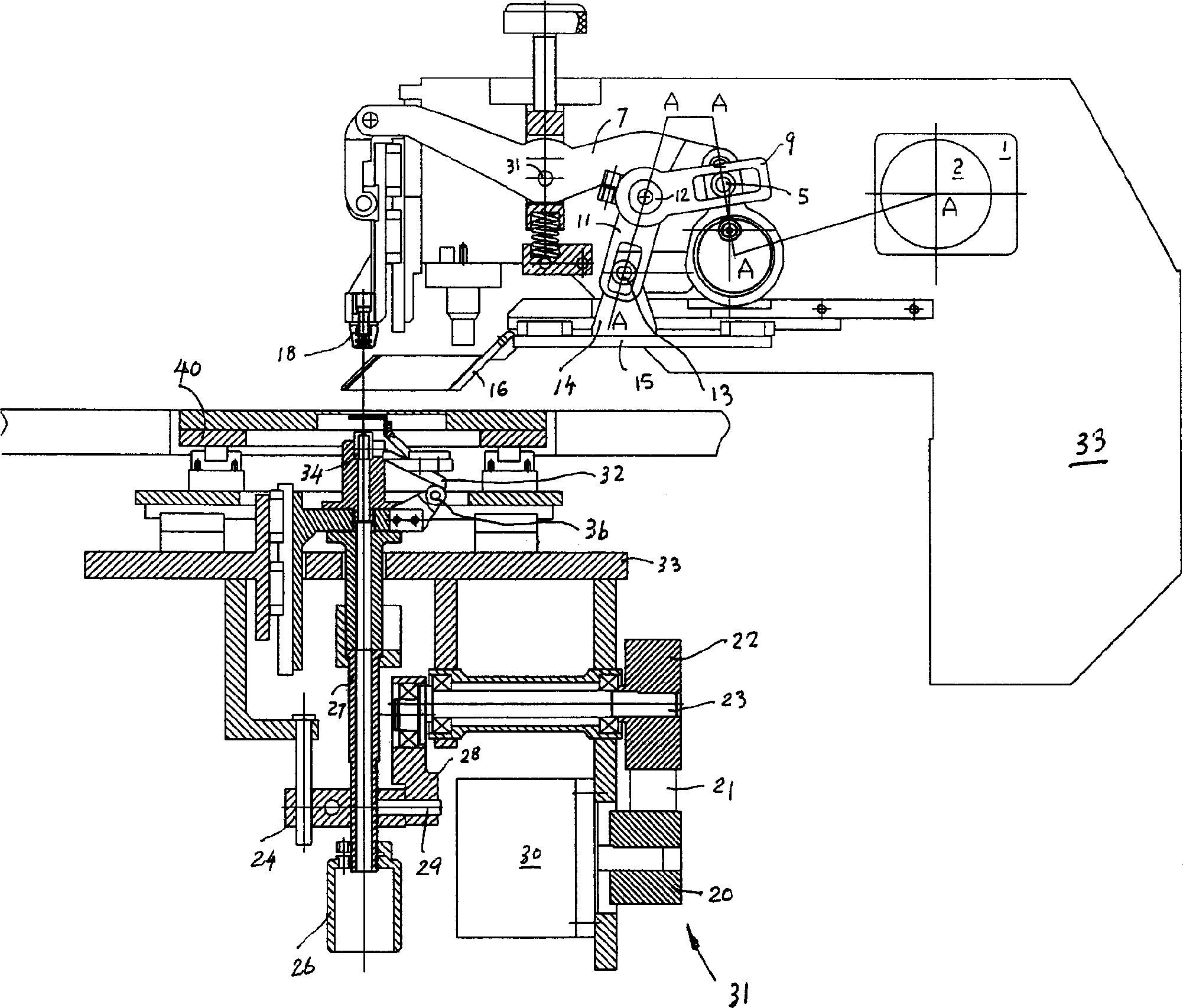

Mechanical hole punch

The mechanical punch includes one frame, one power device connected to a ram head with upper mold, one viewing device connected to the power device, one movable panel with workpiece holder, one lower mold driving device and one scattering mechanism. The power device includes a motor, a sync belt wheel transmitting pair, a crank, a link rod, an upper mold swing link and an upper mold. The viewing device includes a swing rod, a driven swing rod, a viewing bar with viewing frame. The lower mold driving device and the scattering mechanism include a motor and a lower mold driving pair. The present invention has the advantages of simple and reasonable structure, high use reliability, high punching efficiency, low noise and easy maintenance.

