Efficient three-dimensional injection molding factory and efficient injection molding production method

A high-efficiency, three-dimensional technology, applied in the direction of coating, can solve difficult problems such as production efficiency, and achieve the effect of improving efficiency, reducing floor area, and efficiently utilizing space resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

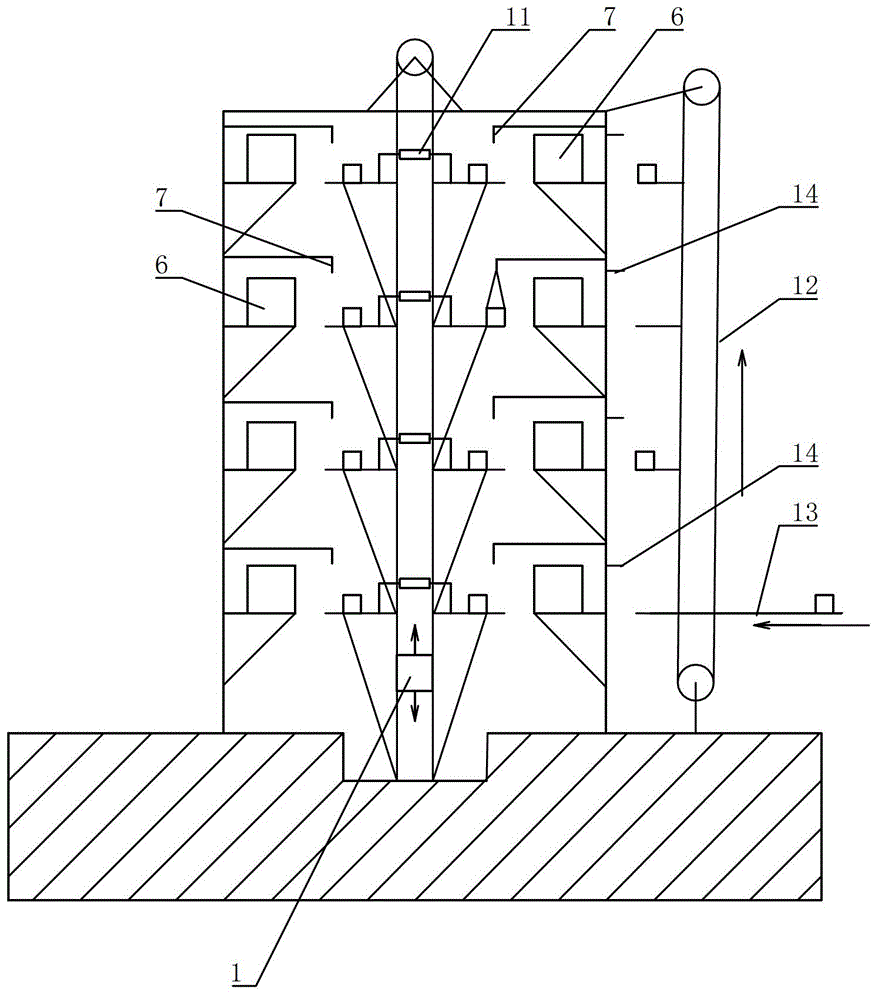

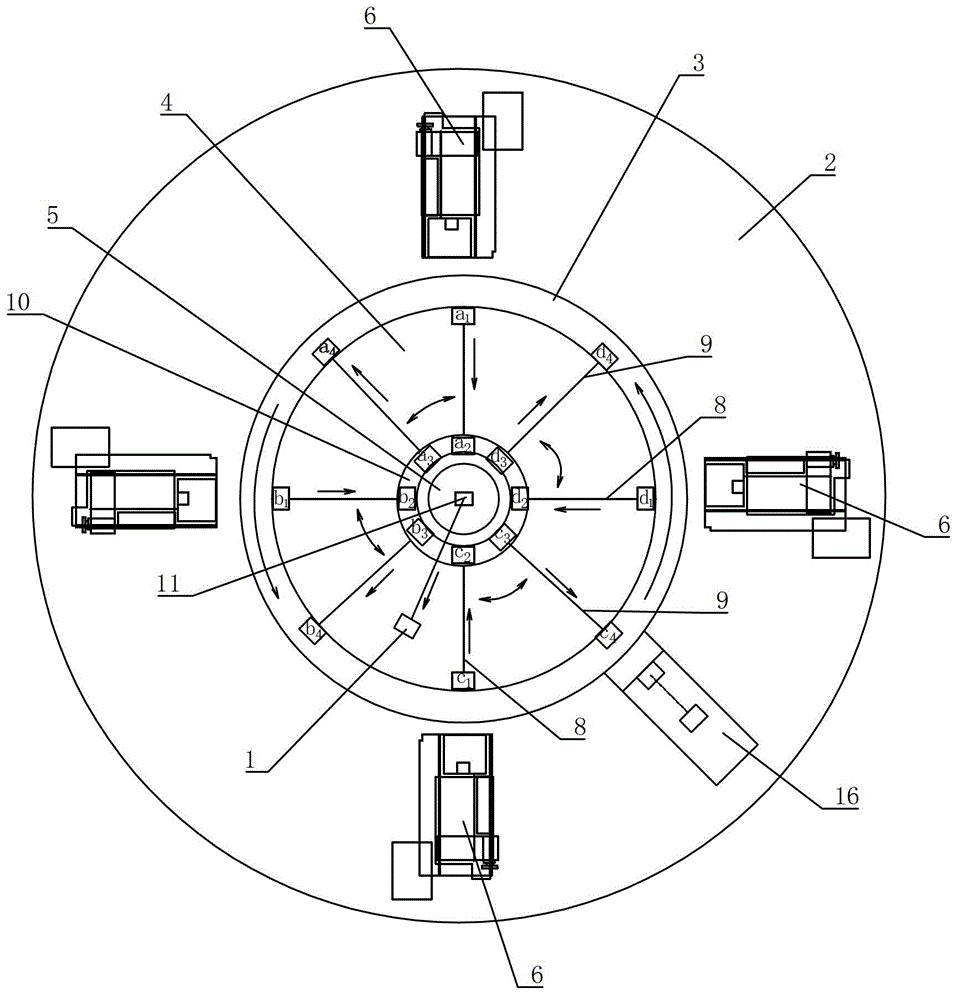

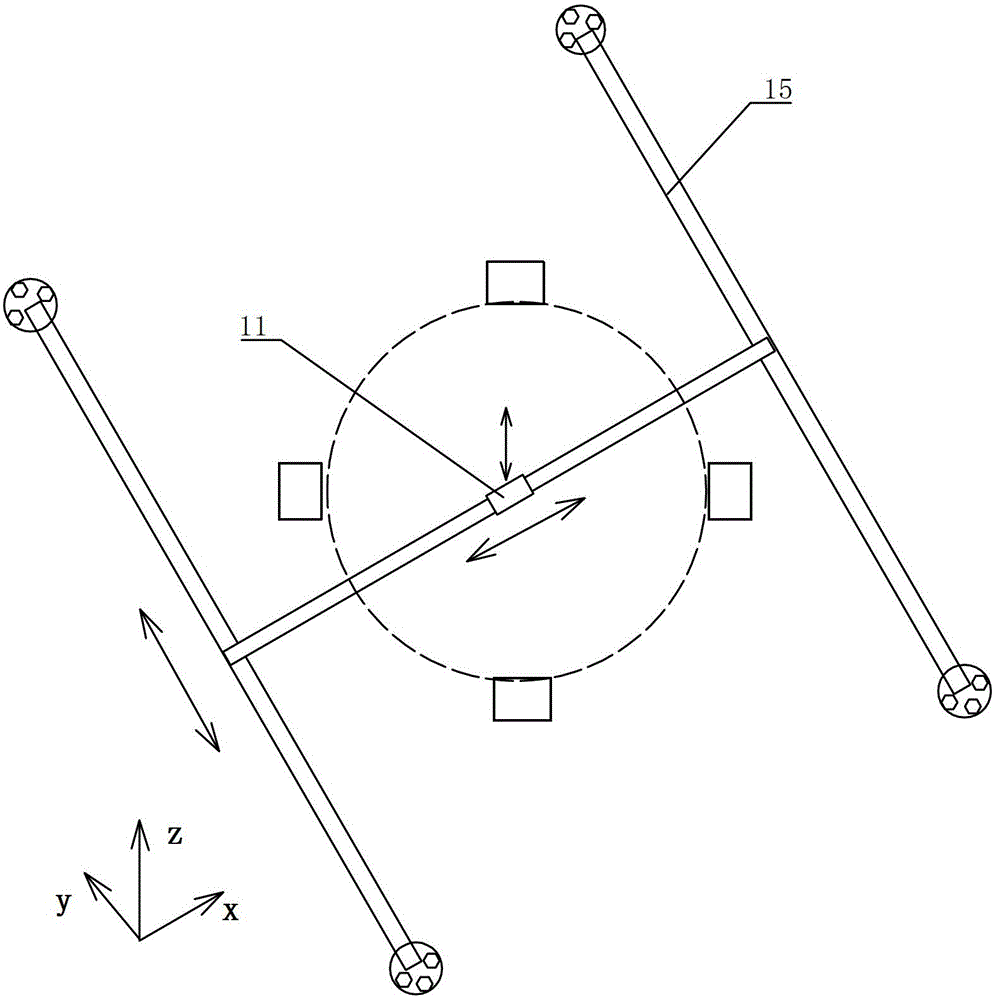

[0022] Such as figure 1 and figure 2 As shown, a high-efficiency three-dimensional injection molding factory includes 4 working floors from low to high and a product transport elevator 1 that can stop on each working floor. Each working floor is circular, and there are installation platform 2, feeding turntable 3, mold unloading platform 4 and pick-up platform 5 in sequence from the outer periphery to the middle, among which the loading turntable 3 can make a 360-degree rotation in the plane of the working floor. Turn around. On the installation platform 2, four injection units 6 are arranged symmetrically with the center of the circle, and each working floor is provided with a mold unit that will be used in conjunction with the injection unit 6 on the injection unit 6, the unloading platform 4, the pick-up platform 5 and the upper 4 sets of mold unloading devices for loading and unloading back and forth between the material turntables 3, and the pick-up platform 5 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com