Aluminum oxide melamine ecological wooden door and manufacturing method thereof

A technology of aluminum oxide melamine and melamine board, applied in the direction of manufacturing tools, wood processing utensils, etc., can solve problems such as complicated processes, and achieve the effects of rapid processing, environmental protection, less materials, and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

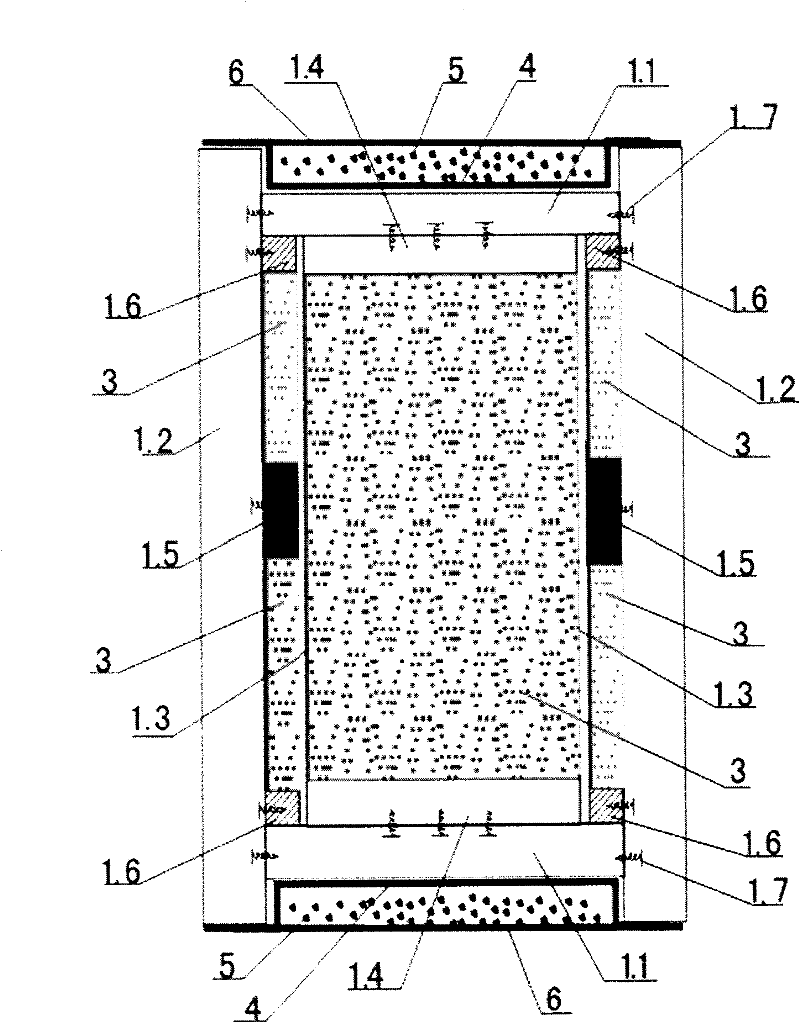

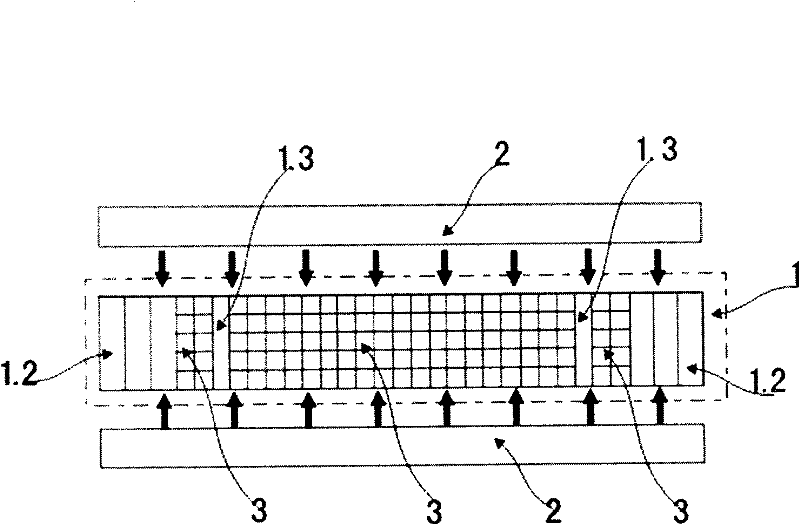

[0044] Embodiment 1: comprise the steps:

[0045] (1) trimming:

[0046] A. Preparation of outer frame vertical bars 1.2: Cut the laminated lumber or glulam into 2020mm long, 50mm wide, and 30mm thick wooden strips, two for spare;

[0047] B. Preparation of outer frame horizontal strips 1.1: Cut the laminated lumber or laminated timber into 520mm long, 50mm wide, and 30mm thick wooden strips, two for spare;

[0048] C. Make two metal strips 1.3 with a length of 1800mm, a width of 4mm, and a thickness of 25mm, two for spare;

[0049] D. Preparation of inner frame horizontal strips 1.4: Use laminated lumber or laminated timber to cut into 320mm long, 50mm wide, and 29mm thick laminated wooden strips, two for spare;

[0050] (2) Form the door frame:

[0051] A. Embed the outer frame horizontal bar 1.1 in the above steps into the outer frame vertical bar 1.2, and connect them with wave nails 1.7 to form the outer frame;

[0052] B. Set the locking mesh 1.5 and the wooden squar...

