Punching device of rubber belt

A belt punching and rubber technology, applied in the mechanical field, can solve the problems of unstable air pressure, long punching time, high equipment cost, etc., and achieve the effects of high punching precision and efficiency, low noise and cost, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

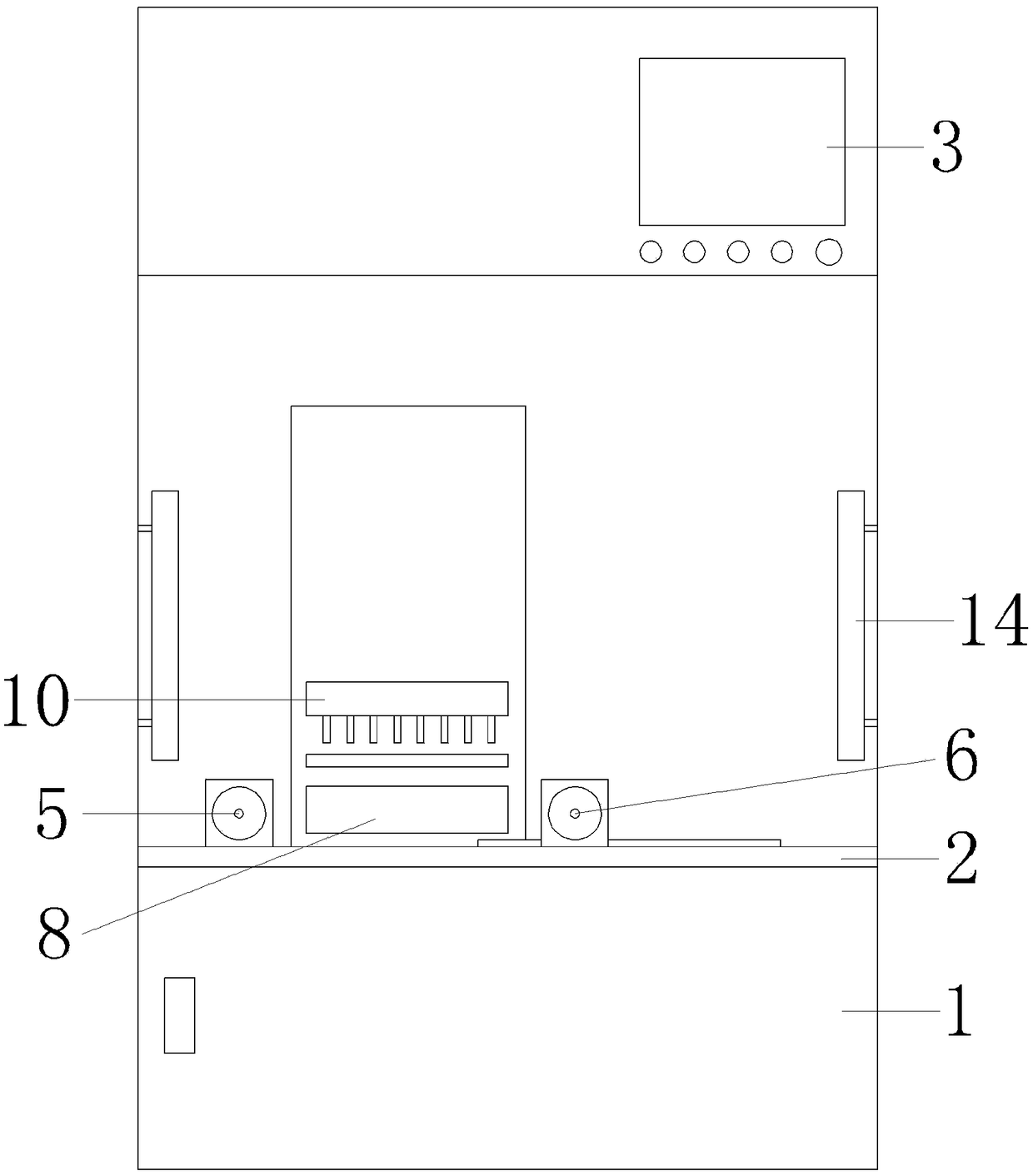

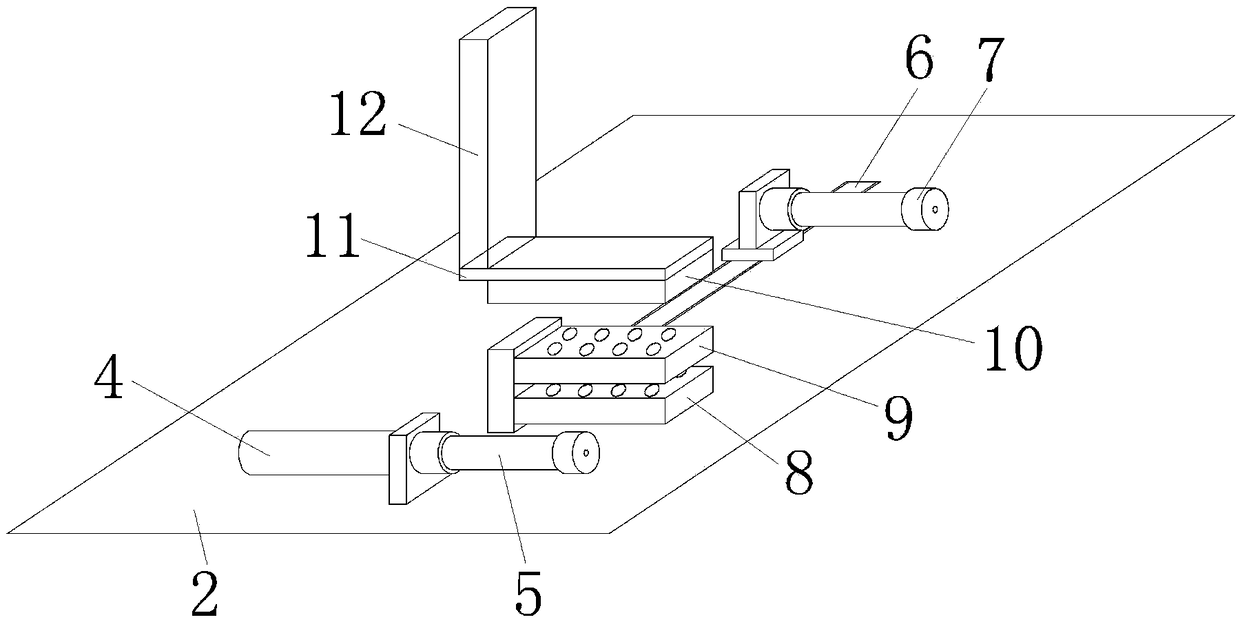

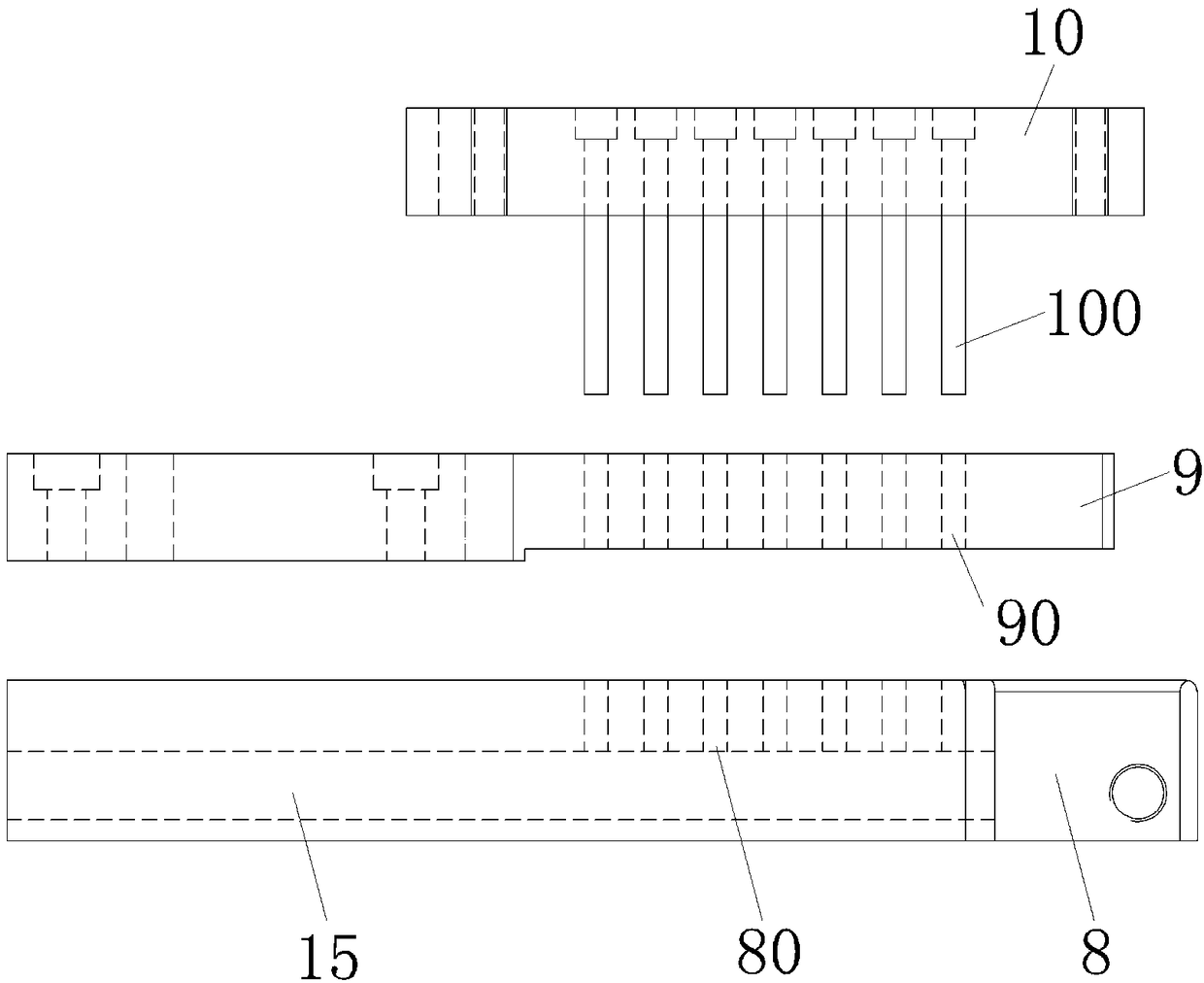

[0013] Refer to Figure 1-3 As shown, a belt punching device includes a frame 1 and a workbench 2 and a controller 3 arranged on the frame 1. A belt rotation mechanism and a belt punching mechanism are installed on the workbench 1; The belt rotation mechanism includes a drive shaft 5 driven and rotated by a servo motor A4, and a tension shaft 7 mounted on a horizontal guide rail 6 driven by a servo motor B (not shown) to move along the horizontal guide rail 6, and the horizontal guide rail 6 is mounted on On the workbench 2; the belt punching mechanism includes a die 8, a guide plate 9, a die 10, a die fixing plate 11, and a linear servo motor 12. The die 8 is installed on the workbench through a mounting plate 13 2 and located between the drive shaft 5 and the tension shaft 6, the guide plate 9 is mounted on the mounting plate 13 and located above the die 8, the linear servo motor 12 passes through the bracket (Not shown) installed on the workbench 2, the die fixing plate 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com