Automatic alignment bar shearing top knife component

A knife assembly and tangent technology, which is applied in metal processing and other directions, can solve the problems of not meeting the size accuracy requirements of cutting ribs, offset cutting rib size, vibration of molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

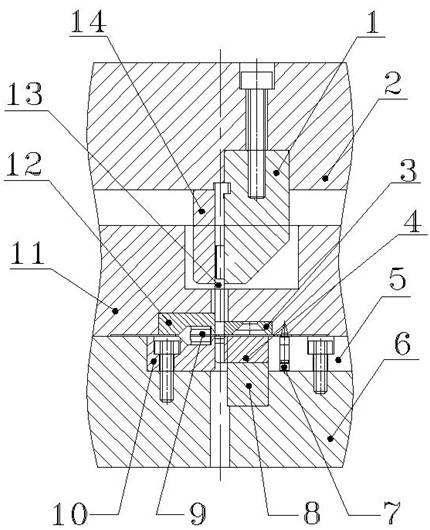

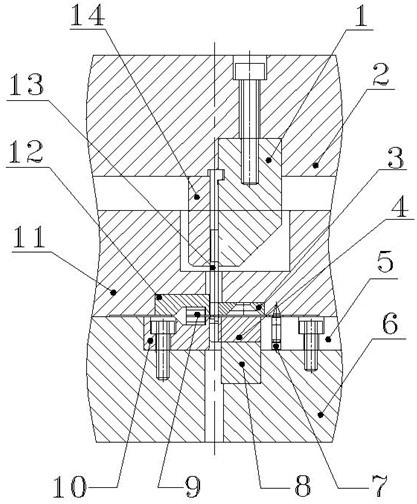

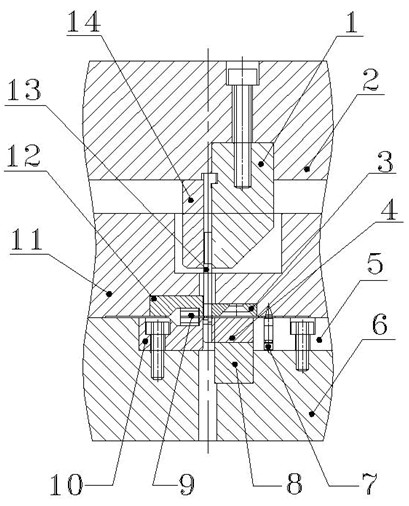

[0010] Such as figure 2 As shown, a kind of automatic aligning and rib-cutting upper knife assembly provided by the present invention includes an upper knife fixing seat 2, an upper knife positioning block 1 is arranged on the upper knife fixing seat 2, and an upper knife 13 for rib cutting is fixed on the upper knife fixing seat 2. On the seat 2, the two sides of the rib cutting upper knife 13 are pressed by the upper knife bead 14, the unloading plate 11 is arranged under the upper knife positioning block 1, and the unloading insert 3 and the unloading block 12 are arranged on the side of the unloading plate 11. At the bottom, a die 4 and a material receiving block 10 are respectively provided under the discharge insert 3 and the discharge block 12, the die 4 and the material receiving block 10 are arranged on the top of the die fixing plate 6, and the positioning pin 7 passes through the positioning Needle seat 5 is arranged in die fixed plate 6, and die 4 is positioned by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com