Patents

Literature

35results about How to "Increase the speed of unwinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-woven fabric dying production line

InactiveCN103820962AAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

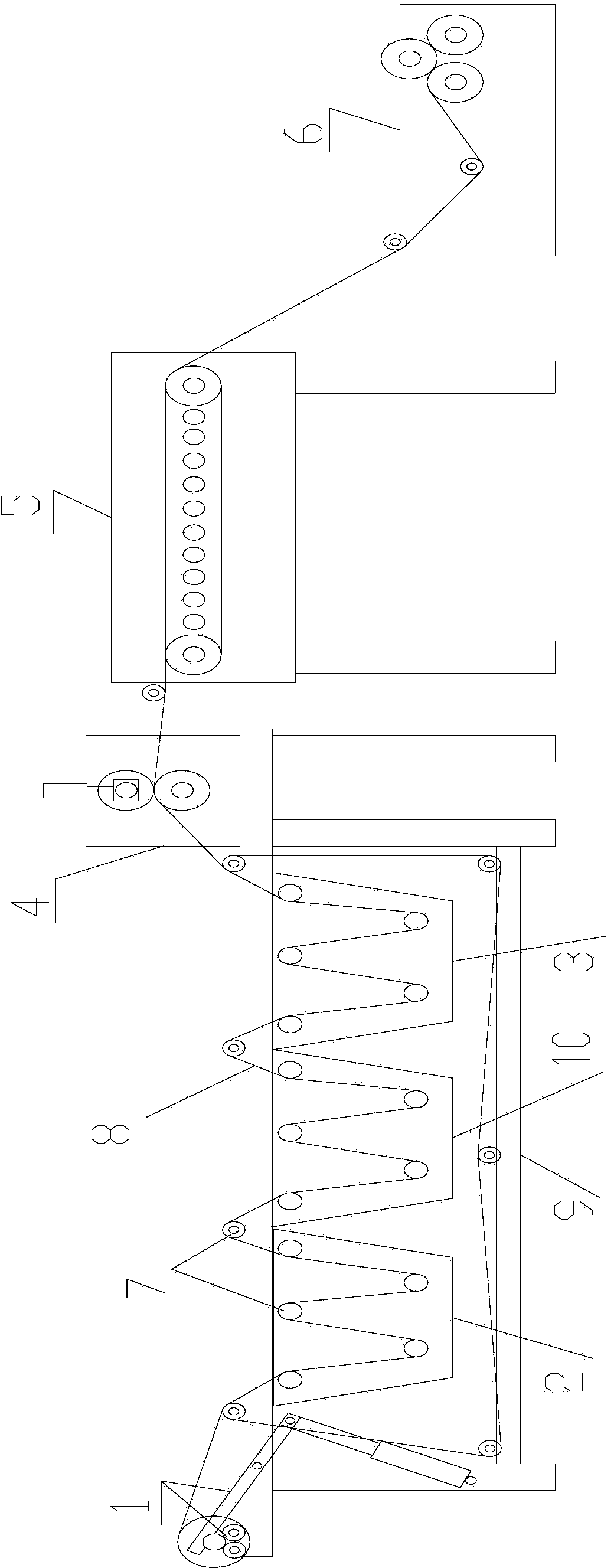

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

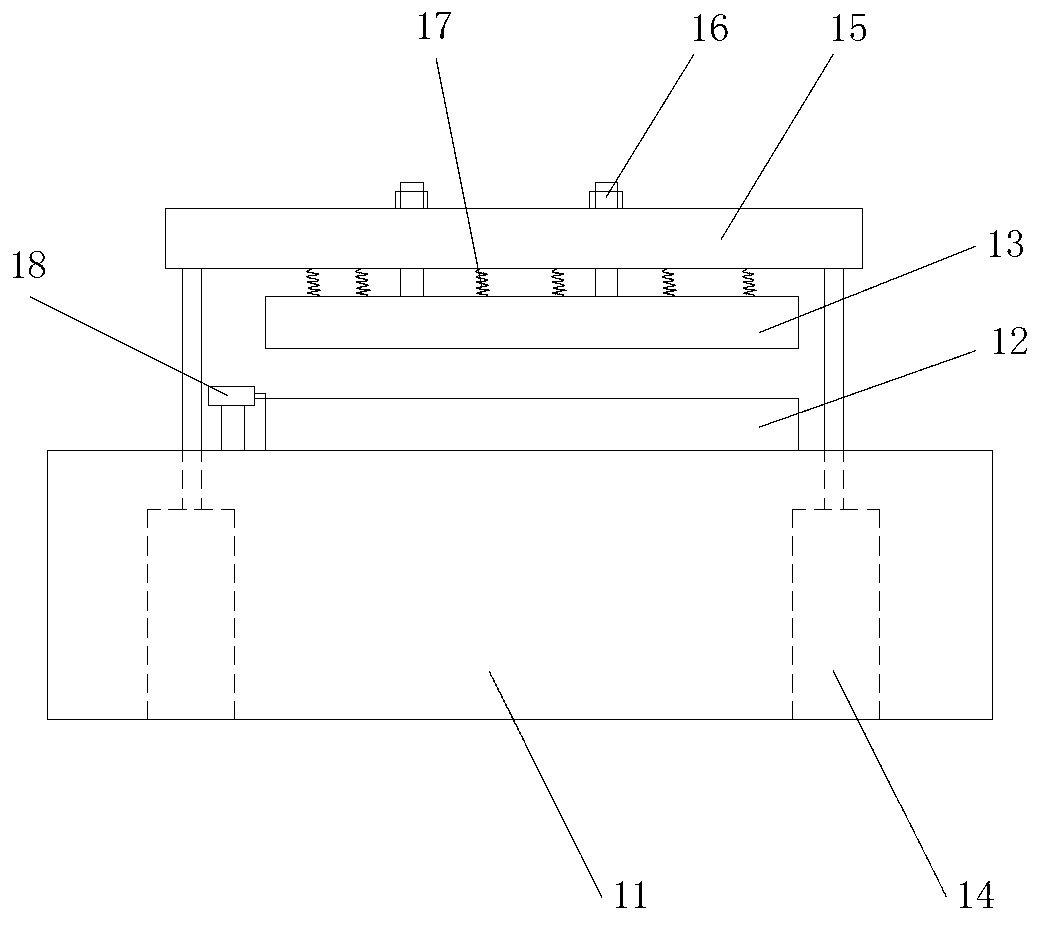

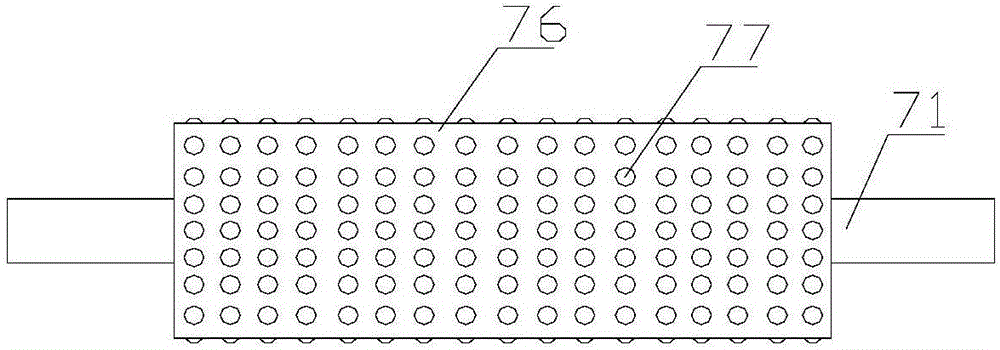

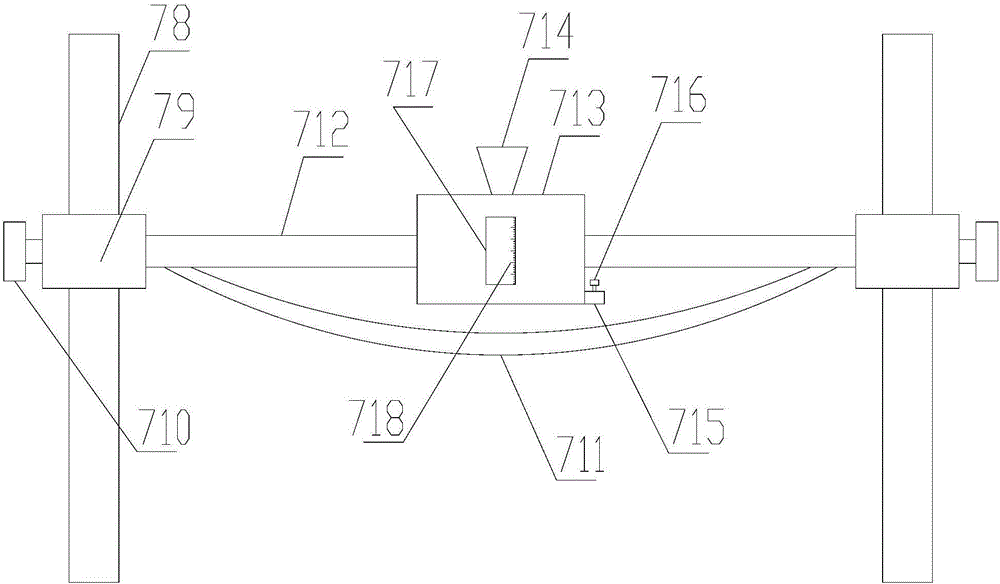

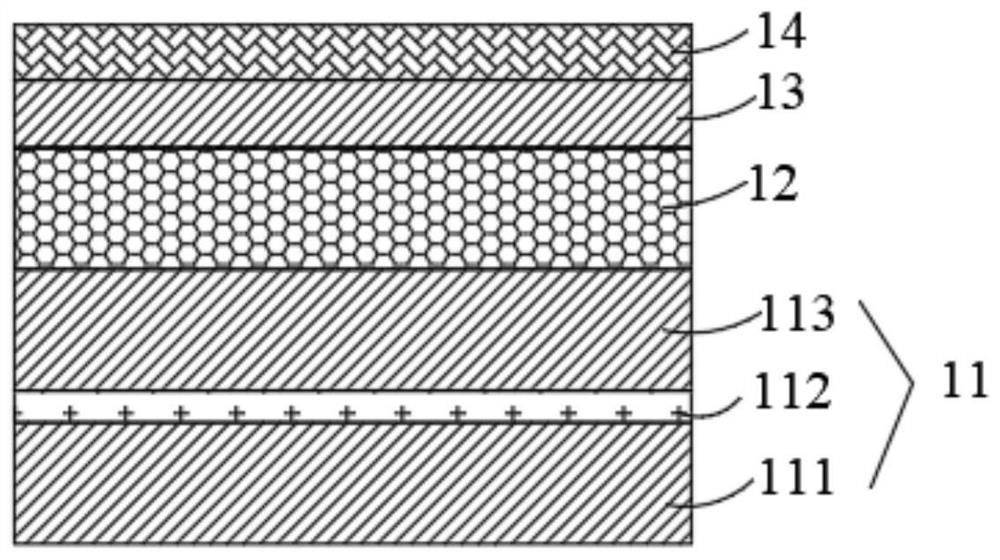

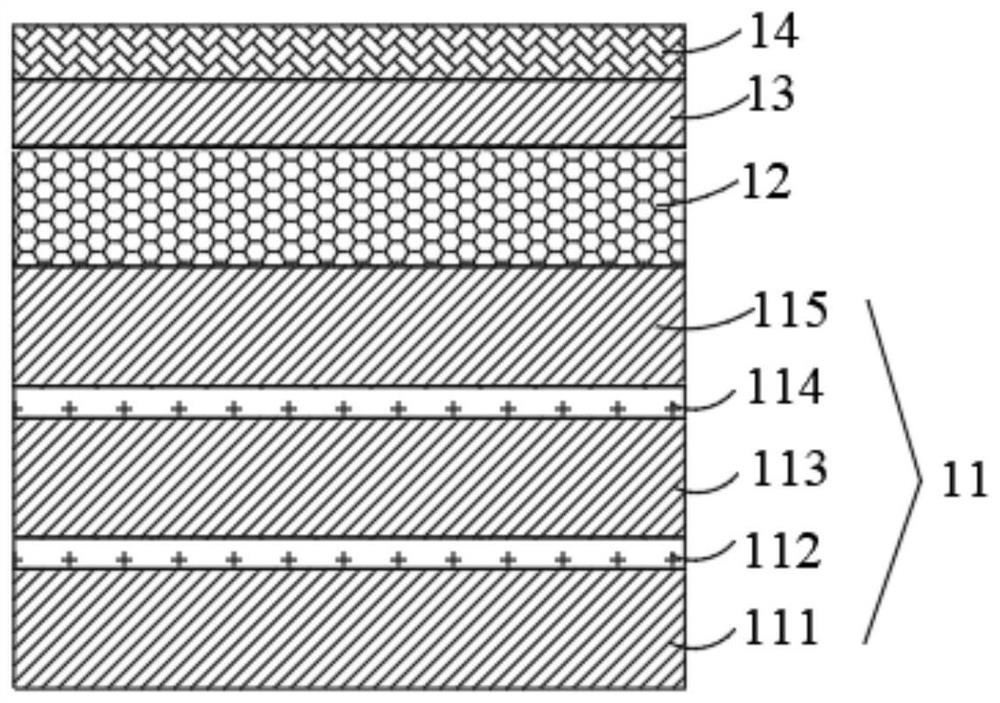

Double-point coating production line for hot-melt adhesive padding cloth

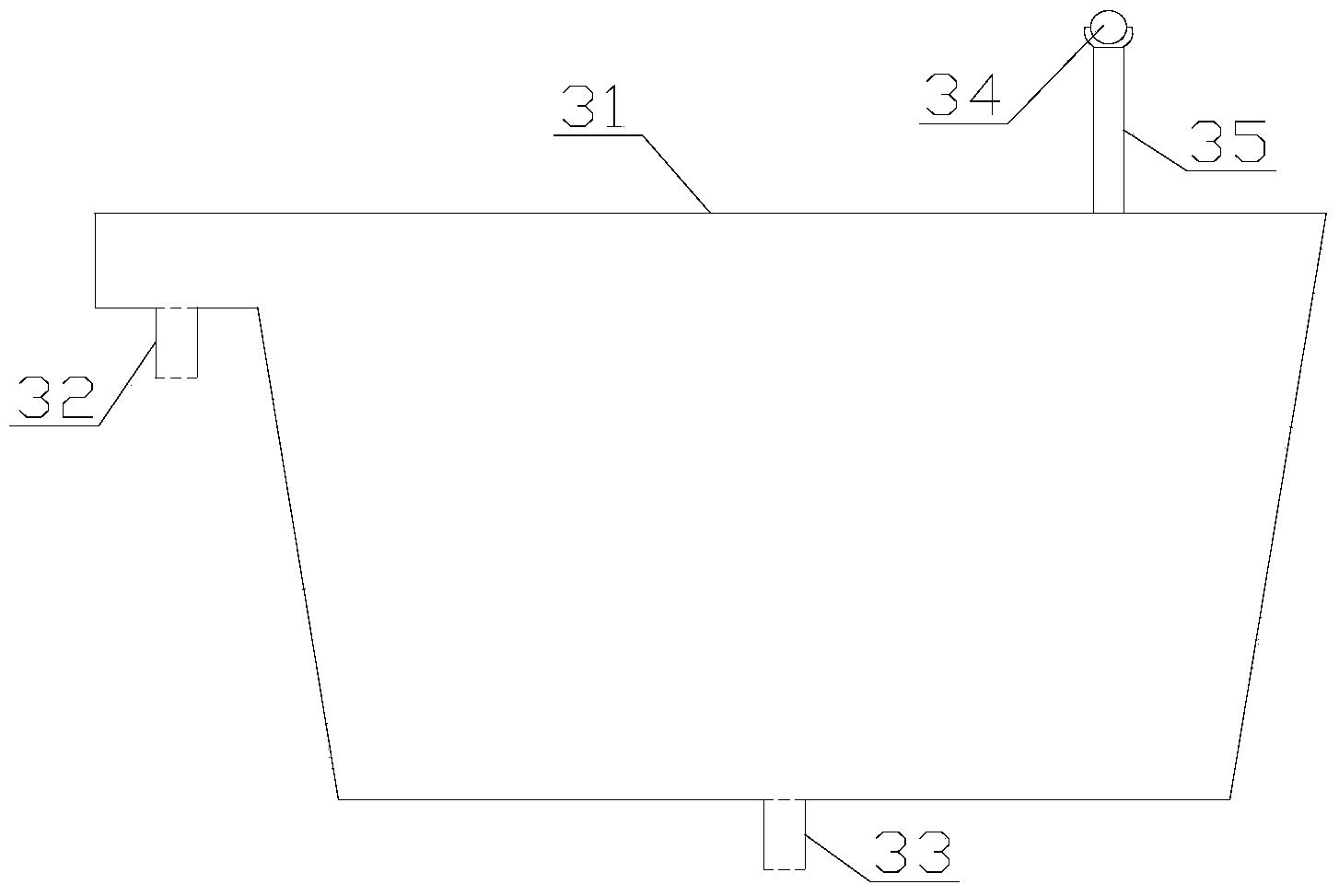

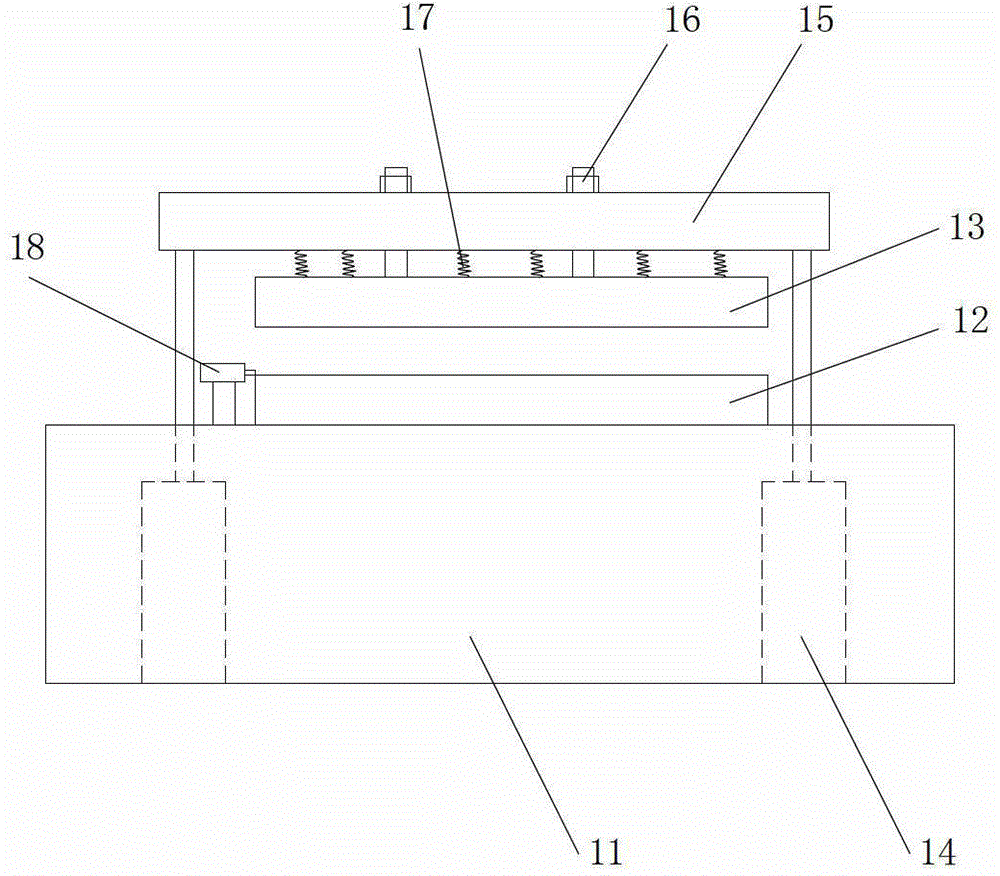

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

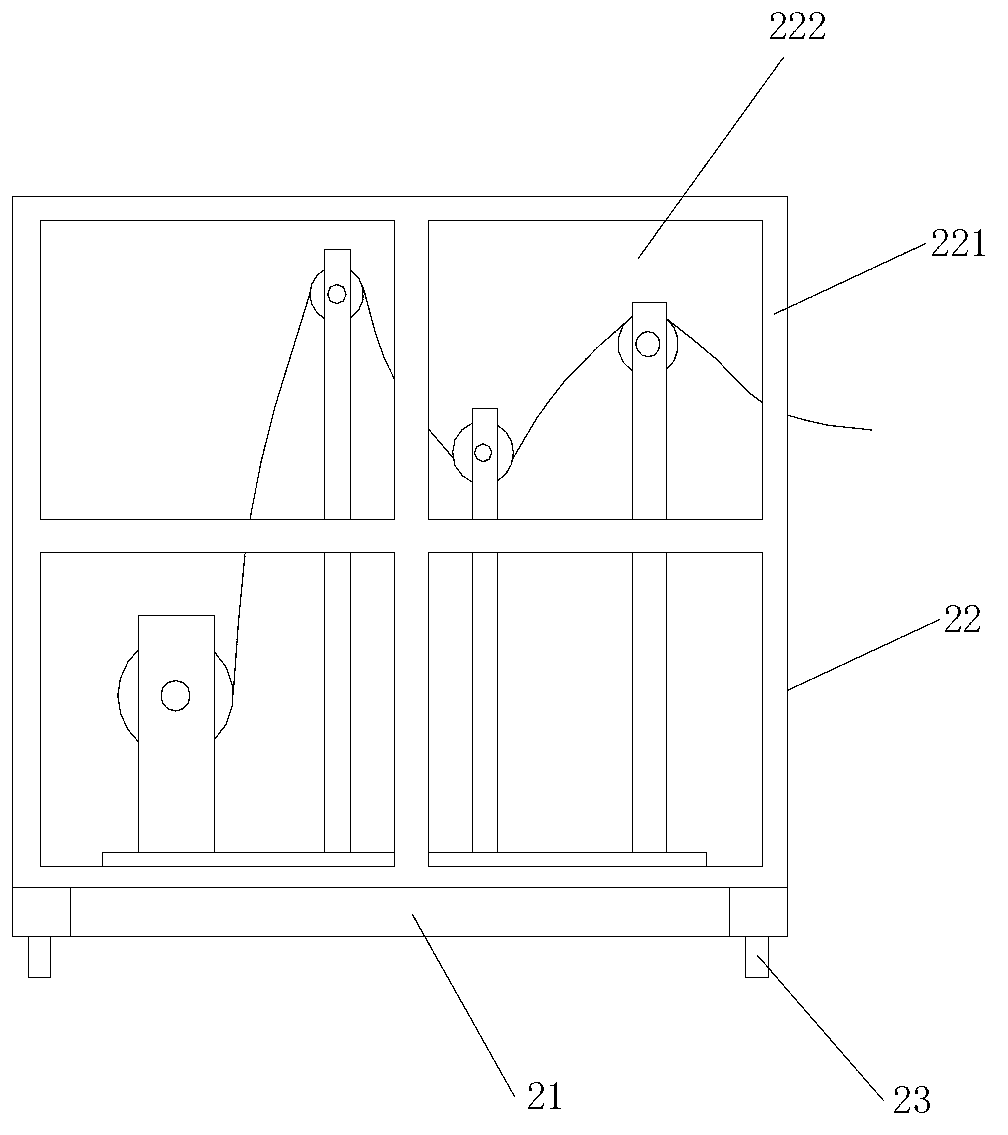

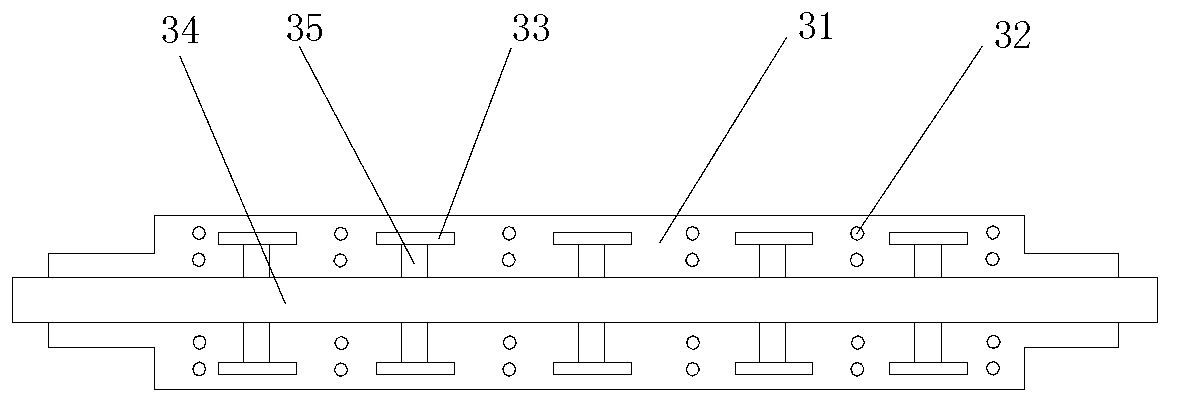

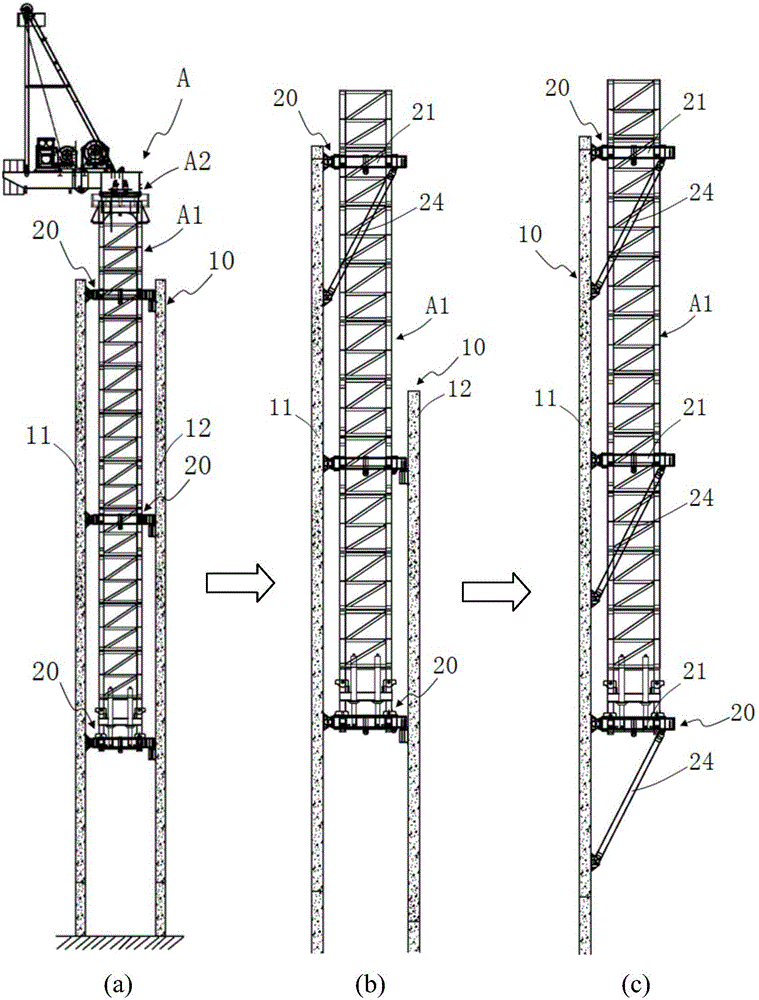

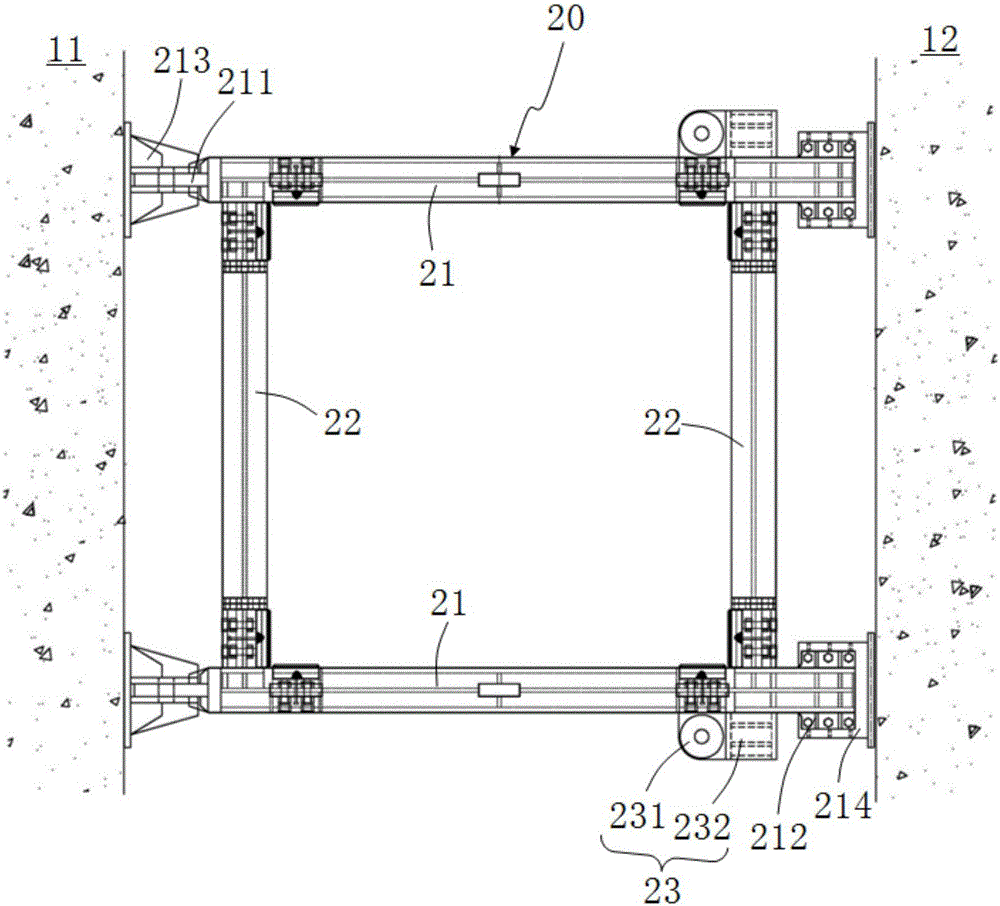

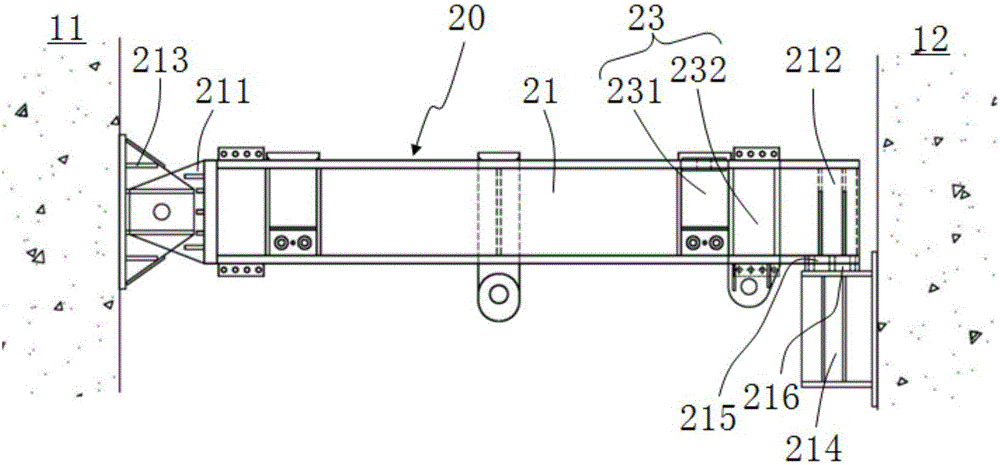

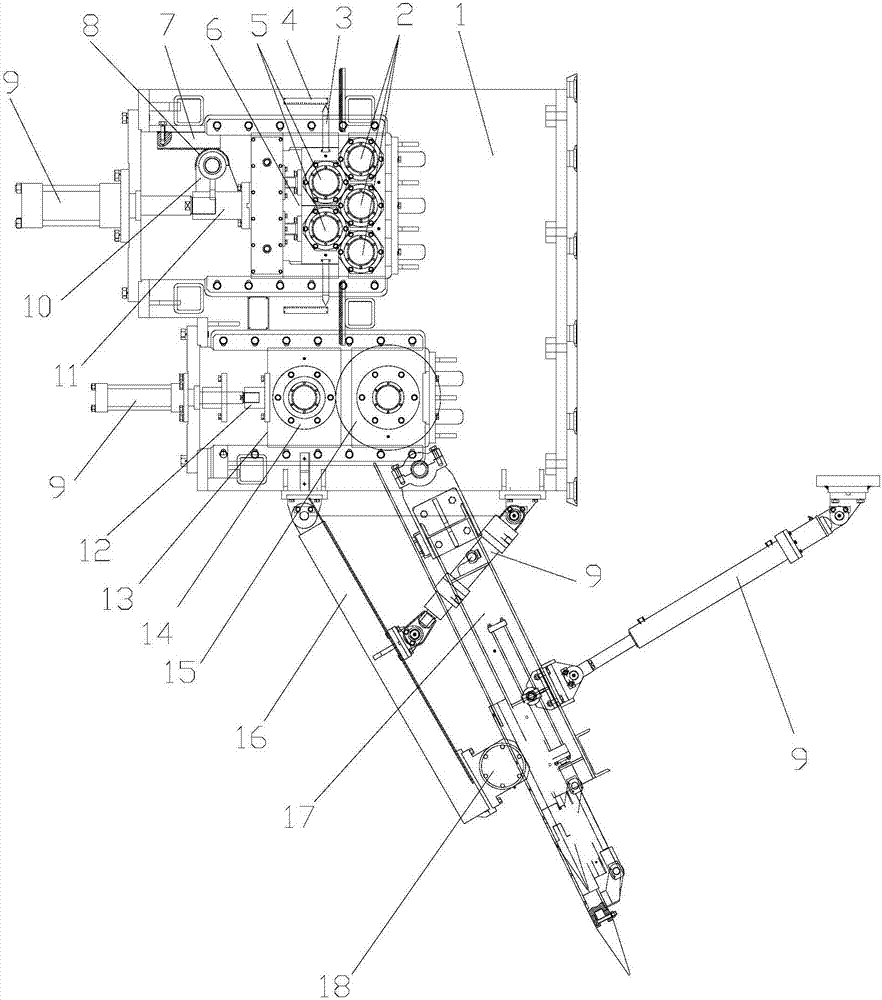

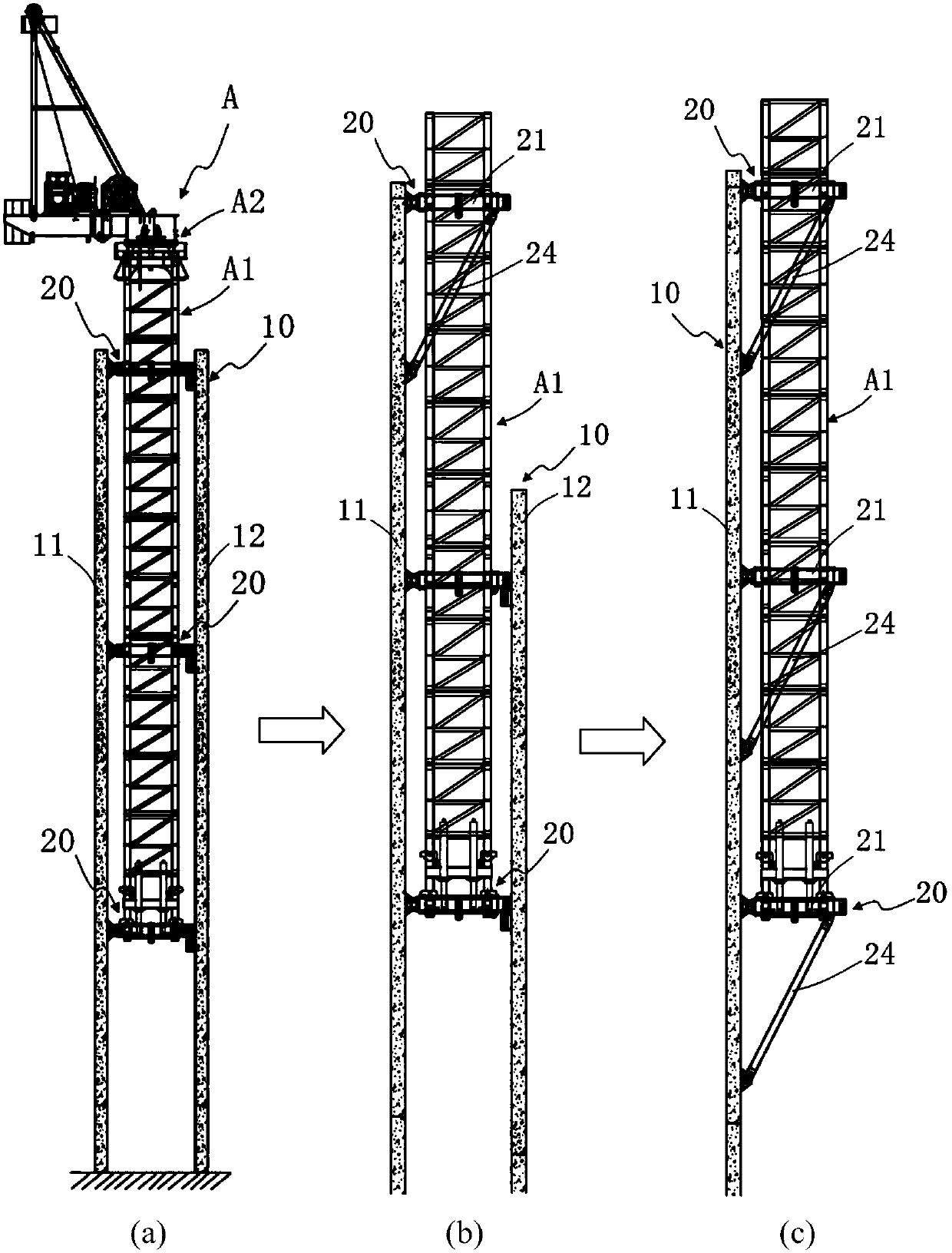

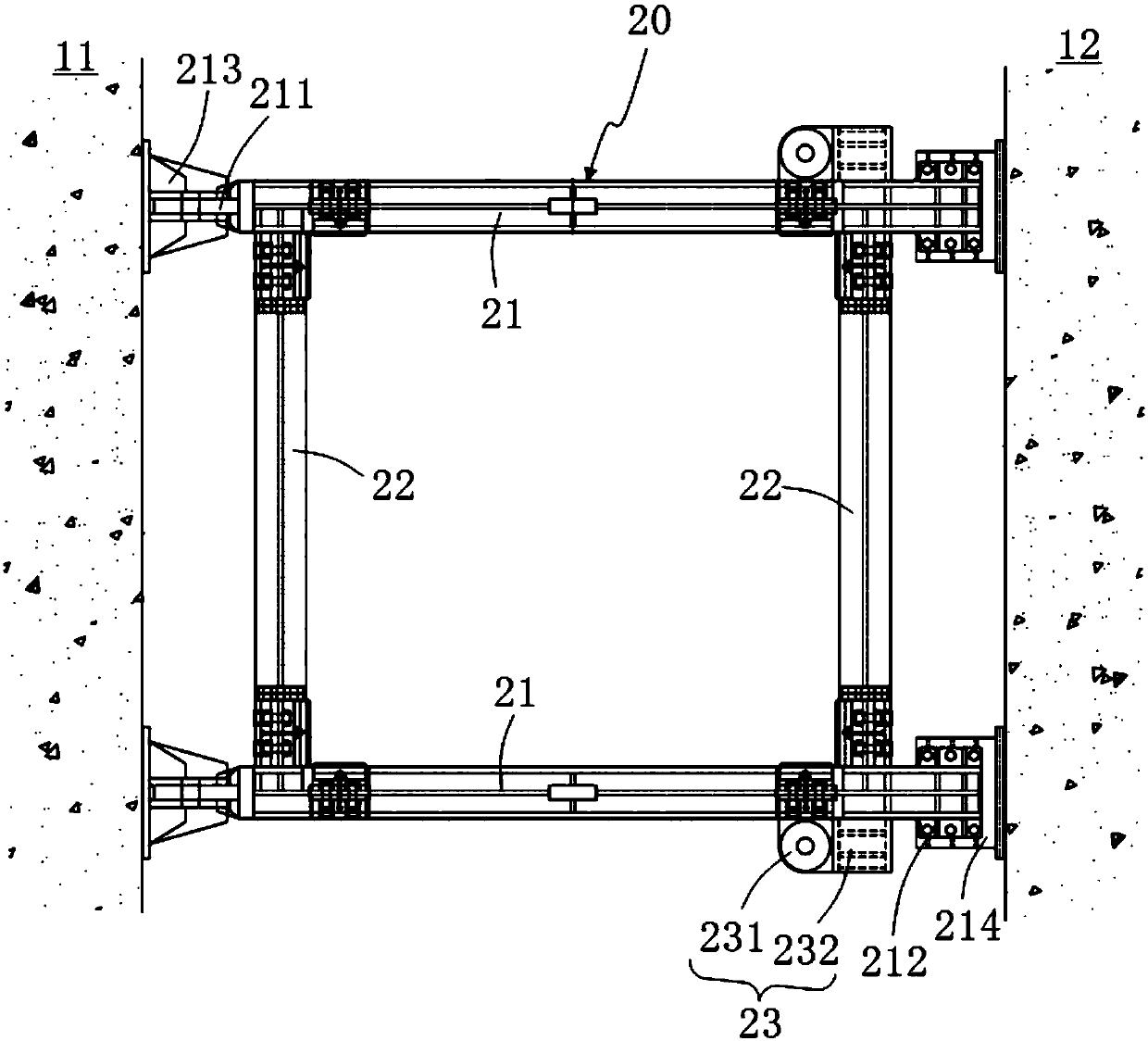

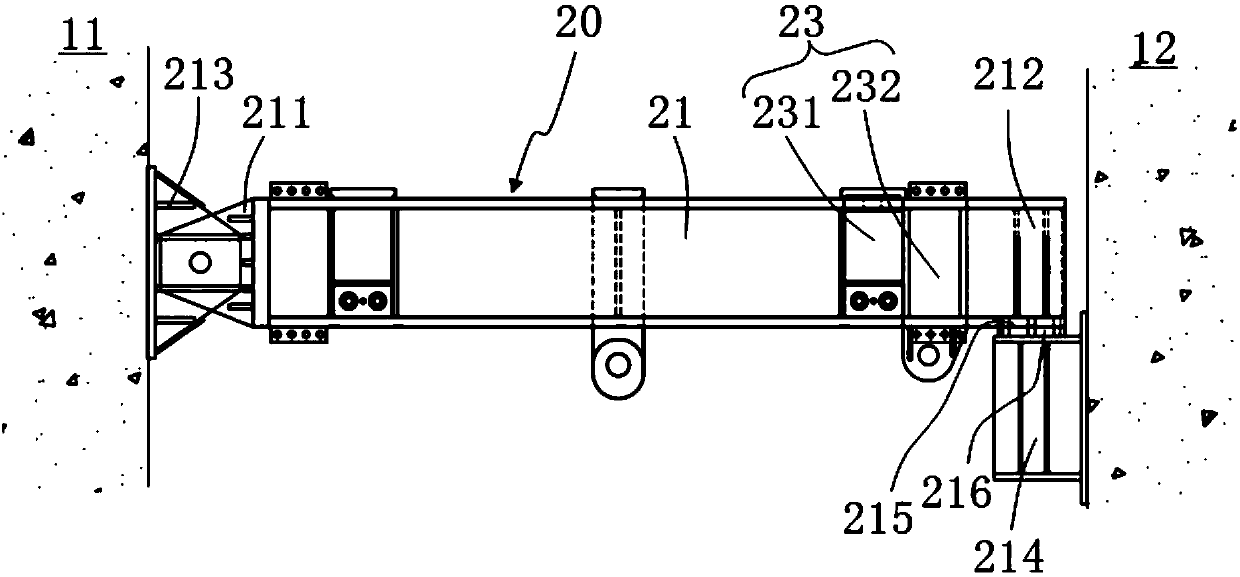

Construction method of super high-rise building large movable arm tower crane in-situ converted from inner climbing to outer hanging

The invention provides a construction method of a super high-rise building large movable arm tower crane in-situ converted from inner climbing to outer hanging. A tower body of the tower crane is arranged between an inner wall and an outer wall of a core cylinder through a support beam mechanism; the support beam mechanism includes a support beam structure consisting of two bearing main beams and two bearing secondary beams; and the bearing main beams are fixedly joined with base tooth blocks of a bracket arranged on the outer wall of the core cylinder through beam tooth blocks thereof. The construction method comprises the following steps: a lower support rod is arranged below the support beam mechanism nearest the top end of the outer wall, and is aslant vertically supported between the outer side ends of the bearing main beams and the inner wall; the outer wall shrinks above next support beam mechanism with a lower height; and the steps are repeated until the outer wall totally shrinks. The construction method solves such technical problems as slow reshipment speed and delayed construction period in conversion from inner climbing conditions to outer hanging conditions, achieves convenience for in-situ conversion of the tower crane from inner climbing to outer hanging, and improves the total construction benefit.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

