Die-cutting mold for easy-tear film on polypropylene infusion bag

A technology of die-cutting dies and easy-tear film, which is applied in metal processing and other directions, can solve the problems of reducing the punching efficiency of easy-tear film, affecting the punching accuracy, and affecting the production output of easy-tear film, so as to achieve the convenience of taking out the easy-tear film, Improve punching efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

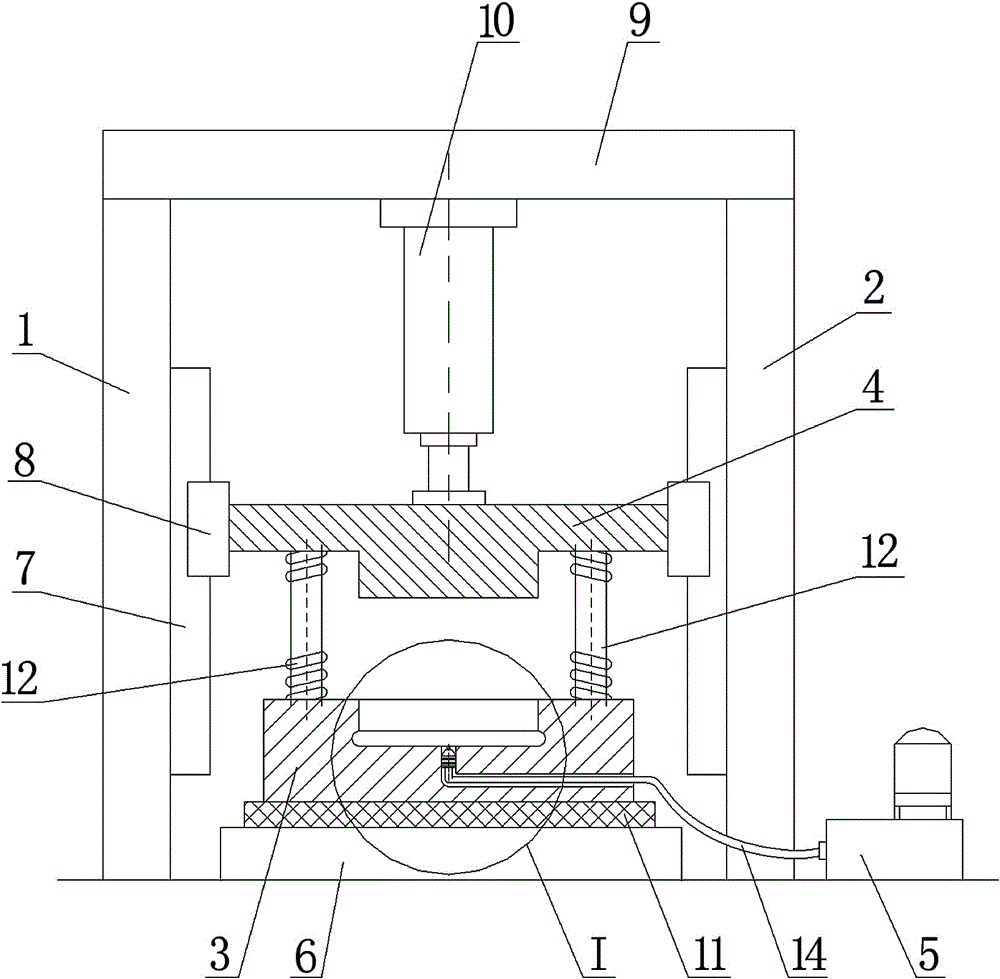

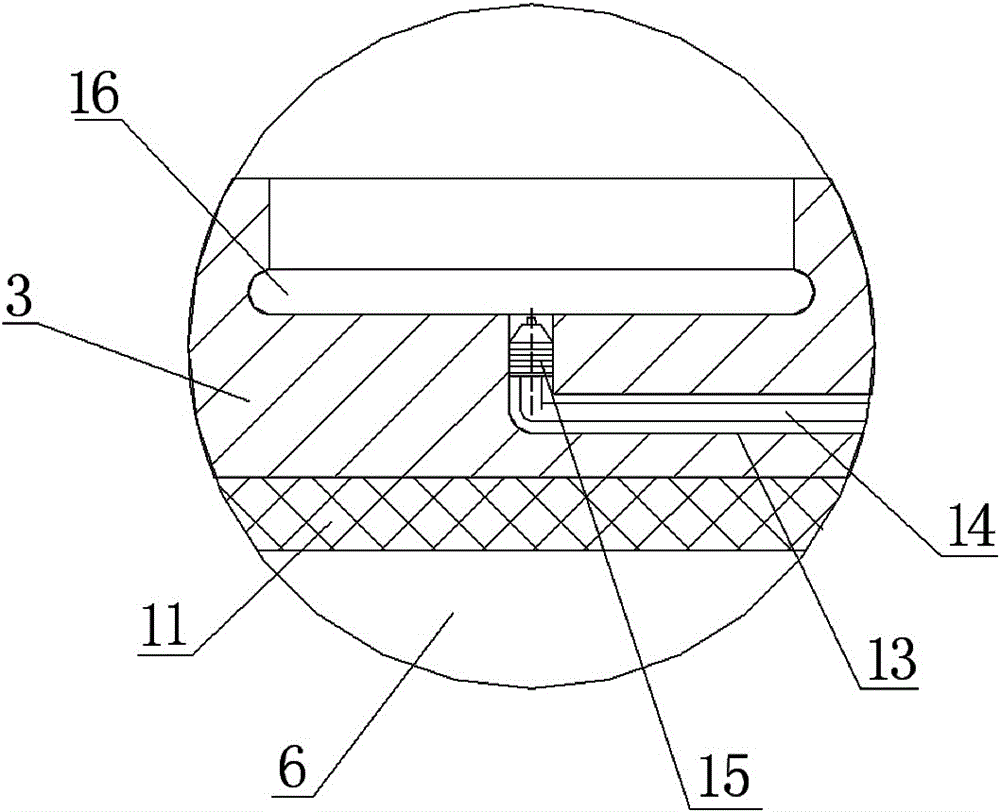

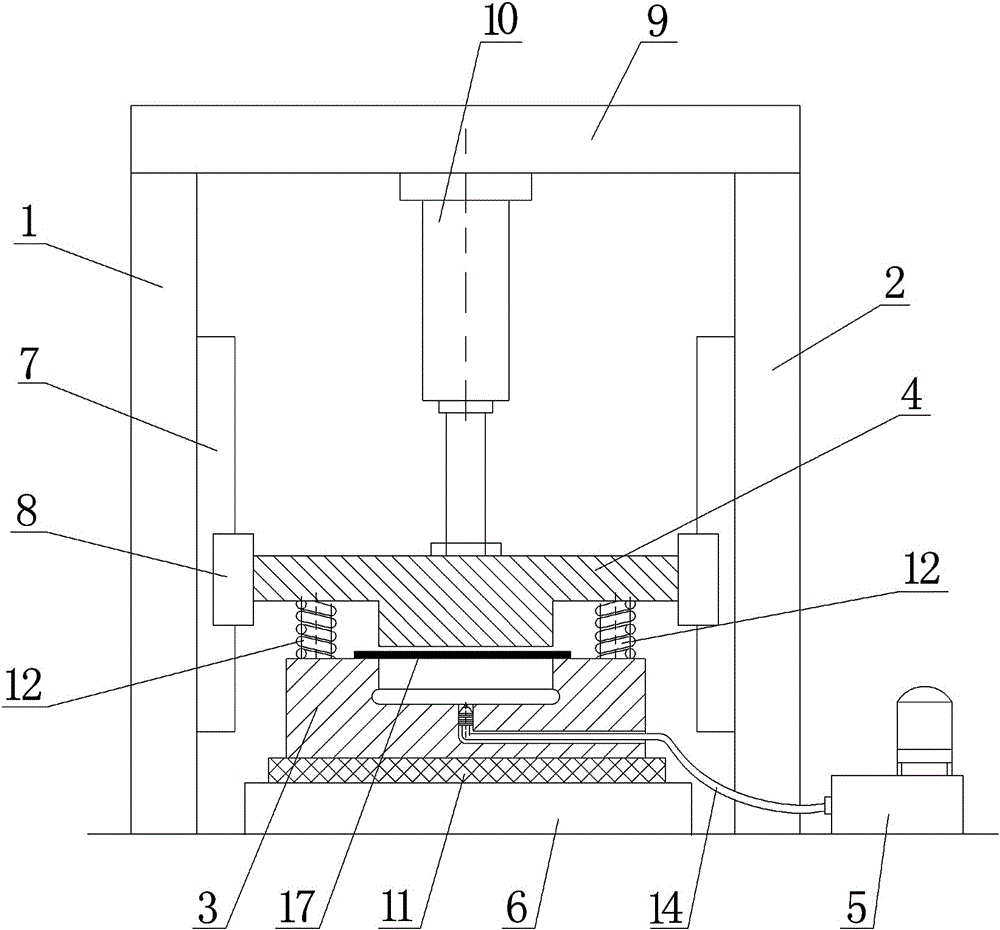

[0015] Such as figure 1 Shown, a kind of die-cutting mold of easily tearing film on the polypropylene infusion bag, it comprises column I1, column II2, die 3, punch 4, constant pressure air source 5 and be arranged on column I1 and column II2 The workbench 6, the column I1 and the column II2 are vertically arranged, the guide rail 7 is arranged on the column I1 and the column II2, the slider 8 is installed on the two guide rails 7, and the support beam 9 is arranged between the column I1 and the column II2 , a cylinder 10 is fixedly installed on the bottom surface of the support beam 9, a punch 4 is provided at the end of the piston rod of the cylinder 10, and the left and right ends of the punch 4 are respectively fixed on two sliders 8, the guide rail 7 and the slider 8 It is ensured that the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com