Owner:应书波

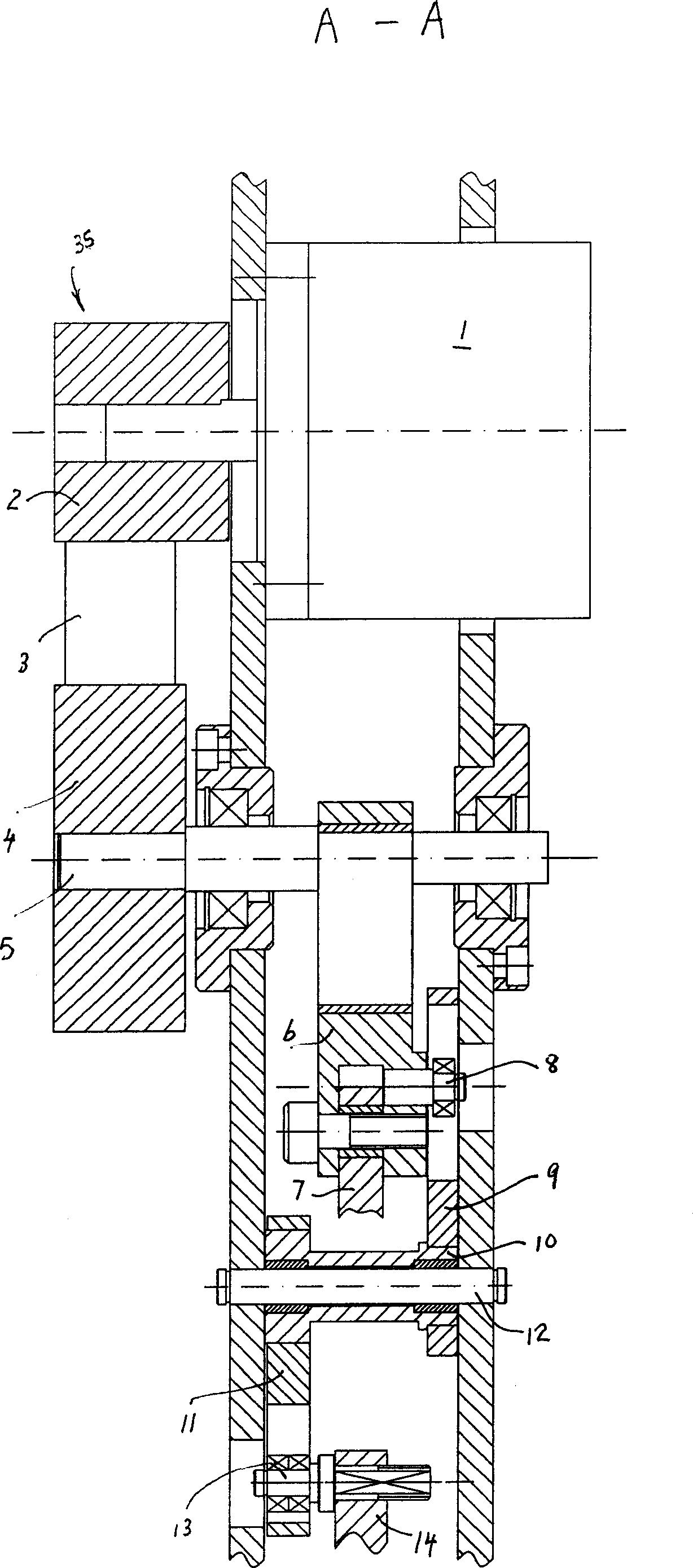

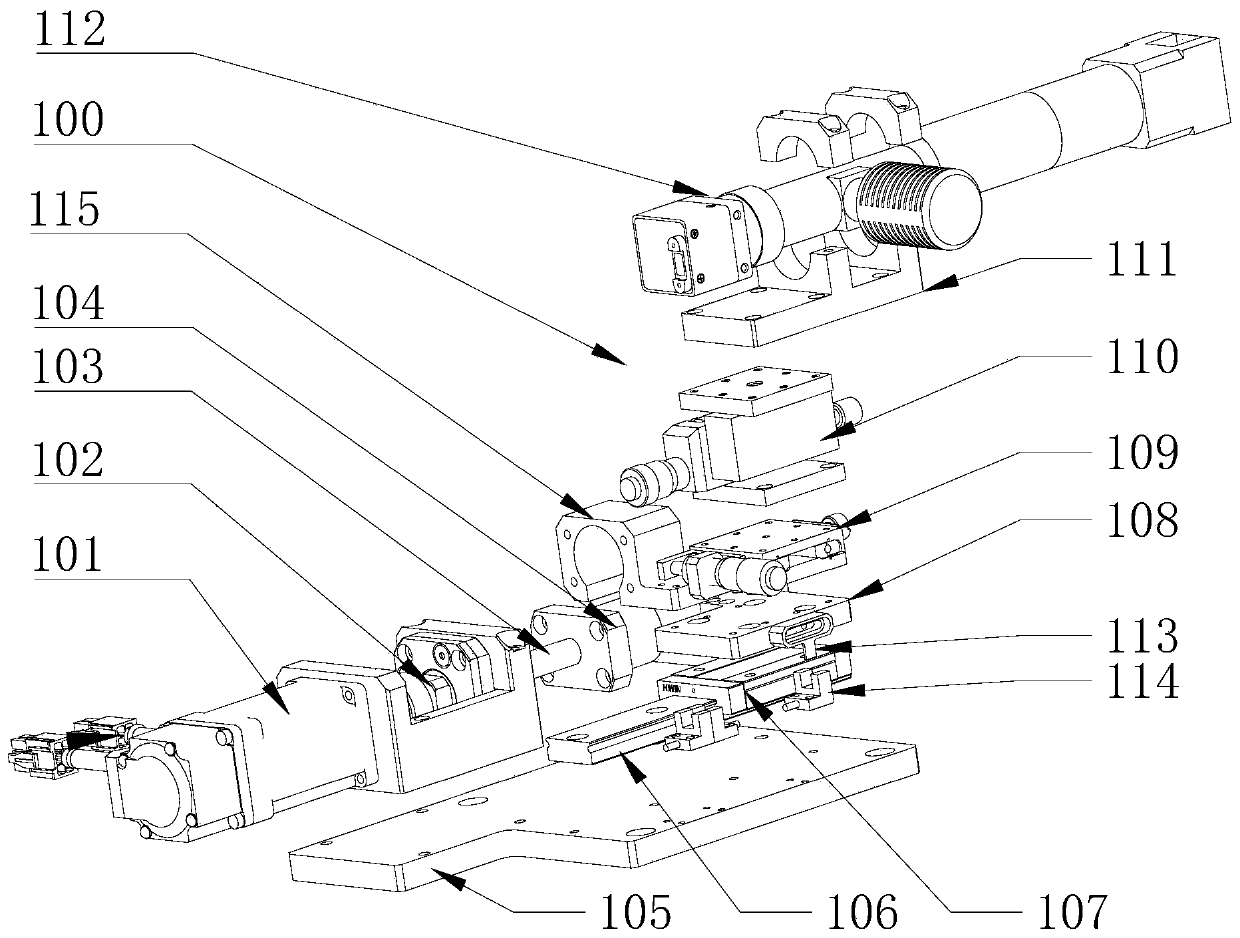

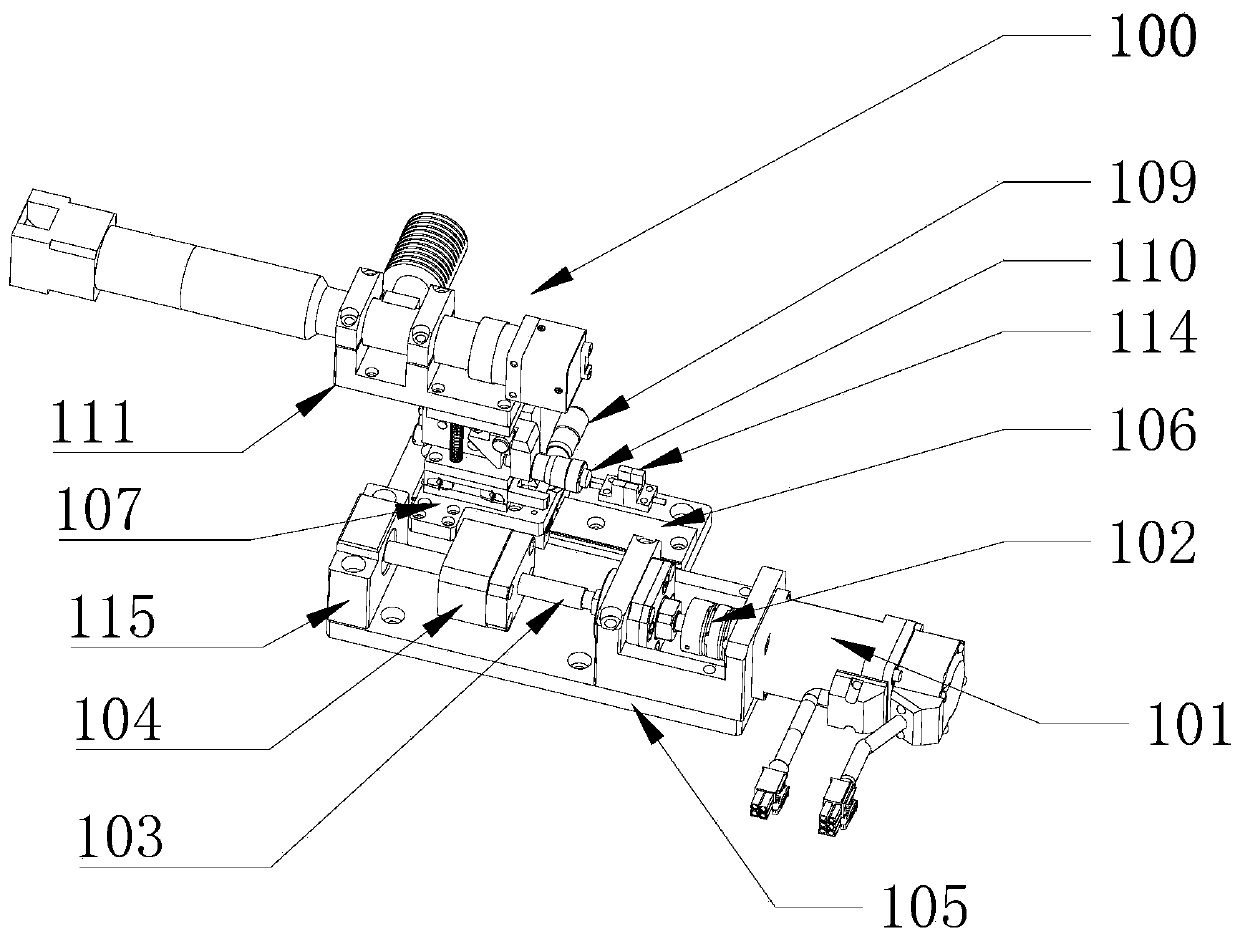

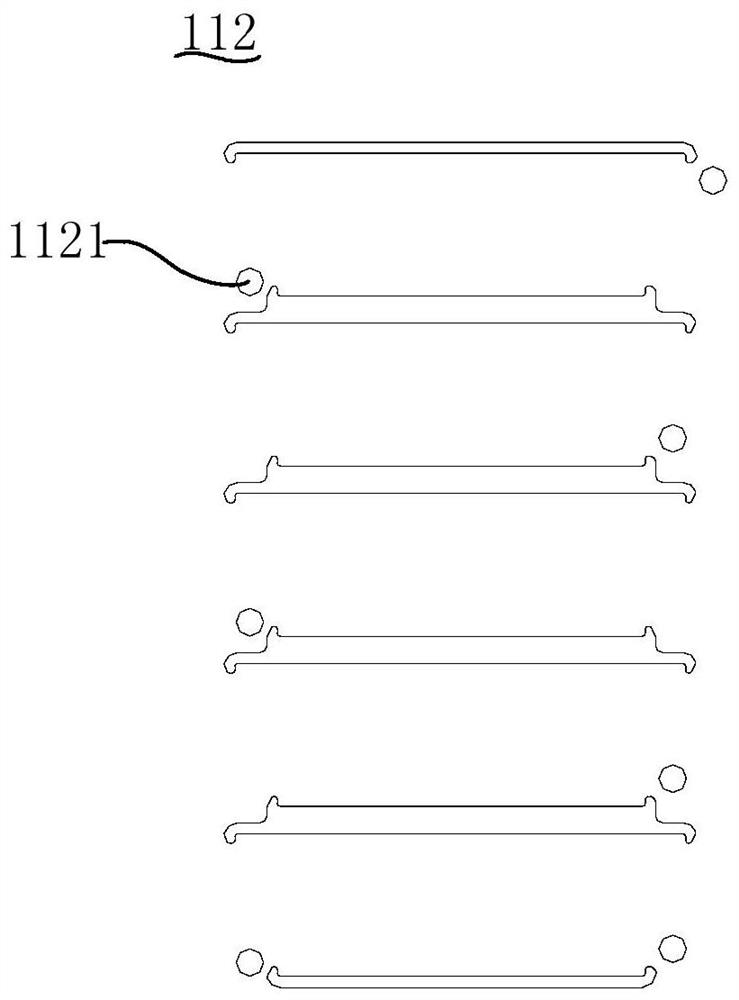

Automatic forming machine for flat metal heald loops

ActiveCN103464565AReduce labor intensityGood for healthMetal-working feeding devicesPositioning devicesWorking environmentEngineering

The invention relates to textile accessory automatic forming equipment, in particular to an automatic forming machine for flat metal heald loops for shuttleless looms. The automatic forming machine comprises a pushing system, a forming system, a clamping system and an electric control system which are mounted of a frame workbench. The pushing system, the forming system and the clamping system are controlled by the electric control system. The products produced by the automatic forming machine is consistent in boundary dimension, the extreme deviation of loop size of the same batch of flat metal healds is not more than + / -0.05mm, and automatic entering requirements of an automatic entering machine are satisfied. The automatic forming machine has the advantages that the products are stable and reliable, production efficiency is increased by 6-8 times, multiple machines can be operated by one person, and production manpower is reduced; the automatic forming machine is high in automation level and low in production noise, working environments of operators are changed thoroughly, labor intensity of the operators is relieved, and the requirements for high-quality flat metal healds in textile industry are satisfied.

Owner:ZHEJIANG DINGFENG TEXTILE EQUIP CO LTD

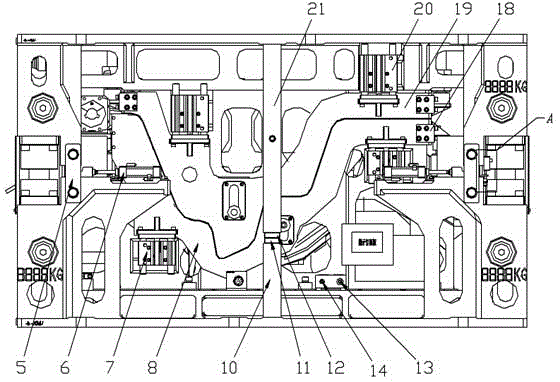

Punching and bending die for rear back plate of refrigerator

ActiveCN106734635AHigh punching precisionImprove punching accuracyShaping toolsPerforating toolsPunchingEngineering

The invention relates to a punching and bending die for a rear back plate of a refrigerator. The punching and bending die for the rear back plate of the refrigerator comprises a lower die base plate, an upper die plate, an upper die base, a lower die ribbed plate, a lower die deck plate, lower blades, a male die base, upper blades, an edge folding base, edge folding strips, a pressing plate, a punch base, punch bodies and a punching column, wherein a punching base is arranged at the top of the lower die deck plate, and a punching cavity is formed in the punching base; the punch base is arranged on the upper die plate, and an injection hole punch is arranged at the bottom of the punch base and provided with a floating pin; an ejection mounting base is arranged on the edge of the top of the lower die deck plate, and an ejection air cylinder is arranged on the outer side of the ejection mounting base; and the ejection mounting base is provided with a supporting rod, and the supporting rod is connected with an ejection rod in a pivoted mode. According to the punching and bending die for the rear back plate of the refrigerator, waste is ejected out rapidly through the ejection rod, the structure is simple, production efficiency is high, and safety is high; edge folding of the rear back plate of the refrigerator is conducted during punching through the upper blades and the lower edge folding strips; the floating pin is arranged on the injection hole punch, and the bottom of the injection hole punch is an oblique surface, so that when big holes are punched, the edges of the punched holes are uniform and not prone to deformation.