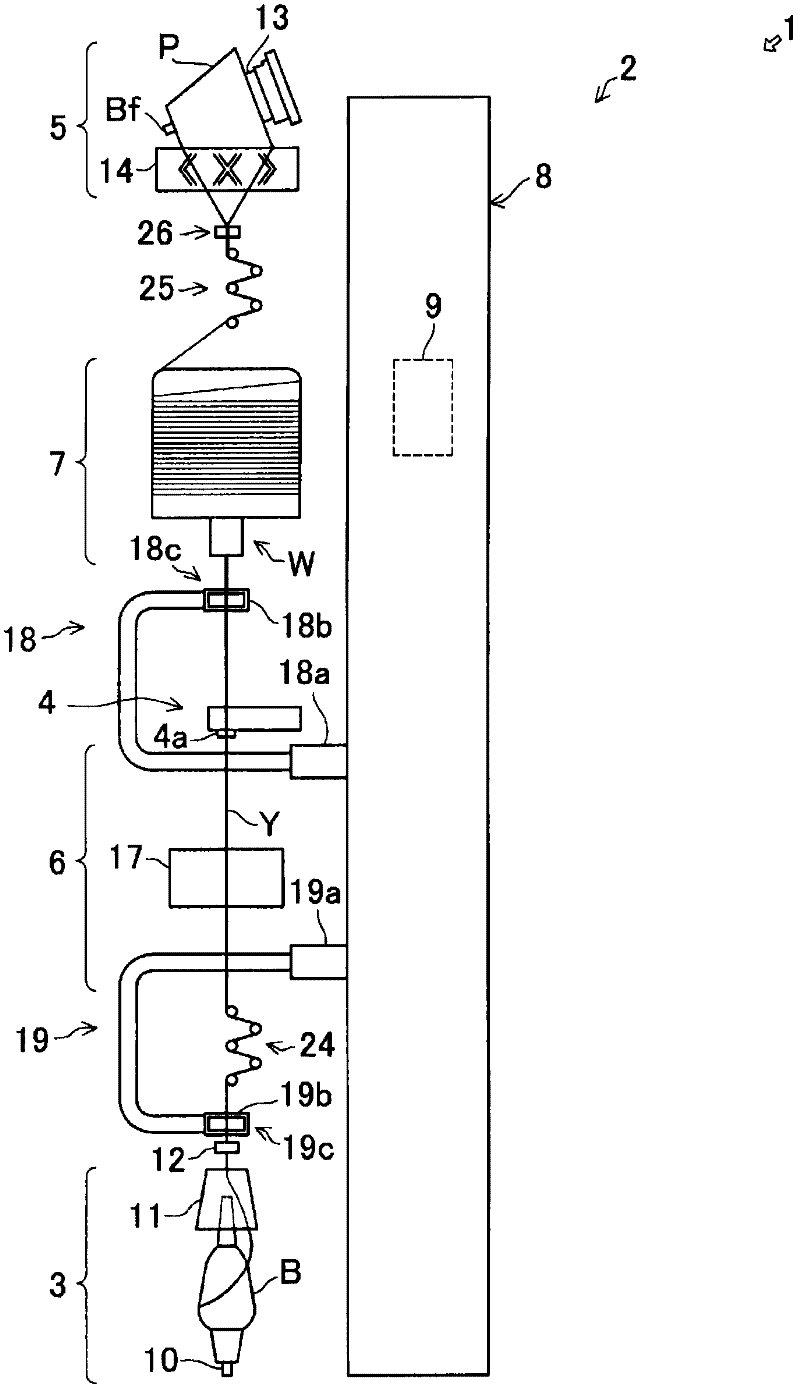

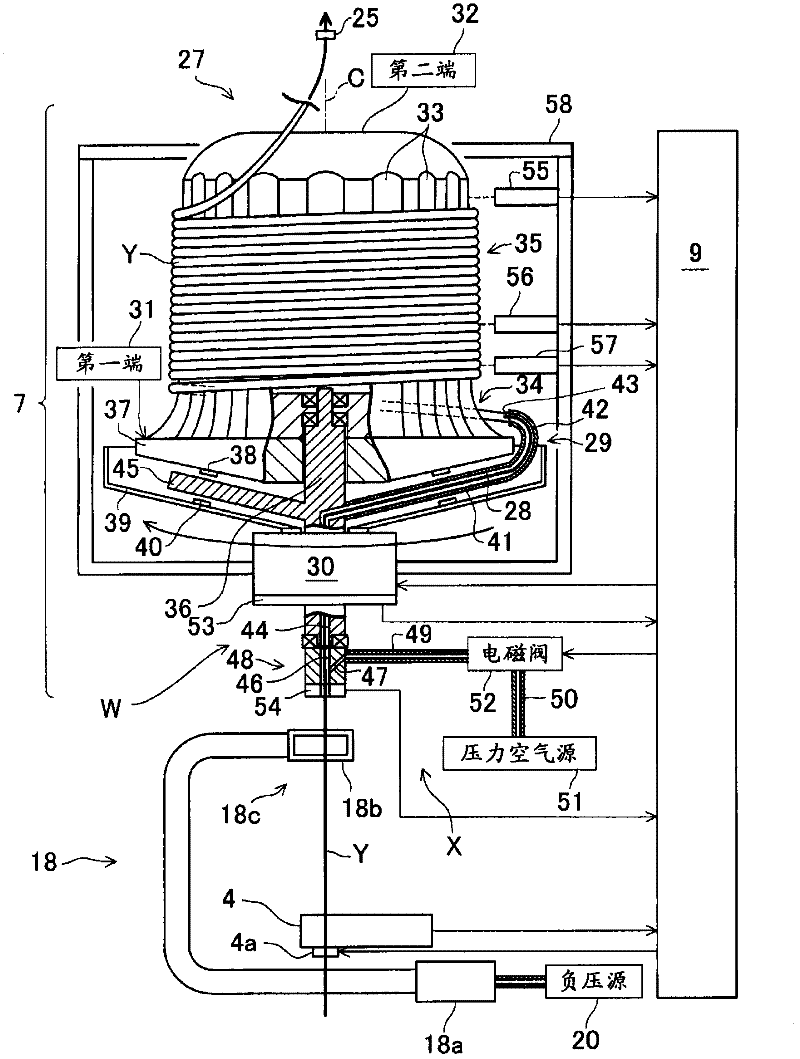

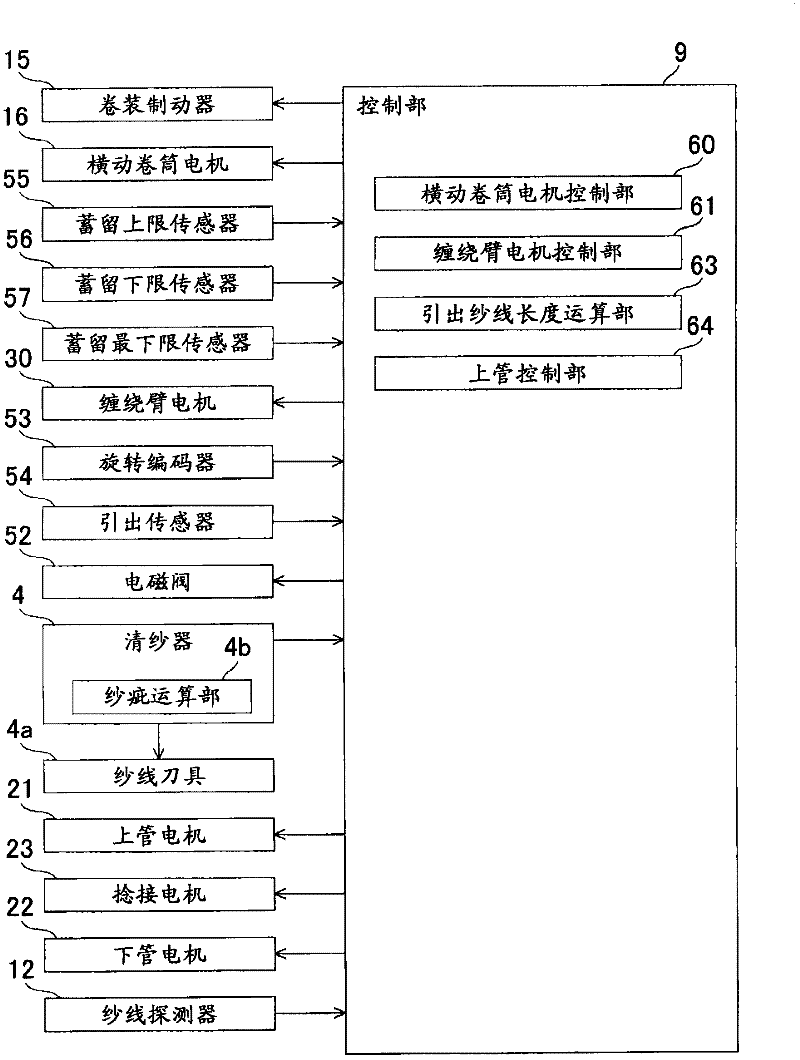

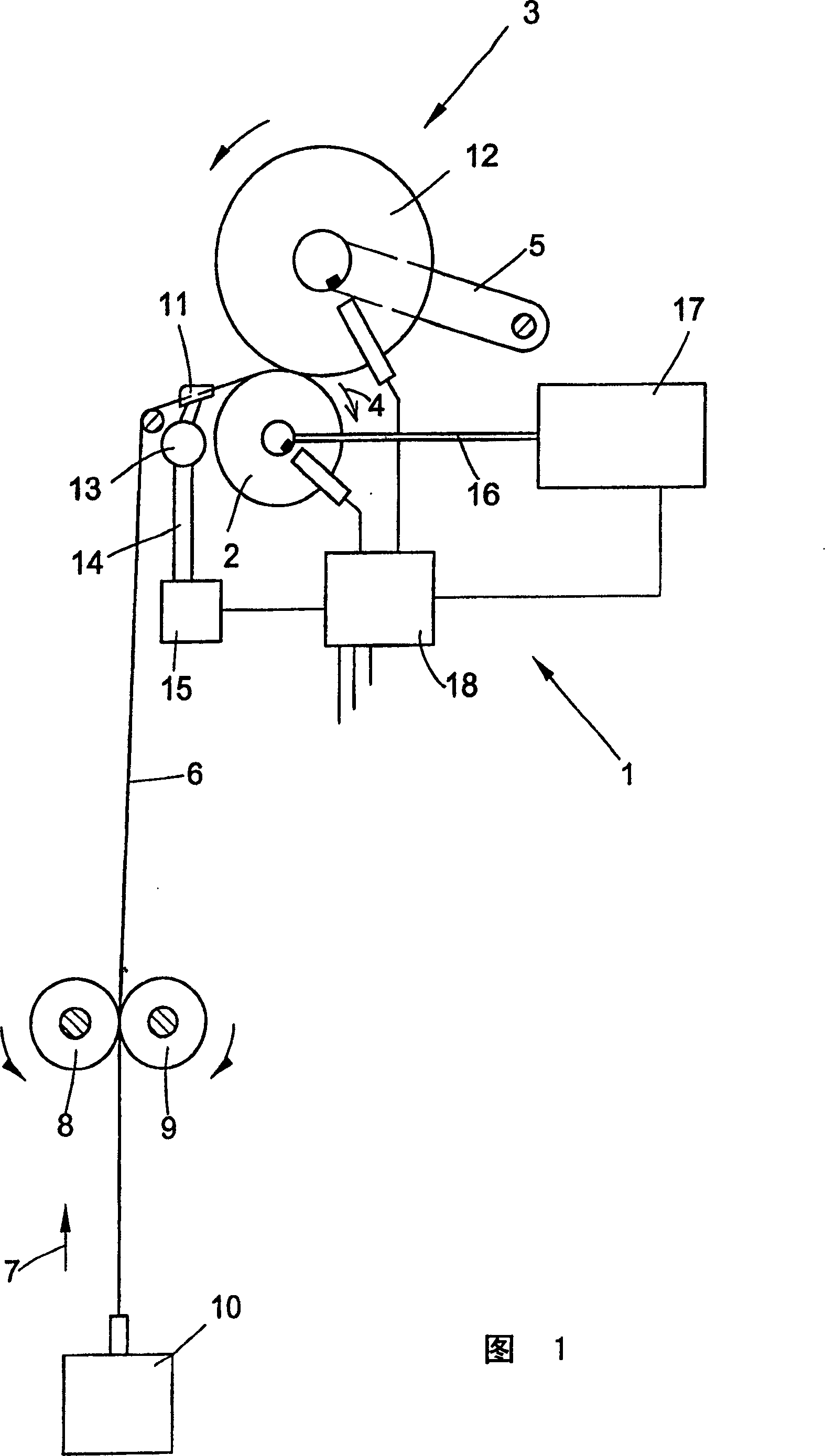

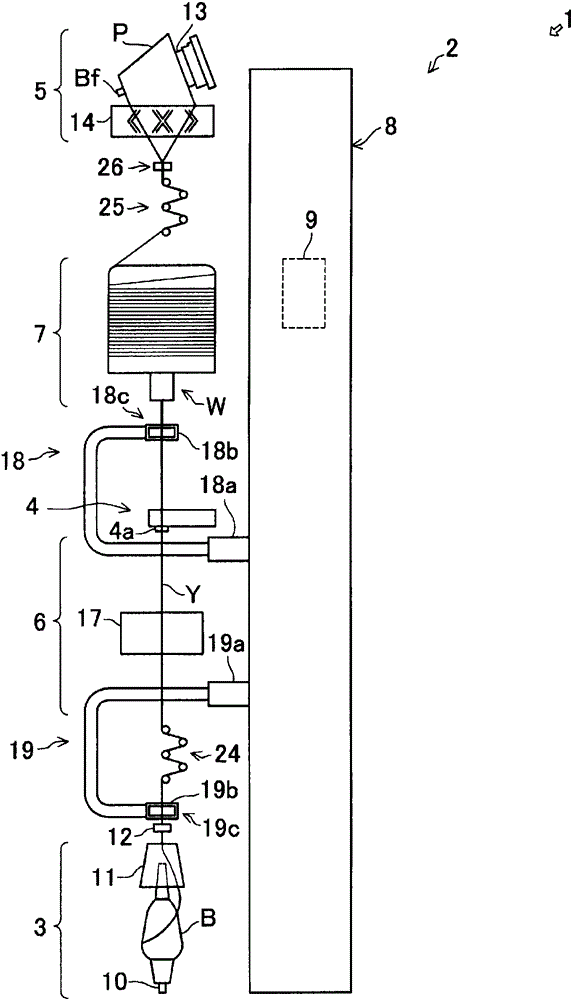

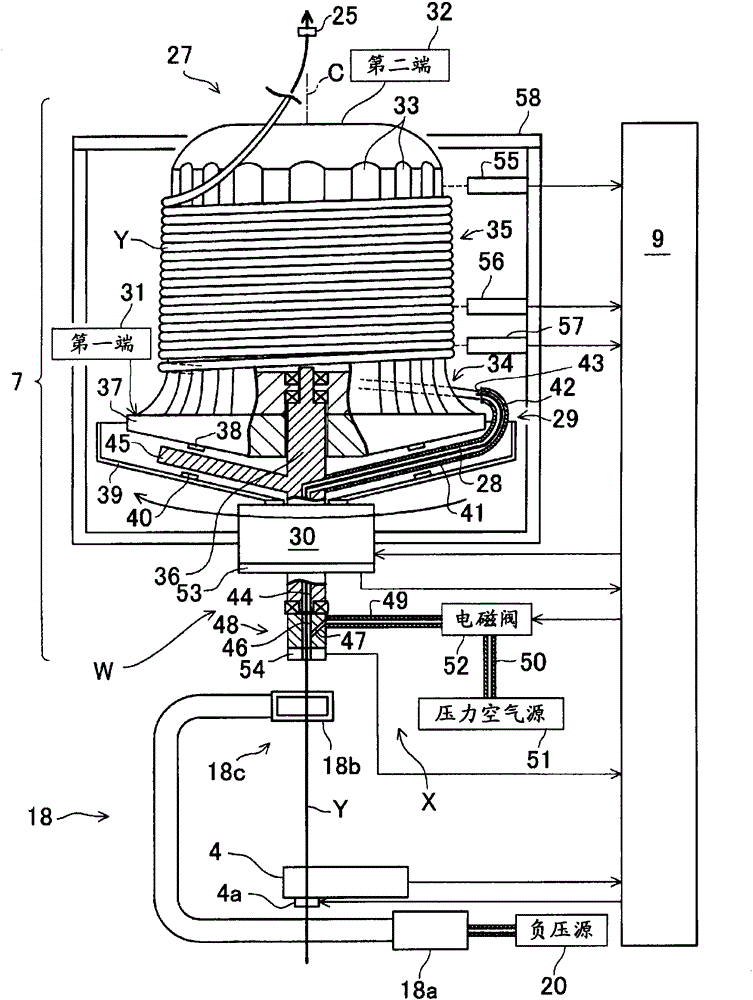

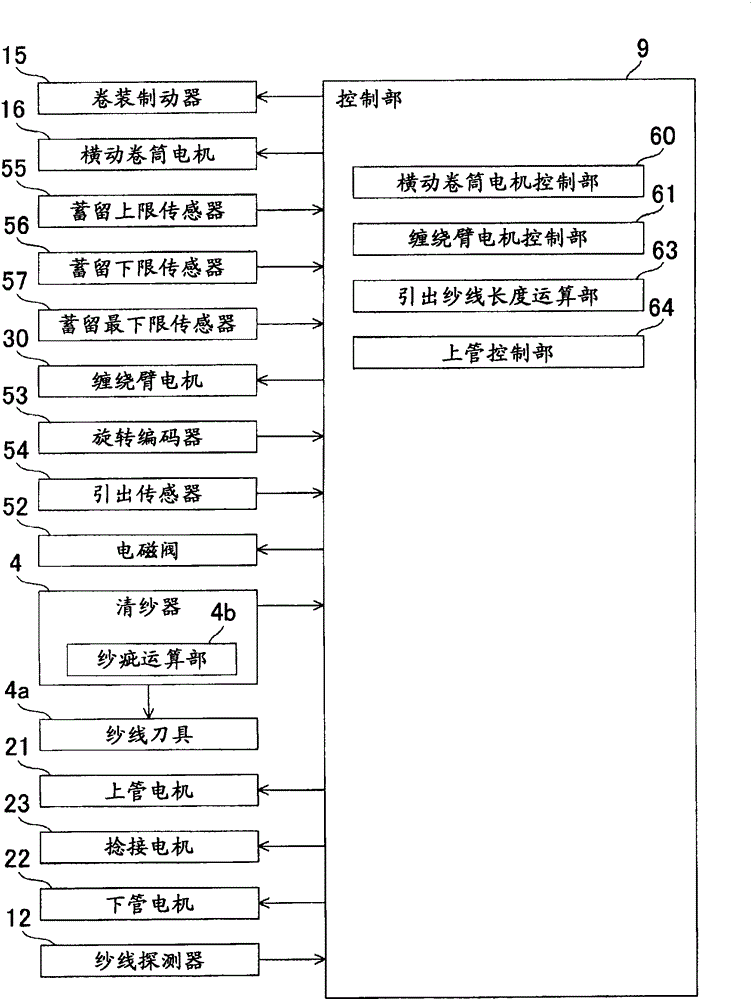

Yarn winder

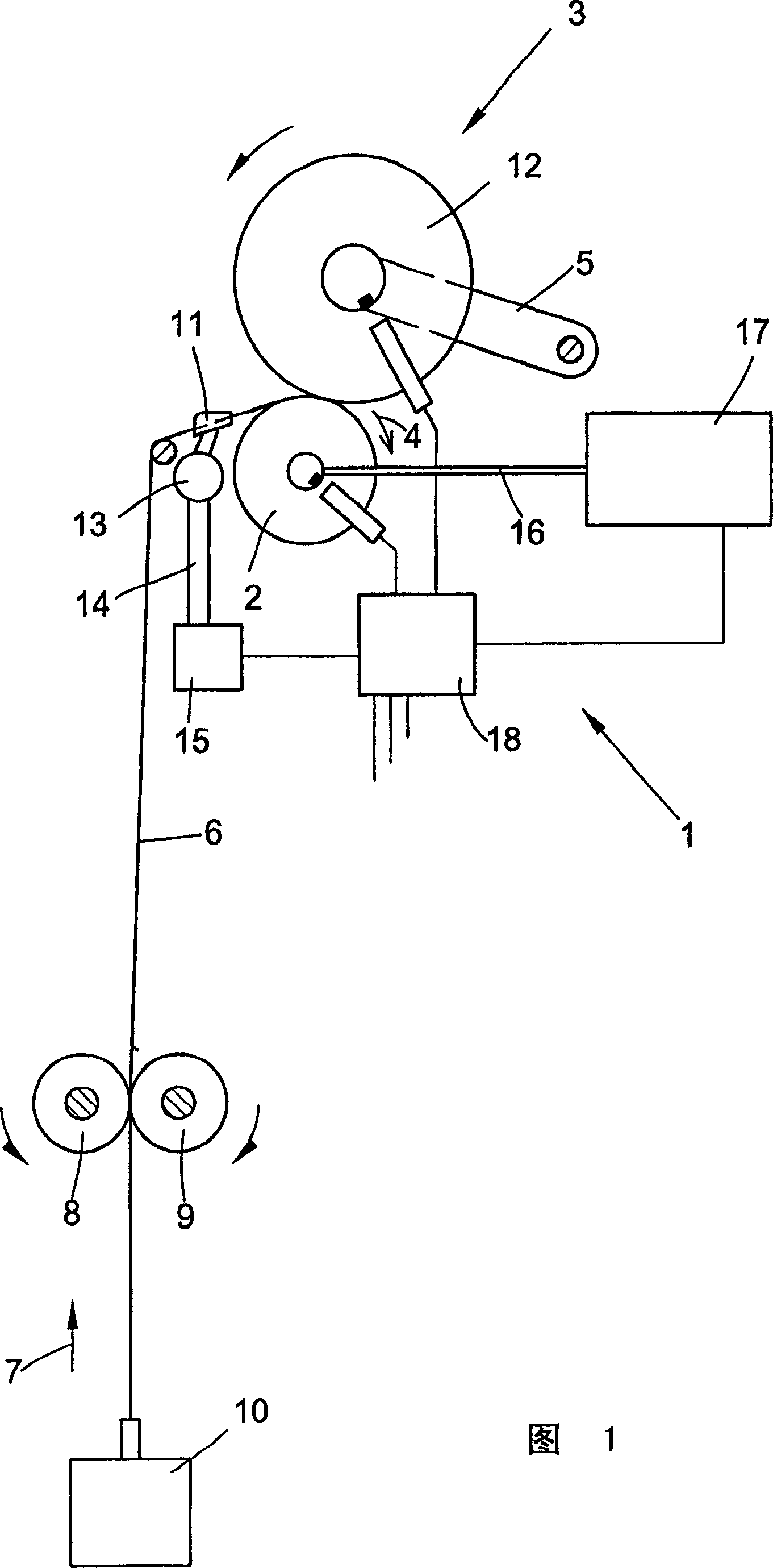

ActiveCN102548884AExcellent power consumption reductionIncrease power consumptionFilament handlingYarnBobbin

Disclosed is a yarn winder capable of continuing winding yarn during knotting of the yarn. Specifically disclosed is a yarn winder which comprises a yarn supplying unit (3) that unwinds yarn (Y) from a yarn supplying bobbin (B); a yarn winding unit (5) that winds the yarn (Y) as a package (P); an accumulator (7) that is disposed between the yarn supplying unit (3) and the yarn winding unit (5) and that accumulates the yarn (Y); and a yarn end drawing mechanism (W) that draws an end of the accumulated yarn (Y) to the yarn supplying unit (3) when the yarn supplying bobbin (B) is changed, when the yarn is cut, or when the yarn runs out.

