Automatic alignment correction mechanism of COF punching die

An automatic alignment and gold type technology, applied in metal processing and other directions, can solve problems such as failure to meet precision requirements, strict requirements for ratchet machining accuracy, and increased machine debugging requirements, so as to improve punching accuracy and reduce ratchet. Machining accuracy requirements, solving the effect of low punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

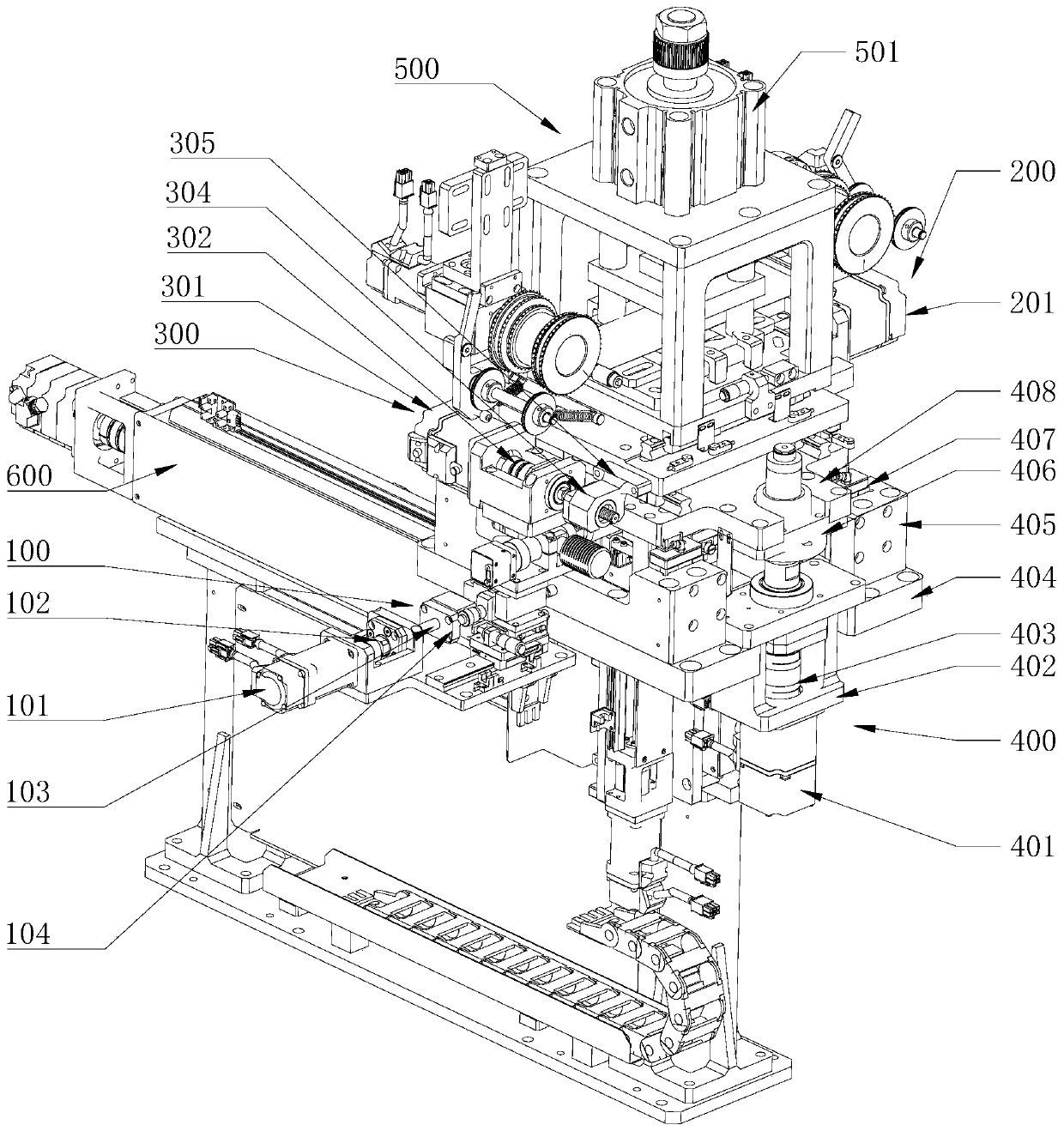

