Automatic forming machine for flat metal heald loops

An automatic forming machine and steel sheet technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as poor product size consistency, low production efficiency, and inability to meet highly consistent process requirements. The effect of good shape and size consistency, improved production efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

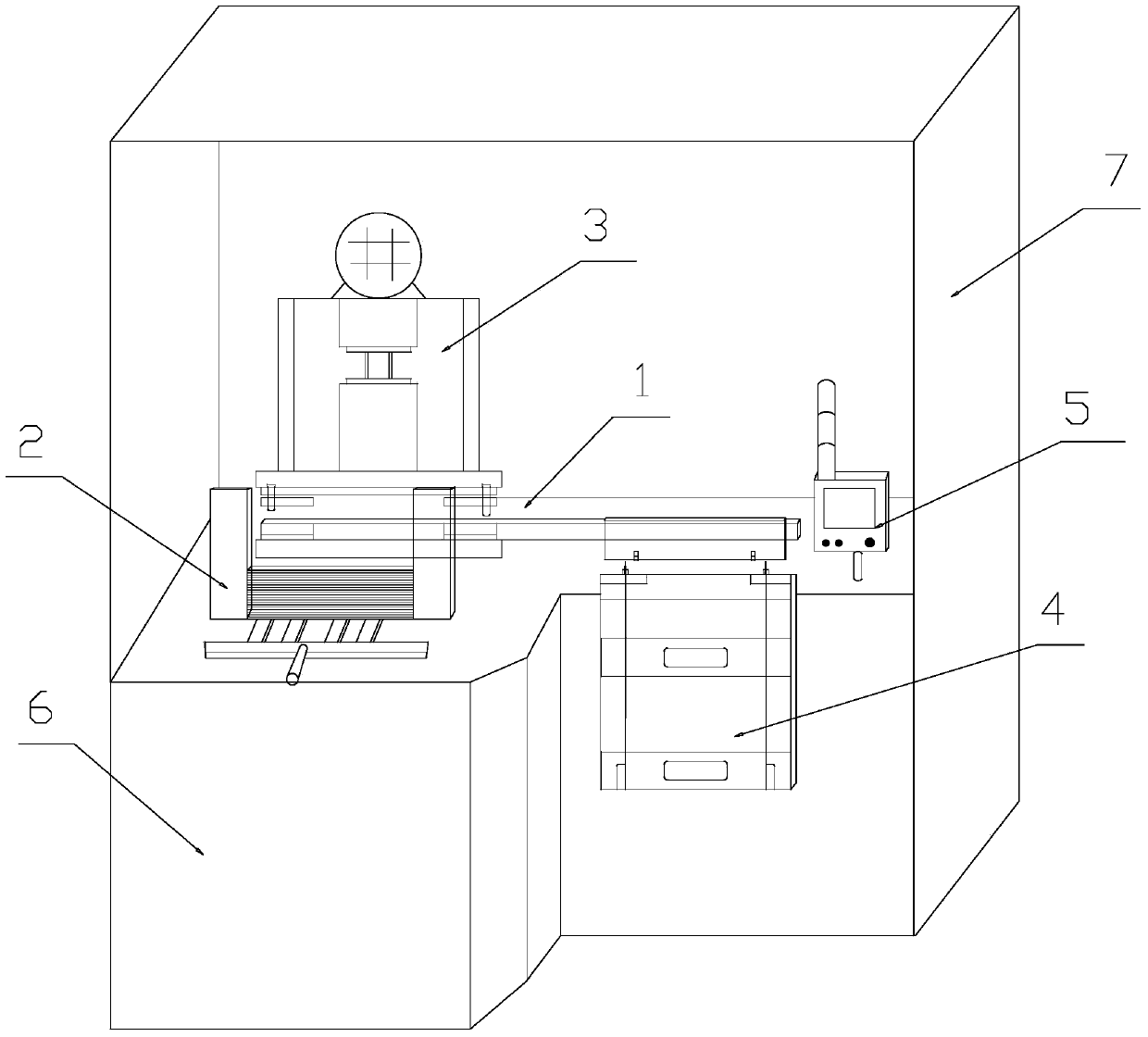

[0020] Such as figure 1 As shown, the steel sheet heald ear automatic forming machine of the present invention includes a frame workbench 1, a material pushing system 2, a forming system 3, a clamping system 4, an electric control system 5, a waste collection system 6, and a machine cover 7. The forming system 3 