Automatic production line for green tea

An automatic production line, green tea technology, applied in the direction of tea processing before extraction, can solve the problems of increased enterprise expenditure, tea splashing, low processing efficiency, etc., and achieve the effects of improving rolling efficiency, rolling speed, and increasing contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

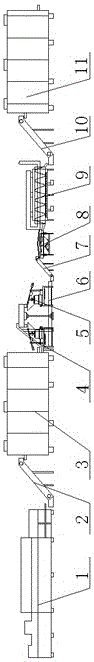

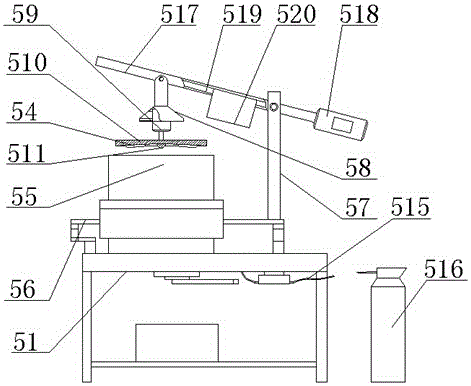

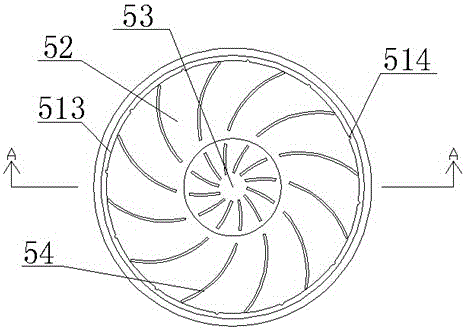

[0029] Embodiments of the present invention: a green tea automatic production line, as attached Figure 1-6As shown, it includes a de-enzyme machine 1, the discharge port of the de-enzyme machine 1 is connected with the feed port of the dryer 3 through the first elevator 2, and the discharge port of the dryer 3 passes through the second elevator 4 and the kneading unit The feeding port of the kneading unit is connected with the feed port, and the kneading unit is provided with a conveying trough 6, and the discharge port of the conveying trough 6 is connected with the feed port of the vibrating conveyor 8 through the third elevator 7, and the discharging port of the vibrating conveyor 8 is connected with the multi-functional The feed port of machine 9 is connected, and the discharge port of multifun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com