On-site purification up-to-standard processing method for toilet waste

A treatment method and waste technology, applied in biological sludge treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of on-site treatment of feces such as urine that cannot meet the standards, and on-site purification of no toilet waste found Reaching the standard treatment method, increasing the overall cost of toilet treatment, etc., to achieve the effect of increasing the unit treatment capacity and economic benefits, reducing the process, and accelerating the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

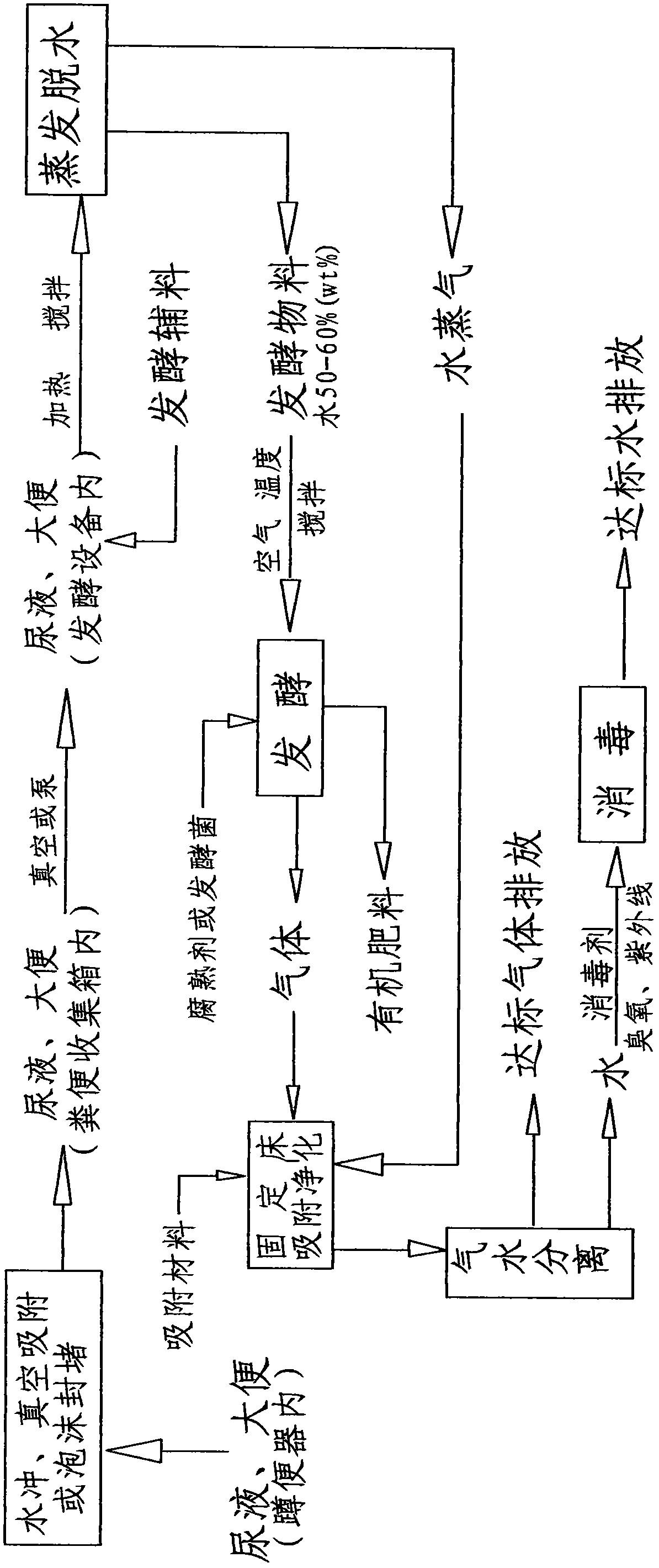

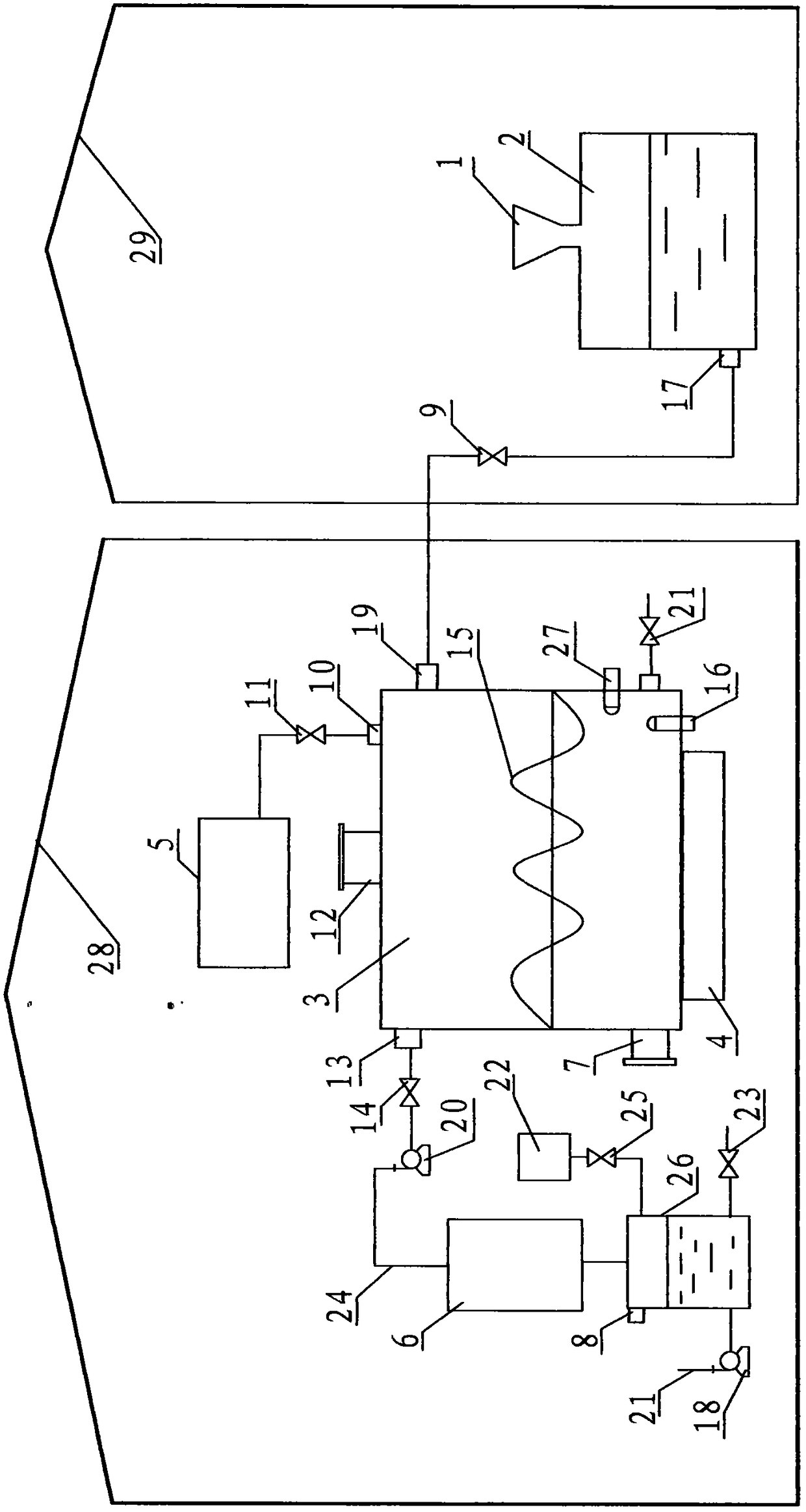

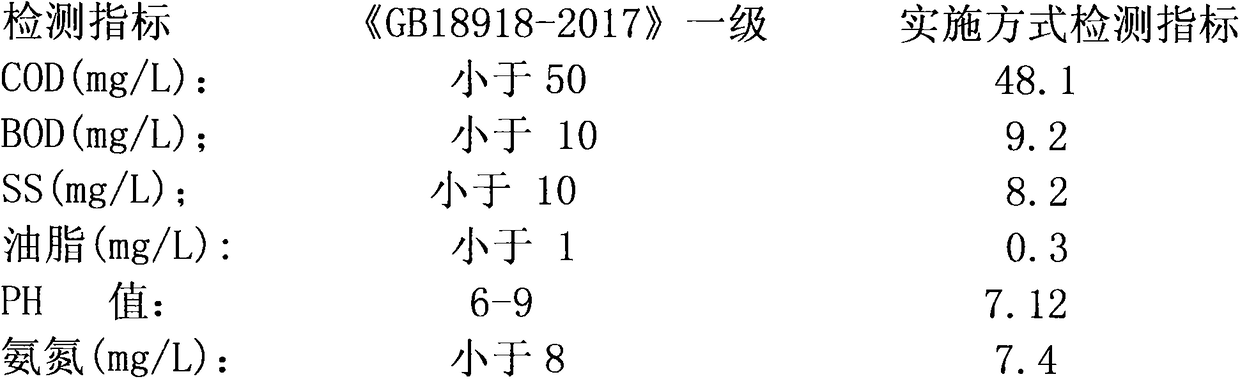

[0046] According to attached figure 1 And attached figure 2 As shown, first add 0.6 cubic meters of fermentation auxiliary material (mixture of sawdust and straw powder) and an appropriate amount of fermenting agent into the fermentation equipment (3), seal the feeding cover (5), then use the squatting toilet (1); The feces in the squatting toilet (1) are discharged into the feces collection box (2) by means of water flushing, vacuum negative pressure adsorption or foam blocking, etc., and the vacuum regulating valve (11) and control valve one (9) are opened to ferment The vacuum negative pressure generated in the equipment (3) sucks the feces in the feces collection box (2) into the fermentation equipment (3), closes the control valve one (9), and the squatting pan (1) and the feces collection box (2) are restored. The normal condition of defecating at normal pressure; when the feces in the fermentation equipment (3) is collected to a certain volume, fermentation begins; ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com