Automatic Belt Tensioner for Electric Vehicles

An automatic tensioning device, electric vehicle technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of low efficiency, heating of bearings, heating of pulleys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

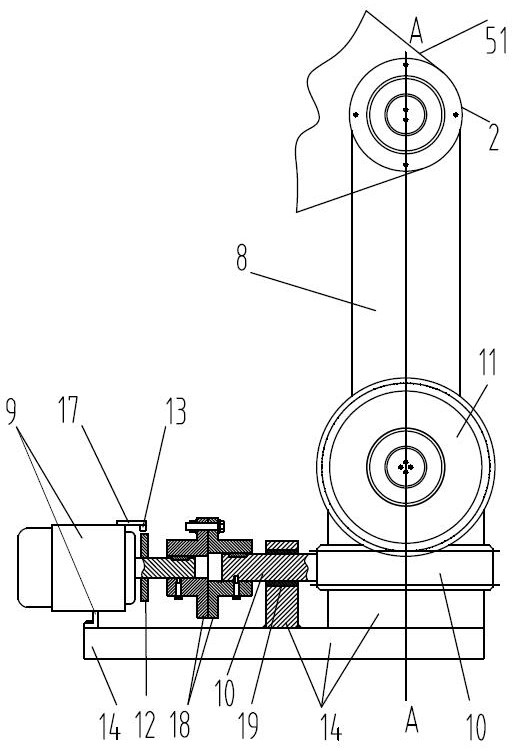

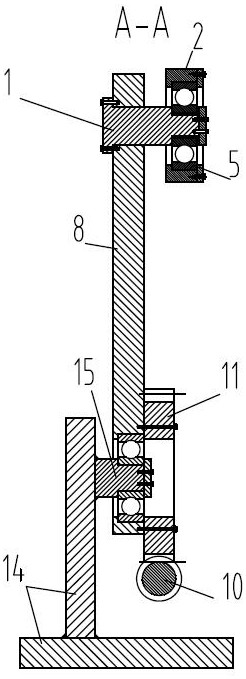

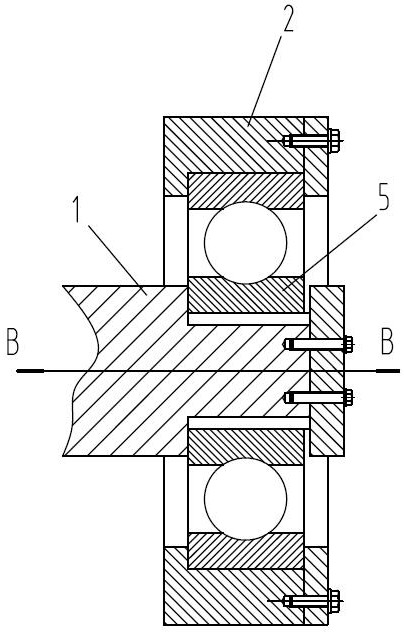

[0017] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

[0018] Such as Figure 1 to Figure 7 As shown, an automatic belt tensioning device for an electric vehicle includes a tensioning belt 51; it also includes a pulley shaft 1, a tensioning pulley 2, a pressure sensor 3, a main controller 4, a bearing 5, a pressure plate 6, a spring 7, a tensioning Tight bracket 8, tensioning motor 9, worm screw 10, worm wheel 11, magnetic ring 12, sensor 13, fixed frame 14, support shaft 15 and motor driver 16; the magnetic ring 12 in this embodiment is produced by Jiangsu Xinxu Magnetoelectric Technology Co., Ltd. two pairs of polar magnetic rings. The sensor 13 is a Hall sensor with a model number of MT4401. The pressure sensor 3 is a compression force sensor of model LH-Y03-D. Tensioning motor 9 selects the servo motor that model is TLSM04-M00330 for use. The main controller 4 is a PLC programmable controller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com