Glue film punching and attaching device

A film, cutting and sticking technology, applied in metal processing and other directions, can solve the problems of low production efficiency, high mold manufacturing cost, and high labor consumption, and achieve the effect of improving production efficiency, reducing manufacturing cost, and improving the level of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

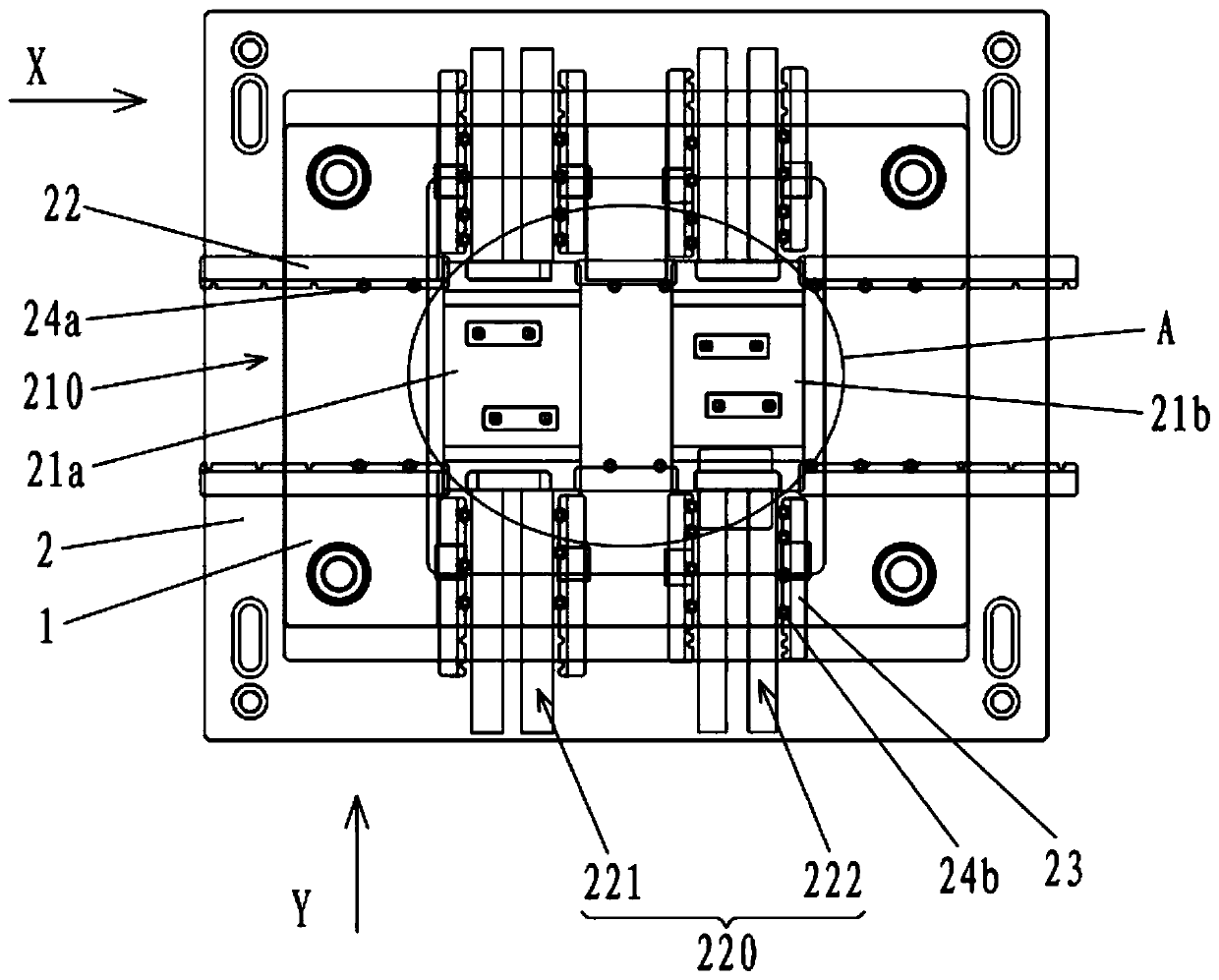

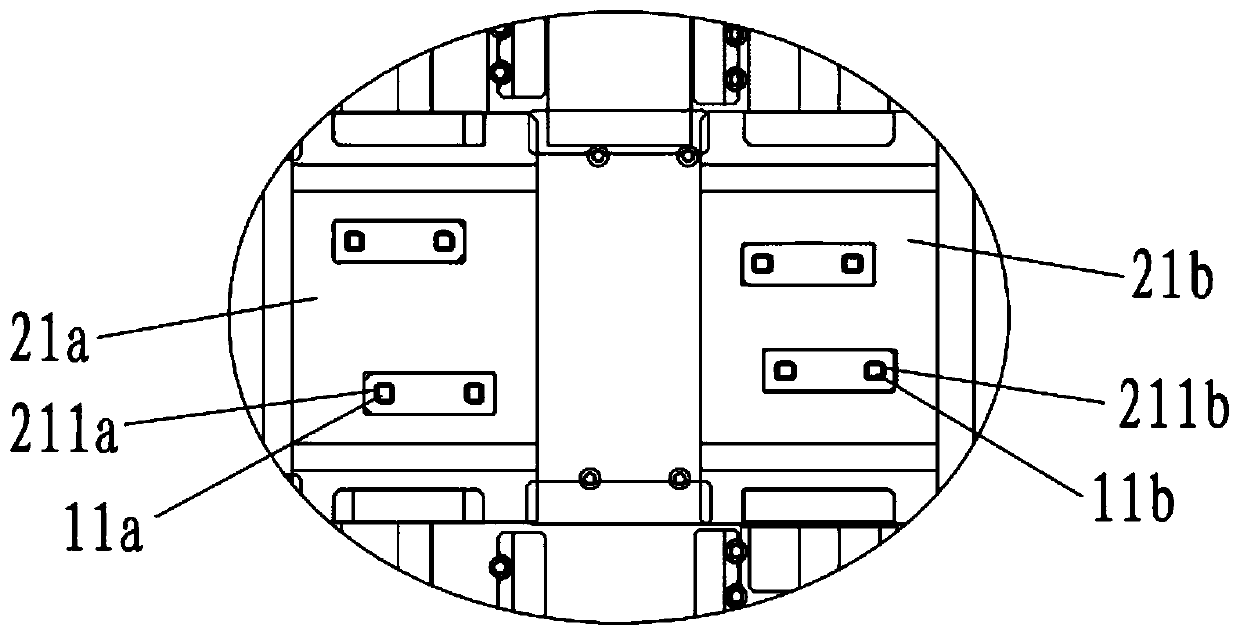

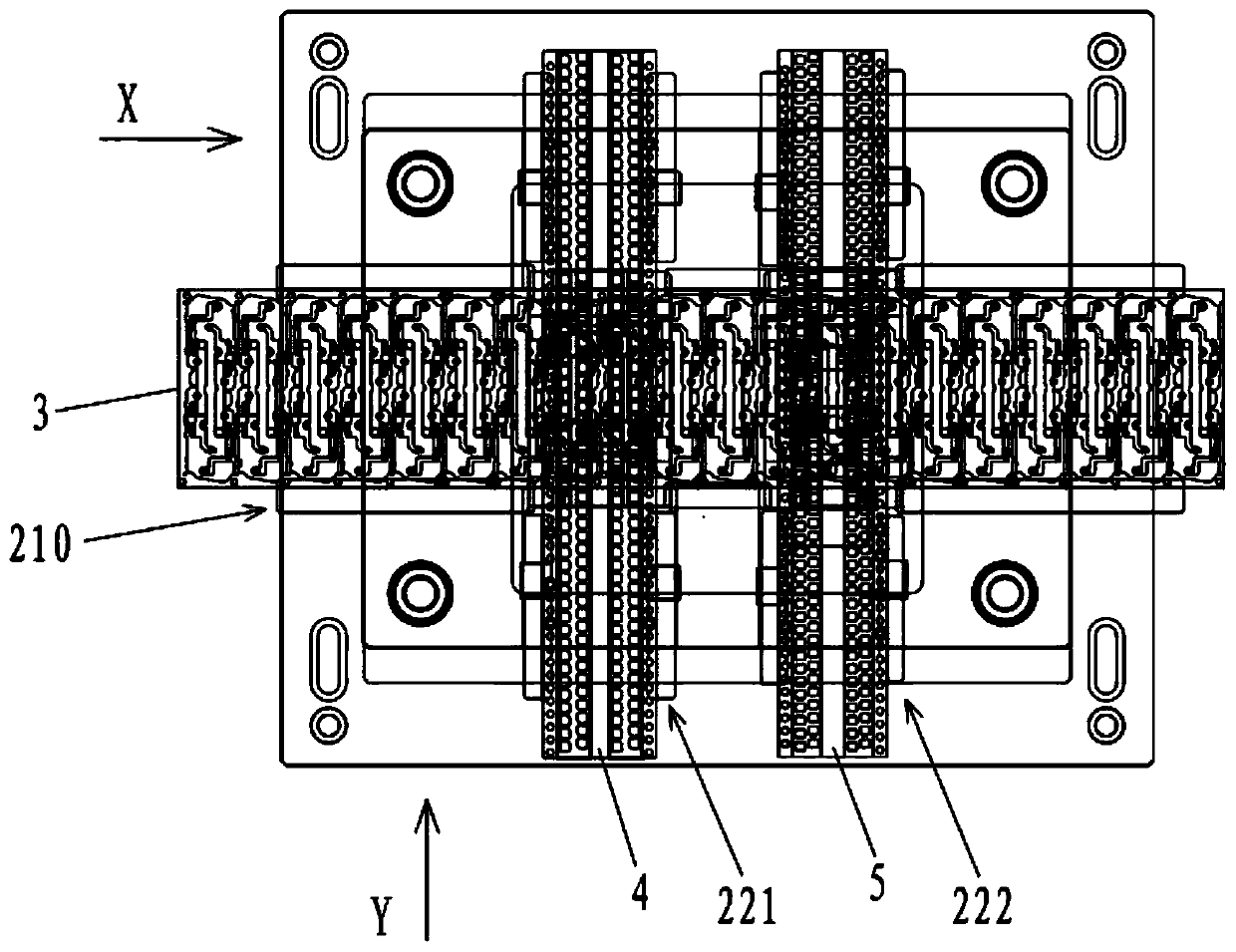

[0054]refer to Figure 1 to Figure 12 , film punching and mounting device, including an upper mold 1 and a lower mold 2, the upper mold 1 is provided with a punch;

[0055] The lower mold 2 is provided with an X-axis feed channel 210 and a Y-axis feed channel 220, and the X-axis feed channel 210 is arranged below the Y-axis feed channel 220;

[0056] A support plate is provided at the intersection of the X-axis feed channel 210 and the Y-axis feed channel 220 , and the support plate is provided with a cutout matched with the punch.

[0057] To further illustrate, the intersection point is the position of the intersection of the X-axis feed channel 210 and the Y-axis feed channel 220 in the top view of the device.

[0058] To further illustrate, the support plate is located above the X-axis feed channel 210 and below the Y-axis feed channel 220 , and the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com