Hugely-thick inclined coal seam mining area steering method

A technology for coal seams and mining areas, which is applied in the field of turning of mining areas of extremely thick inclined coal seams, can solve the problems of unconnected coal mining in open-pit mines, affecting the normal production of open-pit mines, complicated production organization and management, etc. The effect of shortening the turning time and increasing the annual production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below with reference to the accompanying drawings

[0021] The method for turning a mining area of a thick inclined coal seam of the present invention comprises the following steps:

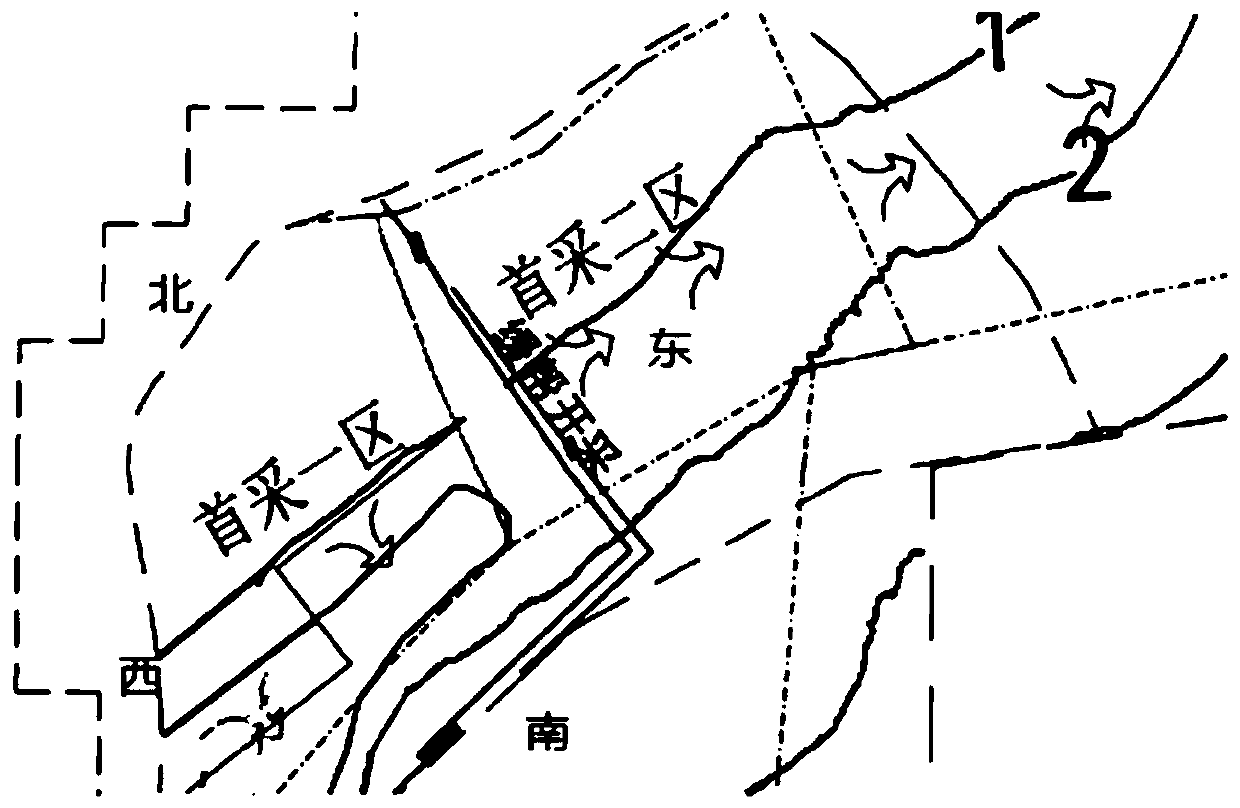

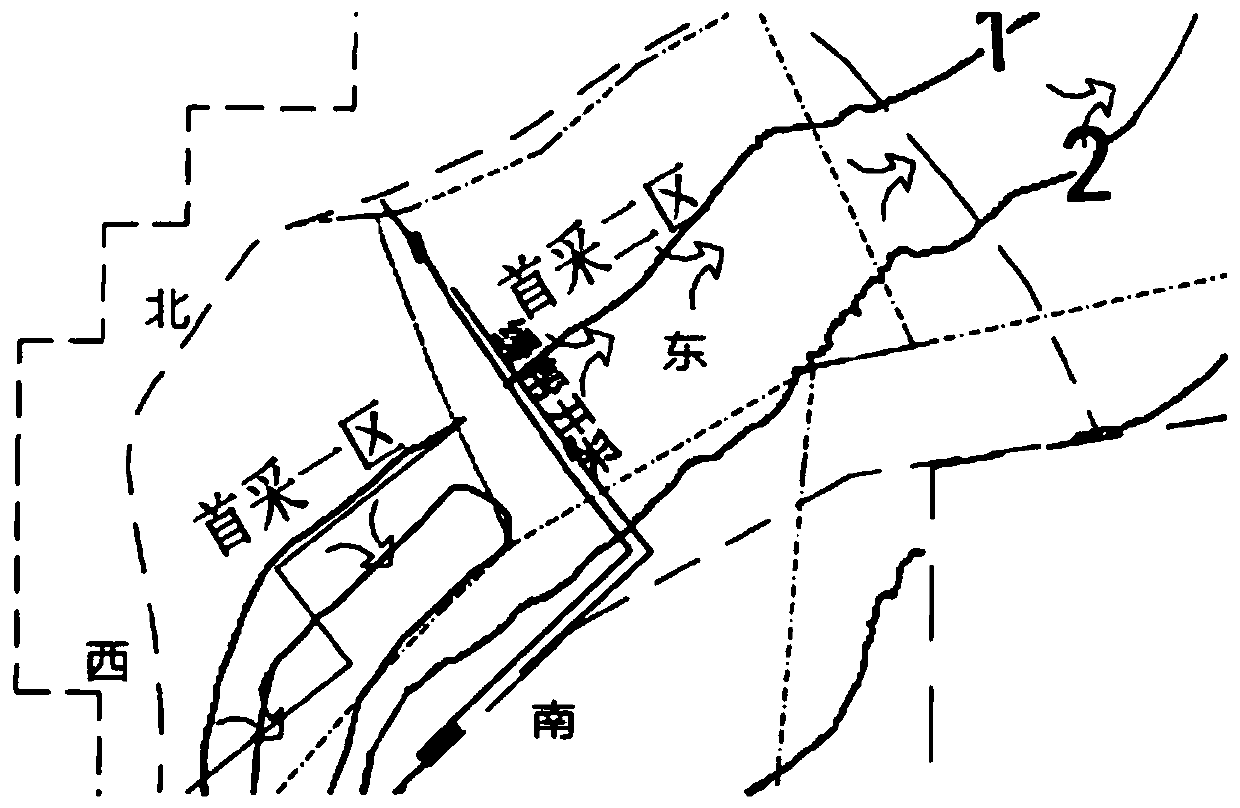

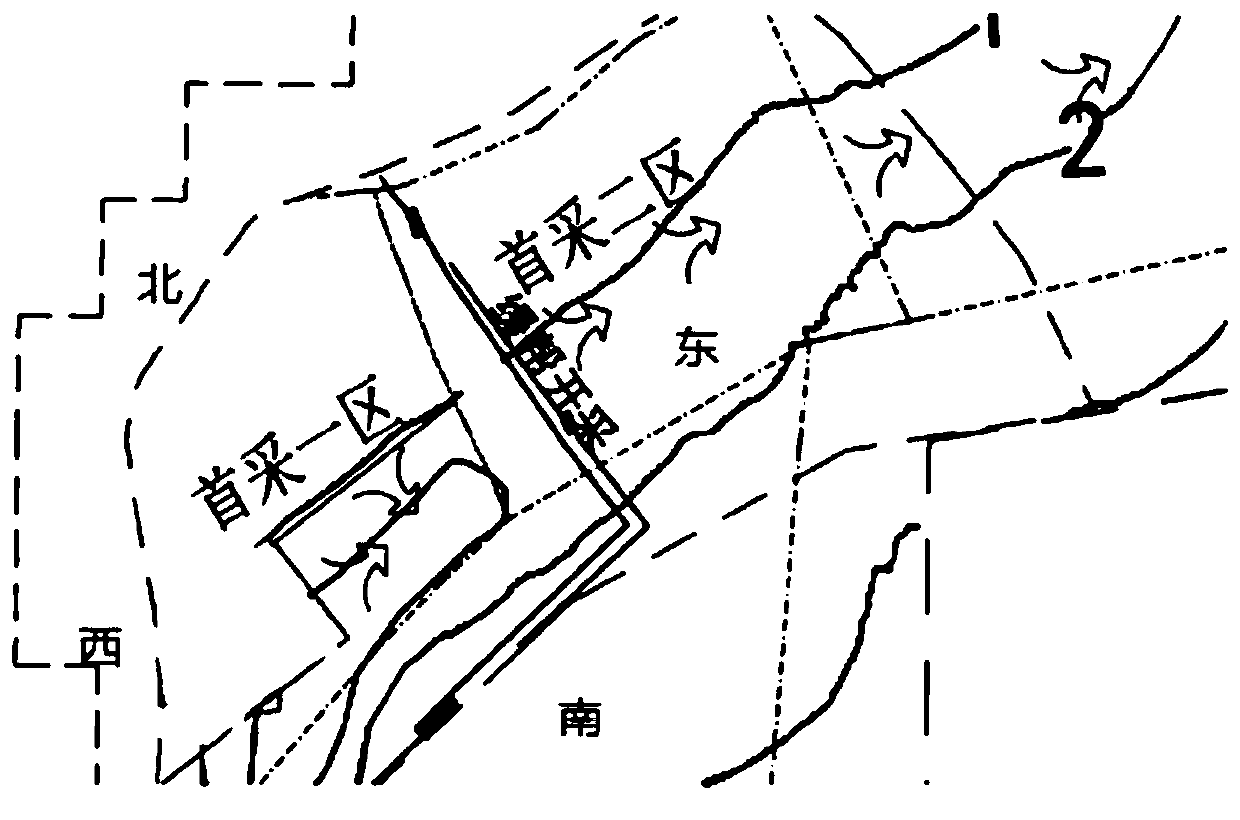

[0022] like figure 1 Step 1: Divide the open-pit huge thick inclined coal seam area into multiple mining areas, with the inclination as the north-south direction, the coal seam being higher in the north and lower in the south, the strike being the east-west direction, and advancing from west to east. The mining area of the first area is ditched and the working line is arranged, the entire mining area is divided into two parts by the working line, and the coal seam stripping is carried out along both sides of the working line. Therefore, when the coal seam is stripped at the same speed on both sides of the working line, there must be the result that one side of the coal seam is stripped before the other side of the coal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com