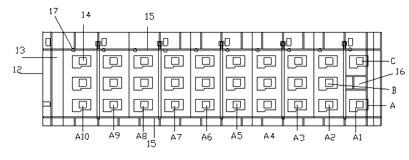

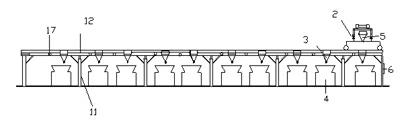

Automatic feeding system

A technology of automatic feeding and binning, which is applied in metal processing and other directions, and can solve the problems of occupying aisles, mixing materials, and inconvenient loading for workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

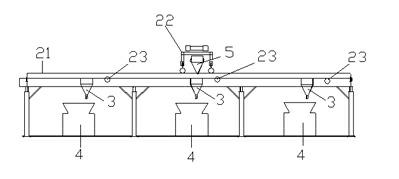

[0023] The initial position of the trolley is at the position of the feeding port 16, the hanging basket 5 is at the bottom of the derrick 9, and the control cabinet 6 receives the material-free information from the material-free detection device 32 on the material box 3 at position A10, and the worker puts the material Put it into the feeding trolley 7, push the feeding trolley 7 into the tipping trolley 81, start the feeding program on the control cabinet 6, the third cylinder 85 works, lift the bracket 82 centered on the shaft 84, and turn it 90 degrees Stop, when it is in place, the second cylinder 86 extends quickly, turns over the turning cart 81 centered on the shaft 84, and pours the material into the hanging basket 5. After the material is poured, the second cylinder 86 recovers and retracts the turning cart 81 to the bracket 82, the third cylinder 85 retracts the bracket 82 to the support 83, and after the detection device (not shown in the figure) detects that all th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com