Owner:昆山市三建模具机械有限公司

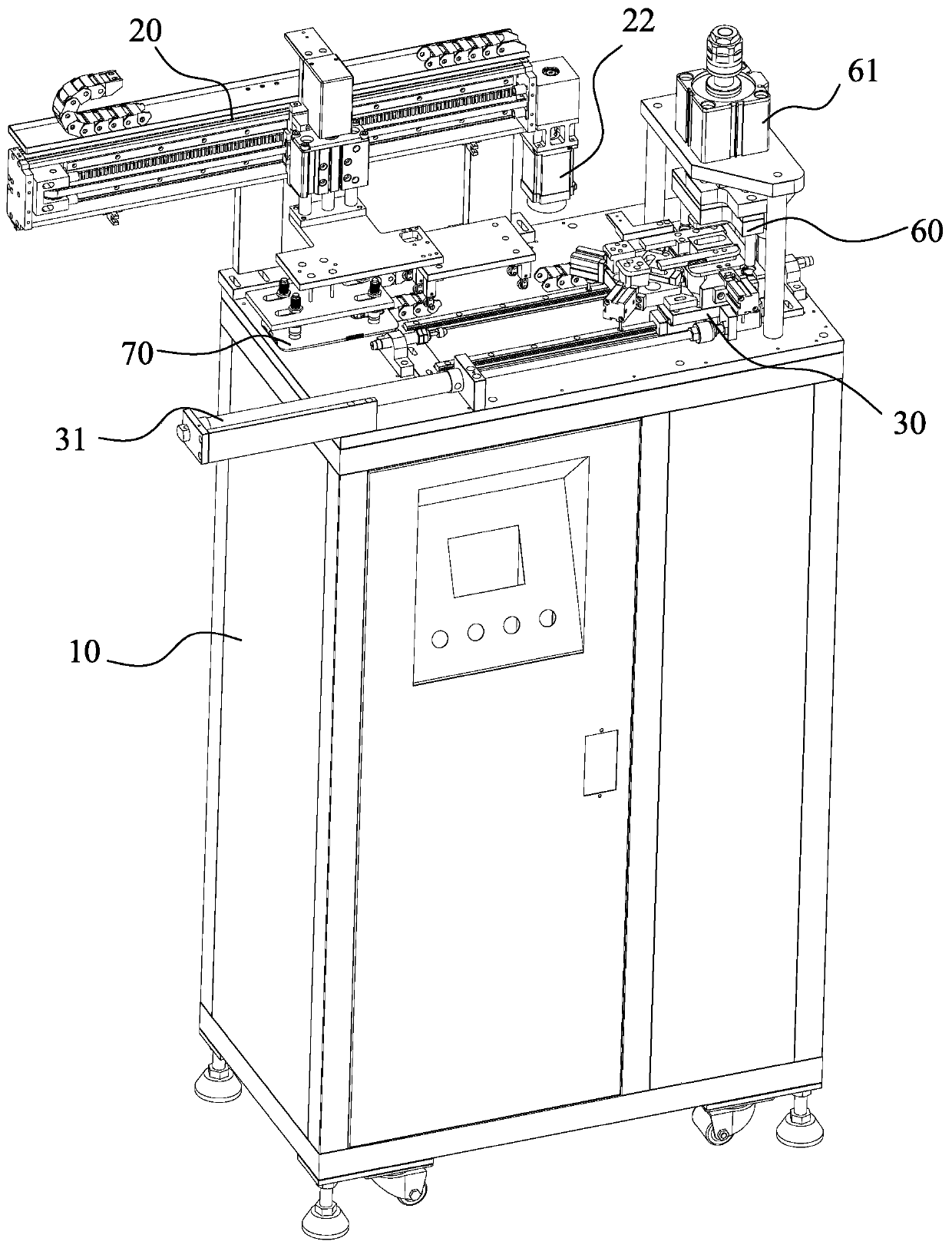

Shell sleeve automatic punching machine

PendingCN110815737AHigh punching precisionIncrease productivityDomestic articlesPunchingStructural engineering

The invention provides a shell sleeve automatic punching machine. The shell sleeve automatic punching machine comprises a rack, wherein a material taking manipulator, a feeding mechanism and a punching mechanism are arranged on the rack, the feeding mechanism comprises a feeding seat and a driving mechanism for controlling the feeding seat to move in the direction of the punching mechanism, the feeding seat is provided with a positioning assembly for positioning a shell sleeve, and the material taking manipulator is provided with an abutting assembly used for flattening the shell sleeve on thefeeding seat and a material taking assembly used for grabbing the shell sleeve. According to the shell sleeve automatic punching machine, the water opening cutting quality stability of the shell sleeve is convenient to control, full-automatic production can be realized, the production period can be shortened, the production cost of enterprises can be reduced, the production efficiency can be improved and the shell sleeve can be protected, meanwhile, the structure is simple and reasonable, the shell sleeves with different sizes can be subjected to water opening punching operation, the universality is good, and popularization and use are facilitated.

Owner:江苏造裕智能装备有限公司

Punching device of rubber seal part

ActiveCN110883859AReduce deformationHigh punching precisionMetal working apparatusStructural engineeringMaterials science

The invention discloses a punching device of a rubber seal part. The device comprises a rack, a worktable is arranged in the rack, a close plate is mounted on the lower portion of the worktable, a discharging opening is formed in the bottom of the rack, a first electric cylinder is mounted in the rack, the output end of the first electric cylinder is connected with the bottom of the worktable, thefirst electric cylinder drives the close plate to close or open the discharging opening, a lower punching assembly is mounted on the upper portion of the worktable, an upper punching assembly is mounted on the upper portion of the rack, and the upper punching assembly and the lower punching assembly are matched for work. The upper punching assembly and the lower punching assembly are arranged, and are matched to punch a needed rubber seal part, deforming generated during punching of the rubber seal part is reduced, the punching precision of the rubber seal part is improved, and the product quality is improved.

