ECFF (electric-flocculation+electrolytic-flotation+filtration) type integral electric-flocculation car-washing waste water treatment device

A technology for car washing wastewater and treatment device, which is applied in the direction of vehicle washing facility wastewater treatment, water/sewage treatment, water/sewage treatment equipment, etc. The small device occupies space and manufacturing cost, the functional structure is reasonable, and the industrial practicability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

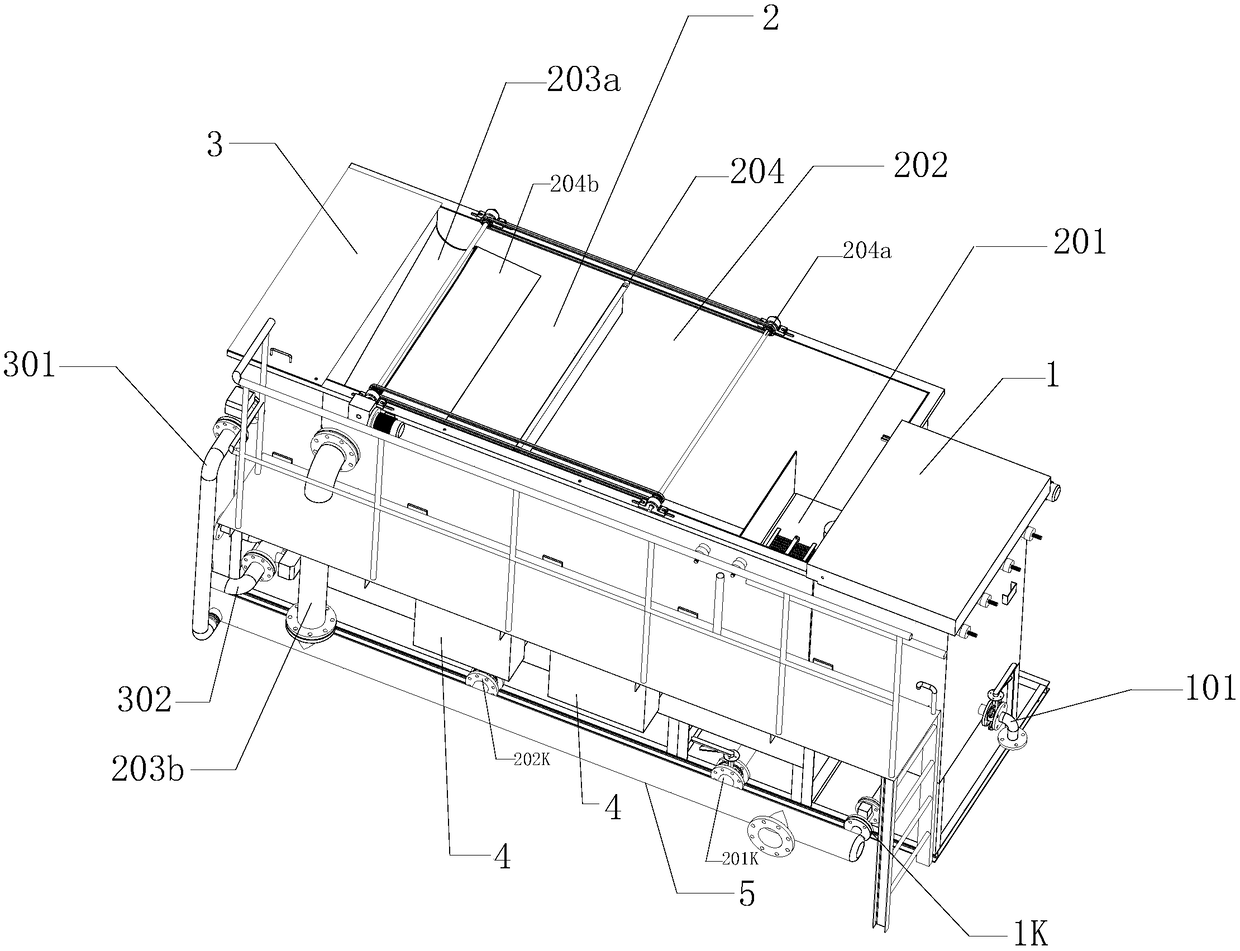

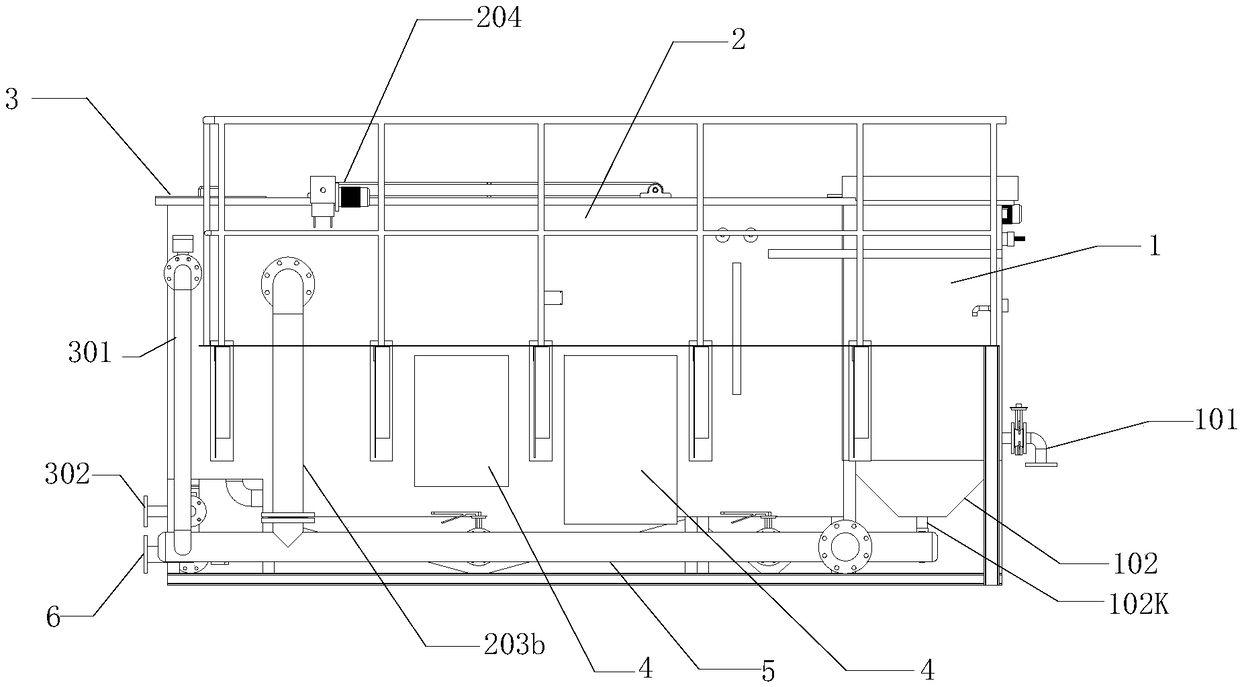

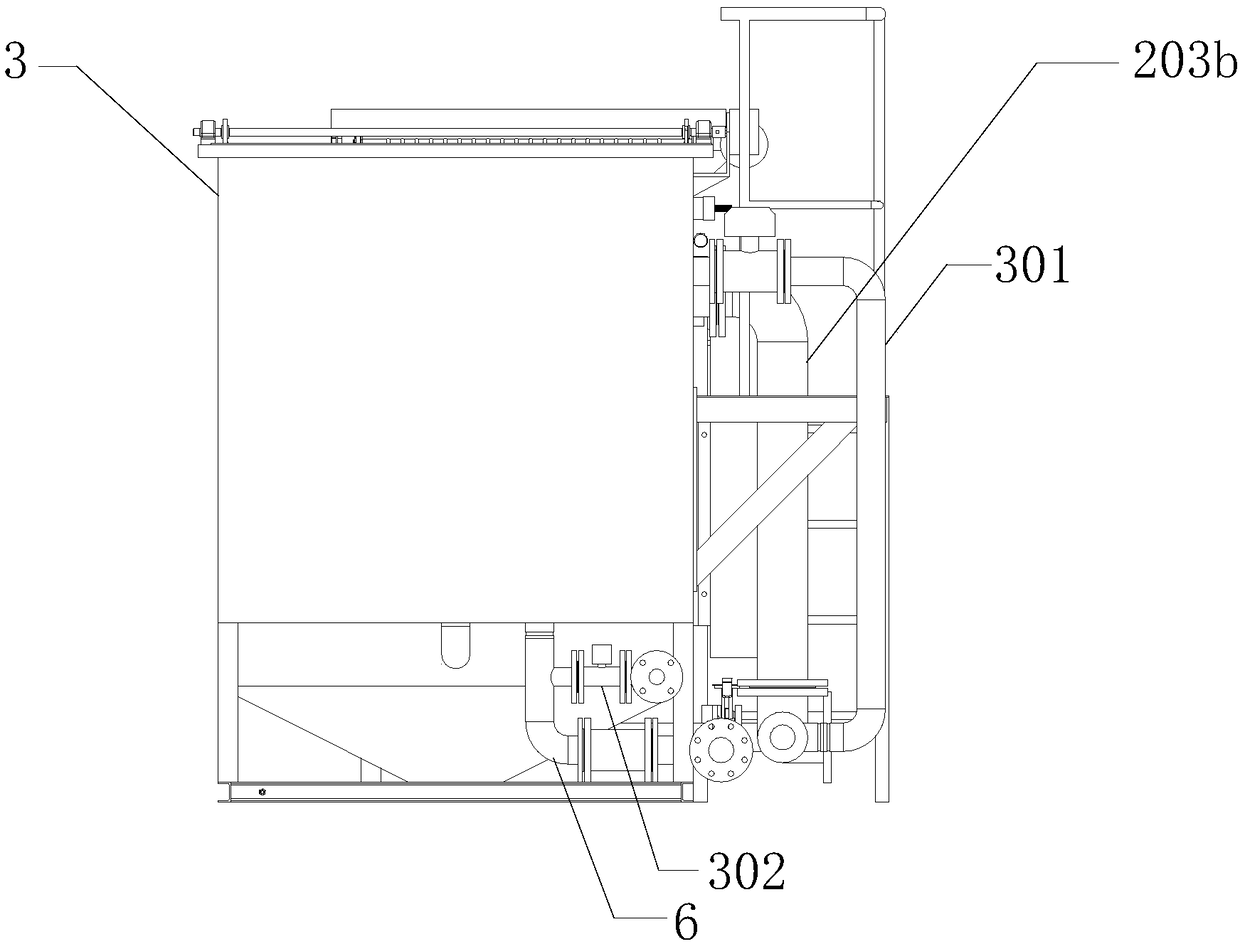

[0049] Such as Figure 1-6 As shown, the ECFF type integrated electrocoagulation car wash wastewater treatment device includes a shell A, which is provided with an electroflocculation reaction chamber 1 , an electrolytic air flotation chamber 2 and a filter chamber 3 connected in sequence.