Embodiment 2

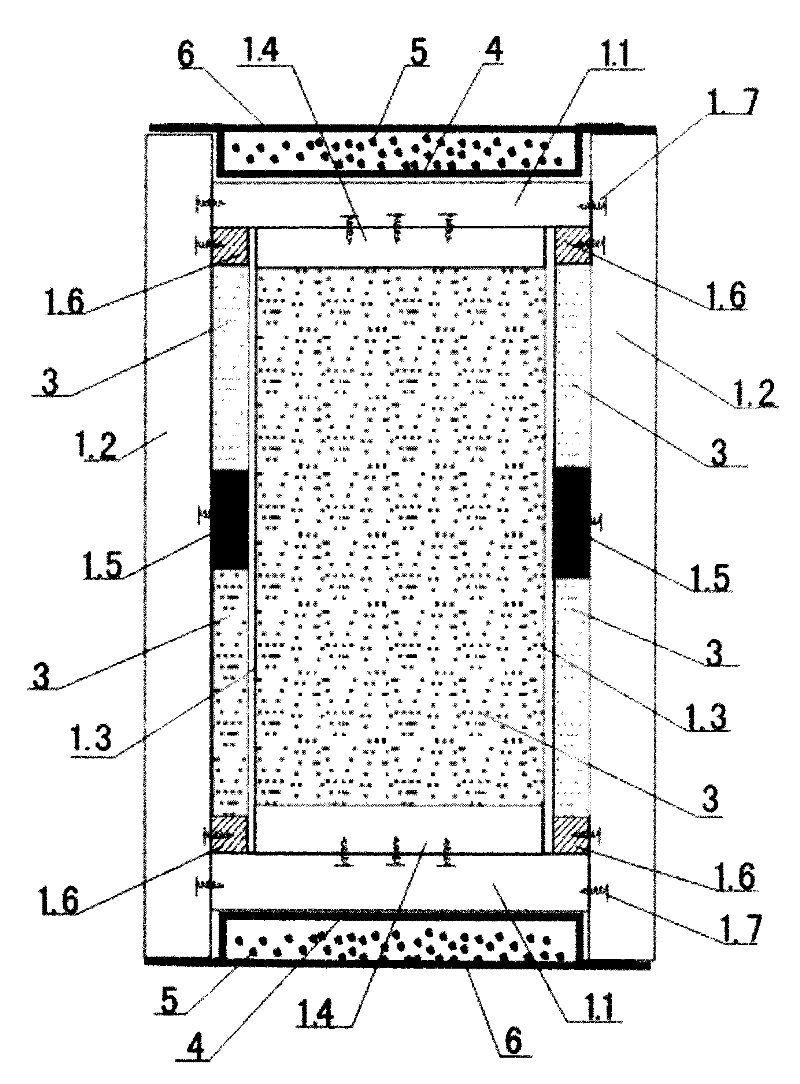

[0062] Embodiment 2: comprise the steps:

[0063] (1) trimming:

[0064] A. Preparation of outer frame vertical strips 1.2: Cut the laminated lumber or laminated timber into 2420mm long, 150mm wide, and 50mm thick wooden strips, two for spare;

[0065] B. Preparation of outer frame horizontal strips 1.1: Cut the laminated timber or laminated timber into 920mm long, 150mm wide and 50mm thick wooden strips, two for spare;

[0066] C. Make two metal strips 1.3 with a length of 2050mm, a width of 8mm, and a thickness of 45mm, for standby;

[0067] D. Preparation of inner frame horizontal bars 1.4: use laminated lumber or glued lumber to cut into 720mm long, 150mm wide, and 49mm thick laminated wooden strips, two for spare;

[0068] (2) Form the door frame:

[0069] A. Embed the outer frame horizontal bar 1.1 in the above steps into the outer frame vertical bar 1.2, and connect them with wave nails 1.7 to form the outer frame;

[0070] B. Set the locking mesh 1.5 and the wooden...

Embodiment 3

[0080] Embodiment 3: comprise the steps:

[0081] (1) trimming:

[0082] A. Preparation of outer frame vertical bars 1.2: Cut the laminated lumber or glulam into 2220mm long, 100mm wide, and 40mm thick wooden strips, two for spare;

[0083] B. Preparation of outer frame bars 1.1: Cut the laminated lumber or glulam into 720mm long, 100mm wide, and 40mm thick wooden strips, two for spare;

[0084] C. Make two metal strips 1.3 with a length of 1900mm, a width of 6mm and a thickness of 30mm, two for spare;

[0085] D. Preparation of inner frame horizontal bars 1.4: use laminated lumber or glued lumber to cut into 520mm long, 100mm wide, and 39mm thick laminated wooden strips, two for spare;

[0086] (2) Form the door frame:

[0087] A. Embed the outer frame horizontal bar 1.1 in the above steps into the outer frame vertical bar 1.2, and connect them with wave nails 1.7 to form the outer frame;

[0088] B. Set the locking mesh 1.5 and the wooden square packing 1.6 in the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com