Owner:MURATA MASCH LTD

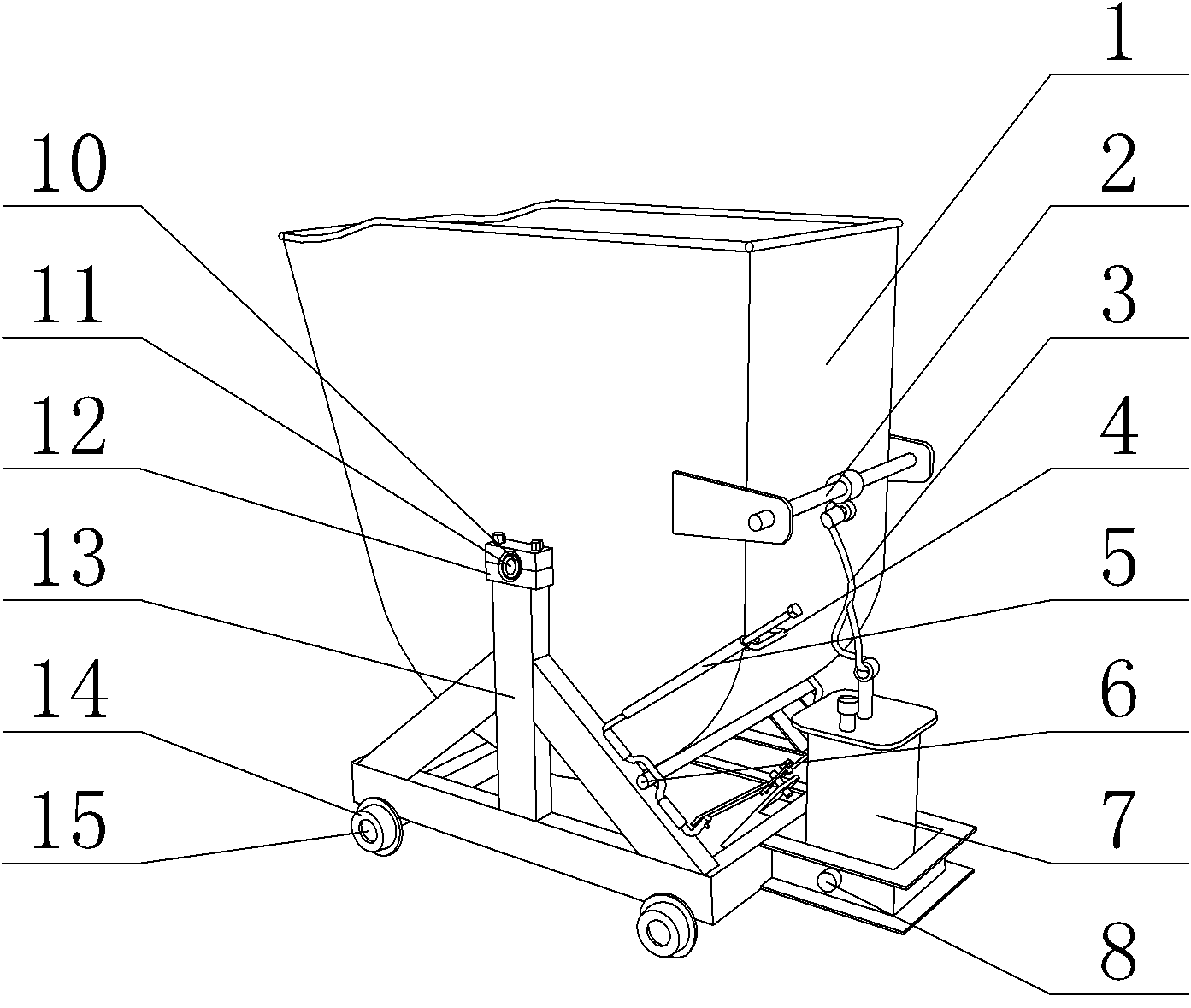

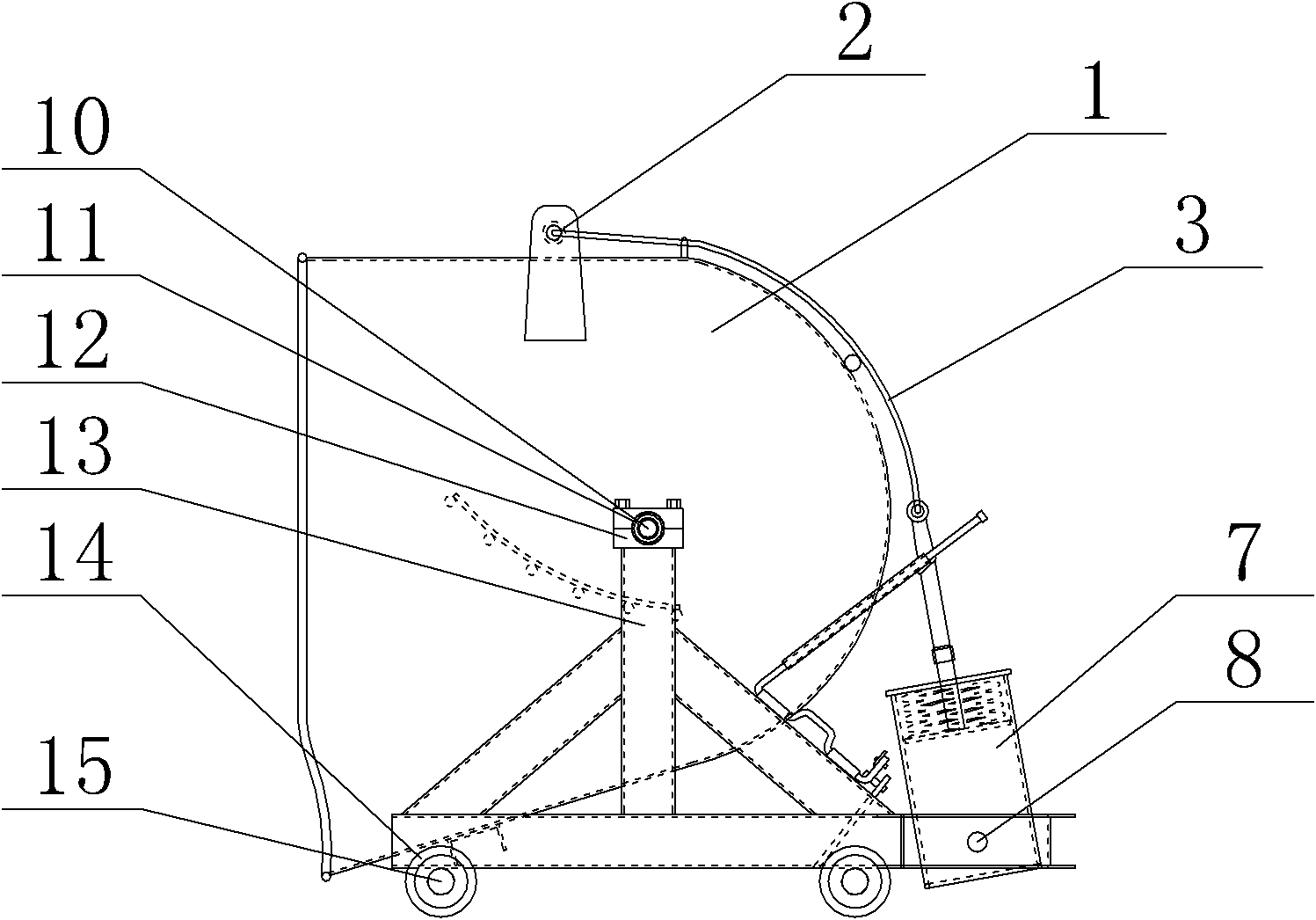

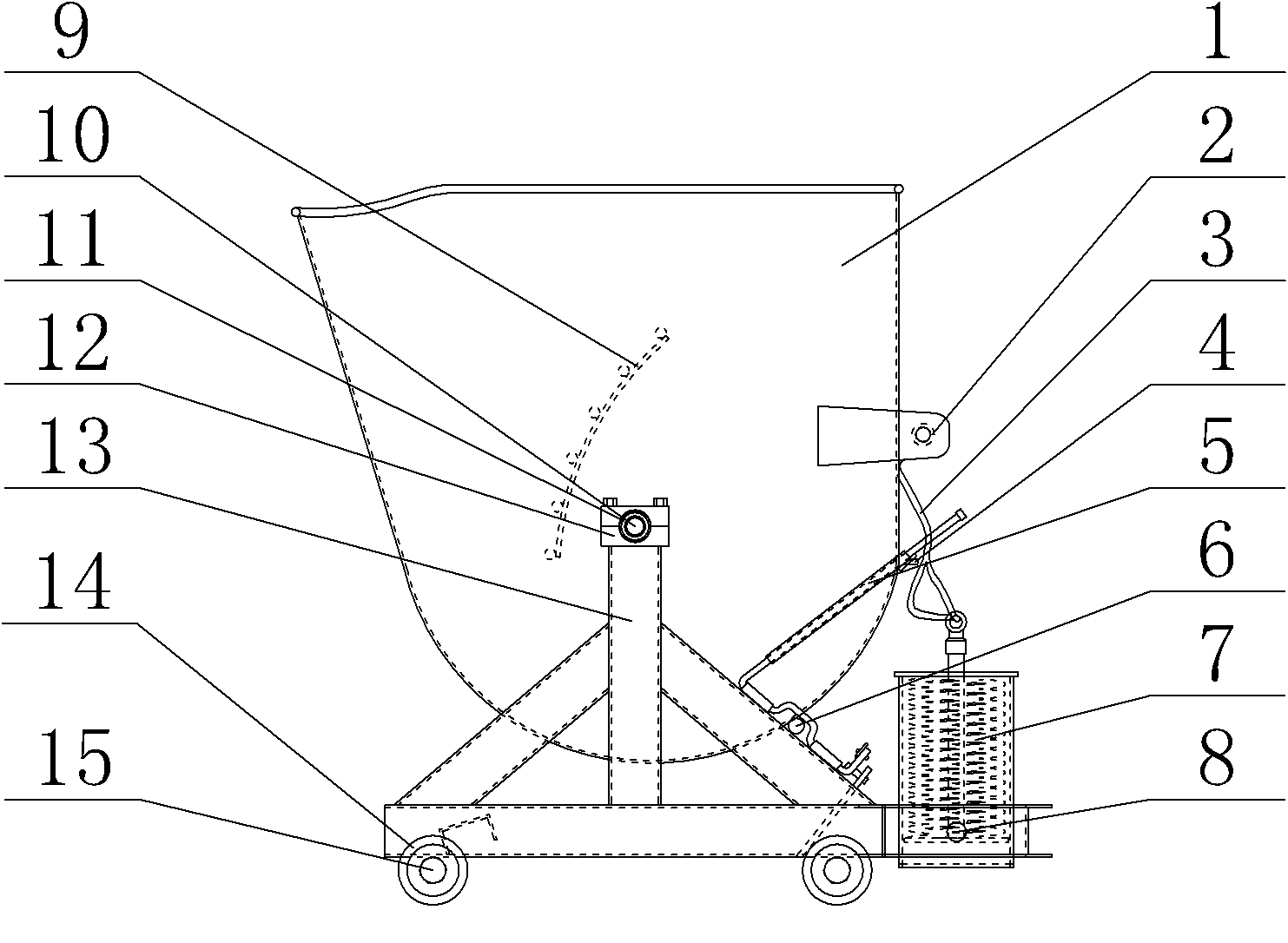

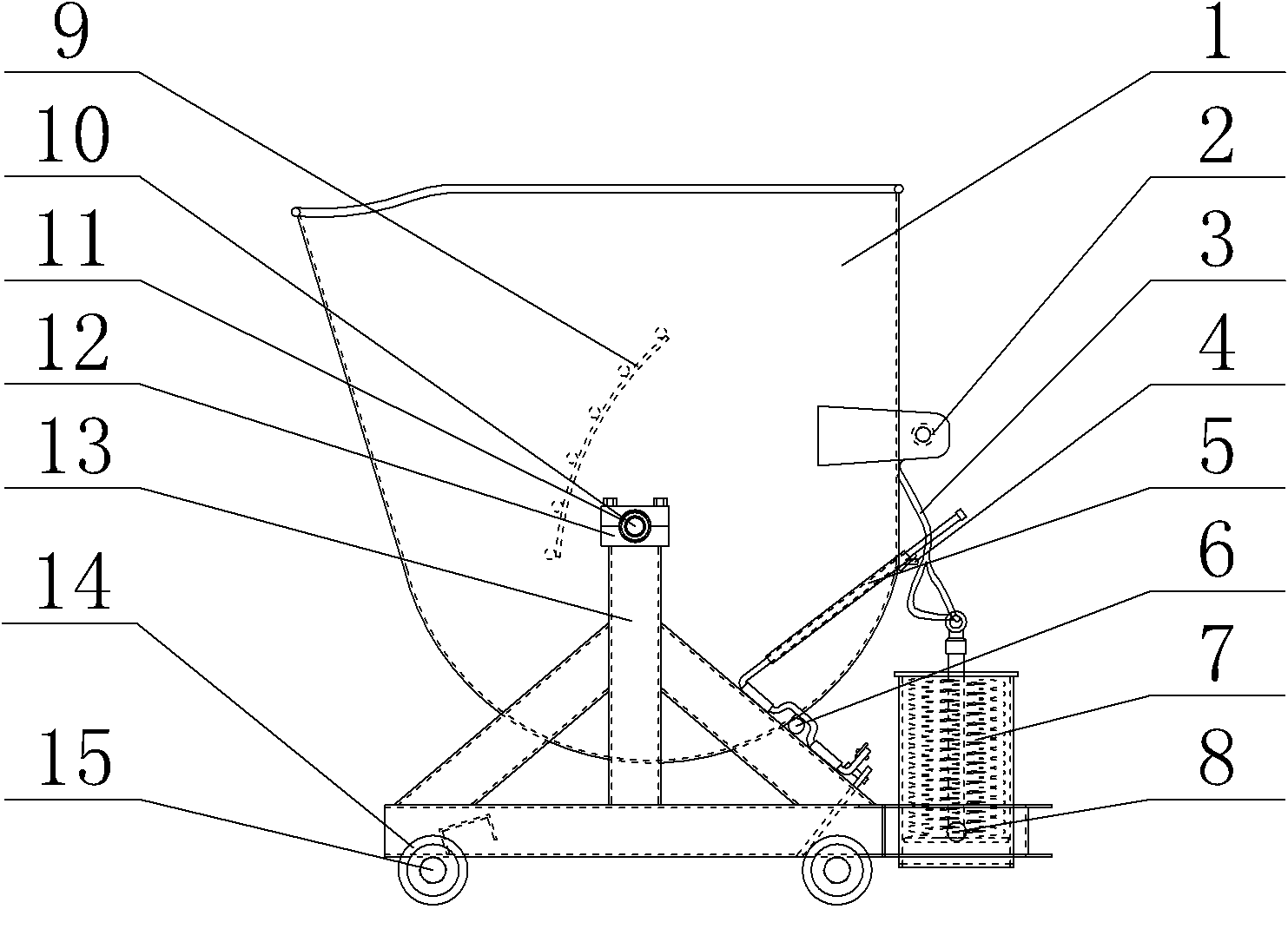

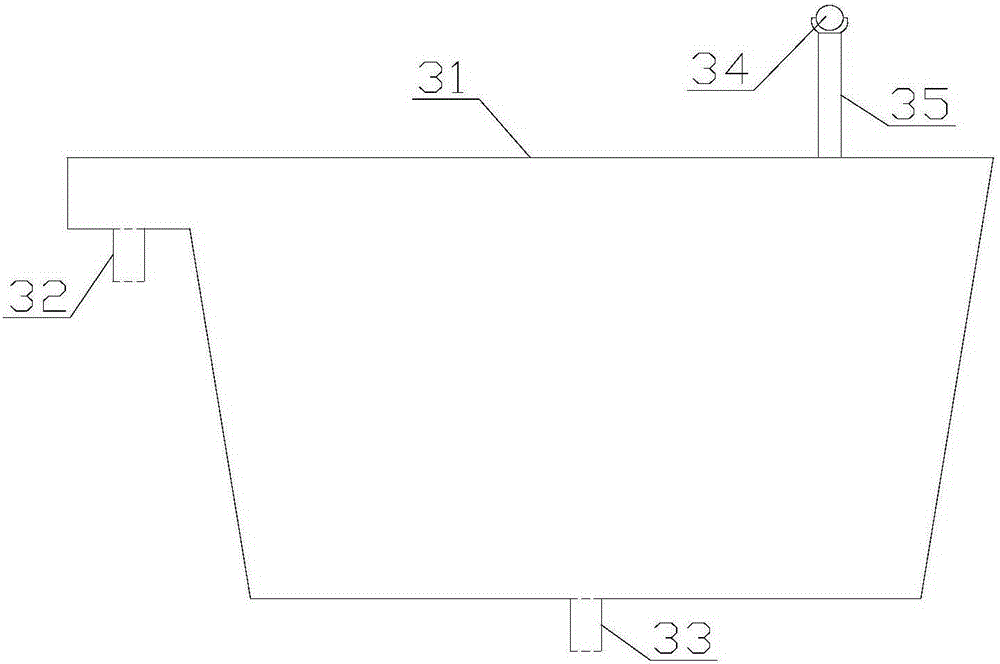

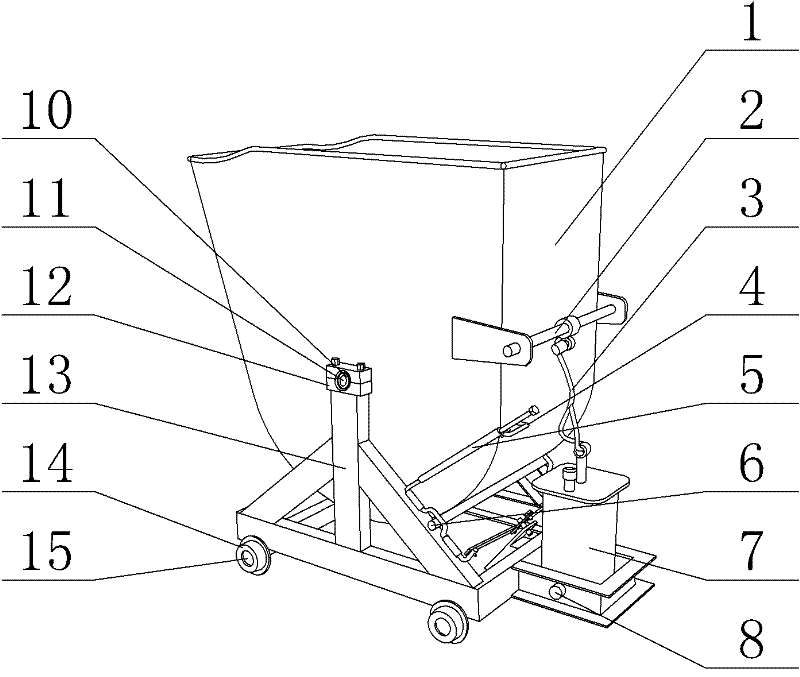

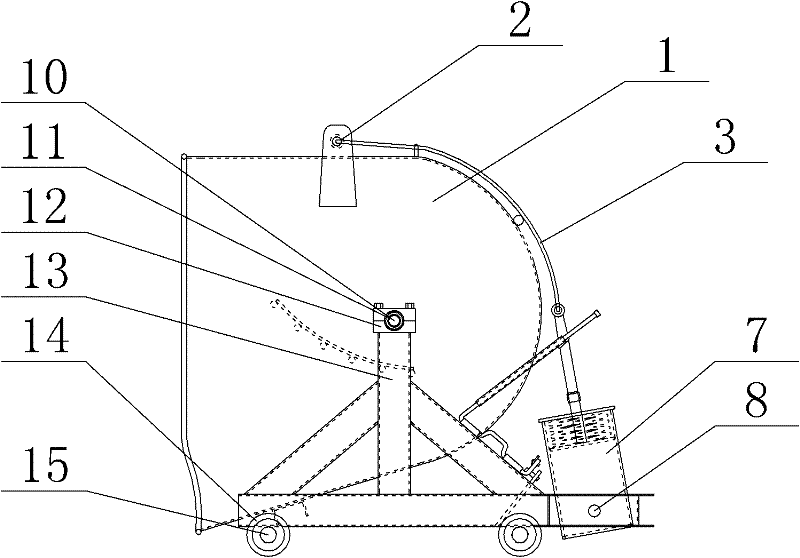

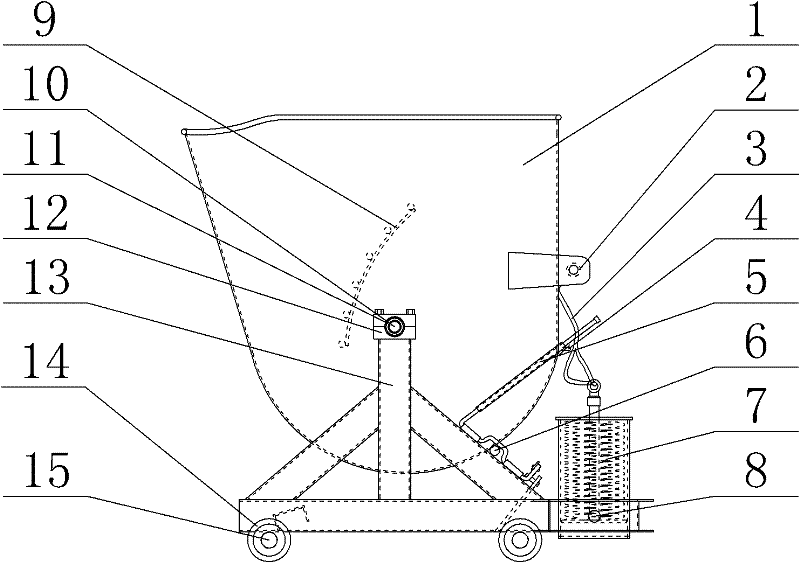

Method for conveying concrete by adopting track trolley with buffer unloading and empty bucket restoration

