Integrated plant and method for rice wine semi-solid fermentation

A semi-solid, rice wine technology, applied in the preparation of alcoholic beverages and other directions, can solve the problems of increasing the difficulty of feeding semi-solid materials and controlling the temperature, the difficulty of temperature control in the fermentation process, and increasing the construction cost of a rice wine factory. Reduce equipment investment and improve the effect of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following describes the technical implementation method of the present invention in conjunction with the accompanying drawings.

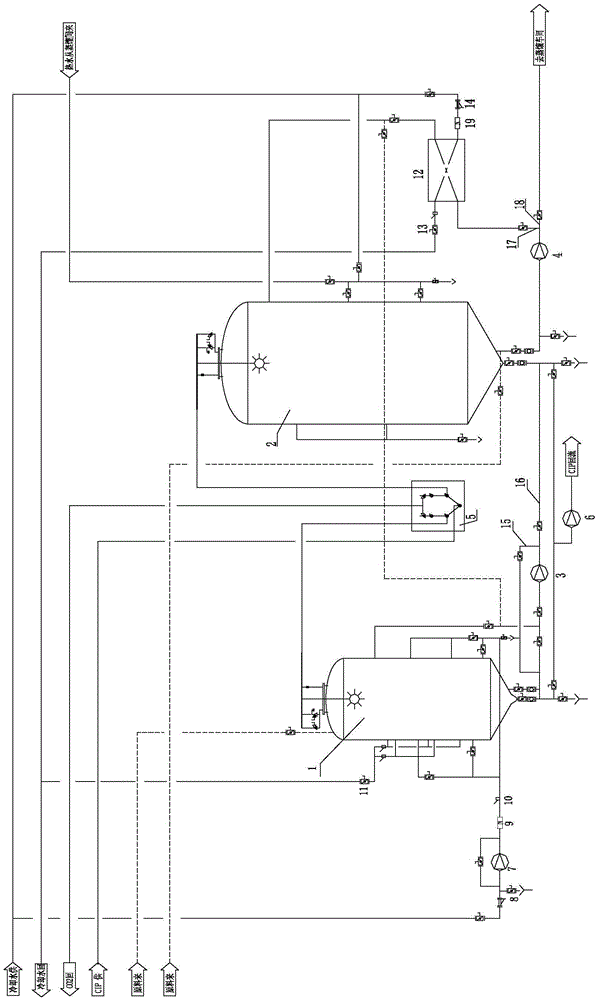

[0018] Such as figure 1 As shown, it is the integration of equipment used in the present invention, which includes a front fermentation tank group and a rear fermentation tank group, and the front fermentation tank group includes at least one main fermentation tank 1, a cooling coil arranged in the main fermentation tank 1 and a set Circulation feeding pump outside the main fermenter 3, CO 2 Recycling and CIP tube sheet and other equipment. The top of the main fermentation tank is provided with a raw material inlet, the upper part of the main fermentation tank is provided with a main fermentation tank circulation discharge pipe, and the bottom of the main fermentation tank is provided with a main fermentation tank return / discharge pipe. The post-fermentation tank group includes at least one post-fermentation tank 2, a plate heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com