Punching and bending die for rear back plate of refrigerator

A technology of back plate and bending die, which is applied in metal processing equipment, perforating tools, forming tools, etc., can solve the problems of low production efficiency, high risk, and inability to fold edges, etc., and achieve high production efficiency and high safety , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

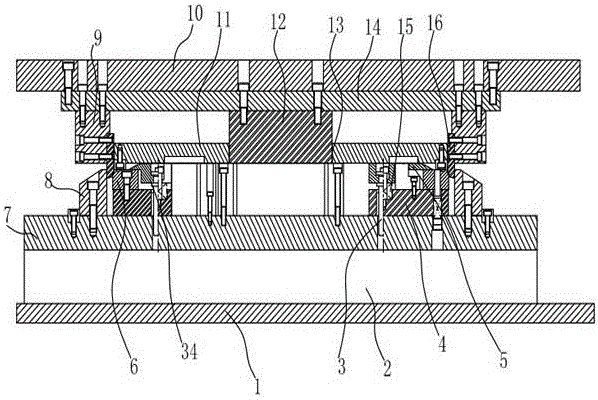

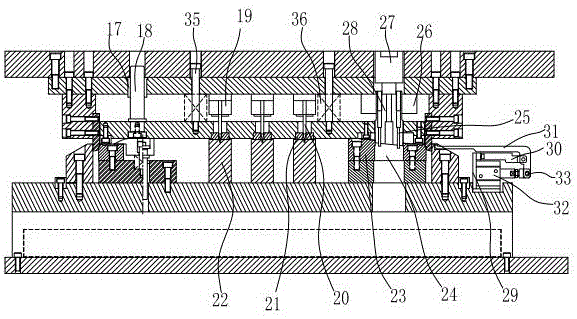

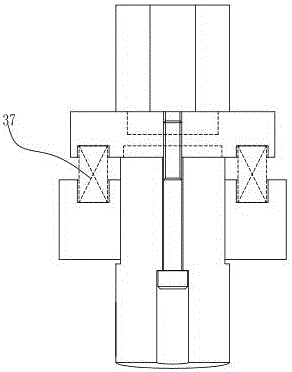

[0018] Embodiment: a punching and bending die for the back panel of a refrigerator, comprising a lower die bottom plate 1, an upper die plate 10, an upper die base 14, a lower die rib plate 2 arranged on the top surface of the lower die bottom plate 1, The lower mold platform panel 7 on the top of the lower mold rib plate 2, the lower knife bar 8 arranged on the outer edge of the lower mold platform panel 7 top surface, the punch seat 9 arranged on the outer edge of the upper mold base 14 bottom, The upper knife bar 16 that is arranged on the inner side of the punch seat 9, the outer side of the upper knife bar 16 is attached to the inner side of the lower knife bar 8 when the mold is closed, and the lower mold table panel 7 on the inner side of the lower knife bar 8 The top is provided with a hemming seat 4, and the top of the hemming seat 4 is provided with a lower hemming strip 6 cooperating with the upper blade 16, and the upper mold base 14 is provided with an upper slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com