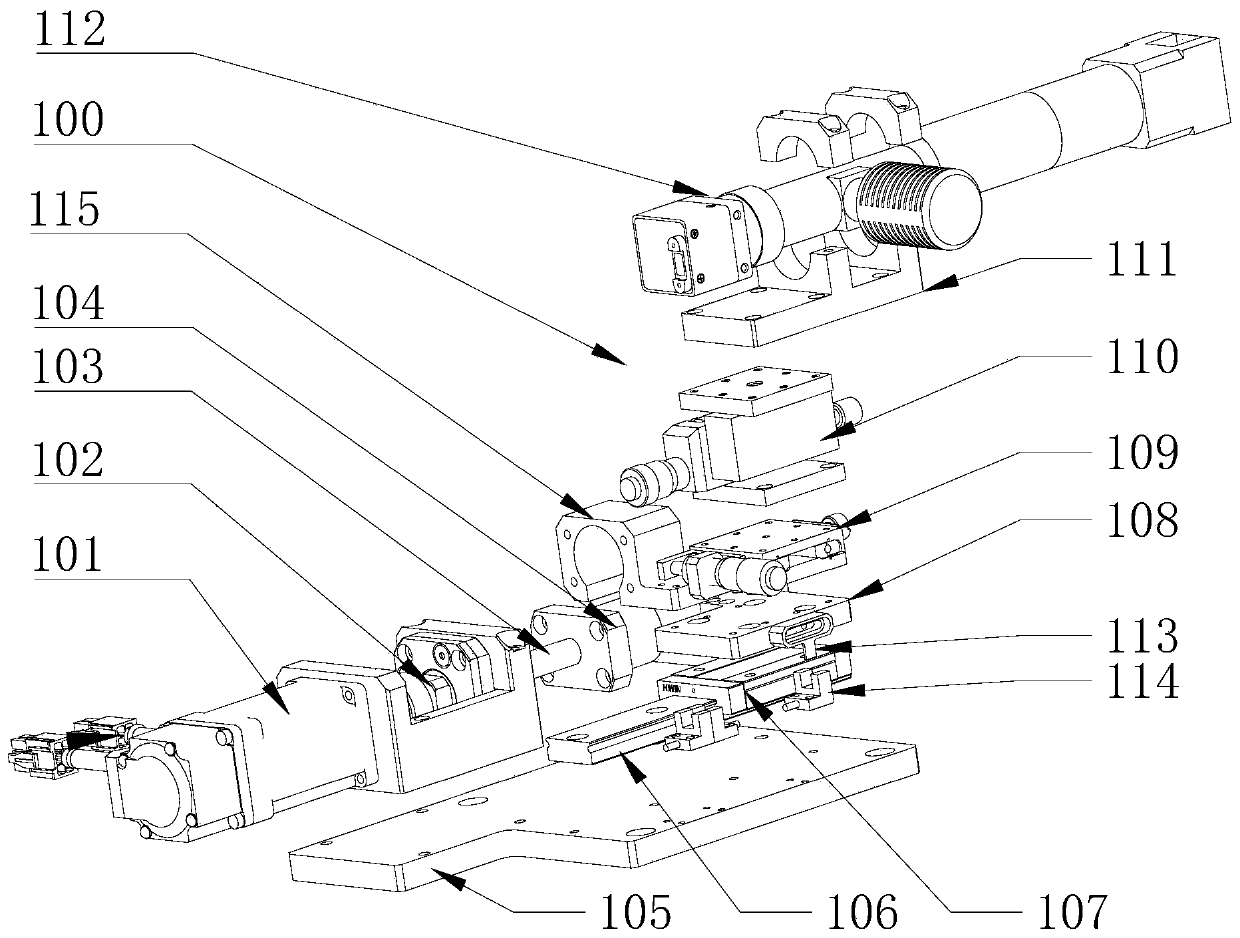

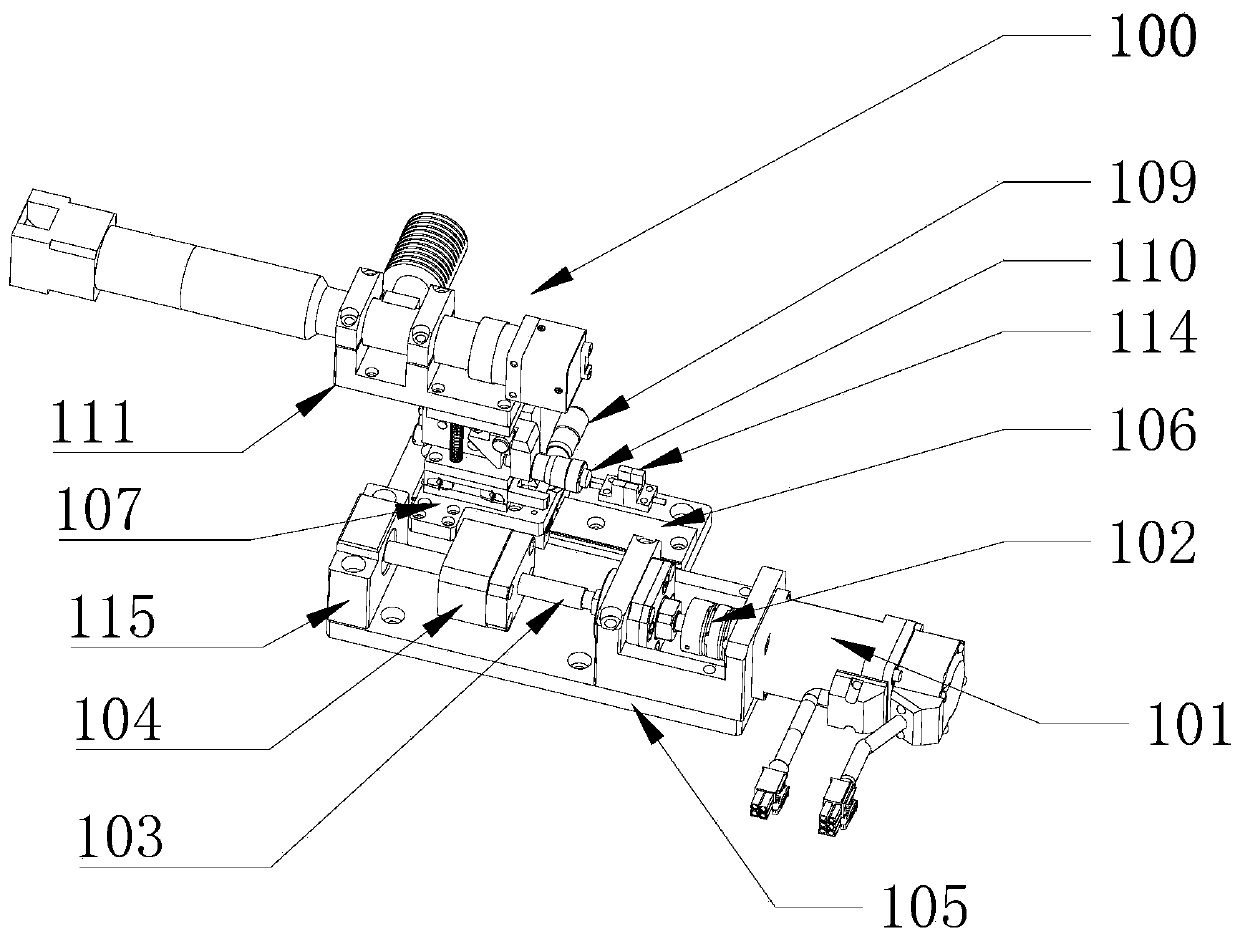

[0024] like figure 1 As shown, the COF die-cut gold mold 500 automatic alignment correction mechanism of the present invention includes a mold correction platform unit and a visual camera alignment unit 100, and the mold correction platform unit includes an XYZ axis correction component; On the XYZ axis correction assembly and under the drive of the XYZ axis correction assembly, it reciprocates along the X axis, Y axis and / or Z axis. The XYZ axis correction assembly and the visual camera alignment unit 100 are respectively installed on On the frame and the vision camera alignment unit 100 is driven by the motion drive assembly to move to or away from the position where the COF roll material located in the die-cut gold mold 500 is photographed, the vision camera alignment unit 100 The motion drive assembly is installed on the frame, the mold correction platform unit and the visual camera alignment unit 100 are arranged above the COF product retrieving manipulator 600, and the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com