InactiveCN101929246ALarge capacityEasy to useBuilding material handlingVehicle frameControl material

Owner:CHINA FIRST METALLURGICAL GROUP

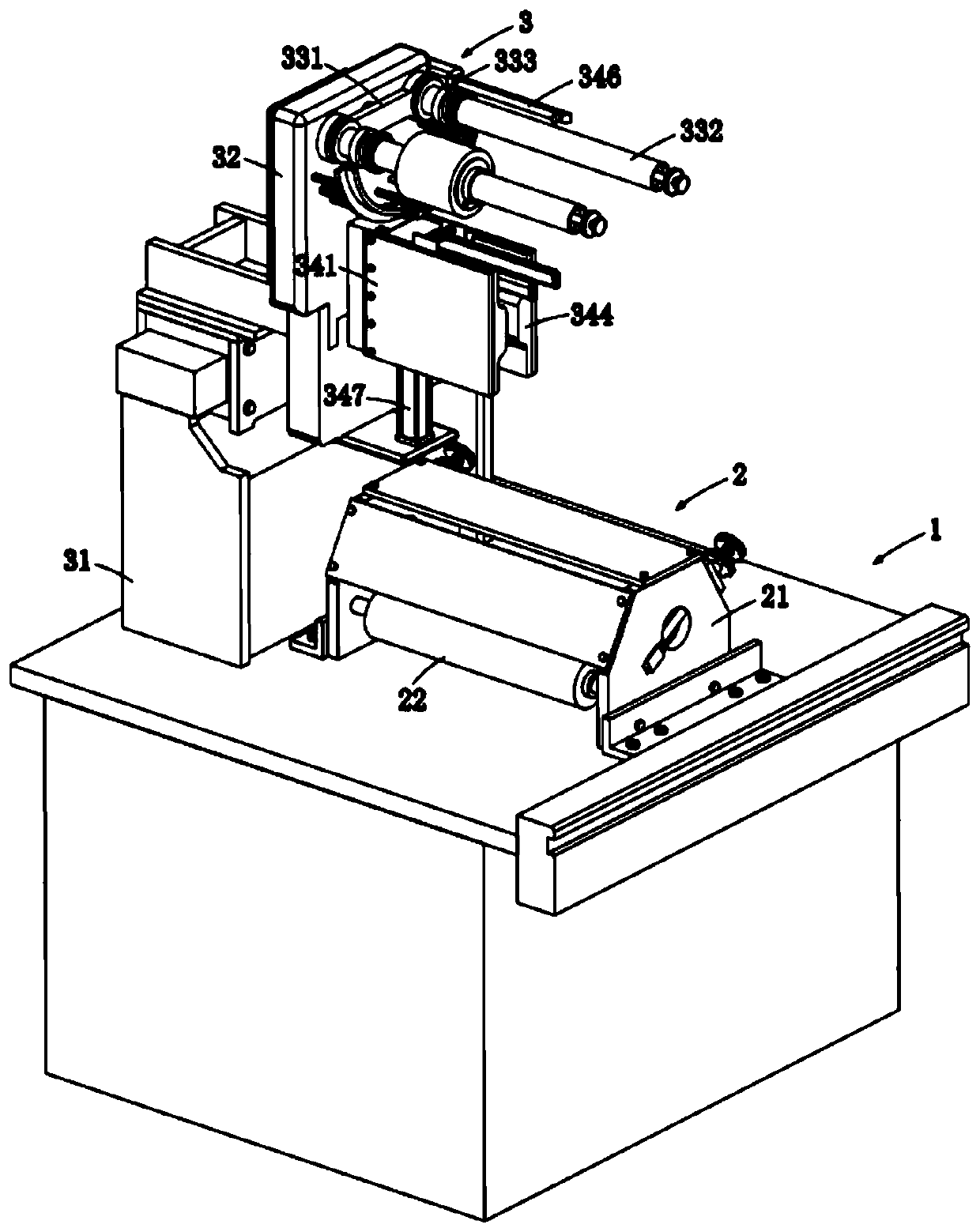

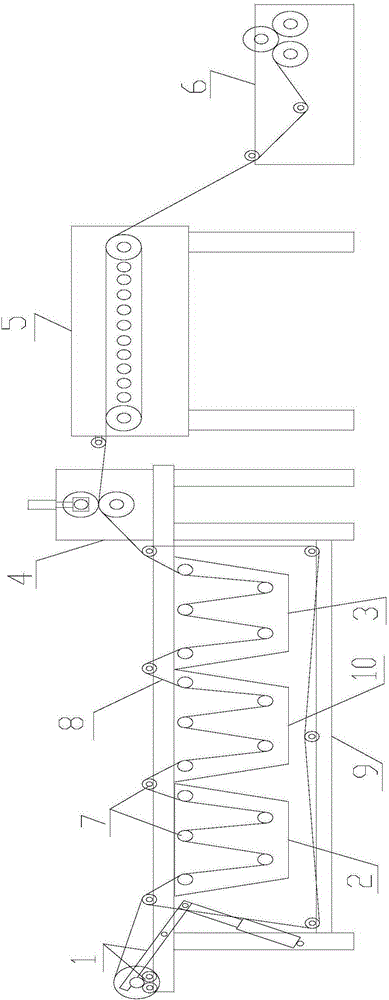

Improved non-woven fabric dyeing production line

ActiveCN106120213AIncrease frictionGuaranteed tensionSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersState of artVolumetric Mass Density