Owner:利辛县宝隆橡塑密封件有限责任公司

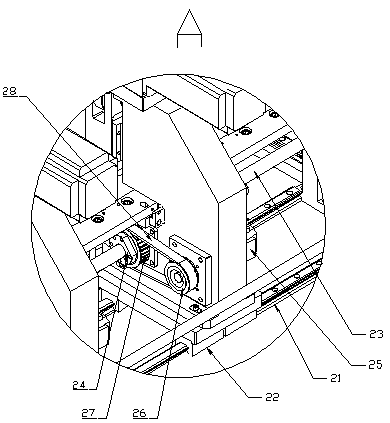

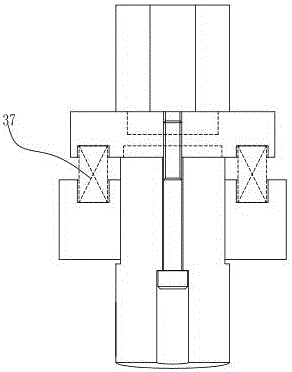

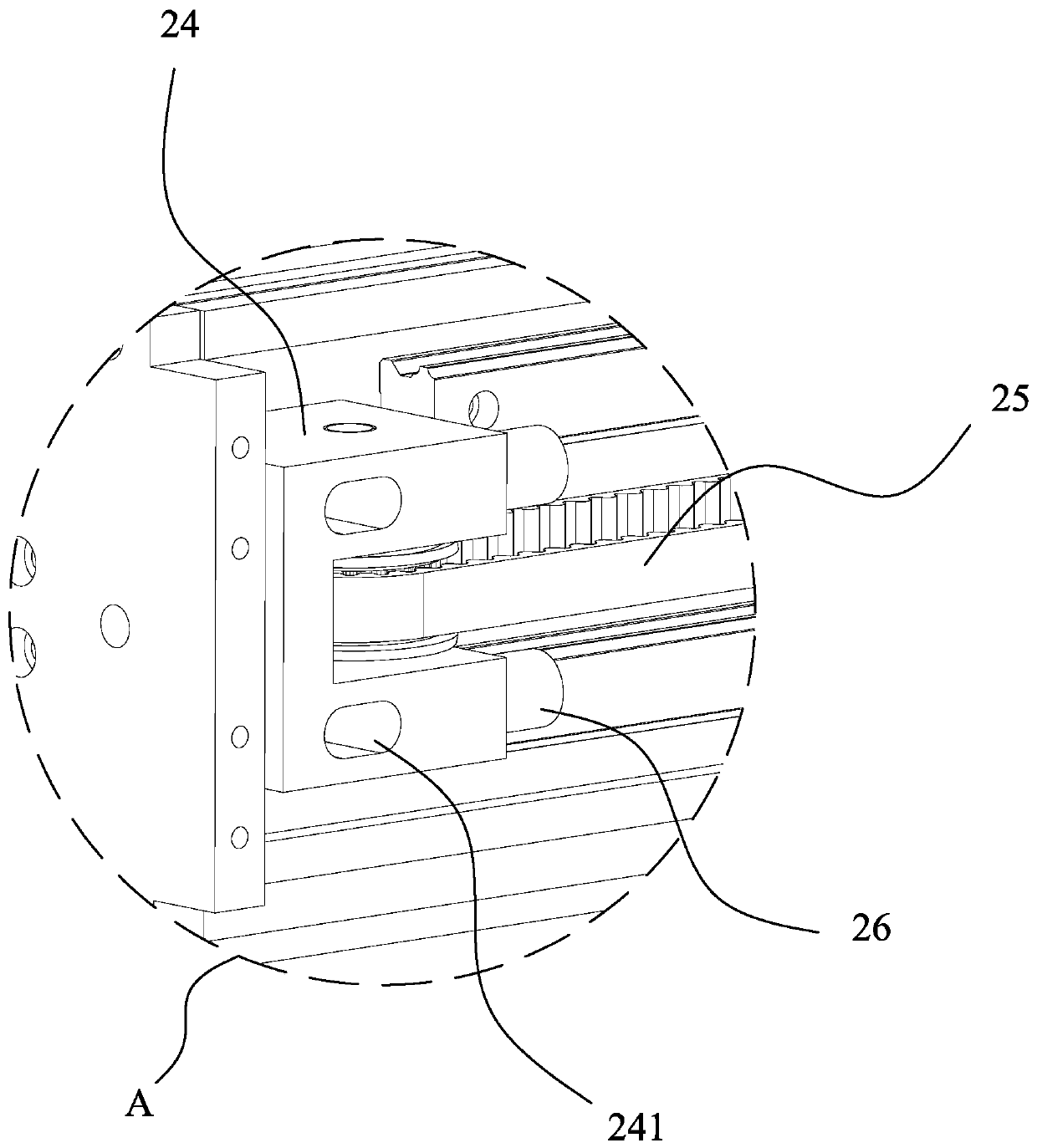

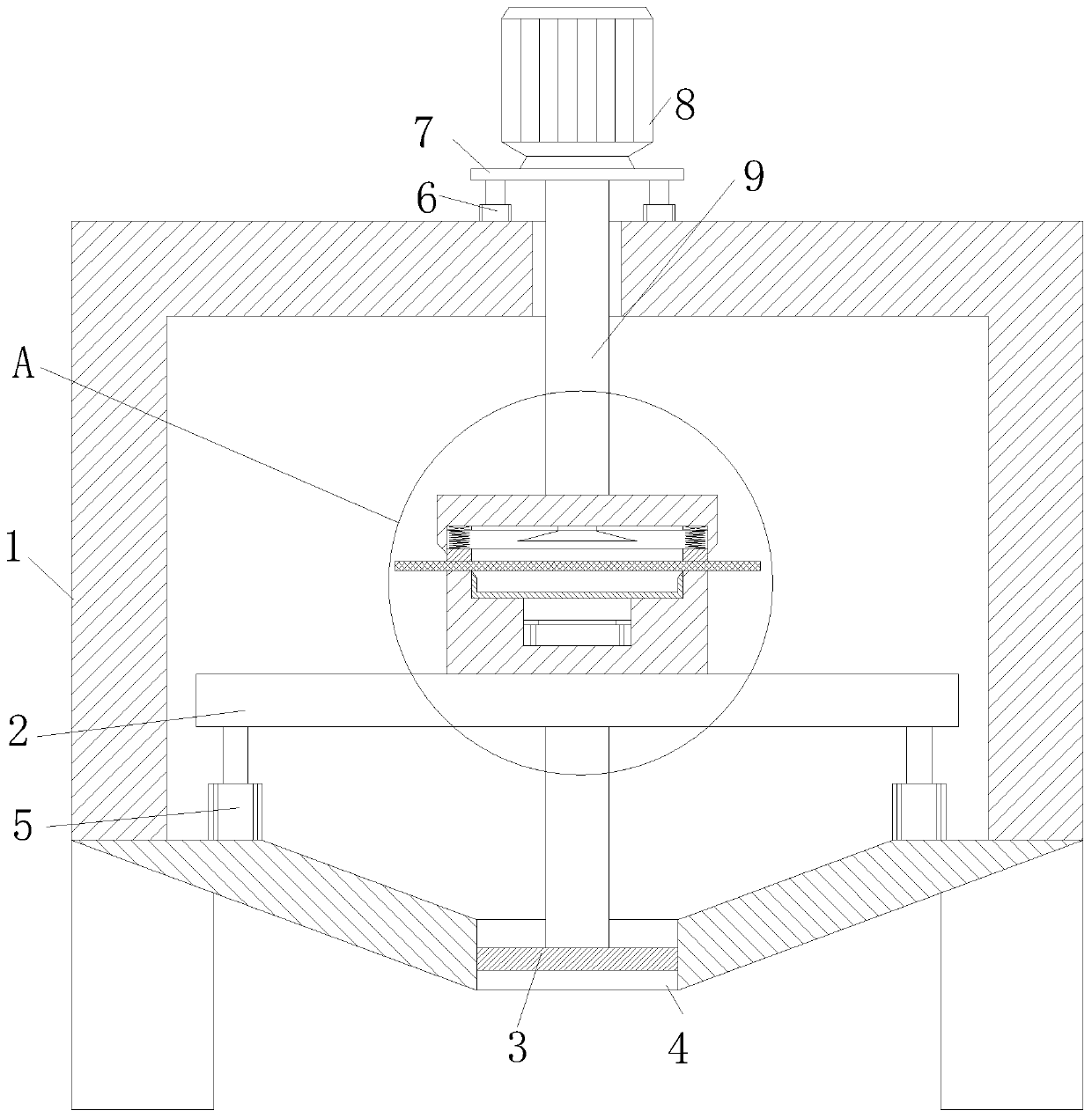

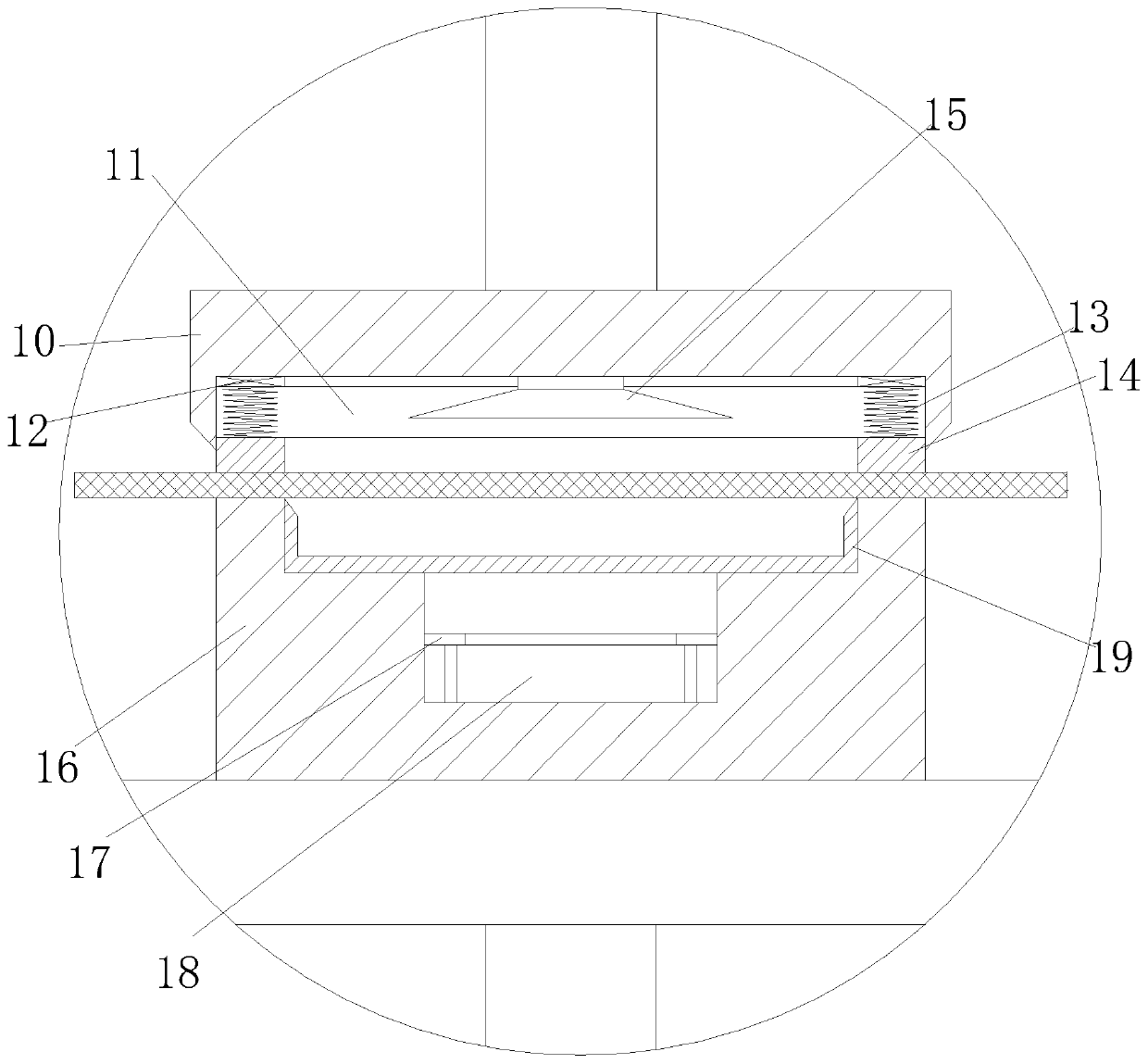

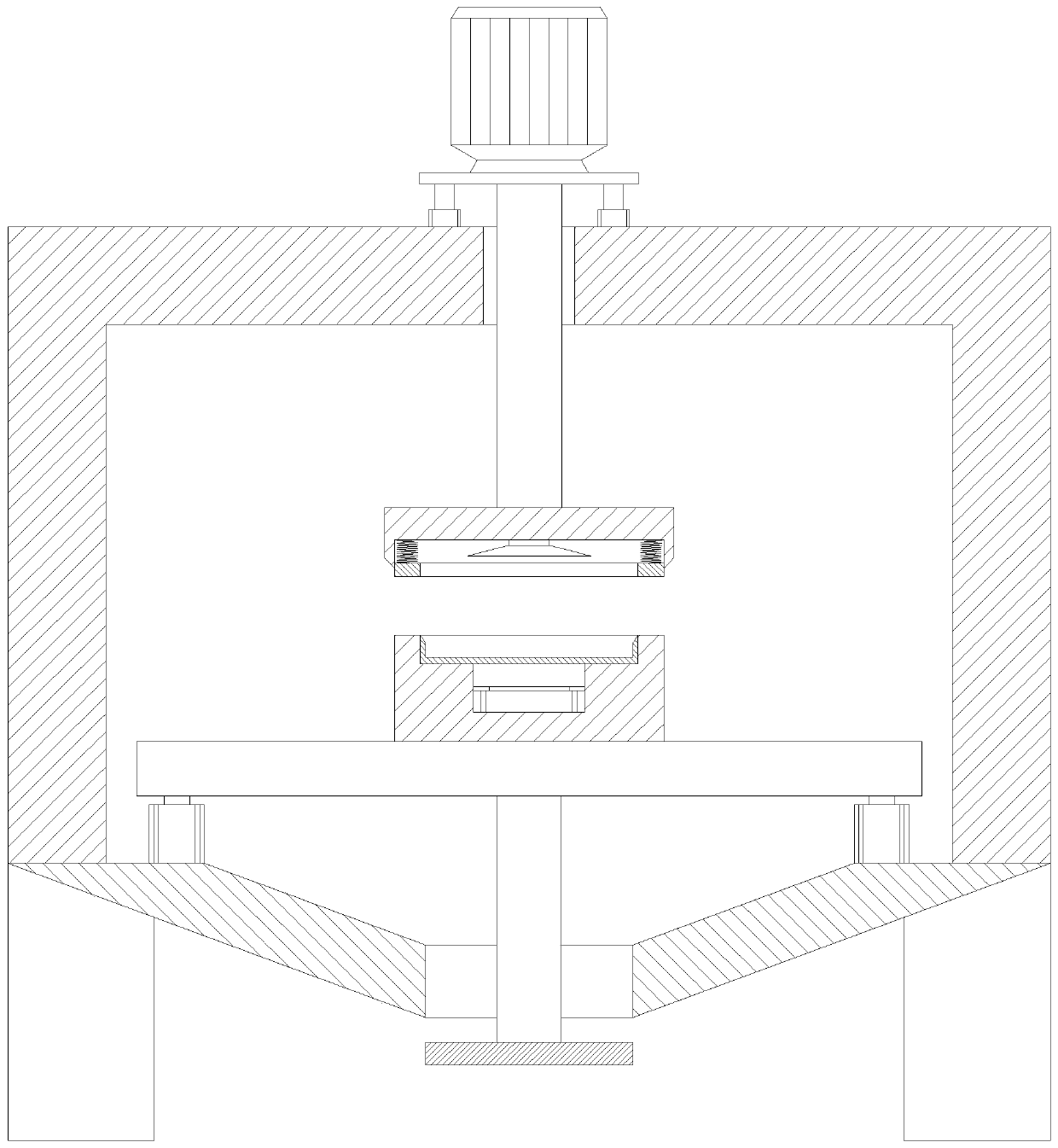

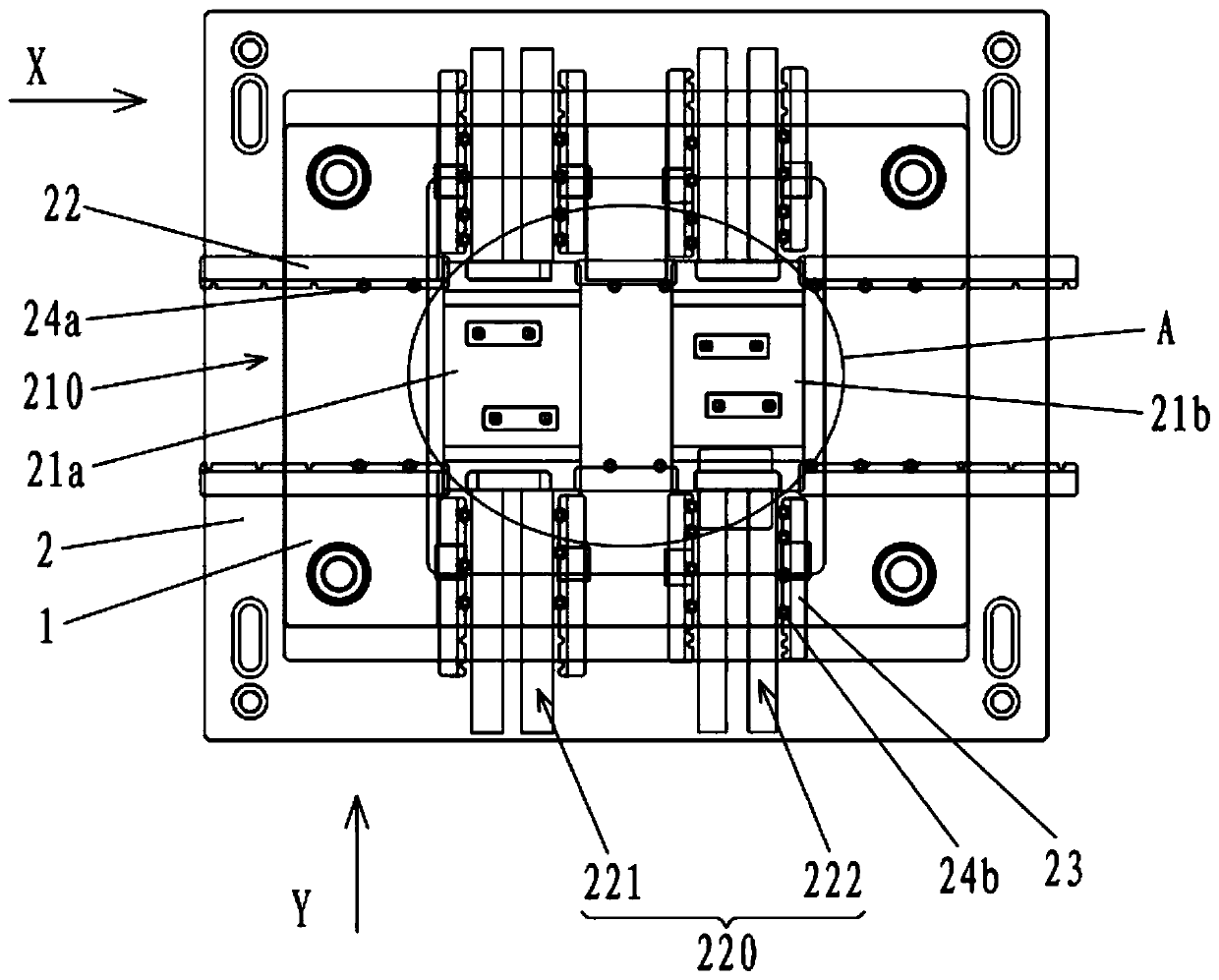

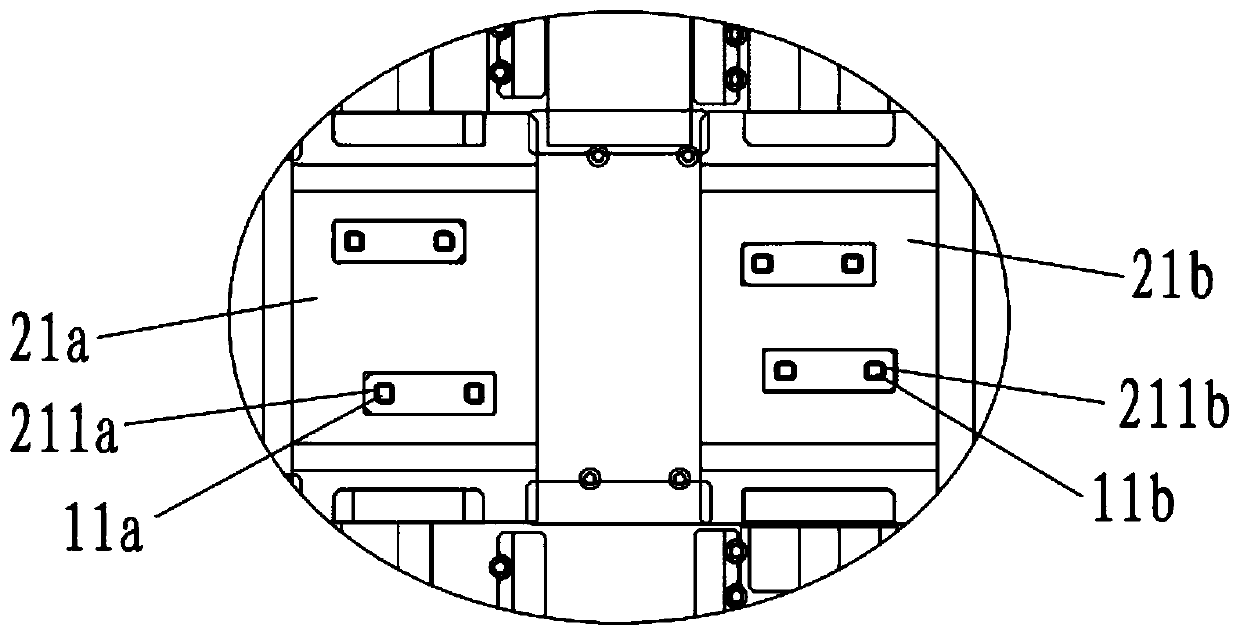

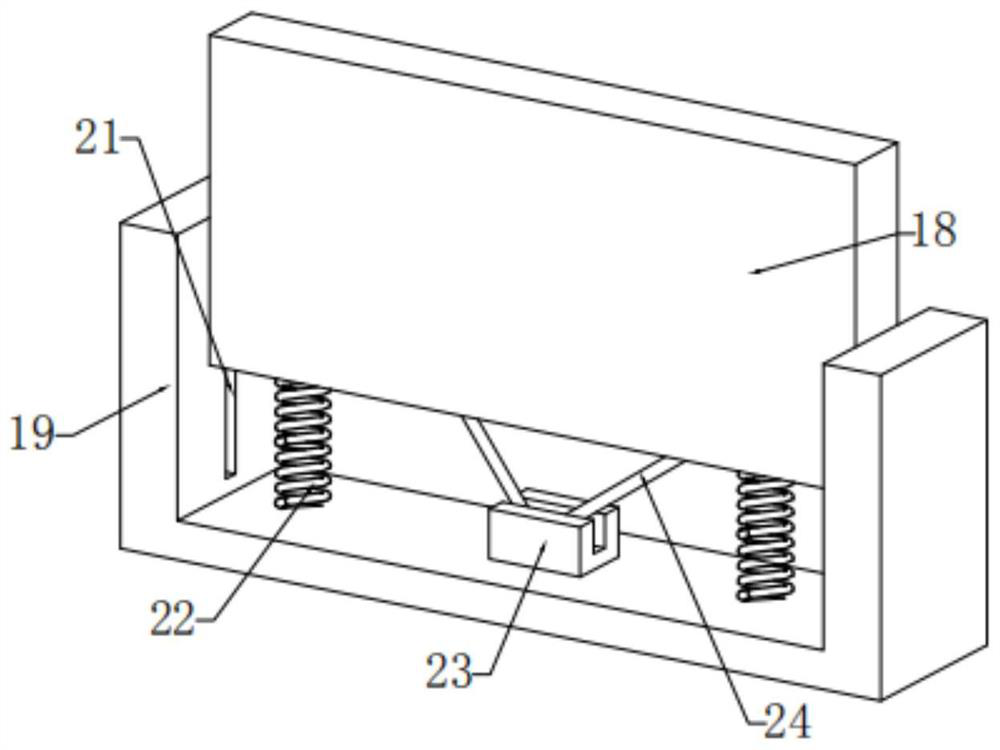

Automatic alignment correction mechanism of COF punching die

ActiveCN109895184ALow machining accuracy requirementsSimplify debugging difficultyMetal working apparatusPunchingReciprocating motion

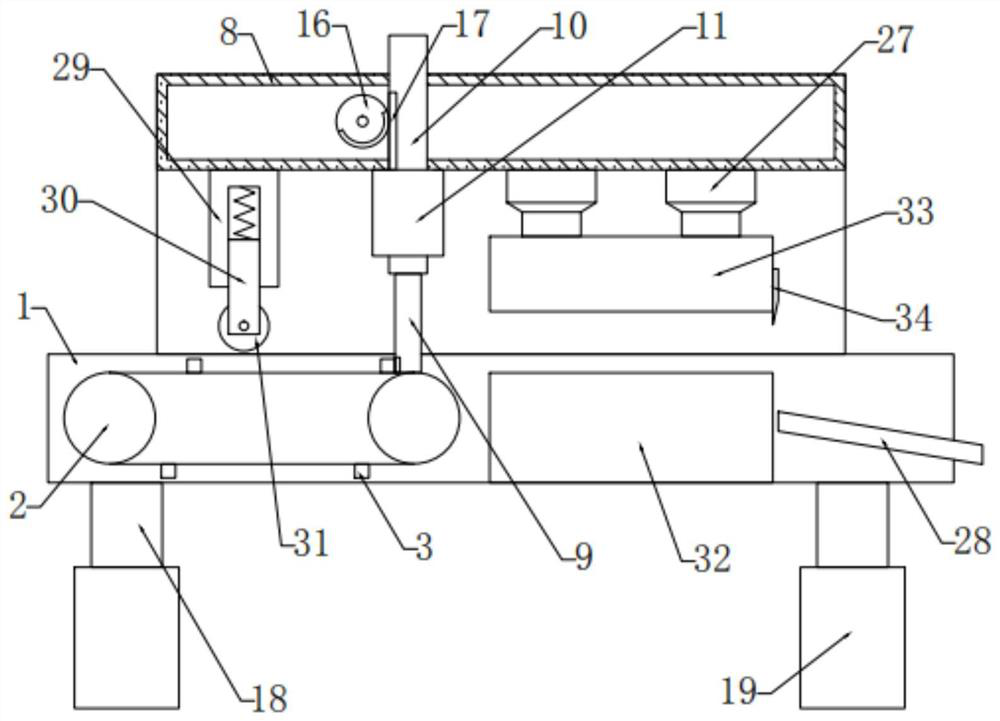

The invention discloses an automatic alignment correction mechanism of COF punching. The automatic alignment correction mechanism of the COF punching comprises a mold correction platform unit and a visual camera alignment unit, wherein the mold correction platform unit comprises an XYZ axis correction assembly, the COF punching is installed on the XYZ axis correction assembly and is driven by theXYZ axis correction assembly to do reciprocating motion along the X axis, the Y axis and / or the Z-axis, the XYZ axis correction assembly and the visual camera alignment unit are installed on a rack correspondingly, and the visual camera alignment unit moves to or moves apart from a position of photographing a COF coiled material in the COF punching under the driving of a movement driving assembly.According to the automatic alignment correction mechanism, the precision of a COF punching product can be improved, the mold correction platform unit and the visual camera alignment unit are used forcarrying out calibration on the relative positions of the COF punching and the COF coiled material, and the precision of the COF punching product is improved.

Owner:SHENZHEN COMWIN AUTOMATION TECH

Secondary punching wheel cover forming punching mold

The invention relates to a secondary punching wheel cover forming punching mold in the field of stamping molds. The upper portion of a lower mold base is connected with a lower mold core, and the lower portion of an upper mold base is connected with an upper mold core. Four corners of the lower mold base are symmetrically provided with guide column seats and guide columns and