is installed on the upper left of the frame workbench 1, the pusher system 2 is installed in front of the forming system 3, the clamping system 4 is installed on the right side of the forming system 3, the electric control system 5 is installed on the right side of the clamping system 4, and waste materials are collected The system 6 is installed in the rack workbench 1 cabinet under the forming system 3 . Pushing system 2, molding system 3, and clamping system 4 are all controlled by the program of electric control system 5.

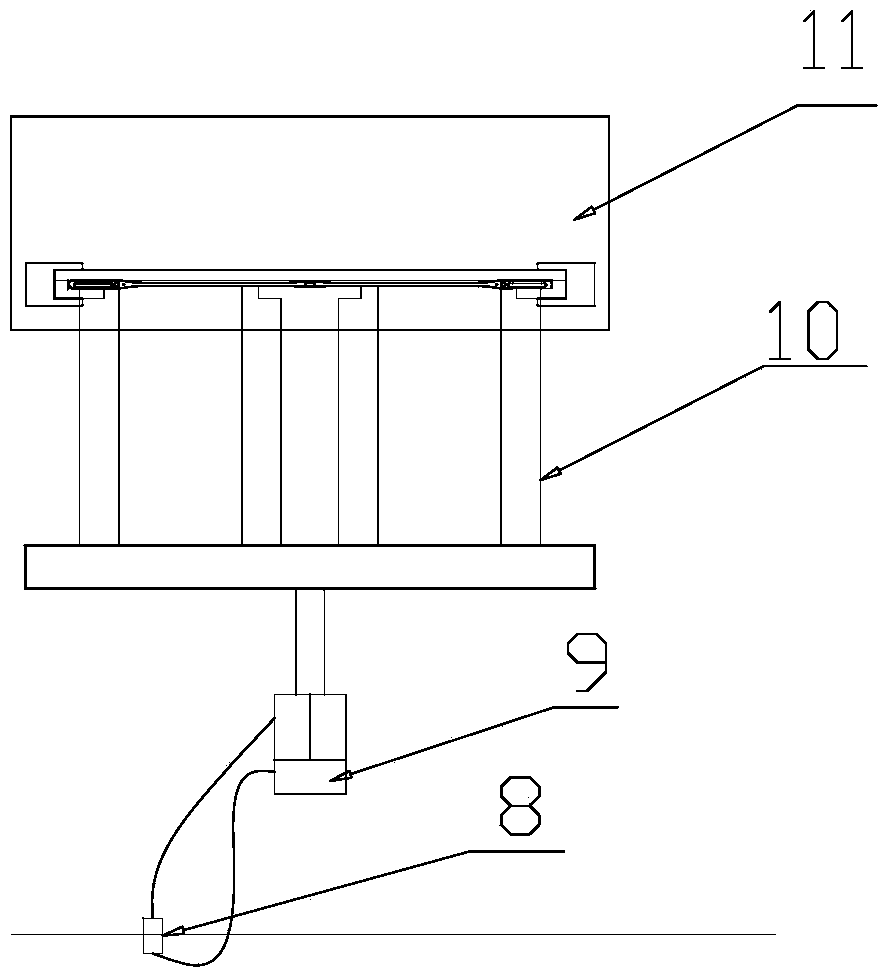

[0021] Such as figure 2 As shown, the pushing system 2 includes an induction switch 8, a cylinder 9, a push knife 10, and a hopper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com