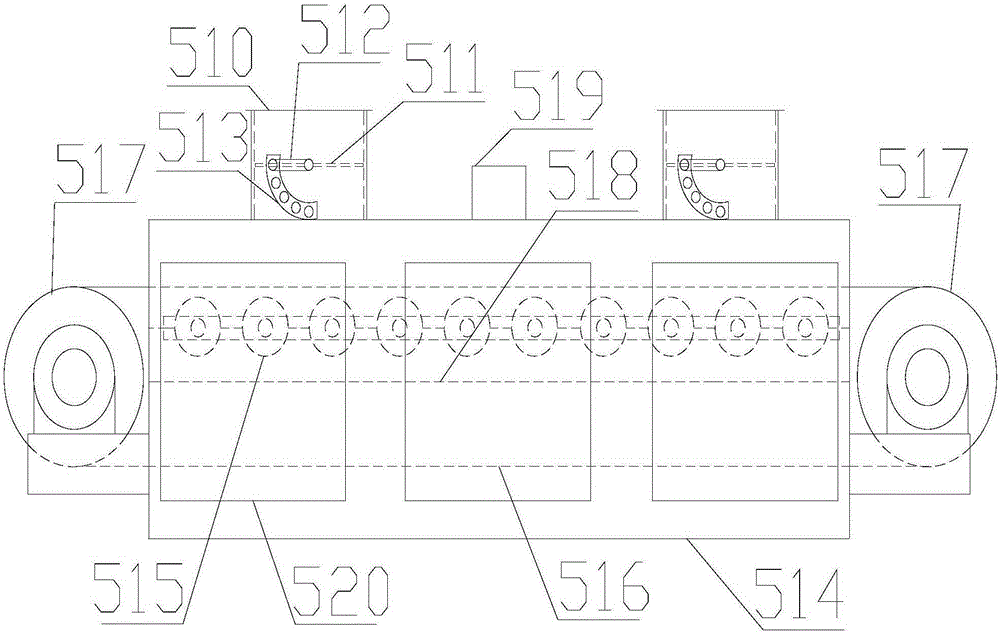

The invention discloses an improved non-woven fabric dyeing production line. The improved non-woven fabric dyeing production line comprises an unreeling device, a dye vat, a transition area, a washing vat, a rolling device, an oven, a reeling device, multiple guide rollers, mesh belts and a frame body. The unreeling device, the dye vat, the transition area, the washing vat, the rolling device, the oven and the reeling device are sequentially arranged from front to back, and the dye vat, the transition area and the washing vat are arranged on the frame body; the guide rollers are arranged in the dye vat, the transition area and the washing vat and on the frame body, and the mesh belts are tensioned on the guide rollers; the unreeling device comprises a seat body, multiple rollers, two rails, an unreeling shaft, two guide seats, a sliding seat, a connecting seat, a regulating screw, a regulating disc, first bearings, second bearings, a regulating pressure applying device and two supporting bodies. Compared with the prior art, fixation and detachment can be convenient, fixing reliability is high, working efficiency is improved, product quality is improved, and the reeling degree of density of non-woven fabric is good.

Owner:ZHEJIANG KINGSAFE INTERLINING

Small railcar with buffering unloading and empty hopper resetting

Owner:CHINA FIRST METALLURGICAL GROUP

Cloth inspecting method

The invention relates to the technical field of textile machinery, in particular to a cloth inspecting method. When cloth is inspected, a gray fabric is intermittently unrolled and rolled up, a clothinspection step is carried out at the intermittent pause time, and rolling-up and unrolling steps are carried out simultaneously at the non-pause time. The cloth inspecting method is achieved througha cloth inspecting machine, and the cloth inspecting machine comprises a driving device, a transmission device, a rolling-up device, an unrolling device and a cloth inspecting device. According to thecloth inspecting method, pause in the gray fabric transportation process is achieved through the intermittent driving force provided by the driving device to facilitate staff to inspect the gray fabric, a single drive source is used for simultaneously driving the rolling-up device and the unrolling device with opposite rotation directions, it is ensured that the unrolling speed is the same as therolling-up speed, tension stability of the gray fabric is ensured in the process of cloth inspection, and the stability of transmission of the grey fabric is also ensured in the process of cloth inspection.

Owner:张凡

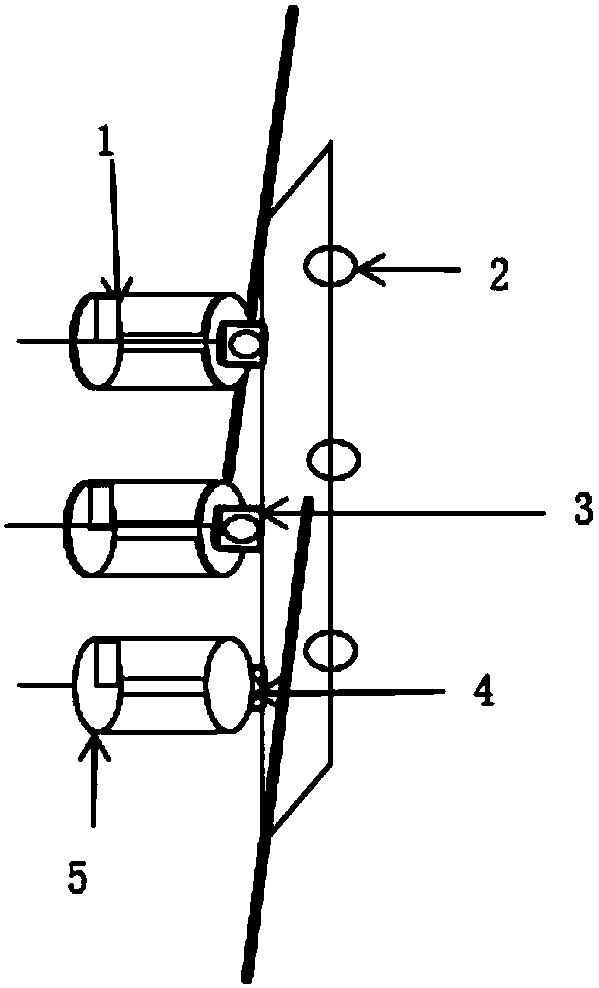

Driving device of hank yarn shed frame

InactiveCN110713073AReduce wire breakage or loose wireSimple structureFilament handlingYarnClockwork

The invention discloses a driving device of a hank yarn shed frame. The driving device comprises a driving mechanism, a tension monitoring mechanism which is located below the driving mechanism, and acontroller. The driving mechanism and the tension monitoring mechanism are controlled with the controller. The tension monitoring mechanism comprises a mounting seat, two fixed guide wheels, a movable guide wheel, a sliding rack, a driving gear, a driving shaft, a constant-force clockwork spring, a shell, three sensors and a sensed body. The two fixed guide wheels and the sliding rack which is capable of being slideably mounted are disposed on the outer side of the mounting seat; the movable guide wheel which is located in the rear of the middle of the two fixed guide wheels is disposed at the front end of the sliding rack; the sensors which are located below the sliding rack are disposed on the outer side of the mounting seat; and the three sensors are arranged in sequence from front toback. Compared with the prior art, the phenomenon of yarn breaking or loosening can be greatly reduced, the structure is simple, and constant-force tensioning can be achieved.

Owner:海盐县梦芝舟毛纺厂

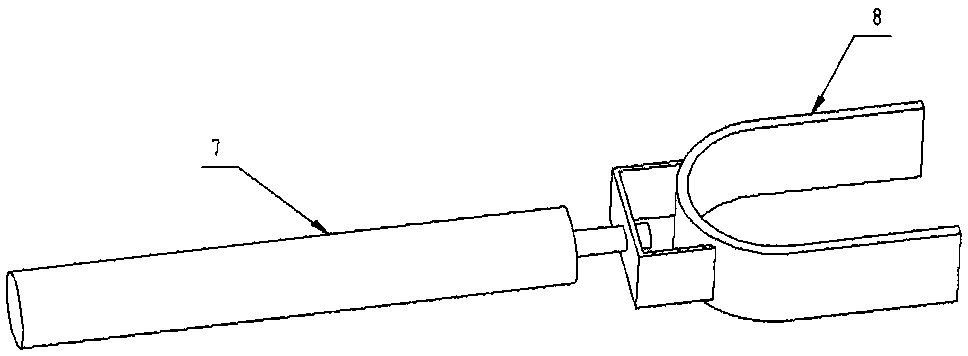

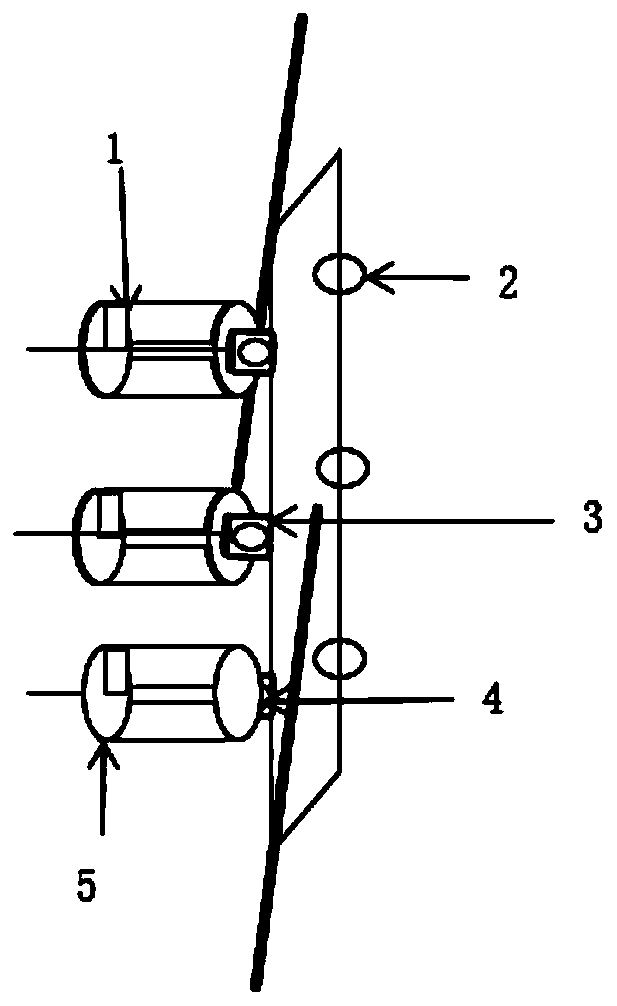

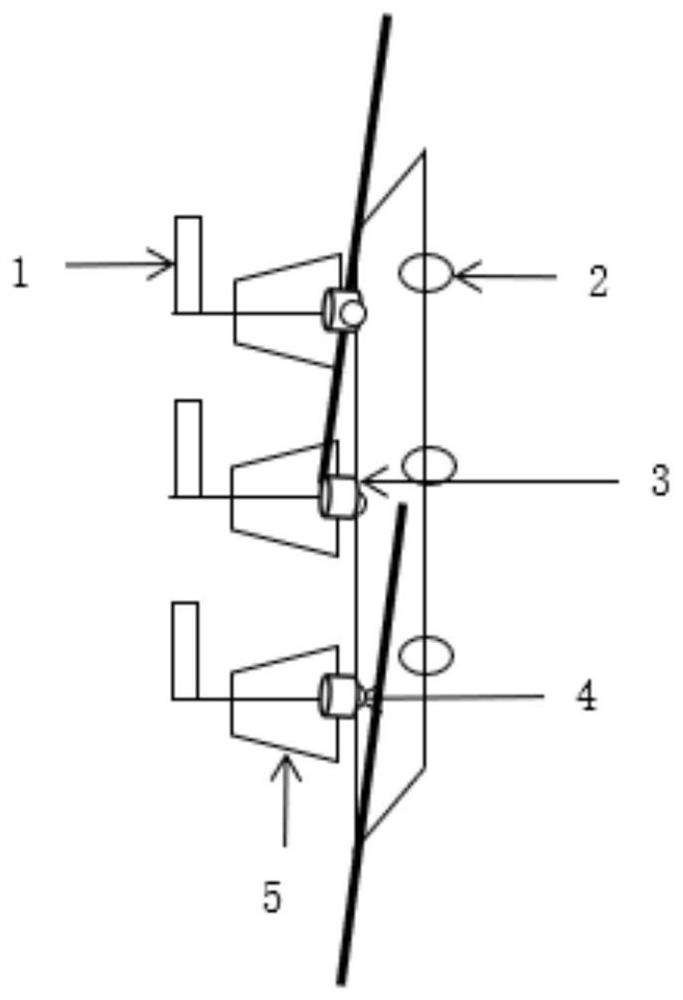

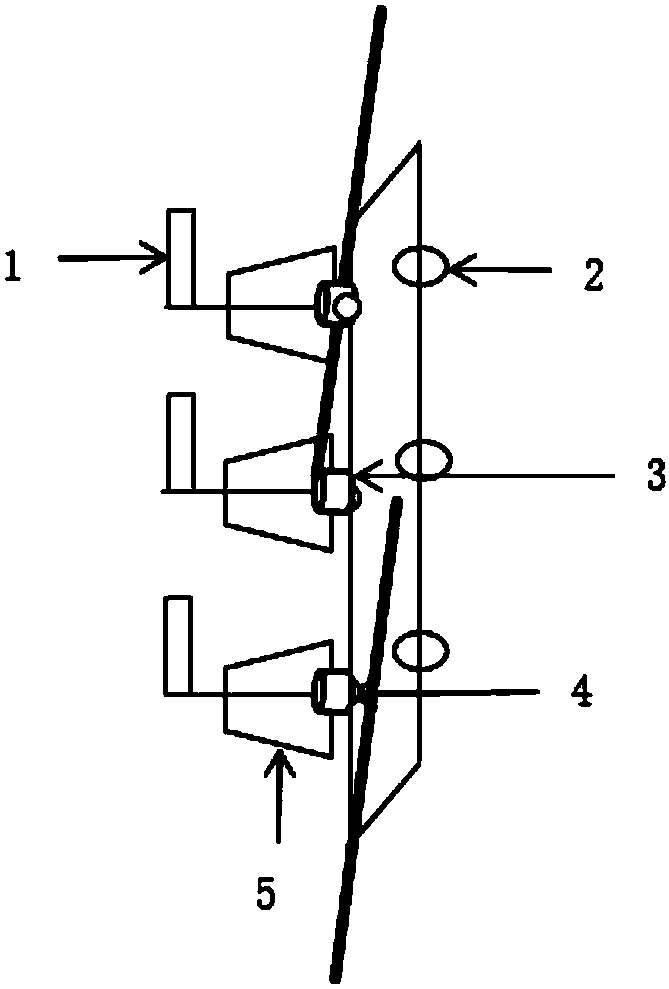

Air ring breaking device

The invention relates to an air ring breaking device. The air ring breaking device comprises an air ring breaking mechanism I and an air ring breaking mechanism II, wherein the air ring breaking mechanism I is used for wrapping a tube and partial yarns which are exposed to one end of cop yarns, the air ring breaking mechanism II is arranged in the 1 / 3 position of a cop yarn return line, the air ring breaking mechanism I comprises a fixed bracket, an air ring breaking protecting plate which is installed on the fixed bracket and a yarn guide which is arranged in the air ring breaking protectingplate, and the air ring breaking protecting plate wraps partial cop yarns. The air ring breaking device has the beneficial effects that the yarn unreeling speed is increased, the working efficiency ofan automatic winder is improved, high speed and high yield of the automatic winder are realized, and the product competitiveness is increased.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

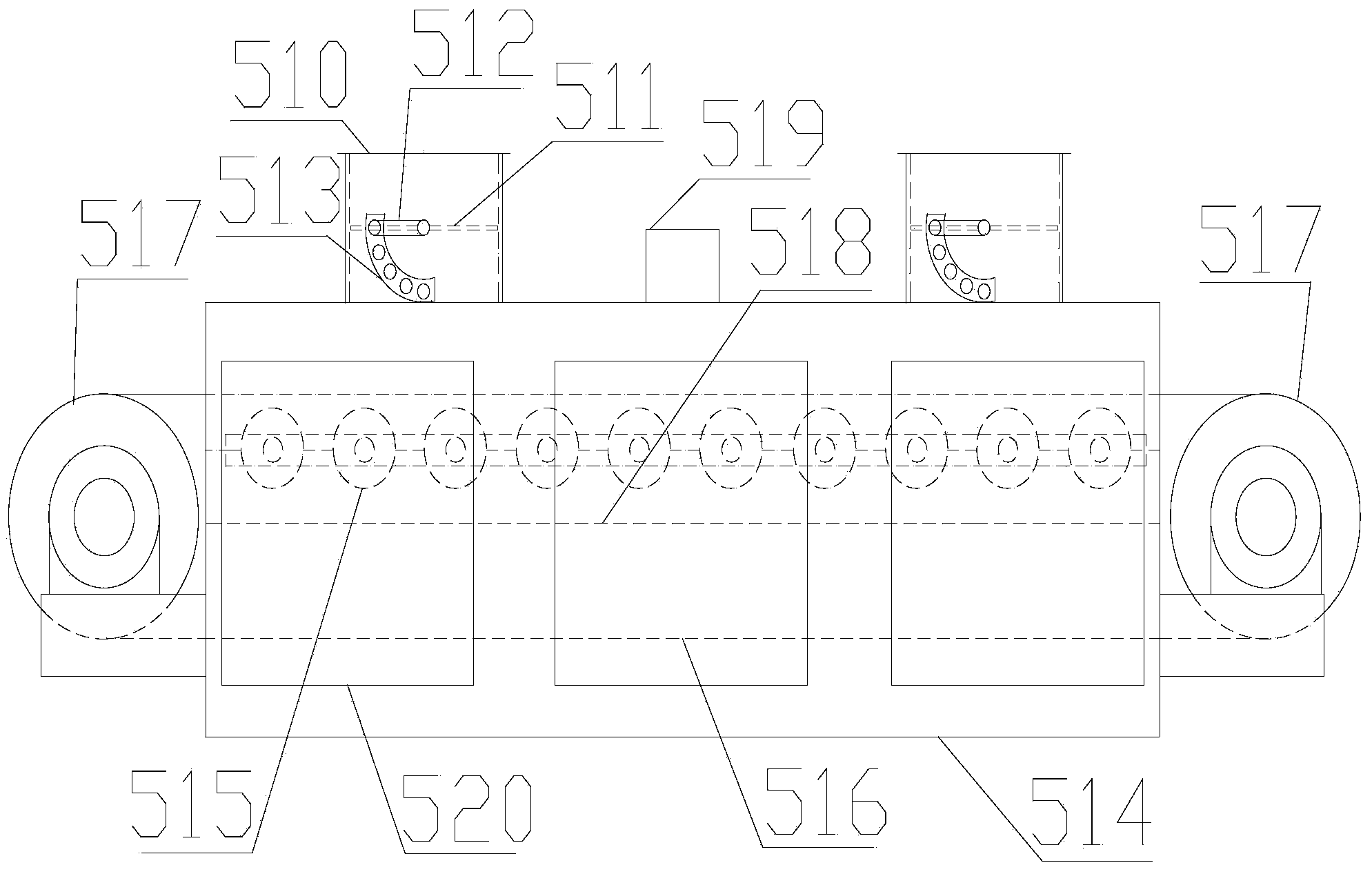

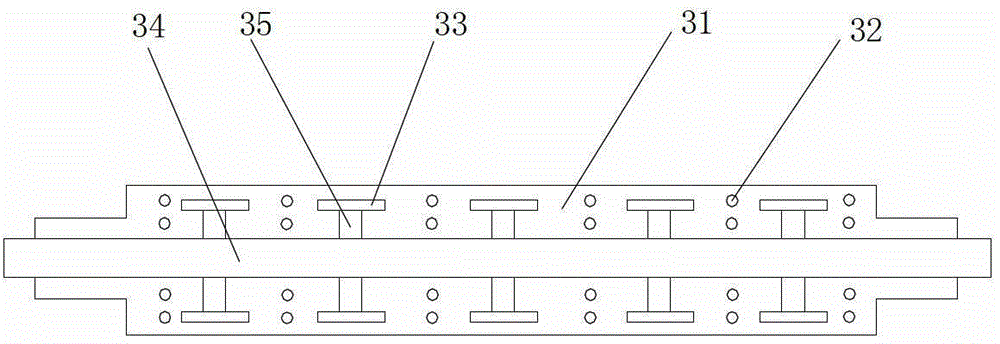

Five-roll straightener

The invention discloses a five-roll straightener which comprises an upper compression roll set, a lower compression roll set and a rack. The lower compression roll set is fixedly arranged on the rackand comprises three parallel lower compression rolls. The upper compression roll set and the lower compression roll set are arranged oppositely up and down, the centers of two upper compression rollsin the vertical direction are each aligned with a position between the corresponding two adjacent lower compression rolls. An upper fixing base is connected to a lifting device. The lifting device candrive the upper fixing base to move up and down, and accordingly the distance between the upper compression roll set and the lower compression roll set in the vertical direction is regulated. Compared with the prior art, the five-roll straightener provided by the invention can be used for improving the steel belt straightening efficiency, accordingly the uncoiling speed is increased, and accordingly the production efficiency is improved.

