Liquid crystal polyester, liquid crystal polyester composition composed of liquid crystal polyester, and applications of liquid crystal polyester composition

A technology of liquid crystal polyester and composition, applied in the field of polymer materials, can solve the problems of reduced width of pin hole resin, influence of fluidity of LCP material, poor filling, etc., and achieve excellent fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: the preparation of liquid crystal polyester

[0059] Add 6.215kg (45mol) HBA, 0.465kg (2.5mol) BP, 2.75kg (25mol) HQ, 2.92kg (17.6mol) TPA, 2.164kg (10mol) NDA, 11.23kg (110mol) AA and 3g magnesium acetate; after replacing nitrogen, raise the reaction temperature to 145°C under nitrogen atmosphere for 2 hours; then raise the temperature to 330°C at a rate of 60°C / hour ~355°C (the highest reaction temperature for pre-polymerization), keep the reaction at this temperature for 30 minutes, then vacuumize to 200Pa within 30 minutes and continue the reaction until the stirring power reaches the predetermined value. Then add nitrogen into the reactor until the pressure is 0.2MPa, discharge through the valve at the bottom of the reactor, and then granulate after cooling;

[0060] Add 10kg of the above prepolymer particles into a 50L reactor with a stirrer, and then perform solid phase polycondensation reaction at 260° C. and a vacuum of 120 Pa for 5 hours to obt...

Embodiment 2~12

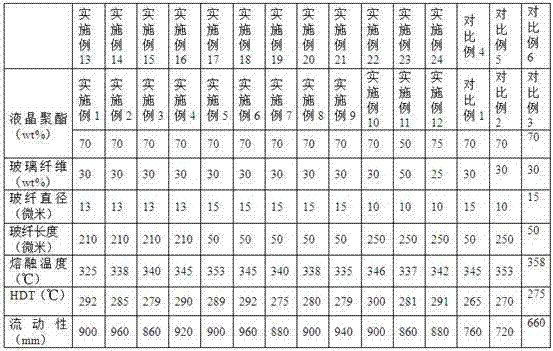

[0061] Embodiment 2~12: the preparation of liquid crystal polyester

[0062] According to the formula in Table 1, HBA, BP, HQ, TPA, NDA, AA and magnesium acetate are charged, the amount of AA is 1.1 times of the total molar number of monomer hydroxyl groups, and the amount of magnesium acetate is based on the total number of monomers. 0.02% by weight, its preparation method is the same as in Example 1; the melting temperature and melt viscosity of the gained liquid crystal polyester are listed in Table 1.

[0063] Table 1

[0064]

Embodiment 13

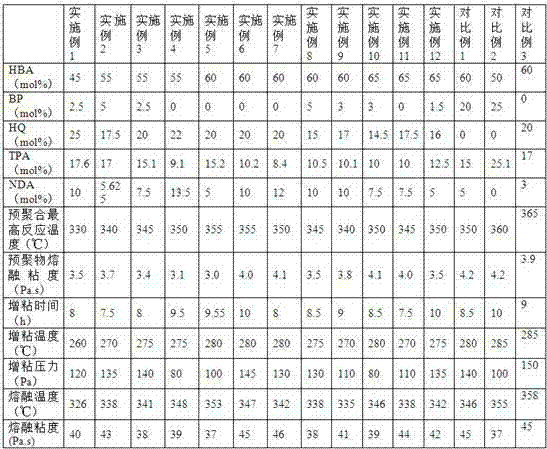

[0065] Embodiment 13: Preparation of liquid crystal polyester composition

[0066] According to the proportioning of table 2, the 70wt% liquid crystal polyester prepared by embodiment 1 is added into the extruder from the main feeding port of the twin-screw extruder, and the 30 wt% glass fiber is fed from the side of the twin-screw extruder Put it into the extruder; melt and mix at the screw speed of 300RPM, the temperature of the screw barrel is 290-355°C, and extrude to obtain the liquid crystal polyester composition. The melting temperature, heat distortion temperature and flow properties of the liquid crystal polyester composition were tested respectively, and the test results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com