Solar energy marsh gas, gas production and gas storage integrated glass fiber reinforced plastic composite device

A technology of glass fiber reinforced plastics and solar energy, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve the problems of increasing electricity consumption and fuel input, large footprint, and poor airtightness and other problems, to achieve good thermal insulation effect, reduce floor space, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

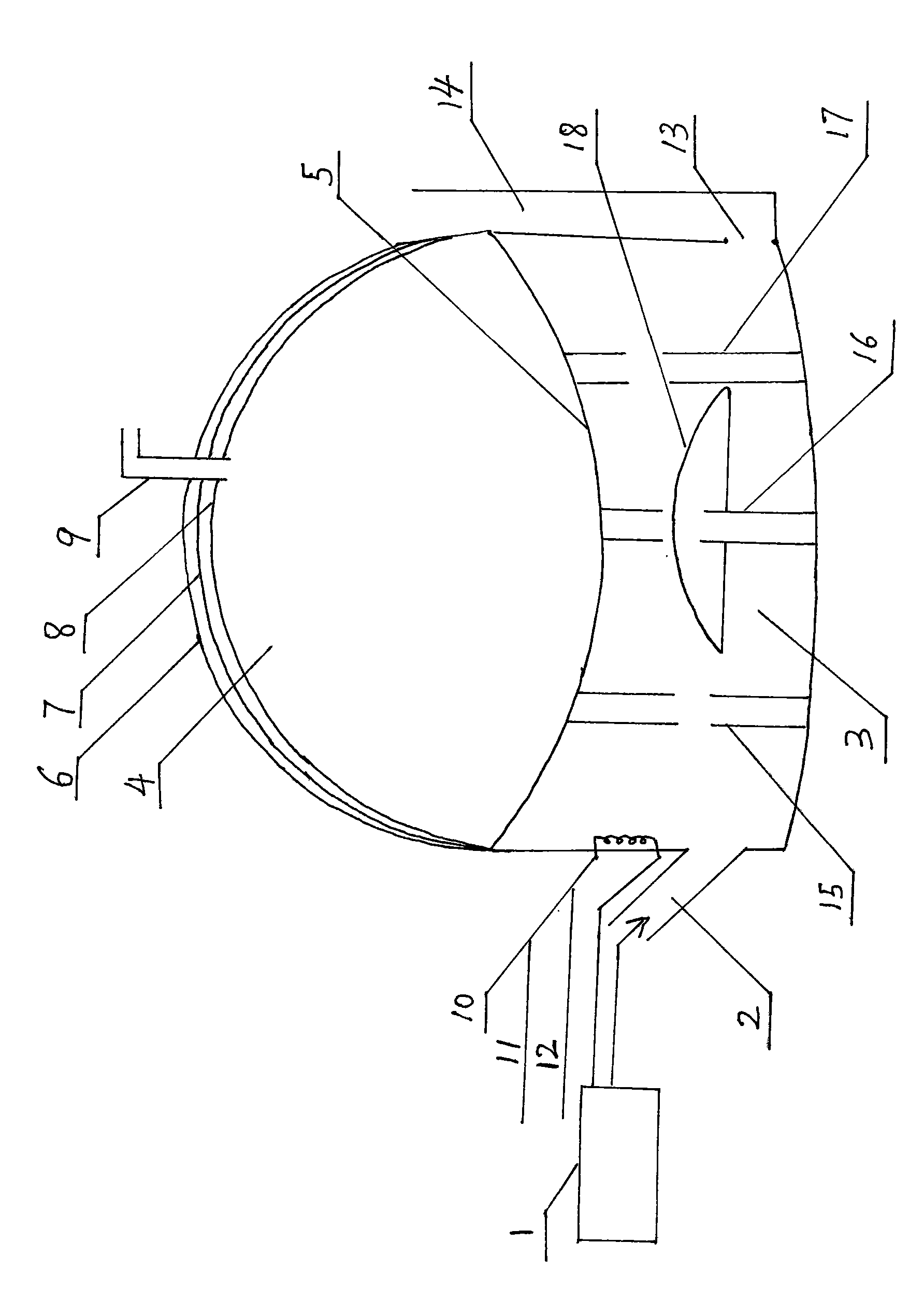

[0007] A FRP composite device integrating solar biogas, gas production and gas storage, which includes a regulating tank 1, a feed port 2, a fermentation tank body 3, a double-membrane gas storage cabinet 4, a support frame 5, and a FRP outer membrane 6 , foam board interlayer 7, FRP inner film 8, air guide pipe 9, power generation waste heat heating pipe 10, solar heating device 11, straw gasification furnace heating device 12, discharge port 13, overflow device 14, the first Fermentation separation wall 15, the second fermentation separation wall 16, the third fermentation separation wall 17 and the gas collecting hood 18, the first fermentation separation wall 15, the second fermentation separation wall 16, the third fermentation separation wall 18 are arranged in the fermentation tank body 3 The wall 17 and the second fermentation separation wall 16 are provided with a gas collection cover 18; the fermenting tank body 3 is provided with a support frame 5, and the support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com