Owner:ZHAOQING HONGWANG METAL IND +1

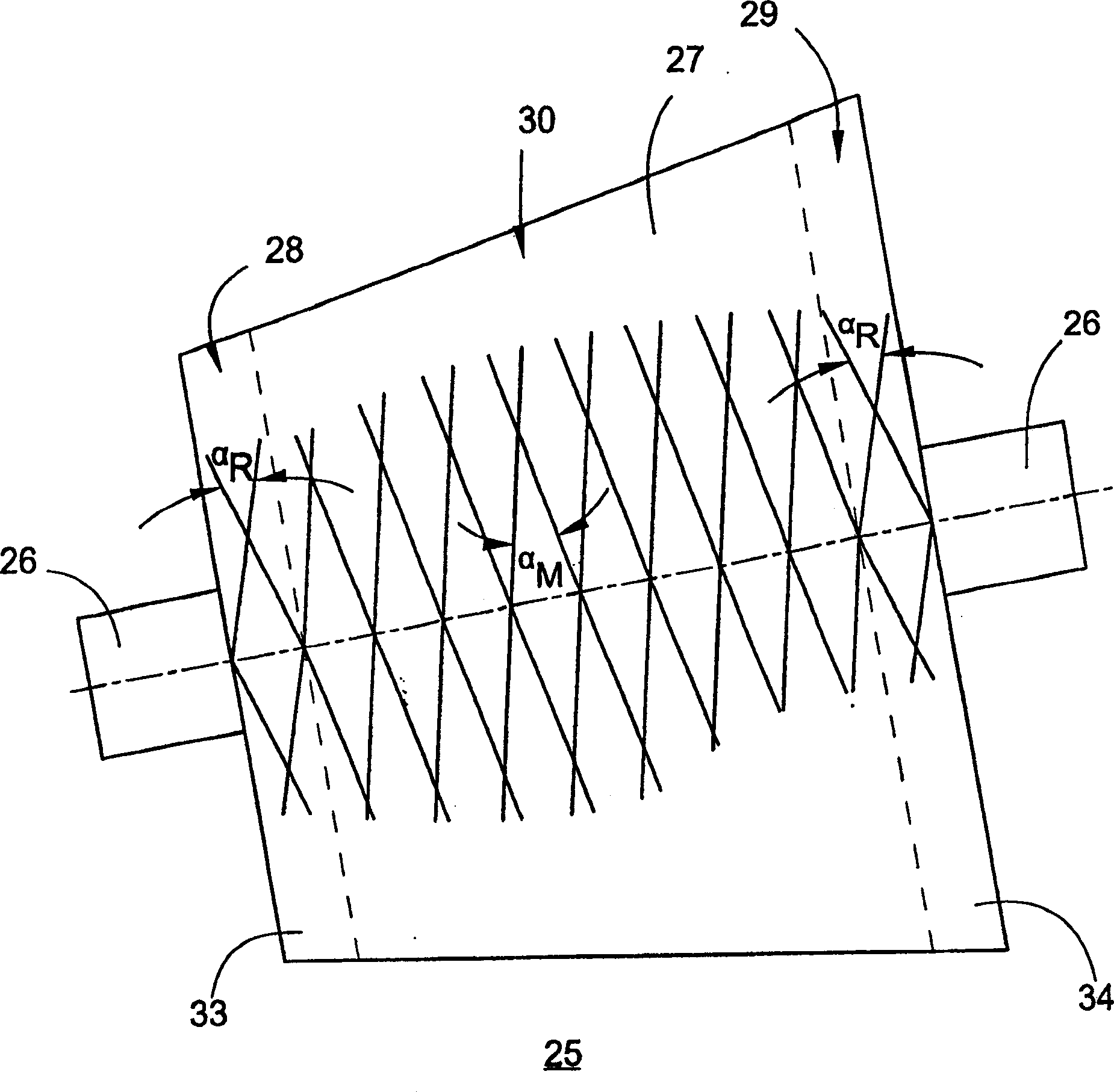

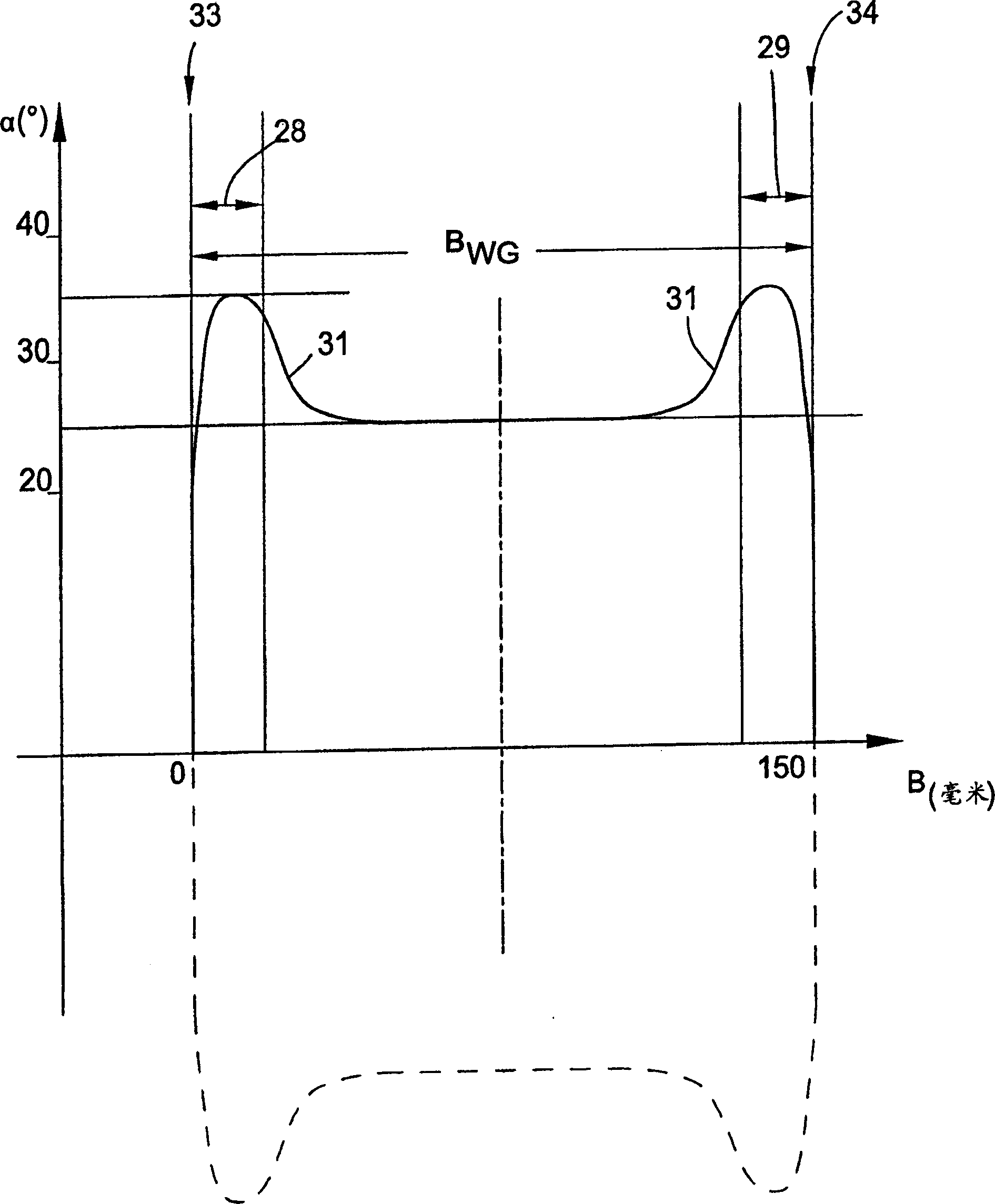

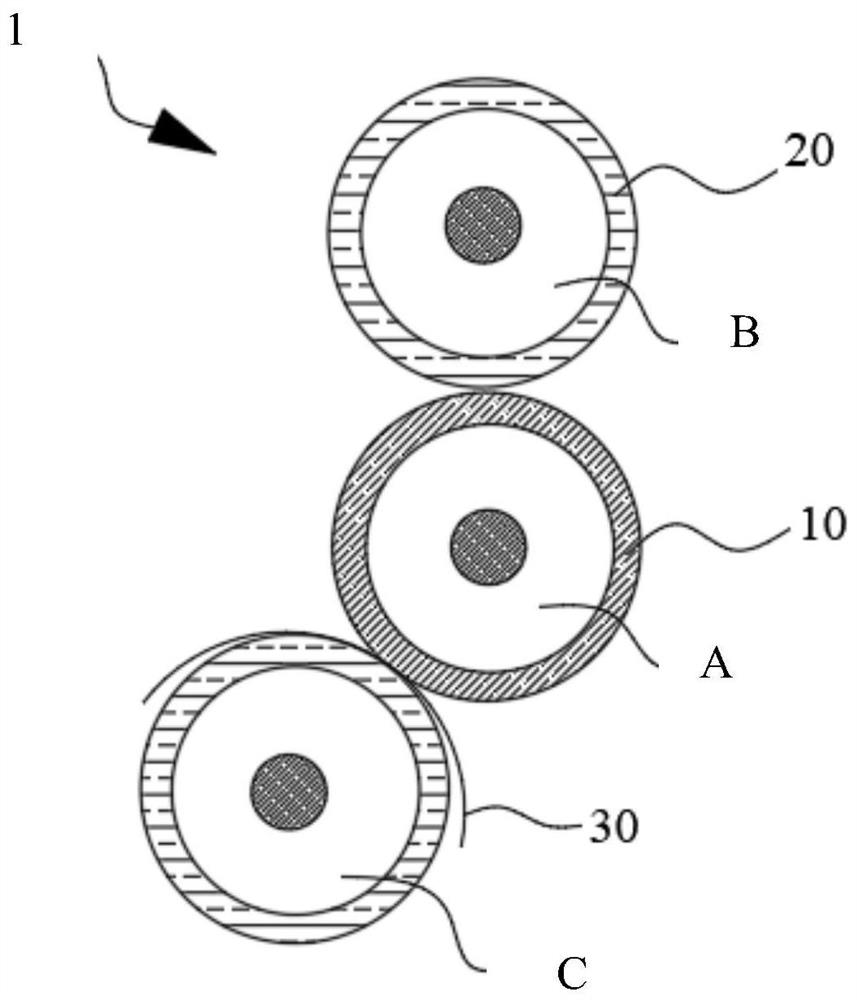

Conic tube and rolling method thereof

InactiveCN1269711CCrossing angle decreasesExcellent unwinding propertyFilament handlingContinuous wound-up machinesYarnBobbin

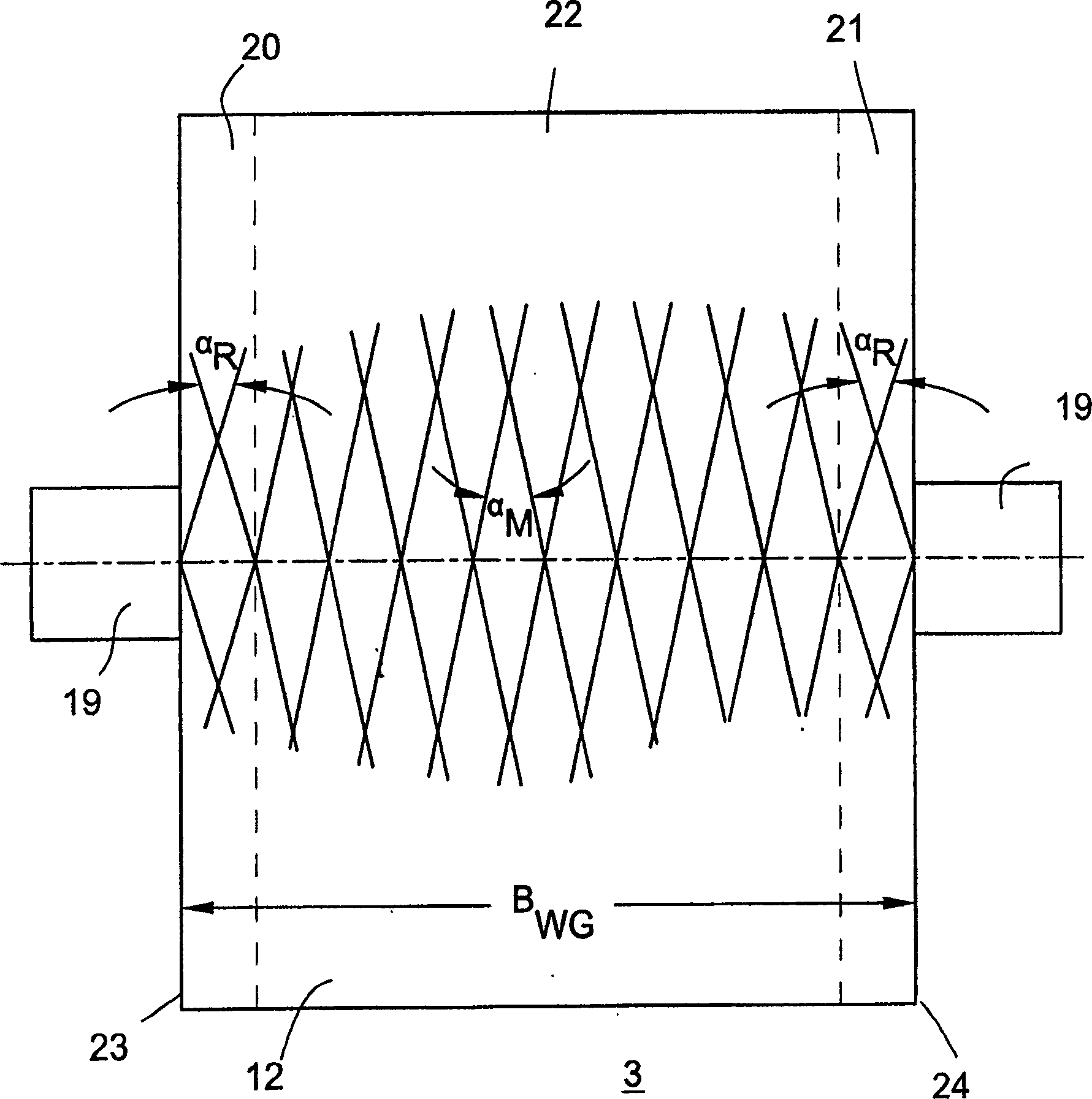

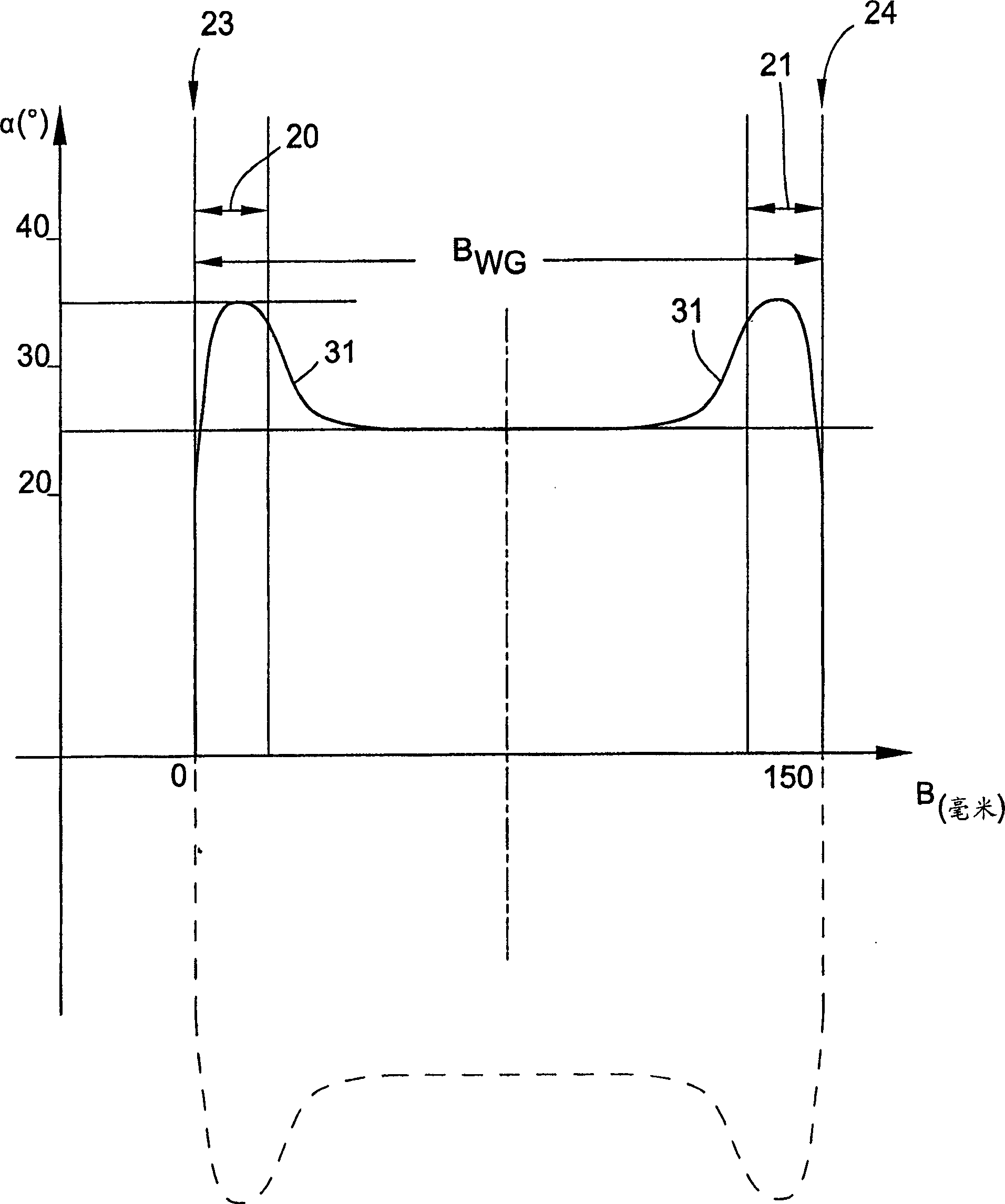

A method for forming a conical cross-wound bobbin by rotor spinning yarn by the following winding the yarn package, that is in a winding process, a crossing angle alpha in the middle section is smaller than that of the other parts of the winding process, and an across alpha M is created between 15-28 degrees in the middle zone, which is produced with this angle across alpha M more than 50% of the total winding width B WG.

