Intelligent wire releasing device for steel cable stranding

A wire feeding device and steel cable technology, which is applied in the field of bridge construction manufacturing, can solve problems such as unsynchronized wire feeding speed, inability to guarantee employee safety, accidental injury to employees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

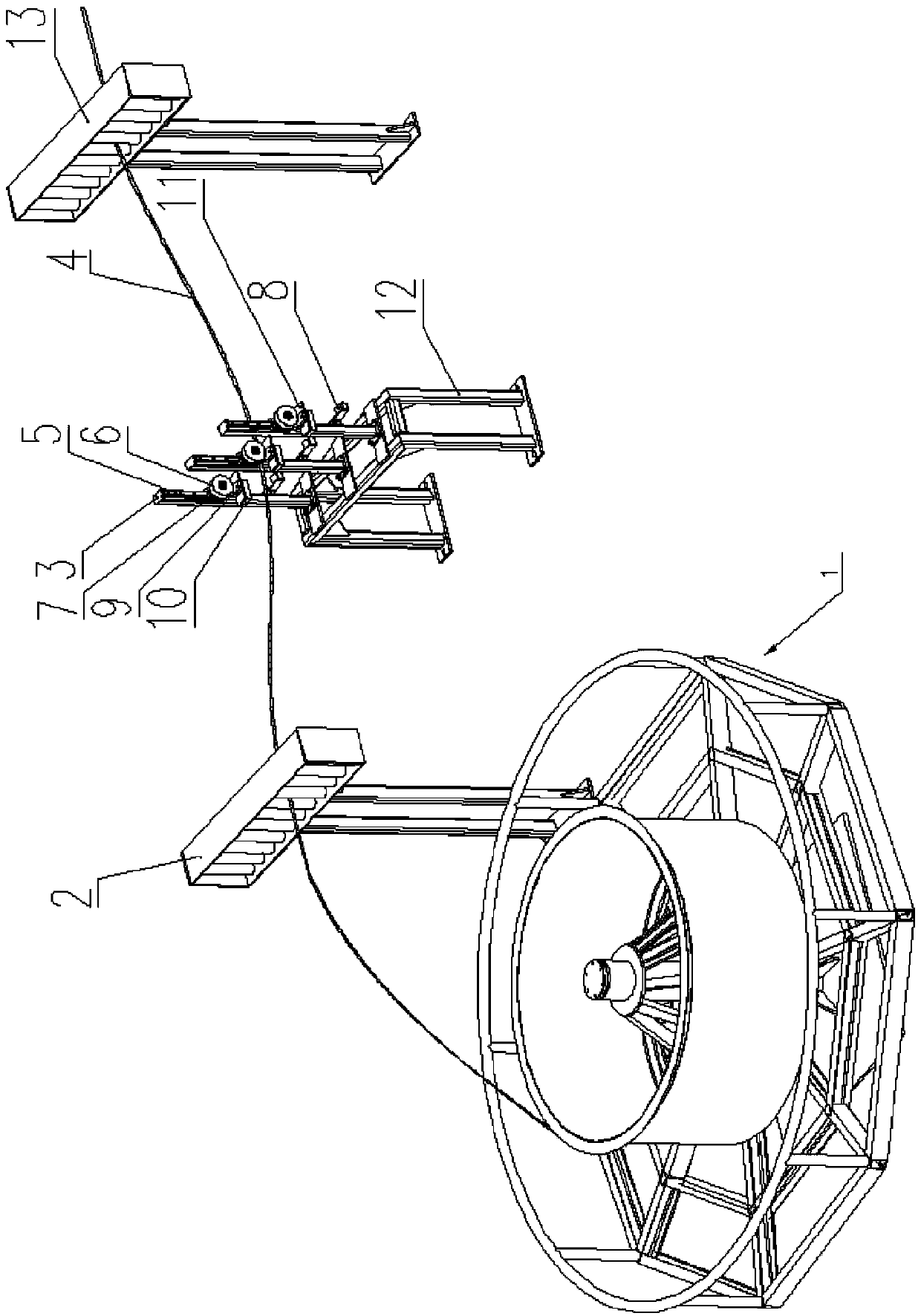

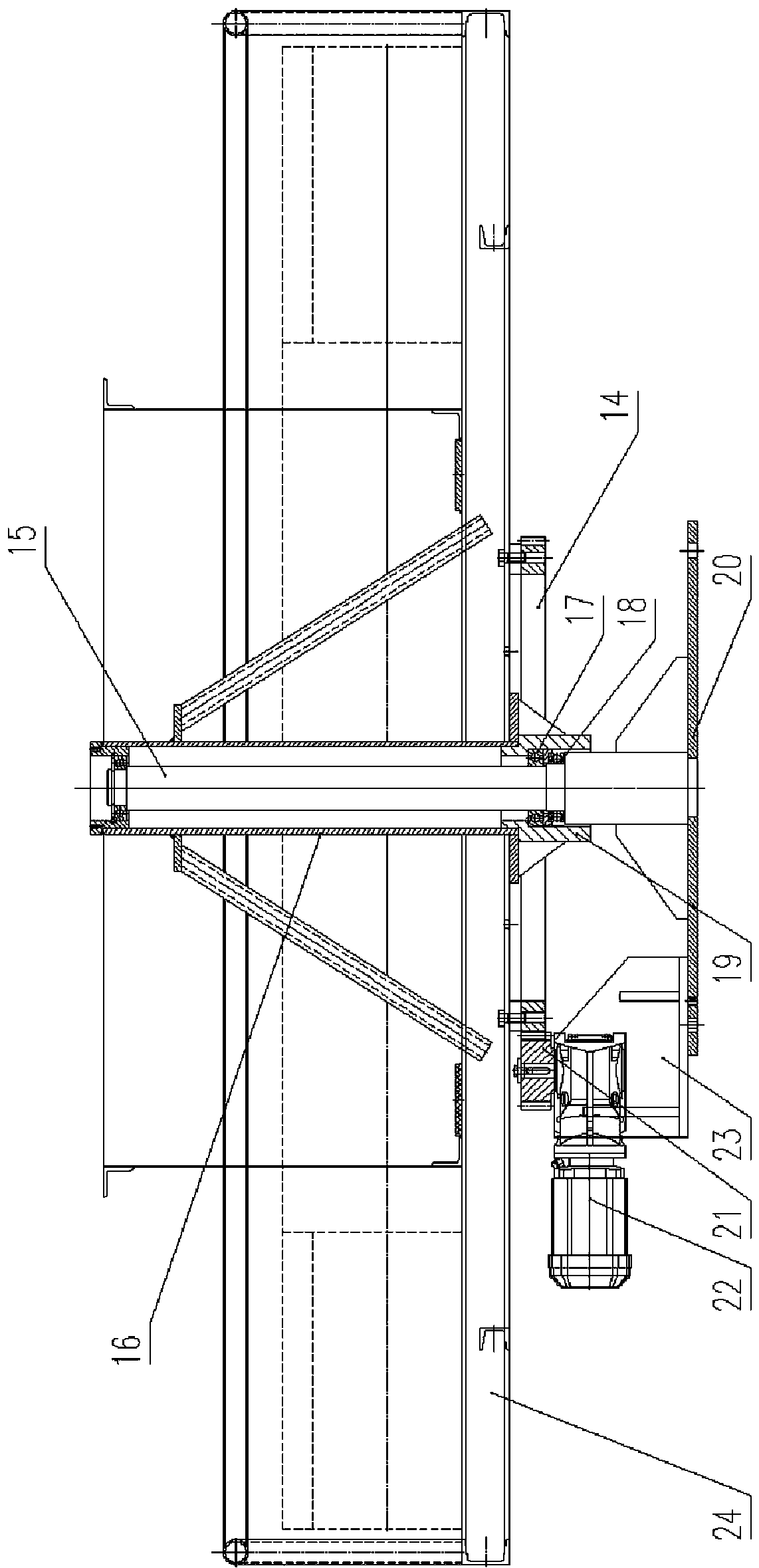

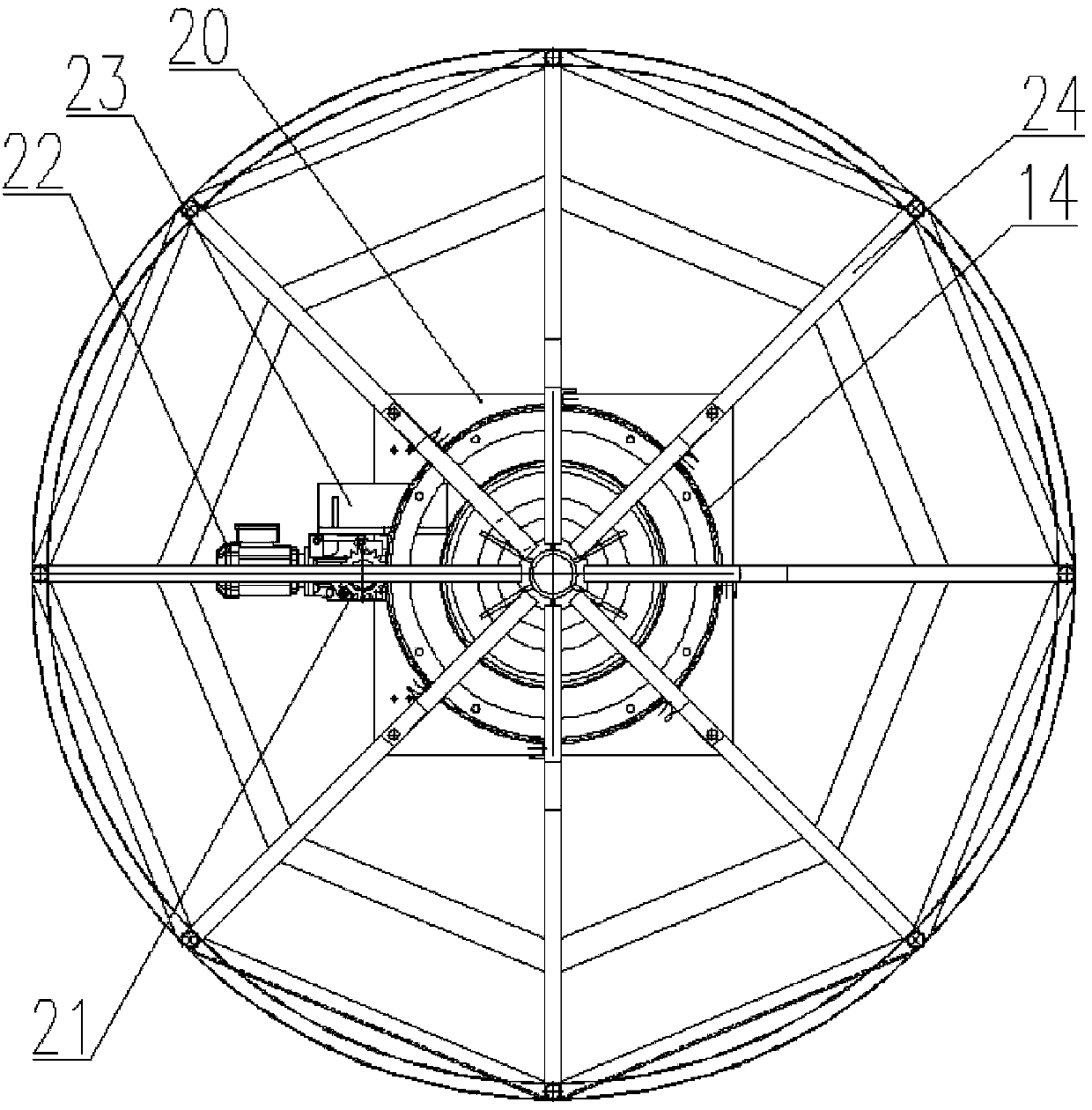

[0021] An embodiment of the steel cable stranding intelligent wire feeding device of the present invention:

[0022] see Figure 1-Figure 3 , a steel cable stranding intelligent wire-releasing device, including a plurality of wire-releasing reels and wire management frames, each of which includes a base 20, a rotating frame 24, a reduction motor 22 controlled by a frequency converter, and a driving gear 21. The reduction driven gear 14, the base 20 is provided with an upright central shaft 15, the center of the rotating frame 24 is provided with a hollow column 16, and the lower end of the hollow column 16 is fixedly connected with a bearing seat 19, the The bearing seat 19 is slidingly matched with the central shaft 15 through the rolling bearing 17, the thrust bearing 18, the thrust bearing 18 is positioned by the shoulder of the central shaft 15, the thrust bearing 18 is used to support the axial load, and the rolling bearing 17 enables the bearing seat 19 to rotate , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com