matched with self-lubricating sliding guide seats of the upper mold base. Upper and lower mold hard limiting and secondary limiting blocks are arranged beside the guide column seats and the self-lubricating sliding guide seats, the lower mold base is provided with at least one rotating press plate, the rotating press plate is connected with a sliding block, and the sliding block is connected with a sliding block limiting rod and a limiting ring. The upper mold base and the lower mold base are provided with guide rod air cylinders, two sides of the lower mold core are provided with air cylinders, piston rods of the air cylinders are connected with the sliding block, one side of the sliding block is provided with the sliding block limiting rod and the limiting ring, and sliding block press plates arranged symmetrically are arranged at two ends. The secondary punching wheel cover forming punching mold has the advantages of being high in product punching accuracy, free of splitting and shrinkage and the like.

Owner:NANTONG CHAODA EQUIP CO LTD

A punching device for rubber seals

ActiveCN110883859BReduce deformationHigh punching precisionMetal working apparatusPunchingStructural engineering

The invention discloses a punching device for a rubber seal, comprising a frame, a workbench is installed inside the frame, a closing plate is installed on the lower part of the workbench, and a discharge port is opened at the bottom of the frame , the first electric cylinder is installed in the frame, the output end of the first electric cylinder is connected with the bottom of the workbench, and the first electric cylinder drives the closing plate to close or open the discharge The upper part of the workbench is equipped with a lower punching assembly, the upper part of the frame is equipped with an upper punching assembly, and the upper punching assembly works with the lower punching assembly. The punching assembly and the lower punching assembly, and through the mutual cooperation of the upper punching assembly and the lower punching assembly, the required rubber seal is punched out, which reduces the deformation of the rubber seal during punching and improves the punching of the rubber seal. Cutting accuracy improves the quality of the product.

