Lever principle-based livestock farming automatic feeding device

A technology of automatic feeding and lever principle, applied in animal feeding devices, applications, poultry industry, etc., can solve the problems of large manual labor, easy to rot, increase breeding costs, etc., to reduce the difficulty of feeding and ensure crushing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

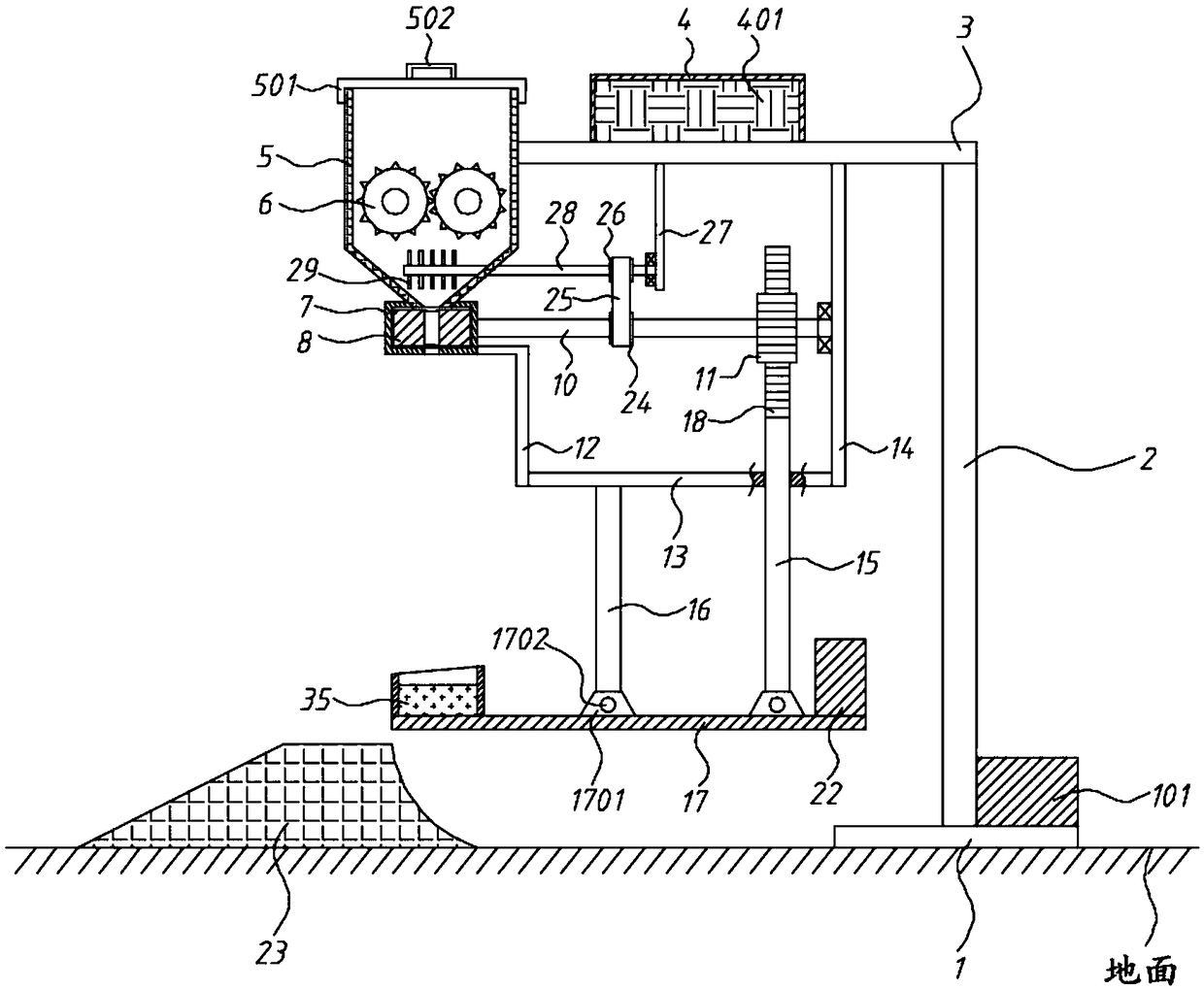

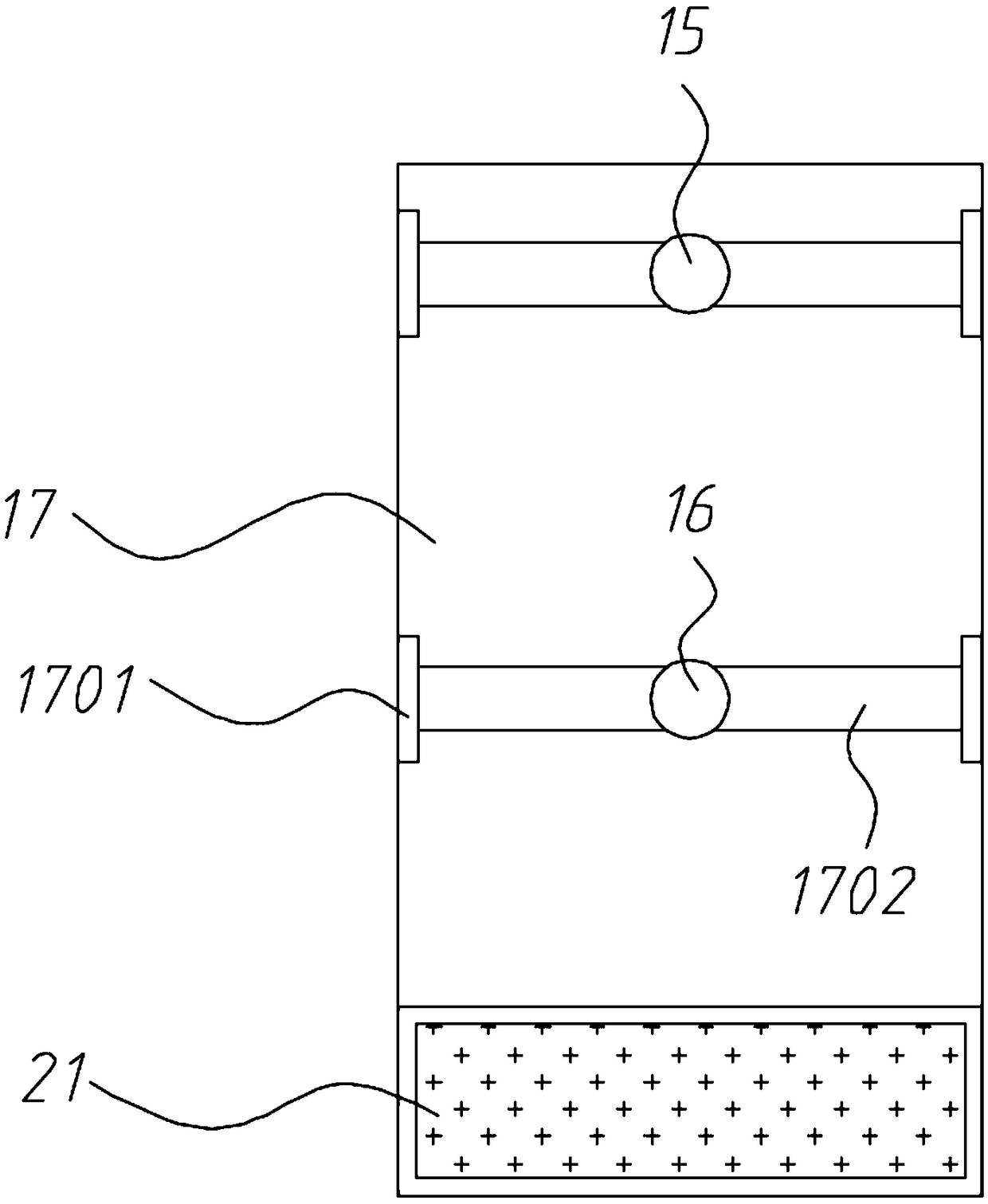

[0042] An automatic feeding device for livestock breeding based on the principle of leverage, comprising a bracket, a feeding hopper 5, a loading chamber 7, a feeding end 8 and a lever assembly;

[0043] The bracket includes a base 1, a column 2 and a top plate 3, the column 2 is vertically fixed on the base 1, the top of the column 2 is horizontally connected to the top plate 3 to the left, and the base 1 is provided with a counterweight 101;

