Cylindrical workpiece end flat-milling and clamping device

A clamping device, cylindrical technology, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of axial dimension, flat thickness dimension symmetry and parallelism are difficult to meet requirements, and achieve a simple structure. , Easy clamping, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

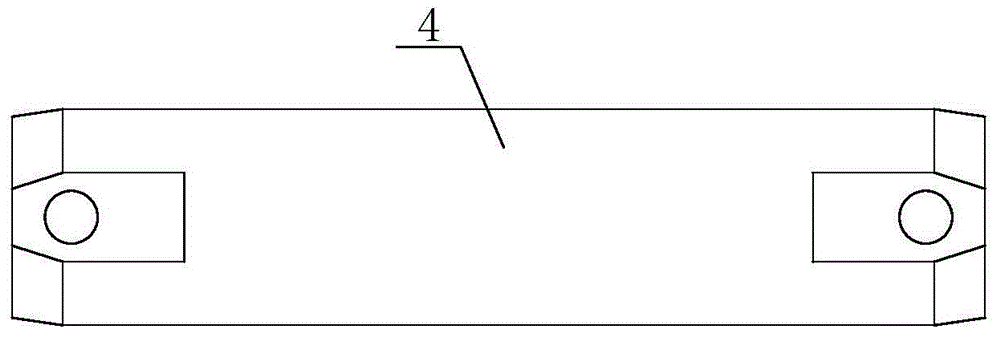

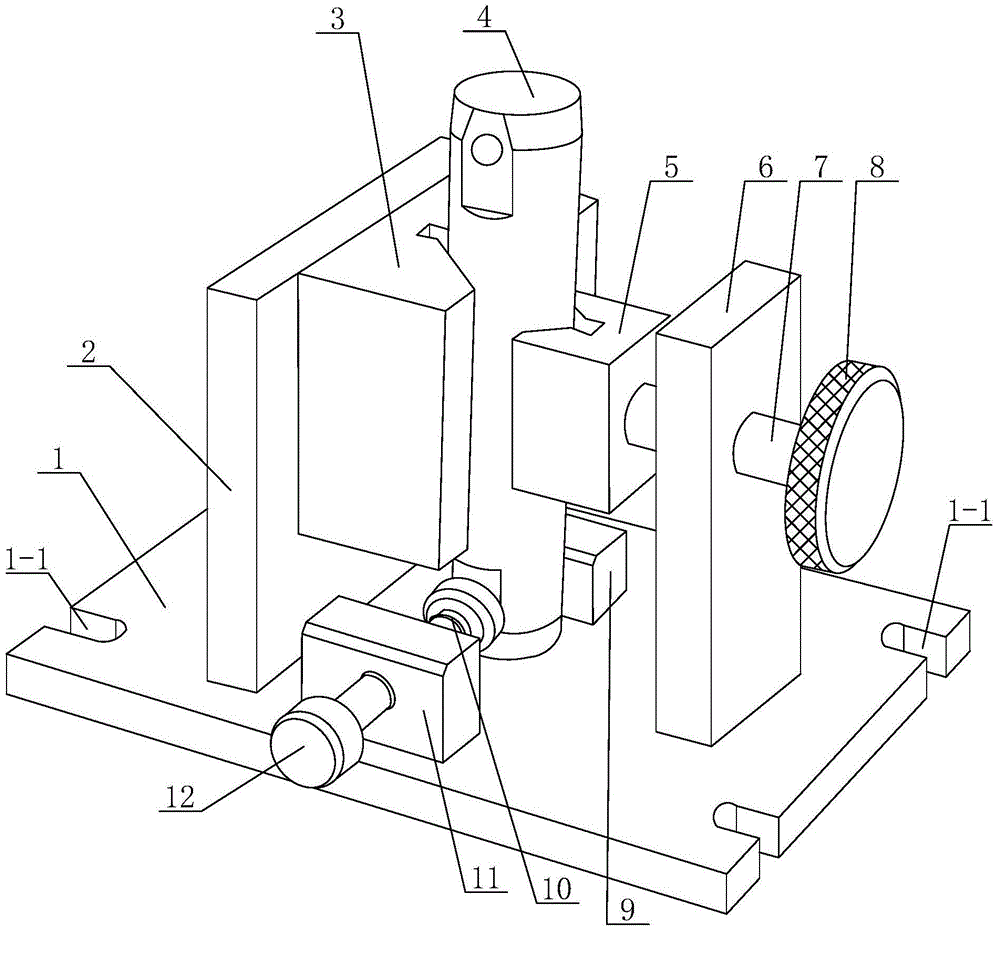

[0023] Such as figure 2 The shown clamping device for milling and flattening the end of a cylindrical workpiece includes a bottom plate 1 that acts as a fixed support, and a V-groove shim 3 and a V-groove indenter 5 that cooperate with each other to clamp the workpiece 4, The drive screw 7 for driving the V-shaped groove indenter 5 to compress the workpiece 4 and the positioning block 9 for positioning the workpiece 4 from the lower end; Plate two 6, one side of the vertical plate one 2 is fixedly provided with the V-shaped groove pad iron 3, the vertical plate two 6 is provided with the driving screw 7 through a threaded hole, and one end of the driving screw 7 is hinged There is the V-groove indenter 5, and the other end of the driving screw 7 is fixed with a circular handle 8, which is convenient for the operator to tighten or loosen the driving screw 7 by hand. The positioning block 9 and the support 11 are fixedly arranged on the upper side of the bottom plate 1 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com