Equipment and method for separating reformed oil

A technology of reforming oil and separation method, which is applied in the field of separating reforming oil to achieve the effect of saving the total investment of equipment, reducing investment cost, and reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

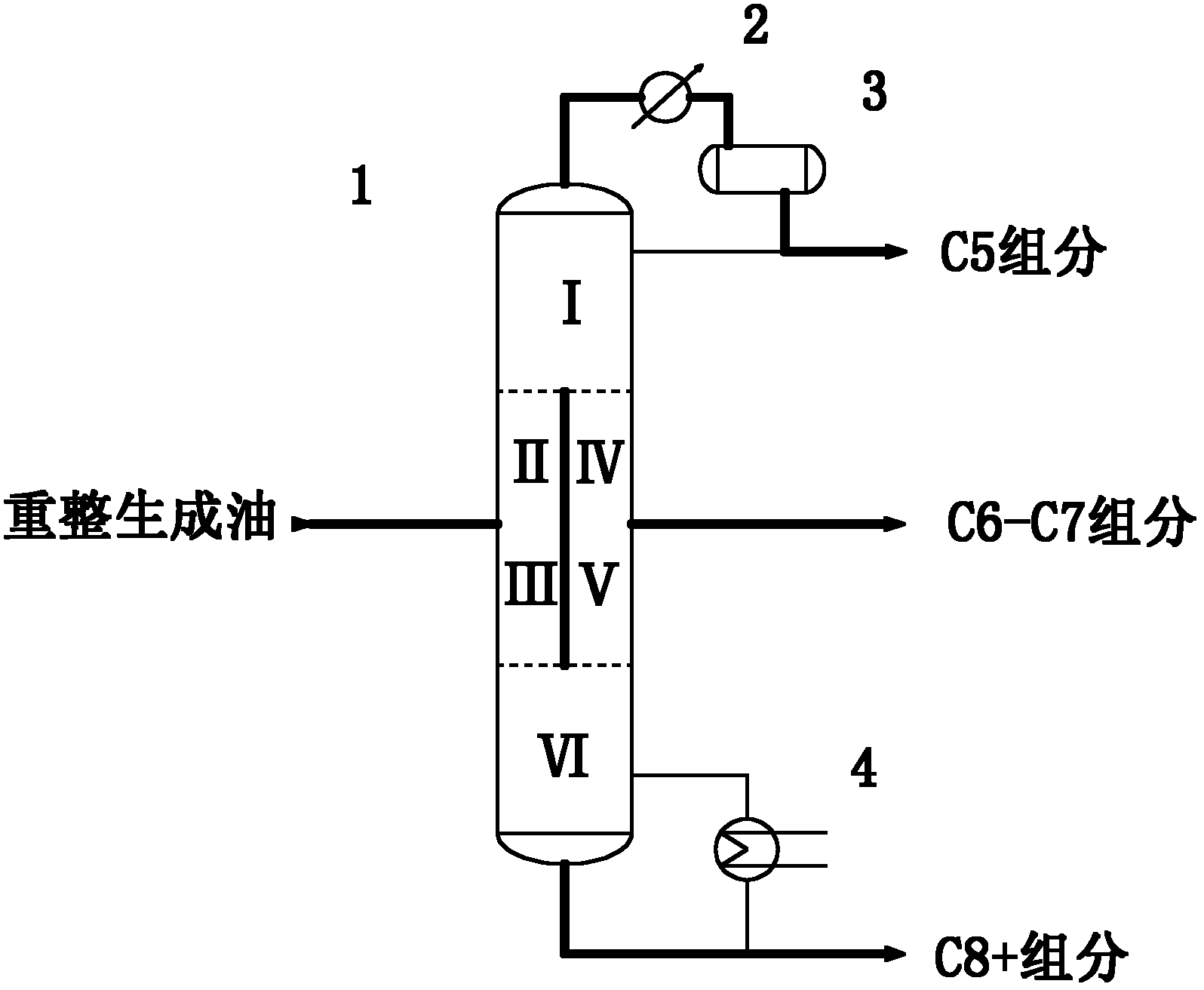

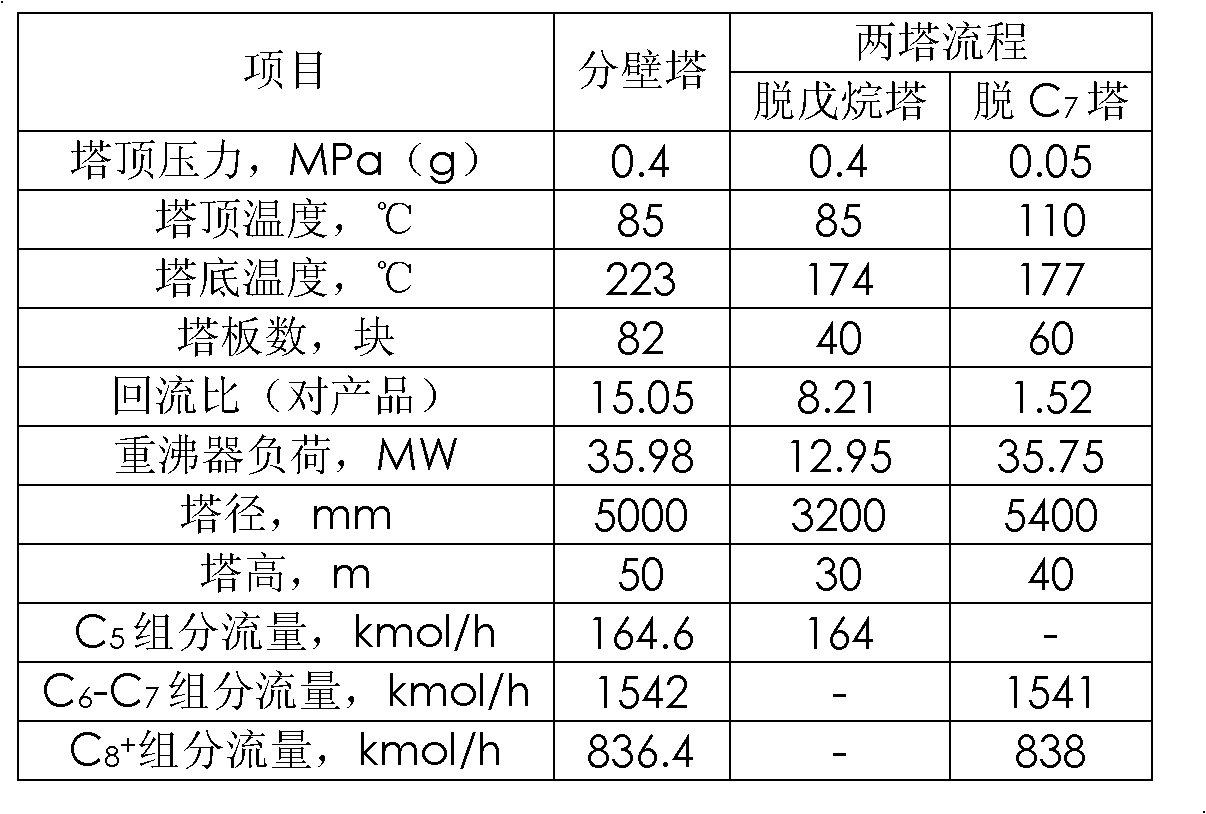

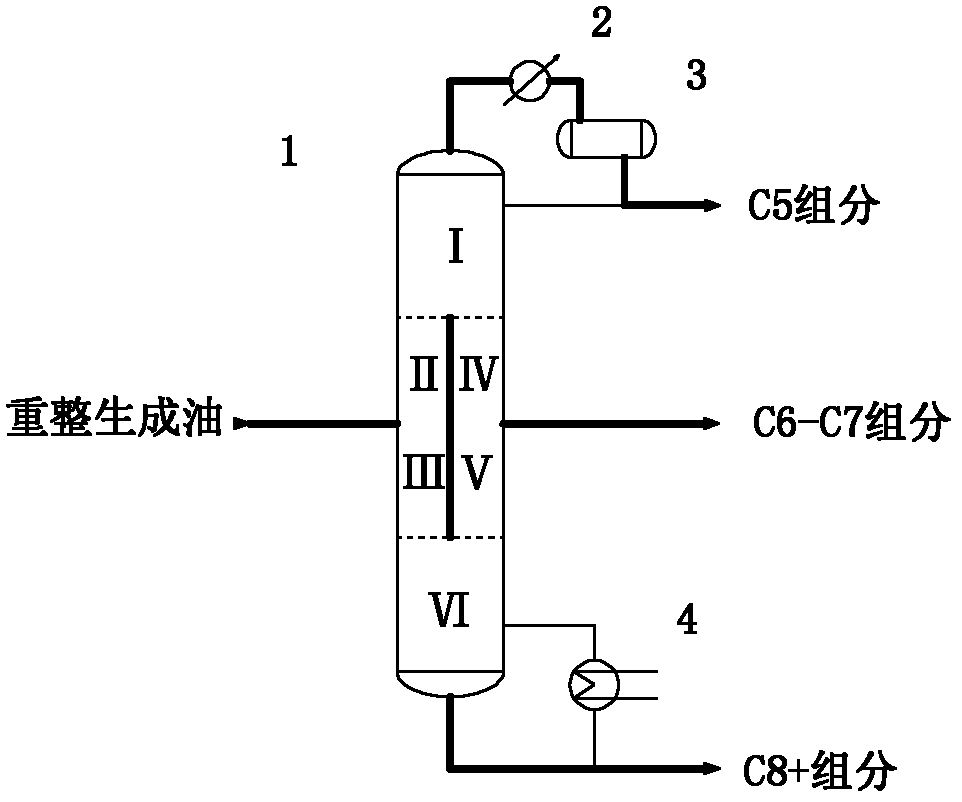

[0022] The reformed oil is separated by dividing wall column process. The process conditions are as follows: the processing capacity is 2 million tons / year, the typical raw material composition is shown in Table 1, the feed pressure is 0.5MPa(g), and the bubble point is fed. Separation requirements: C 5 Component purity is 99% (mol), C 6 -C 7 Component purity is 99.7% (mol), C 8 + The component purity is 99% (mol). The operating pressure of the dividing wall column is 0.4MPa(g), and a total of 82 trays are required. The process flow is shown in Figure 2, and the process parameters are shown in Table 2. It can be seen from Table 2 that the energy saving by adopting the dividing wall tower is 26.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com