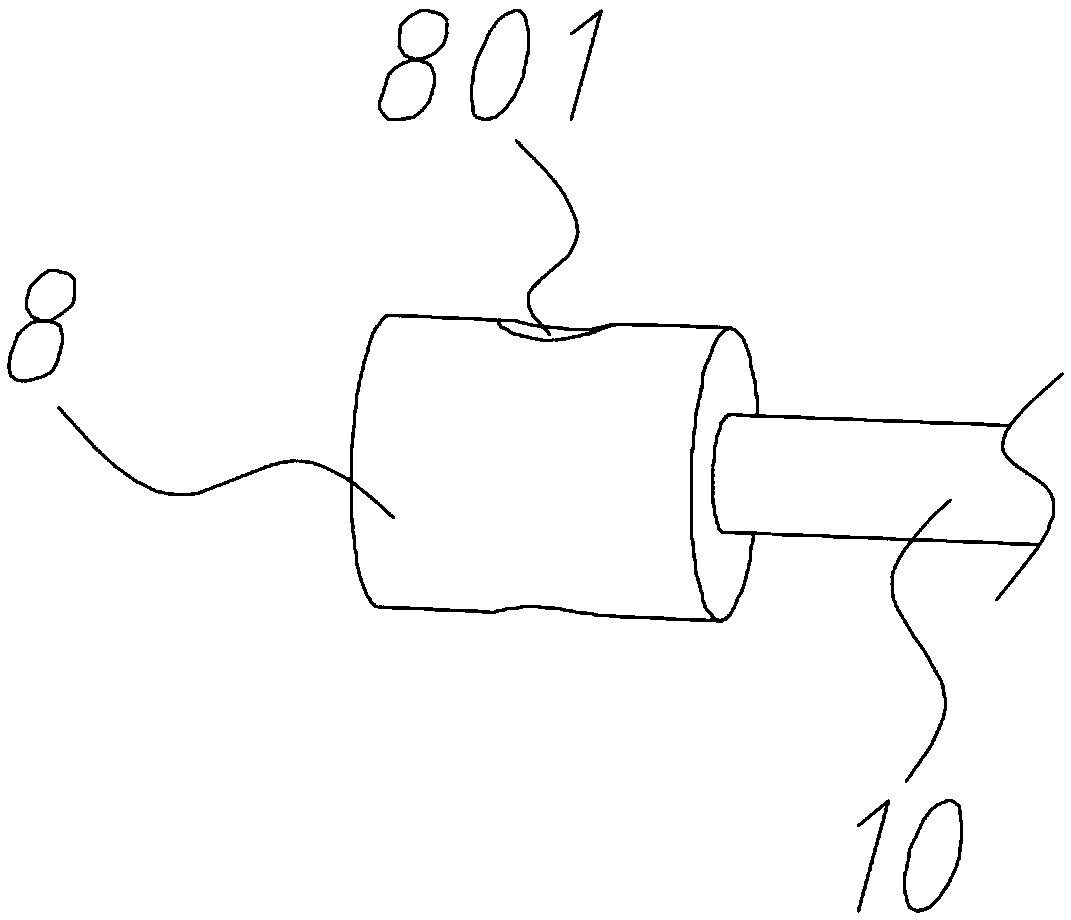

[0044] The feeding hopper 5 is connected to the left end of the top plate 3, and a symmetrical pulverizing knife group 6 is arranged in the feeding hopper 5, and the pulverizing knife group 6 is externally connected with a driving motor; The cavity 7 is rotated with a feeding end 8, the feeding end 8 is provided with a through groove 801 corresponding to the feeding hopper 5 feeding port, and the bottom of the loading chamber 7 is correspondingly provided with a discharge port; the feeding end 8 is connected to a right The No. 1 shaft ...

Embodiment 2

[0049] An automatic feeding device for livestock breeding based on the principle of leverage, comprising a bracket, a feeding hopper 5, a loading chamber 7, a feeding end 8 and a lever assembly;

[0050] The bracket includes a base 1, a column 2 and a top plate 3, the column 2 is vertically fixed on the base 1, the top of the column 2 is horizontally connected to the top plate 3 to the left, and the base 1 is provided with a counterweight 101;

[0051] The feeding hopper 5 is connected to the left end of the top plate 3, and a symmetrical pulverizing knife group 6 is arranged in the feeding hopper 5, and the pulverizing knife group 6 is externally connected with a driving motor; The cavity 7 is rotated with a feeding end 8, the feeding end 8 is provided with a through groove 801 corresponding to the feeding hopper 5 feeding port, and the bottom of the loading chamber 7 is correspondingly provided with a discharge port; the feeding end 8 is connected to a right The No. 1 shaft ...

Embodiment 3

[0058] An automatic feeding device for livestock breeding based on the principle of leverage, comprising a bracket, a feeding hopper 5, a loading chamber 7, a feeding end 8 and a lever assembly;

[0059] The bracket includes a base 1, a column 2 and a top plate 3, the column 2 is vertically fixed on the base 1, the top of the column 2 is horizontally connected to the top plate 3 to the left, and the base 1 is provided with a counterweight 101;

[0060] The feeding hopper 5 is connected to the left end of the top plate 3, and a symmetrical pulverizing knife group 6 is arranged in the feeding hopper 5, and the pulverizing knife group 6 is externally connected with a driving motor; The cavity 7 is rotated with a feeding end 8, the feeding end 8 is provided with a through groove 801 corresponding to the feeding hopper 5 feeding port, and the bottom of the loading chamber 7 is correspondingly provided with a discharge port; the feeding end 8 is connected to a right The No. 1 shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com