Owner:利辛县宝隆橡塑密封件有限责任公司

Glue film punching and attaching device

InactiveCN111452386AReduce manufacturing costIncrease the level of automationMetal working apparatusPunchingEngineering

The invention discloses a glue film punching and attaching device. The device comprises an upper die and a lower die, wherein the upper die is provided with a punch, the lower die is provided with anX-axis feed channel and a Y-axis feed channel, the X-axis feed channel is arranged below the Y-axis feed channel, the intersection of the X-axis feed channel and the Y-axis feed channel is provided with a support plate, and the support plate is provided with a notch matched with the punch. According to the device, the die is provided with two feed channels of metal workpieces and glue films, so that glue film punching and attaching operation can be realized in the same die, the continuous production is achieved, the production efficiency is improved, the manpower consumption is reduced, and the die manufacturing cost is lowered.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Punching device of rubber belt

The invention discloses a punching device of a rubber belt. The punching device comprises a frame and a workbench and a controller arranged on the frame, the workbench is provided with a belt rotationmechanism and a belt punching mechanism, the belt rotation mechanism comprises a driving shaft which is driven by a servo motor A to rotate and a tensile shaft which is arranged on a horizontal guiderail and driven by a servo motor B to move along the horizontal guide rail, the belt punching mechanism comprises a recess die, a deflector, a punch die, a punch die fixed plate and a linear servo motor, the frame is further provided with an induction grating for safety protection, and the servo motor A, the servo motor B, the linear servo motor and the induction grating are all in communicationconnection with the controller. The servo motors replace cylinders and hydraulic cylinders, the stroke is more stable, control is more convenient, the punching precision and efficiency are higher, andnoise and the cost are lower.

Owner:安徽中鼎智能科技有限公司

Coil stock dual-pressure automatic punching all-in-one machine

PendingCN111844218APunching realizationRealize automatic feedingMetal working apparatusElectric machineryStructural engineering

The invention discloses a coil stock dual-pressure automatic punching all-in-one machine, and relates to the technical field of punching. The coil stock dual-pressure automatic punching all-in-one machine comprises a rack, a coil stock feeding device, a dual-pressure punching device, a dual-clamping carrying device, a cutting device and an LPF controller are fixedly arranged above the rack, and the coil stock fe device, the dual-pressure punching device and the cutting device are sequentially arranged from left to right in a separated manner; the dual-pressure punching device comprises a punching frame, punching dies, punching motors and lifters; the two punching dies are arranged in a left-right separated manner, each punching die comprises an upper die and a lower die, the two punching motors and the two lifters are arranged in a left-right separated manner, the punching frame and the lower dies are fixedly arranged at the upper end of the rack, the punching motors and the lifters are fixedly arranged at the upper end of the punching frame, and the punching motors correspondingly drive the upper dies to vertically move through the lifters; the LPF controller correspondingly controls the coil stock feeding device, the punching motors, the dual-clamping carrying device and the cutting device to work; and the punching precision is higher, and the efficiency is higher.

Owner:深圳市欣荣自动化智能设备有限公司

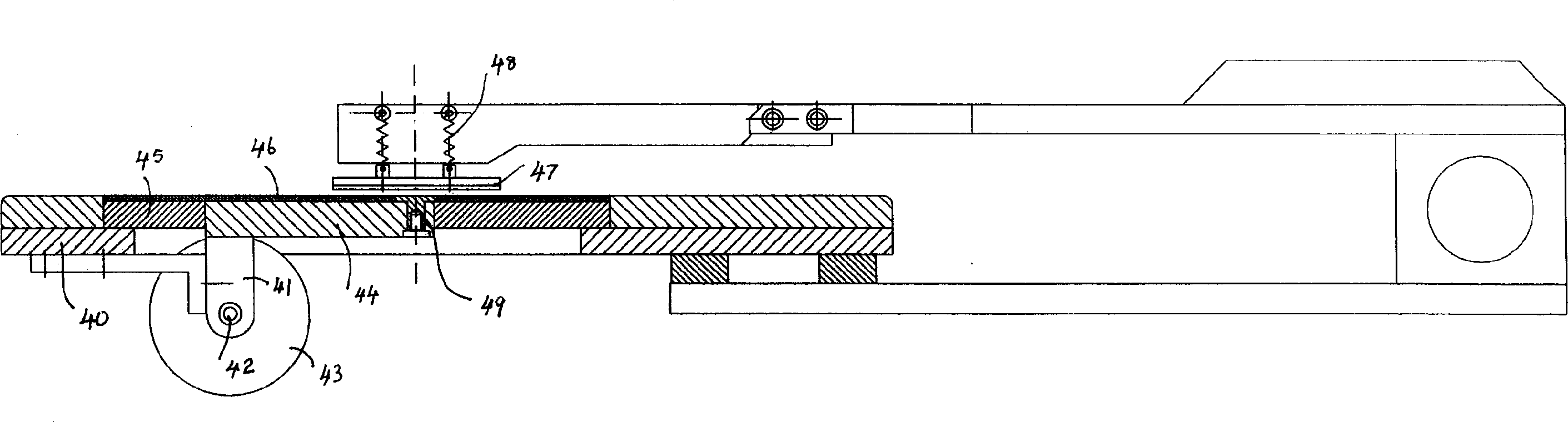

Automatic alignment bar shearing top knife component

InactiveCN102139492AReduce punching deviationHigh punching precisionMetal working apparatusPunchingEngineering

The technical scheme of the invention provides an automatic alignment bar shearing top knife component. The top knife component comprises a top knife fixing seat; a top knife locating block is arranged on the top knife fixing seat; a bar shearing top knife is fixed on the top knife fixing seat; both sides of the bar shearing top knife are compressed tightly by a top knife depression bar; a stripper plate is arranged under the top knife locating block; a material discharging mould insert and a material discharging block are arranged at the bottom of the stripper plate; a concave die and a material receiving block are respectively arranged under the material discharging mould insert and the material discharging block; the concave die and the material receiving block are arranged on the top of a die holder; a locating pin is arranged in the die holder by a locating pin seat; the concave die is fixed by a concave die locating block; the top knife component is characterized in that a guide locating block with the length of 1 to 2mm and thickness of 0.6 to 1mm is arranged at the front end of a knife edge of the bar shearing top knife. In the top knife component, the guide locating block is arranged at the front end of the knife edge of the top knife; when the die is not completely closed, the guide locating block at the front end of the knife edge of the top knife cuts into the frame and automatically aligns so as to achieve the purposes of reducing punching deviation and increasing punching precision.

Owner:NANTONG SHANGMING PRECISION MOLD

Method for manufacturing camera support

ActiveCN111421748ARealize continuous batch manufacturingHigh punching precisionCoatingsInjection mouldingMechanical engineering

The invention relates to a method for manufacturing a camera support. The method comprises the following steps that 1, a material strip containing the camera support and embedded with a steel sheet ismanufactured through stamping forming; and 2, the material strip is placed in an injection mold, and an insulating plastic body of the camera support and the embedded steel sheet are integrated through injection molding. According to the manufacturing method of the camera support, the production efficiency can be improved, and the production cost is reduced.

Owner:深圳市高塑达电子有限公司

Progressive die stamping process equipment for lithium battery heat-conducting fin

PendingCN111687285AHigh punching precisionImprove processing efficiencyMetal-working feeding devicesNon-rotating vibration suppressionStamping processEngineering

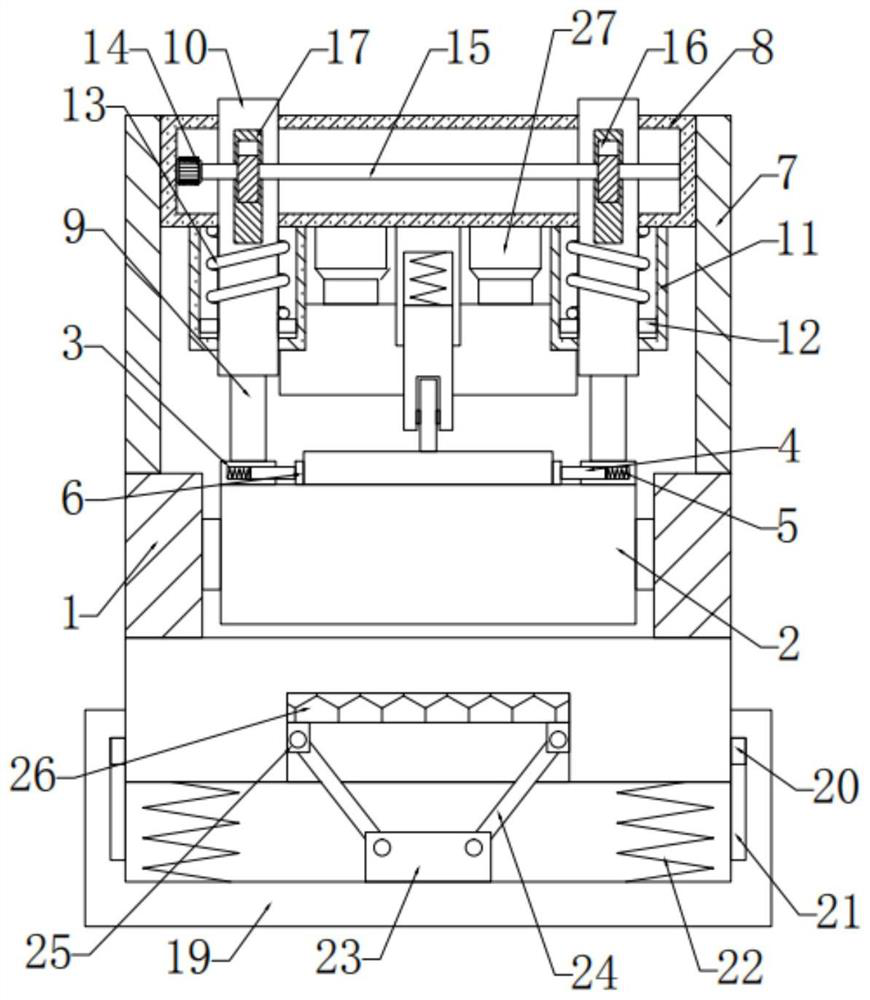

The invention relates to the technical field of lithium batteries, in particular to progressive die stamping process equipment for a lithium battery heat-conducting fin. The progressive die stamping process equipment comprises a workbench, a conveying belt is fixedly connected to the inner side of the workbench, a stamping mechanism is arranged on the right side of the conveying belt, a positioning mechanism is arranged on the upper side of the conveying belt, and a shock absorption base is arranged at the bottom of the workbench. According to the progressive die stamping process equipment forthe lithium battery heat-conducting fin, the positioning mechanism is arranged, a baffle plate is utilized to make contact with a limiting block arranged on the outer side of the conveying belt, so that the length of the heat-conducting fin entering the stamping mechanism is kept stable, accurate positioning is achieved, and the punching precision is improved; the stamping mechanism is arranged,and continuous machining can be carried out under cooperation of the positioning mechanism and the conveying belt, so that the machining efficiency of the heat-conducting fin is greatly improved; anda clamping plate is arranged, and fixing the heat-conducting fin can be carried out, so that the stability of the heat-conducting fin in the feeding process is enhanced, and the stability of the equipment during operation is improved.

