Stamping production line of door pillar plate workpiece and its mechanical arm

A technology for door pillar panels and mechanical arms, which is applied to manipulators, claw arms, manufacturing tools, etc., can solve problems such as the degree of automation of operations, the difficulty in breaking through the quality of production efficiency, the difficulty in controlling the personal safety of operators, and the frequent occurrence of accidents, etc. Achieve the effect of improving the degree of punching automation and punching production efficiency, reducing punching operators, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

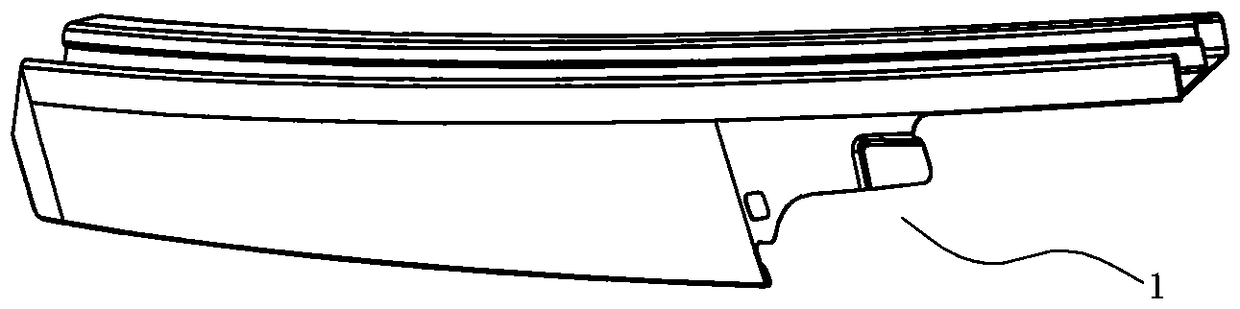

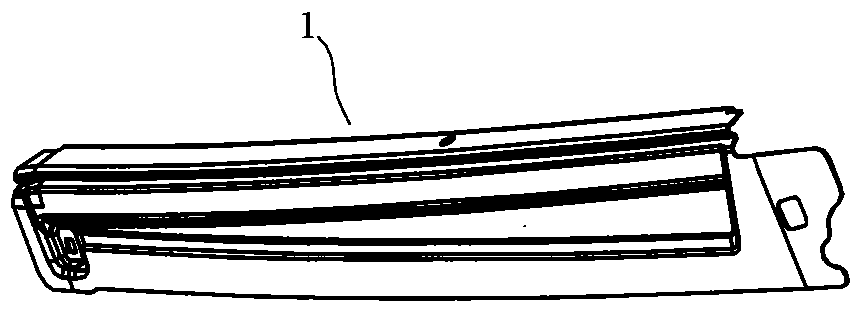

[0035] Below as figure 1 , figure 2 The rear door B-pillar outer panel and the rear door B-pillar inner panel workpiece 1 of a car shown are examples to describe the specific implementation of the present invention in detail.

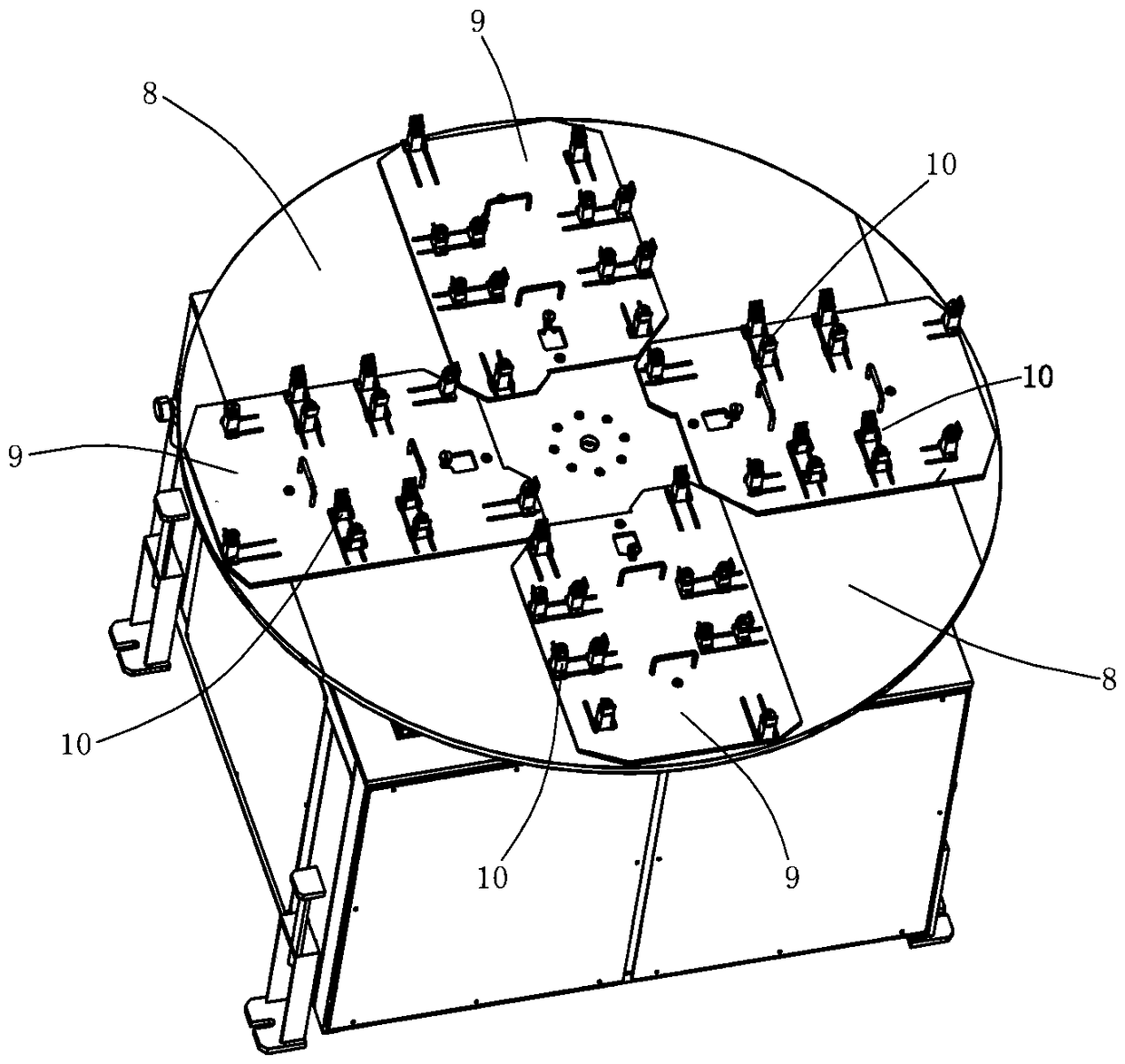

[0036]A kind of stamping production line of door column plate workpiece 1, such as Figure 4 As shown, it includes a plurality of presses 2, and the workpiece 1 is the outer panel of the A-pillar of the front door and the inner panel of the A-pillar of the front door, the outer panel of the B-pillar of the front door and the inner panel of the B-pillar of the front door, the outer panel of the B-pillar of the rear door and the inner panel of the B-pillar of the rear door , any combination of rear door C-pillar outer panel and rear door C-pillar inner panel, such as figure 1 , figure 2 The rear door B-pillar outer panel and the rear door B-pillar inner panel of a car shown; a plurality of presses 2 are arranged equidistantly along a straight line fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com