a textile machine

A textile equipment and yarn bobbin technology, which is applied in the field of textile equipment, can solve the problems of changing the unwinding speed of the yarn bobbin, the equipment cannot weave normally, and the roving cannot be effectively adjusted, so as to change the unwinding speed, automatically and effectively control the tension, and meet the weaving requirements. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the present invention provides a textile device, and the textile device includes:

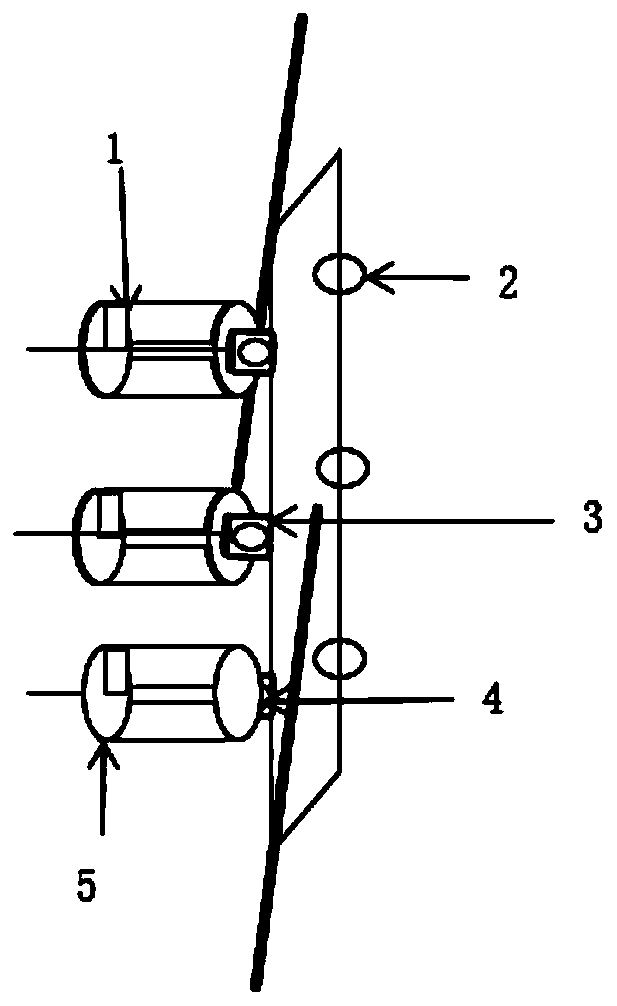

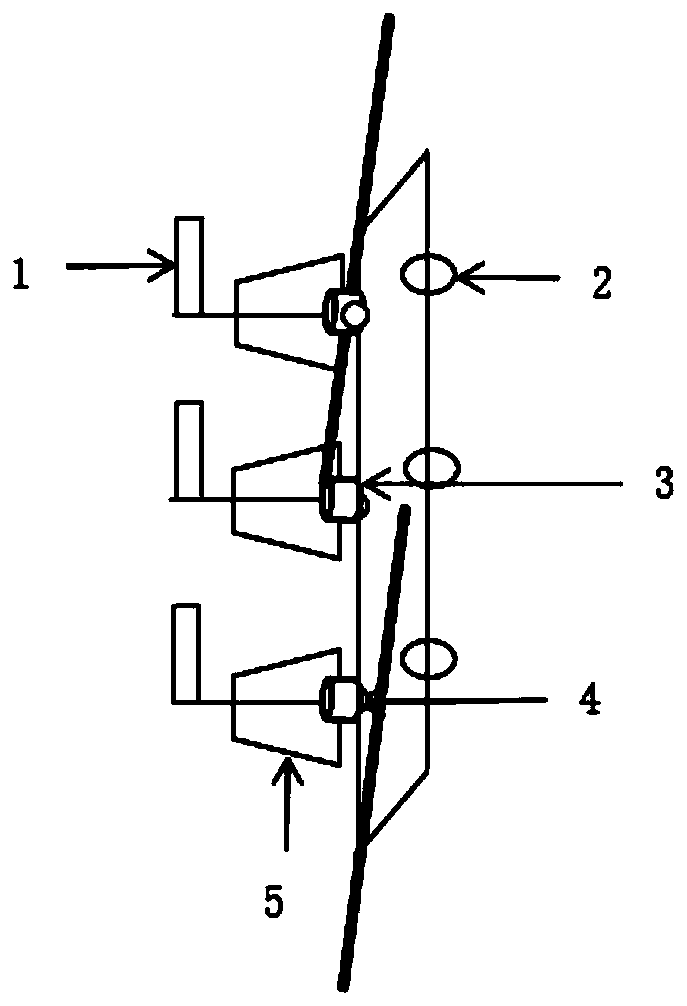

[0032] The yarn spool 5, the outer surface of the yarn spool 5 is provided with a reflective material 1, and the yarn spool 5 is arranged on the bearing 3 of the yarn feeding system.