Owner:迪克斯汽车电器(上海)有限公司

Die-cutting mold for easy-tear film on polypropylene infusion bag

ActiveCN105171844BCompact structureHigh punching precisionMetal working apparatusPunchingEngineering

Owner:SICHUAN KELUN PHARMA CO LTD

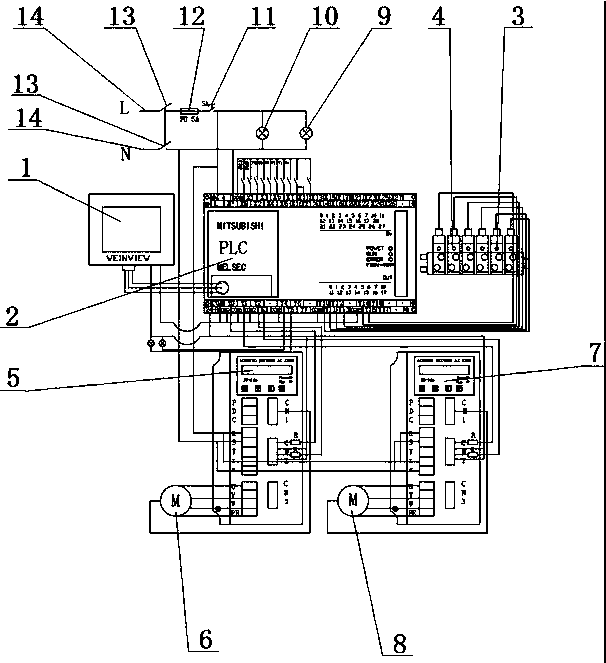

Steel door frame door hinge hole numerical control positioning electric control device

PendingCN108181876AThe structure is novel and uniqueImprove punching efficiencyProgramme controlComputer controlNumerical controlProgrammable logic controller

The invention relates to a steel door frame door hinge hole numerical control positioning electric control device. The device is composed of a Weinview man-machine touch screen, a PLC (Programmable Logic Controller), a right hinge positioning solenoid valve, a right hinge positioning solenoid valve, a servo motor driver A, a servo motor A, a servo motor driver B, a servo motor B, a heat dissipation fan, a power source indicator lamp, a power source switch, a fuse, a short-circuiting device and a power source cord. With the device of the present invention adopted, the numerical value of a doorpanel unloading height is needed to be inputted into a program in the control panel of the PLC, and the positioning pins of a left positioning mechanism and a right positioning mechanism controlled bythe device of the present invention will automatically move to corresponding positions; an operating button is pressed, and operation can be completed; and therefore, the stamping and cutting efficiency of a plurality of metal plate components of the same size can be improved, operators can be reduced, errors in an operation process can be reduced, the stamping and cutting accuracy of products can be improved, and dimensional accuracy can be improved. With the device of the present invention adopted, operation can be performed with no professionals required, and only one person is just required to complete the stamping and cutting of long metal plate components.

Owner:广西富信门业有限公司

Punching equipment for mounting hole of aluminum frame lining strip

The invention belongs to the field of automobile part machining devices, and provides punching equipment for a mounting hole of an aluminum frame lining strip. The punching equipment comprises a rack,a positioning assembly, a support block, a first clamping piece, a punching assembly and a second clamping block, wherein the positioning assembly is movably arranged on the rack; the support block is arranged on the rack; the first clamping piece is arranged on the support block, a first clamping block is arranged at the lower end of the first clamping piece, and the first clamping block is located above the supporting block; the punching assembly is movably arranged on the rack, and a punching cutter is arranged at the front end of the punching assembly; ans the second clamping piece is movably arranged at the front end of the punching assembly, a second clamping block is arranged on the second clamping piece,and is located on the side of the support block, and the punching cutter movably penetrates through the second clamping piece and the second clamping block. Compared with the prior art, the punching equipment has the advantages that the aluminum frame cannot shake in a punchingprocess, the punching precision is improved, manual punching is not needed, and the punching efficiency is improved.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Metal part processing method and metal part

The invention relates to the technical field of metal processing, and particularly discloses a metal part processing method and a metal part. The metal part processing method comprises the steps thatS1, a die-casting die is adopted, a metal blank piece with two oppositely-arranged false lugs is formed in a die-casting mode, and positioning holes are formed in the side faces, away from each other,of the two false lugs correspondingly; and S2, a punching die is adopted, after positioning is carried out by means of the two positioning holes of the metal blank piece in S1, shape punching is carried out on the metal blank piece, and the two false lugs are punched while the shape punching is carried out, so that the metal part is obtained. According to the metal part processing method and themetal part, a processing process of the metal part can be simplified, the processing difficulty is reduced, and the processing precision is guaranteed.

Owner:华孚精密科技(马鞍山)有限公司

Cap pressing head with negative pressure fixing function

InactiveCN107311088AHigh punching precisionImprove pass rateFlanged caps applicationEngineeringMechanical engineering

The invention relates to a cap pressing head with a negative pressure fixing function. The cap pressing head comprises an air cylinder, an upper fixing plate, a lower fixing plate and stand column. The air cylinder is mounted on the upper fixing plate. The two ends of the stand column are mounted on the upper fixing plate and the lower fixing plate correspondingly. A piston rod is arranged in the air cylinder. The tail end of the piston rod is connected with a connector. The bottom end of the connector is connected with a cap pressing head body. The stand column is provided with a center through hole in the axial direction. The piston rod, the connector and the cap pressing head body are located in the through hole of the stand column. The cap pressing head body is provided with an L-shaped hole, and a connecting device is arranged on one side of the cap pressing head for being connected with an air pipe. The bottom end of the cap pressing head body is provided with a groove. The cap pressing head achieves automatic cap pressing through the reasonable structure design and is high in cap pressing precision and yield, the production efficiency is improved, and the production cost is reduced.

Owner:江苏首达机械有限公司

Stamping production line of door pillar plate workpiece and its mechanical arm

ActiveCN104259295BHigh degree of automationImprove efficiencyMetal-working feeding devicesPositioning devicesProduction linePunching

Disclosed are a punching line of automobile door pillar and panel workpieces and mechanical arms for the punching line. A plurality of presses (2) are linearly arranged at equal intervals. Each punching die assembly (3) is provided with an outer plate cavity and an inner plate cavity; a transverse rod (4) crosses the whole punching line; the transverse rod (4) can be driven to move up and down by a vertical drive mechanism; the transverse rod (4) is sleeved with a sliding sleeve (5); the sliding sleeve (5) can be driven to move side to side along the transverse rod (4) by a transverse drive mechanism; the sliding sleeve (5) is provided with the mechanical arms (6) on the left and right sides of each press (2); the mechanical arms are used for gripping and moving automobile door pillar and panel outer plates and inner plates (1) at respective positions; a turnplate (8) on which a plurality of bed plates (9) are evenly arranged is disposed at the left end; an inner plates and outer plates holder (10) is disposed on each bed plate (9). The punching line and the mechanical arms have the advantages that automatic punching level of automobile door pillars and panels is increased greatly, and punching efficiency of the automobile door pillars and panels is greatly improved.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

