Punching and molding die and punching and molding method of workpieces

A stamping forming and die technology, applied in forming tools, punching tools, manufacturing tools, etc., can solve the problems of occupying punching machines, time-consuming and labor-intensive, low efficiency, etc., and achieve the effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

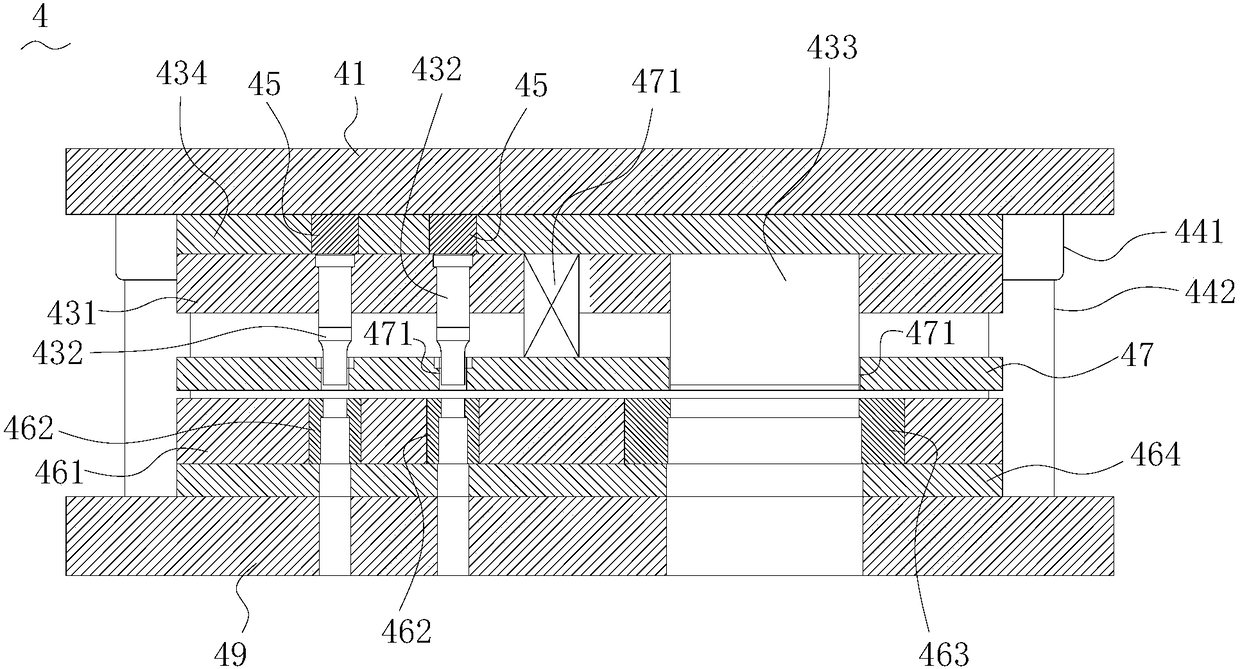

[0037] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0038] The stamping die of the present application is used to realize continuous punching and / or press forming of multiple holes of the workpiece. The structure of the stamping die of the first embodiment of the present application will be described in detail below in conjunction with a workpiece 1 to be punched.

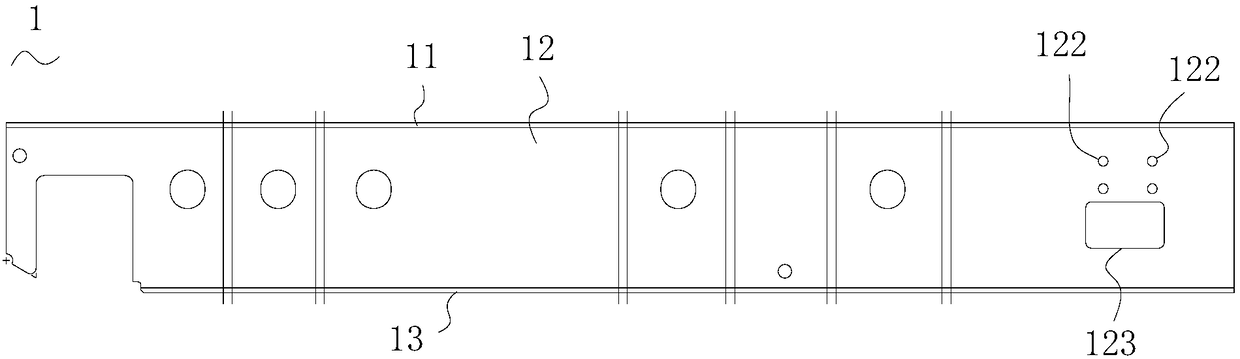

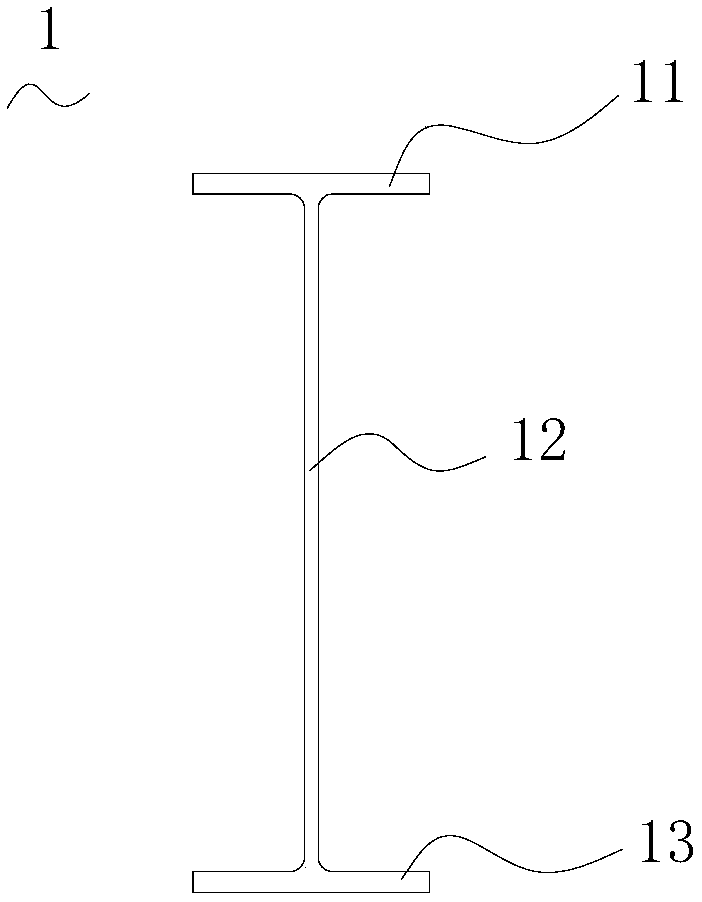

[0039] Such as figure 1 with figure 2 As shown, the workpiece 1 to be punched is an I-beam, and the I-beam includes: an upper wing plate 11, a lower wing plate 13, and a web 12 vertically connected between the upper wing plate 11 and the lower wing plate 13. The web 12 has a plurality of holes to be punched out. There are a plurality of holes near the right end in the figure, that is, four round holes 122 with a smaller diameter and one square hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com