[0033] Further, the textile equipment further includes: a creel on which the yarn feeding system is arranged, wherein a chain of the yarn feeding system drives a gear, and the gear is connected to the bearing 3 .

[0034] Specifically, the yarn feeding system is set on the creel, and the yarn bobbin is set on the bearing 3 of the yarn feeding system, wherein the chain of the yarn feeding system drives the gear, and the gear is connected to the bearing 3 and drive the bobbin 5 to rotate and unwind the yarn, and the outer surface of the bobbin 5 is provided with a reflective material 1 .

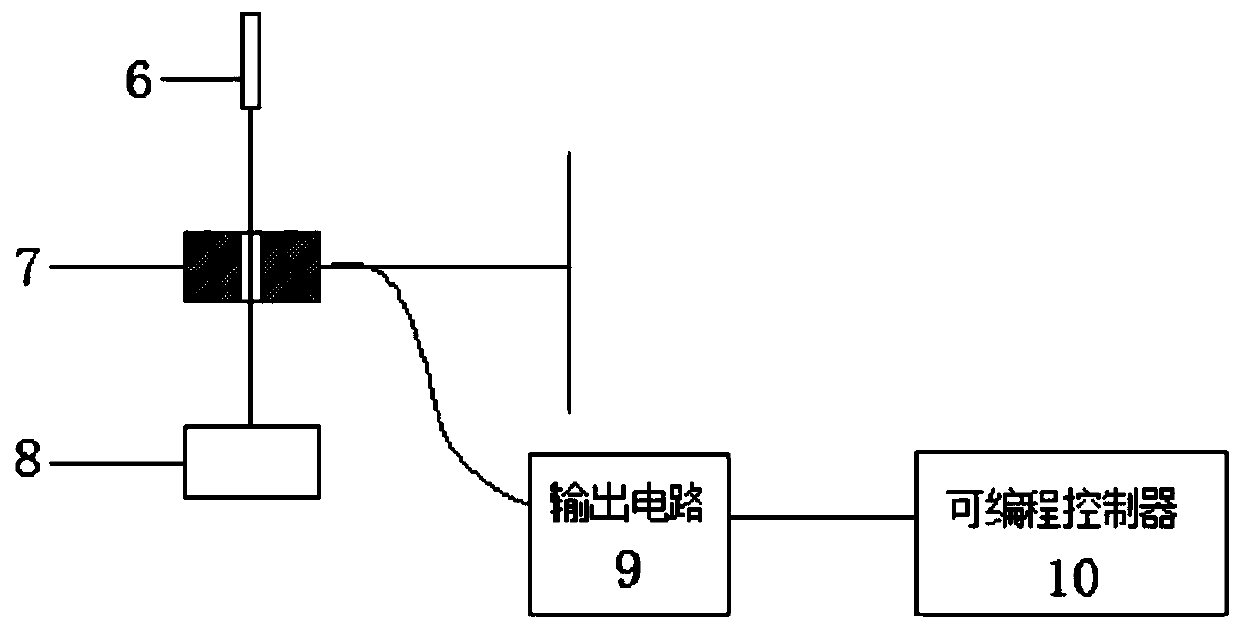

[0035] The photoelectric sensor 2, the receiving end of the photoelectric sensor 2 is arranged corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com