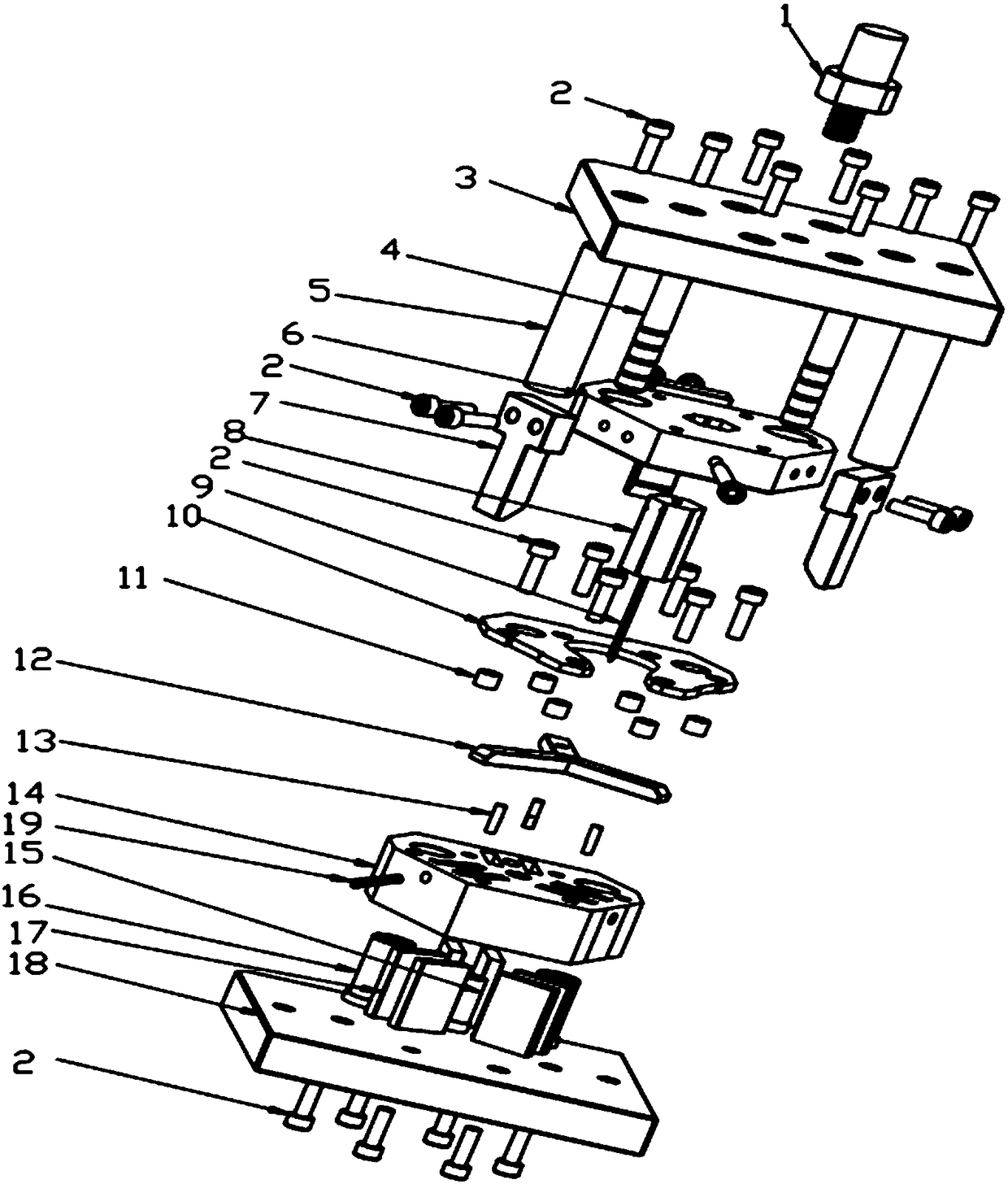

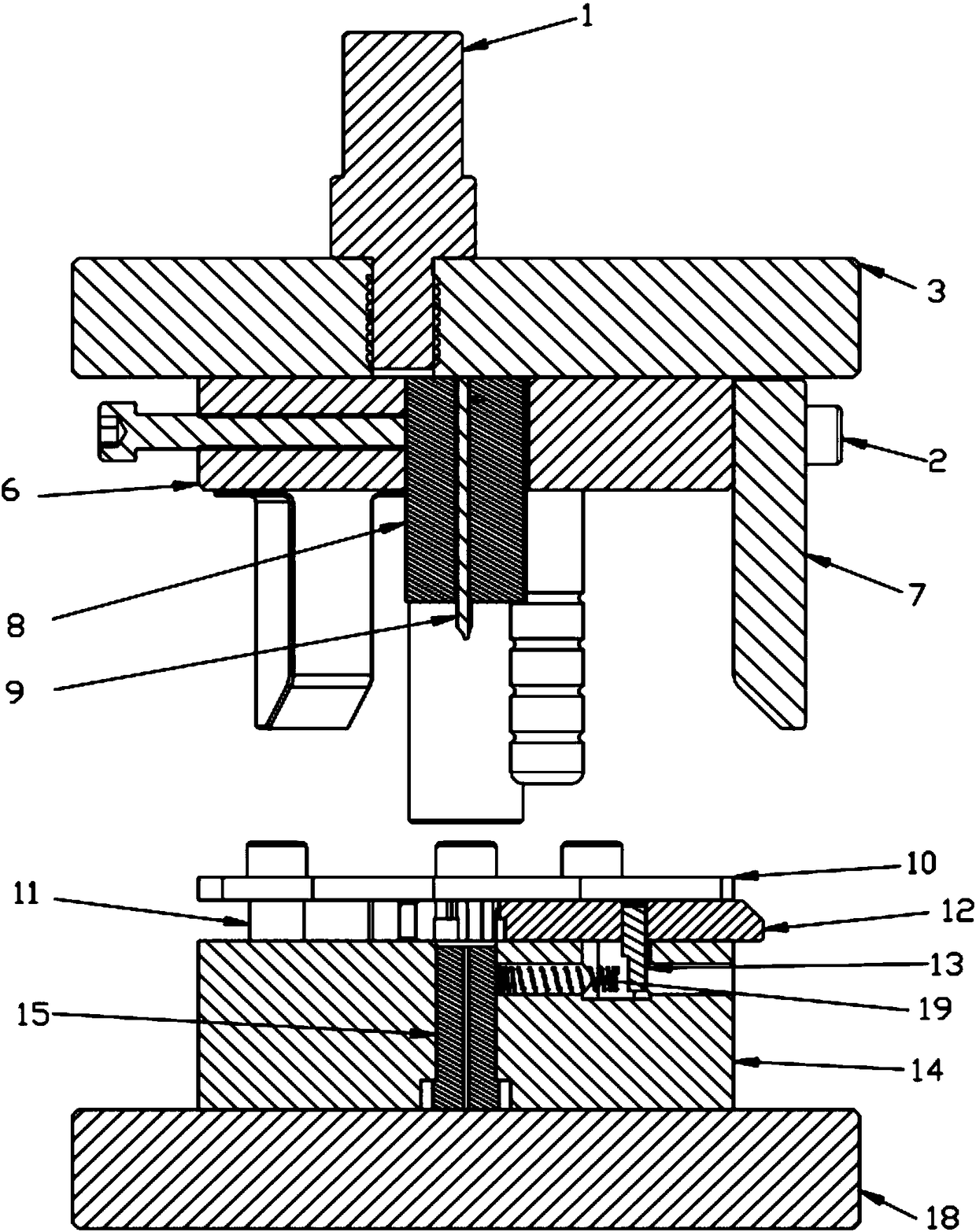

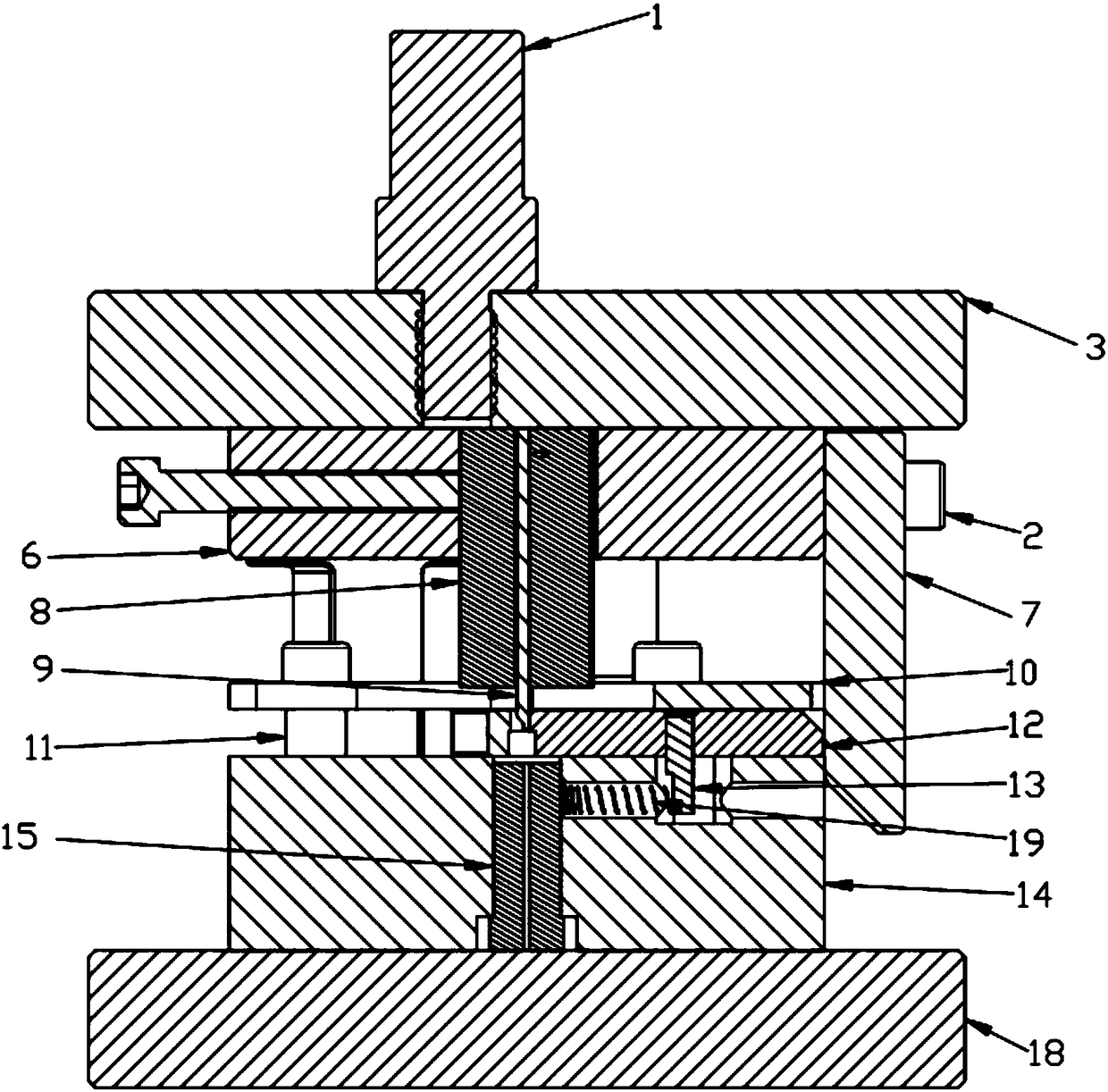

A punching equipment

ActiveCN106216466BExquisite structureEasy to operateShaping toolsMetal-working feeding devicesMaterials scienceNotching

The invention discloses notching equipment which comprises an upper mold plate (3) and a lower mold plate (18). The upper mold plate (3) is located over the lower mold plate (18). An upper mold base (6) is arranged on the lower surface of the upper mold plate (3). A tool apron (8) is assembled in the upper mold base (6). A tool (9) is assembled in the tool apron (8). A lower mold base (14) is arranged on the lower mold plate (18). A fixed mold (15) is assembled in the lower mold base (14). The fixed mold (15) is located under the tool apron (8). A through hole is formed in the fixed mold (15). A cover plate (10) is arranged on the lower mold base (14). A clamping device is assembled between the cover plate (10) and the lower mold base (14). The clamping center of the clamping device is located over the fixed mold (15). According to the technical scheme, the notching equipment has the advantages of being ingenious in structure, easy to operate, high in working efficiency, high in notching precision and the like.

Owner:渭南木王智能科技股份有限公司

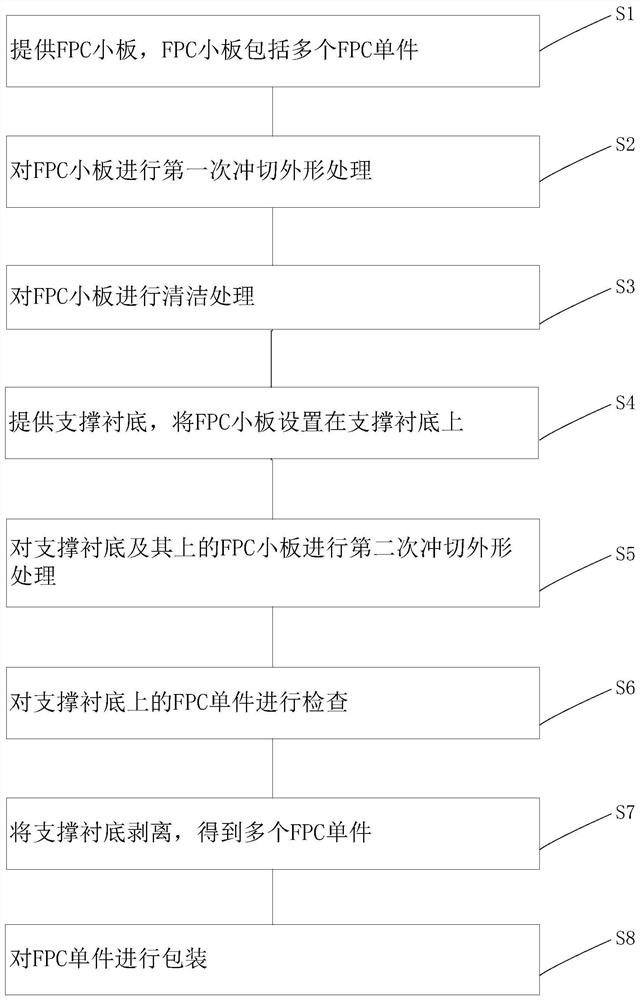

A kind of manufacturing method of fpc

ActiveCN111770634BAvoid wrinklesImprove yieldCircuit board tools positioningPunchingManufacturing engineering

The invention provides a method for manufacturing an FPC, which includes: providing an FPC small board, and at least one FPC single piece is arranged on the FPC small board; performing a first punching shape treatment on the FPC small board; and cleaning the FPC small board ; Provide a supporting substrate, set the FPC small plate on the supporting substrate; carry out the second punching shape processing on the supporting substrate and the FPC small plate on it; inspect the FPC single piece on the supporting substrate; The support substrate is peeled off to obtain a single piece of FPC. Compared with the prior art, the present invention disposes the FPC small board on the supporting substrate before performing the second punching shape processing on the FPC small board, and the FPC small board is supported by the supporting substrate to prevent the FPC small board. Wrinkling or warping improves the punching accuracy, so that the FPC small plate can obtain a flat FPC single piece after the second punching shape treatment, which effectively improves the yield of the FPC single piece and reduces the occurrence of customer complaints. .

Owner:四川上达电子有限公司

High precision punching die

The invention discloses a high precision punching die. The high precision punching die comprises an upper die (1) and a lower die (2), wherein the upper die (1) and the lower die (2) are correspondingly arranged; the upper die (1) comprises an upper die seat (3), an upper padding plate (4) and a stripper plate (7) in sequence; the lower die (2) comprises a lower die plate (8), a lower padding plate (9) and a lower die seat (10) in sequence. The high precision punching die is characterized in that a feed trough (12) is formed in the surface of the lower die plate (8) in the length direction, and a plurality of horizontal rollers (14) perpendicular to the moving direction of a material belt are arranged in the feed trough (12) at equal intervals. The high precision punching die is high in punching precision.

Owner:SUZHOU HUICHENG PRECISION MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com