[0050] The electrocoagulation reaction chamber 1 is a chamber separated by the side wall of the shell A and the first partition B; the side wall of the shell A is provided with a waste water inlet 101 for transporting waste water to be treated into the electrocoagulation reaction chamber; the chamber is provided with an electrocoagulation device 104 for performing electrolytic coagulation and impurity removal on the wastewater to be treated. The electrocoagulation reaction chamber 1 specifically includes electrocoagulation electrode plates, and a power supply device connected to the electrocoagulation electrode plates. The power supply device is an electric control cabinet 4, and the elect...

Embodiment 2

[0068] A kind of process that uses ECFF type integrated electric flocculation car washing wastewater treatment device described in embodiment 1 to carry out the process of wastewater treatment, specifically comprises the following steps:

[0069] S1. Pass the wastewater into the electroflocculation reaction chamber, and undergo electrolytic flocculation reaction treatment to remove impurities in the wastewater by preliminary flocculation and precipitation;

[0070] S2, passing the waste water after step S1 flocculation and impurity removal into the electrolytic air flotation chamber for flocculation and air flotation to remove impurities;

[0071] S3. Finally, pass the waste water removed by flocculation and air flotation in step S2 into the filter chamber for deep filtration to remove impurities to obtain a treated clear liquid.

[0072] According to the above wastewater treatment process, in the whole wastewater treatment process, only need to flexibly adjust the current int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com