Spindle yarn-storing driving device of multifunctional extra-large-stroke yarn storage device

A technology of driving device and yarn storage device, which is applied in the direction of braided fabrics, textiles, and papermaking. It can solve the problems of short spindle strokes and inability to meet the needs of weaving, and achieve the effects of precise transmission, low cost, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

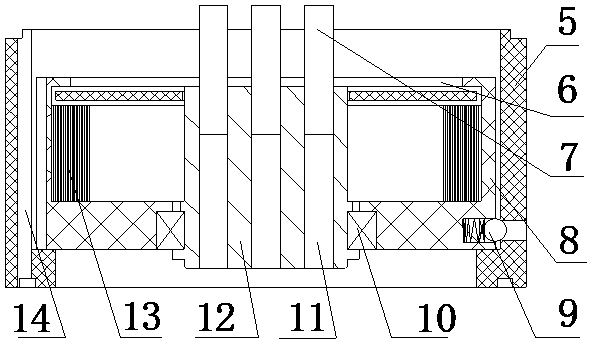

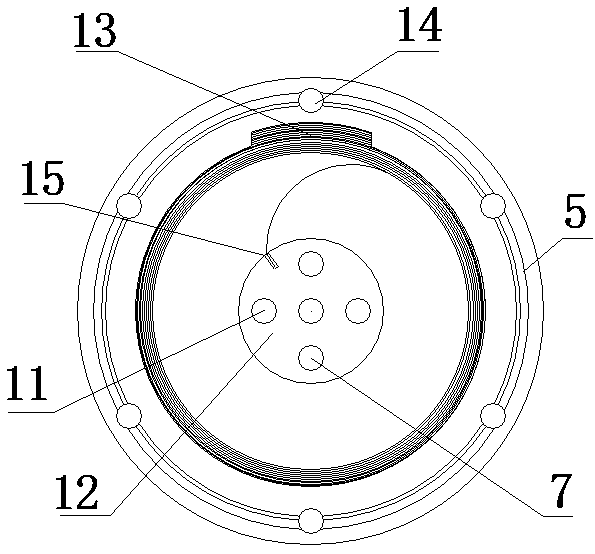

[0025] Embodiment 1: The spindle yarn storage driving device includes: a fixed sleeve 5, a dial shaft 7, a driver seat 8, a driver 13, a rotor shaft 12, a shaft hole 11, a driver bearing 10, a shaft cover 6, a transition hole 14, a fixed Groove 15 and positioning connector 9;

[0026] The driver seat 8 is fixedly connected in the fixed sleeve 5 through the positioning connector 9; there is a transition hole 14 through the fixed sleeve 5; a driver 13 is connected in the driver seat 8, and one end of the driver 13 is embedded in the driver seat 8. In the groove, the other end of the driver 13 is stuck on the fixed groove 15 of the rotor shaft 12; the rotor shaft 12 is connected to the axis center position of the driver seat 8 through the driver bearing 10; there is a dial shaft hole 11 on the rotor shaft 12, and the dial shaft 7 is connected to On the dial shaft hole 11 , the dial shaft 7 passes through the dial shaft cover 6 .

[0027] The driver seat 8 is cylindrical, one end...

Embodiment 2

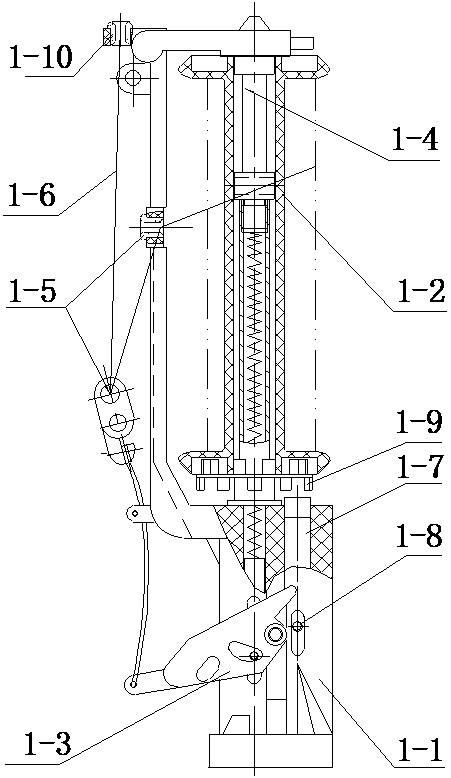

[0031] Embodiment 2: There are four retractable and storage yarn drive devices; the four retractable and storage yarn drive devices are fixed in series by bolts; the first drive device 1, the second drive device 2, the third drive device 3 and the first drive device The four driving devices 4 are sequentially connected in series by bolts from top to bottom.

[0032] The dial shaft 7 protruding from the top of the retractable yarn storage drive device below is inserted into the dial shaft hole 11 at the bottom of the upper retractable yarn storage drive device.

[0033] The uppermost retractable yarn storage driving device dial shaft 7 is inserted into the positioning hole on the lower end surface of the yarn storage device shaft of the constant tension pay-off device.

[0034] The rotation of the rotor shaft 12 of the retractable yarn storage drive device drives the yarn storage device shaft to rotate simultaneously through the dial shaft; in this embodiment, four retractable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com