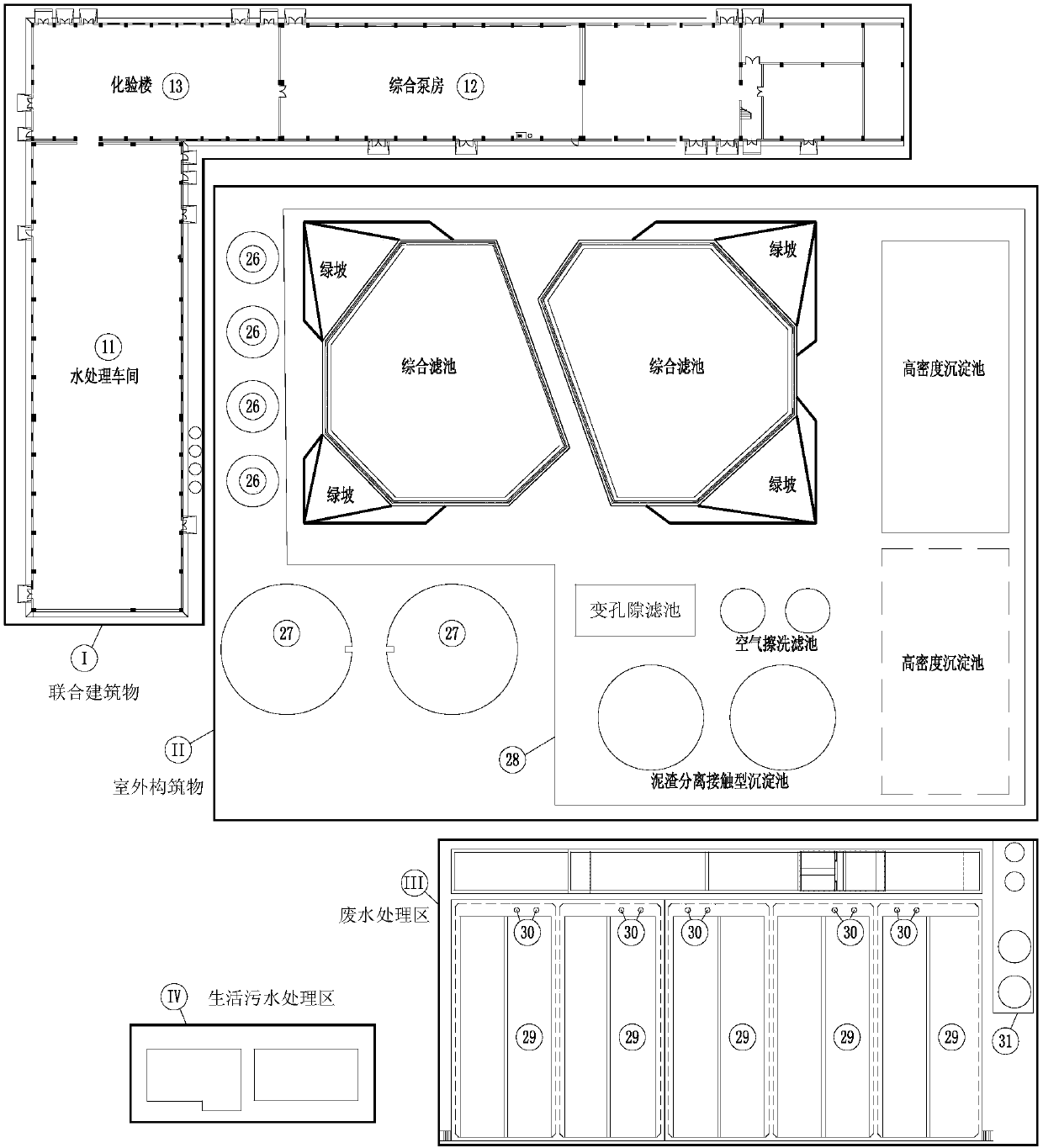

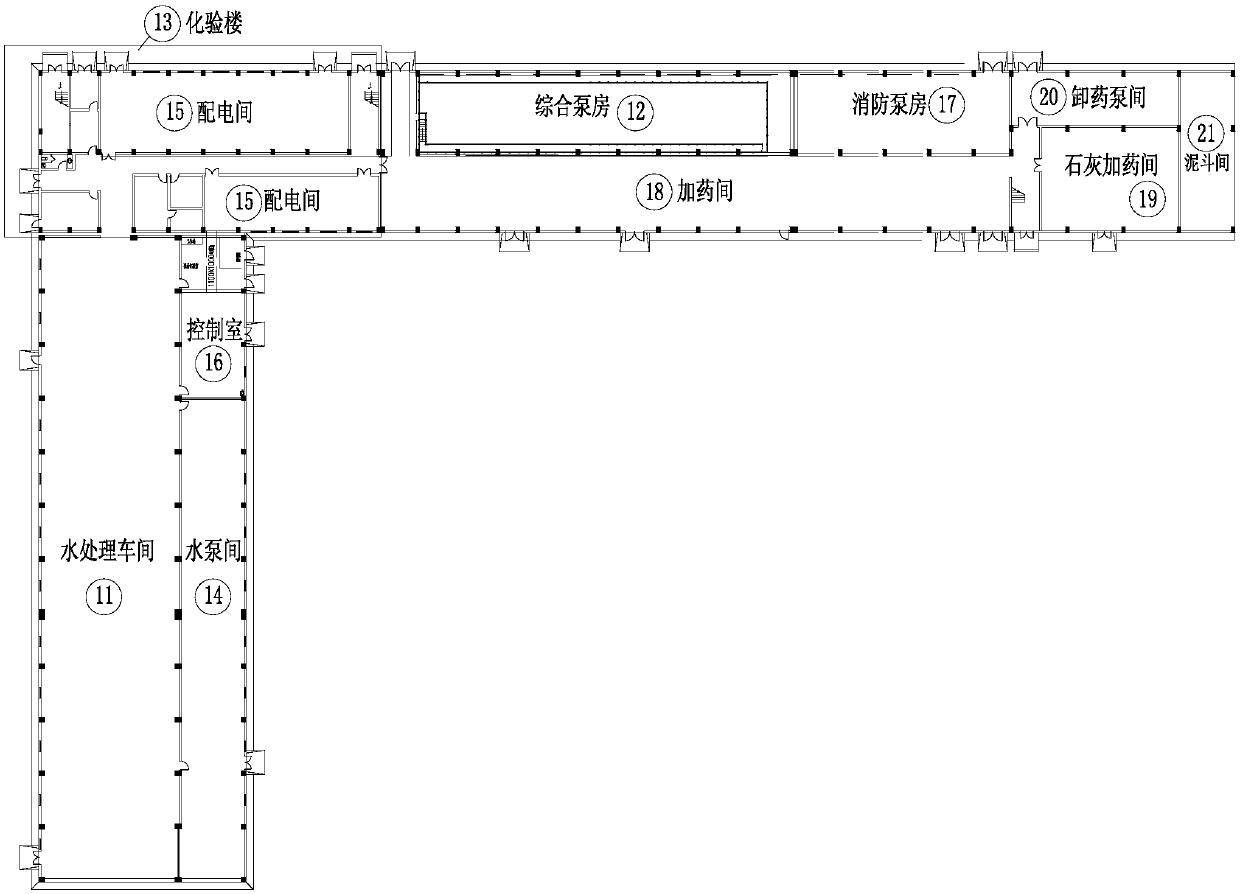

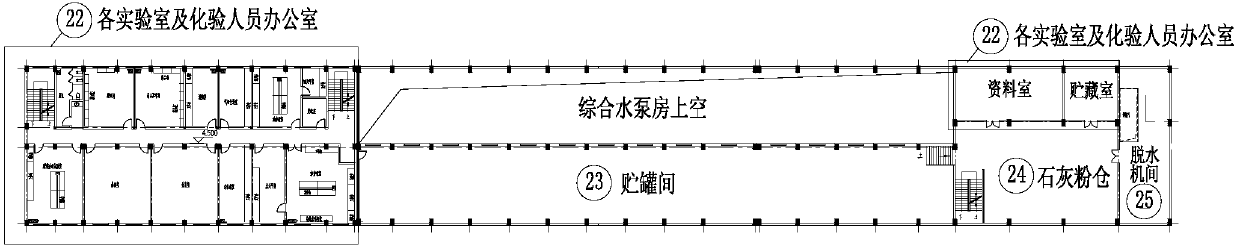

Intensive layout structure of large-scale thermal power plant water center

A thermal power plant and layout structure technology, applied in the direction of general water supply saving, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of large investment in equipment, large area occupied by scattered layout, inconvenient operation and management, etc., and achieve simple system , Saving infrastructure costs, smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The present invention adopts following optimization mode:

[0026] Step 1: After determining the treatment process of "ultrafiltration + reverse osmosis + first-stage desalination + mixed bed" according to the optimization calculation of boiler feed water, the interval between using "ion exchange" units as backup is an average of 15 for each bed type. With the feature of once-a-day regeneration, there is no need to set up emergency plan equipment; Huashui main building is equipped with ultrafiltration reverse osmosis and ion exchange equipment across the water treatment workshop. The channel drains directly to the waste water storage tank.

[0027] The second step: cancel the reverse osmosis water tank and the reuse water pump in the circulating water sewage desalination system, and directly discharge it to the hydraulic reuse water pool through the pipeline.

[0028] The third step: cancel the clean water tank and clean water pump in the industrial wastewater treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com