Owner:SAURER GERMANY GMBH & CO KG

Columnar tube and rolling method thereof

InactiveCN1426948ACrossing angle decreasesExcellent unwinding propertyFilament handlingContinuous wound-up machinesYarnBobbin

A winding method for forming a cylindrical shape bobbin is provided, whereby, an intersection angle (alpha) is varying while the yarn is winded. To guide yarn, a yarn intersection angle (alpha M) at the center zone in the bobbin winding process is between 15-28 degrees and the yarn intersection angle (alpha R) towards the edge zones of two ends of the winding package is larger than that of the center zone.

Owner:SAURER GERMANY GMBH & CO KG

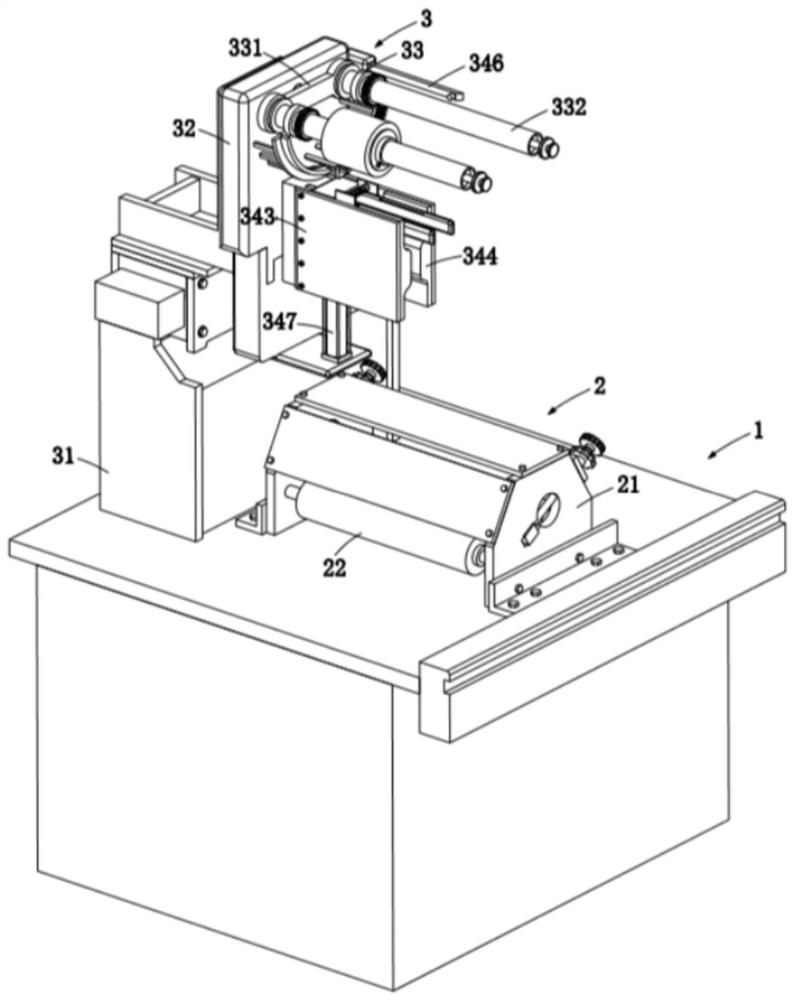

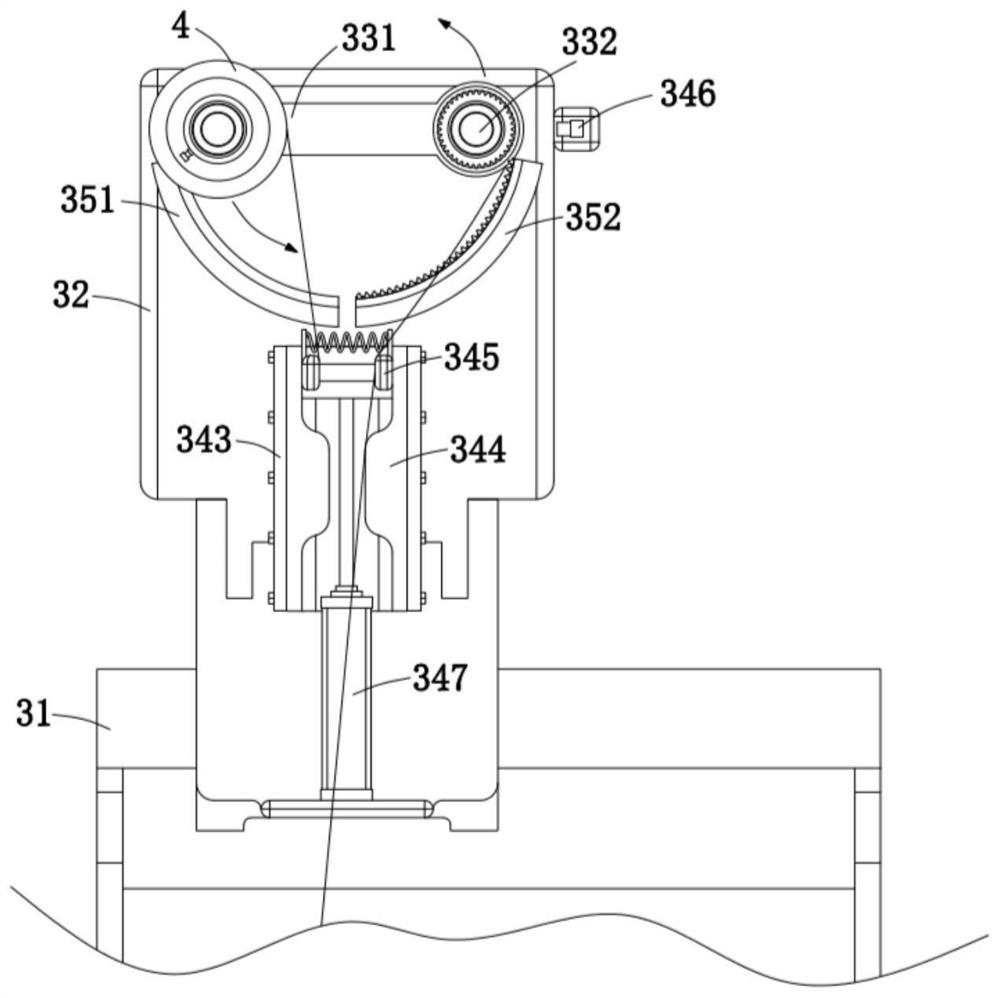

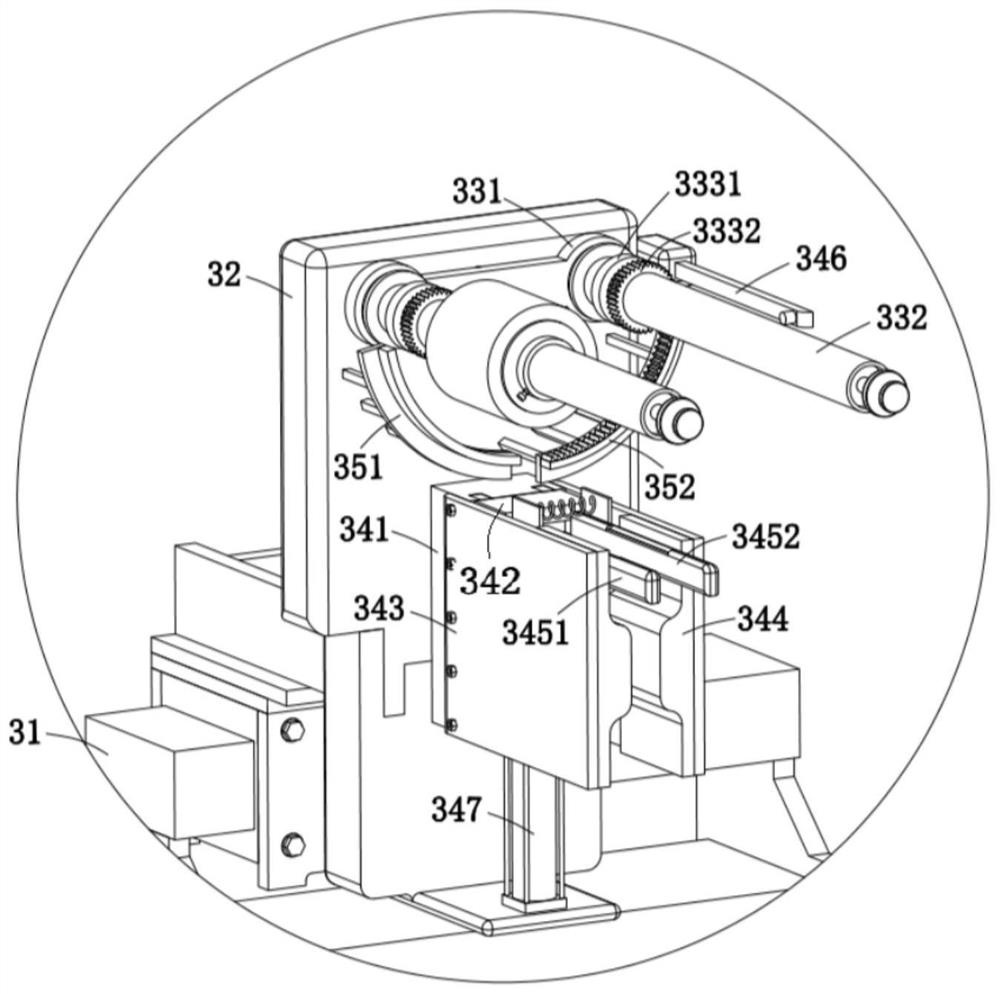

Automatic roll changing and continuous laminating equipment of flexographic printing machine

ActiveCN111392473ARealization of membrane changeMovement speed has beenPrinting press partsWebs handlingMechanical engineeringFilm-coated tablet

The invention relates to automatic roll changing and continuous laminating equipment of a flexographic printing machine. The automatic roll changing and continuous laminating equipment comprises a rack, a laminating assembly and an automatic roll changing part, the film coating assembly comprises a fixing plate, a film coating assembly body and a conveying roller. The automatic roll changing partcomprises a supporting frame, a mounting frame, a roll changing assembly, a film changing assembly and a control mechanism; and according to the equipment, a new protective film on one unwinding roller is pasted to the tail portion of a protective film on the other unwinding roller which is being unwound through the film replacing assembly to achieve automatic roll replacing of the protective film, and the positions of the two unwinding rollers obtained after film replacing are exchanged through the roller replacing assembly to prepare for next film replacing. The equipment is ingenious in mechanism design, the automatic roll changing device is extremely high in automation degree, the film covering efficiency and quality are improved, automatic roll changing of the protective film is achieved through the film changing assembly, and therefore the film covering continuity in the flexographic printing process is kept.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

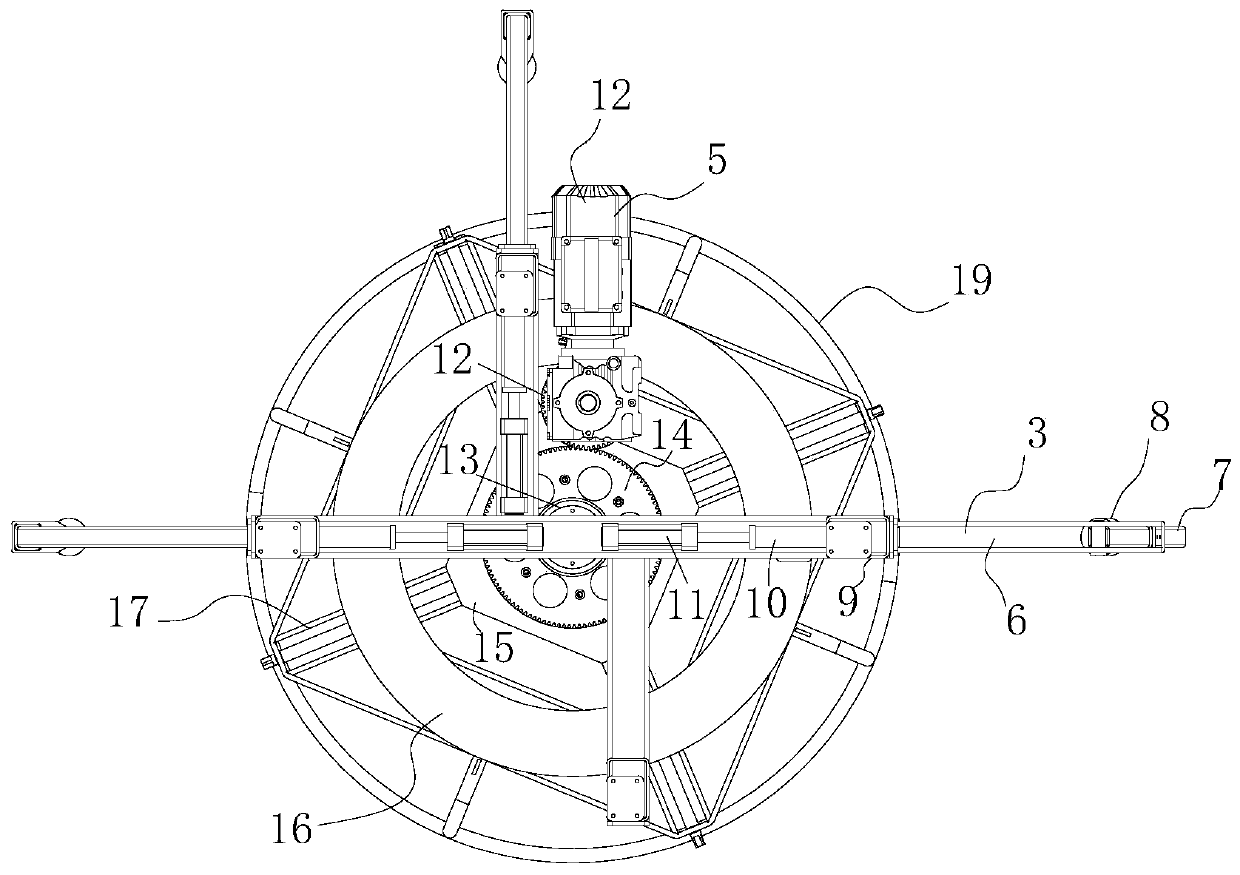

Industrial cable uncoiling equipment

InactiveCN109879106AAvoid tanglesMeet the high requirements of transportationFilament handlingEngineeringPinion

The invention relates to industrial cable uncoiling equipment. The industrial cable uncoiling equipment comprises a support and supporting legs fixedly connected to the support, wherein the support isprovided with a cable guide assembly; an uncoiling assembly is arranged above the support and abovethe cable guide assembly, and the uncoiling assembly is driven by a motor; the cable guide assemblycomprises a transverse plate support fixedly connected to the support and a cable guide transverse plate connected to the transverse plate support in a sliding mode; a cable guide vertical plate is hinged to the outer end part of the cable guide transverse plate, a guide wheel set is arranged on the cable guide vertical plate, the inner end of the cable guide transverse plate is fixedly connectedto a connecting rod, the inner end of the connecting rod is fixedly connected to the output end of a cable guide cylinder, and the cable guide cylinder is fixedly connected to the transverse plate support; the uncoiling assembly comprises an uncoiling support plate, a large gear is fixedly connected to the bottom end of the uncoiling support plate, the large gear is rotationally connected to the support through a support shaft, the large gear is driven by a pinion which is meshed with the large gear, and the pinion is driven by the motor; and a plurality of positioning assemblies are arrangedon the uncoiling support plate, and a90-degree angleis formed between every two adjacent positioning assemblies. According to the industrial cable uncoiling equipment, the universality is good, and cable winding is avoided during uncoiling.

Owner:TIANJIN JUXINGXIANGHAI MACHINERY CO LTD

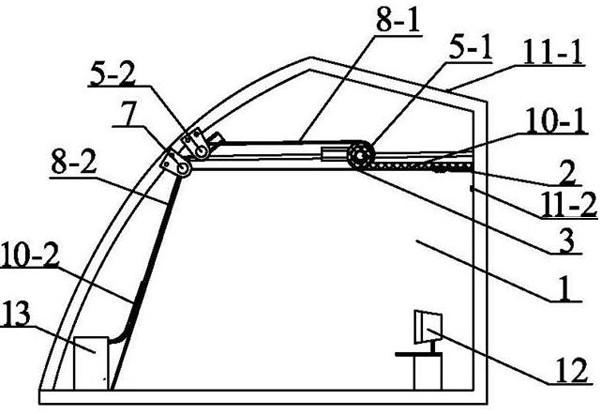

Novel solar greenhouse internal heat preservation device

PendingCN113575213AGuaranteed to workSimplify workClimate change adaptationGreenhouse cultivationElectric machineControl system

The invention relates to a novel solar greenhouse internal heat preservation device which comprises a greenhouse, a horizontal heat preservation quilt, a side heat preservation quilt, a plurality of heat preservation quilt supporting devices and a driving device, wherein each heat preservation quilt supporting device comprises a cableway fixing device, a heat preservation quilt supporting cableway and a driven shaft; the driving device comprises a horizontal heat preservation quilt driving shaft, a horizontal heat preservation quilt driving motor, a side heat preservation quilt driving shaft, a side heat preservation quilt driving motor and a motor sliding way; and the solar greenhouse inner heat preservation device is further provided with a control system. According to the device, two sets of heat preservation quilts are synchronously retracted, released and stretched through winding of different combinations of multiple steel wire ropes and different winding directions of the steel wire ropes on different transmission shafts. During working, the motors are controlled to rotate cooperatively through buttons, a power shaft achieves the heat preservation function in the sunlight greenhouse through rolling of a reel, the whole working process is efficient and simple, and operation by people is facilitated.

Owner:SHENYANG AGRI UNIV

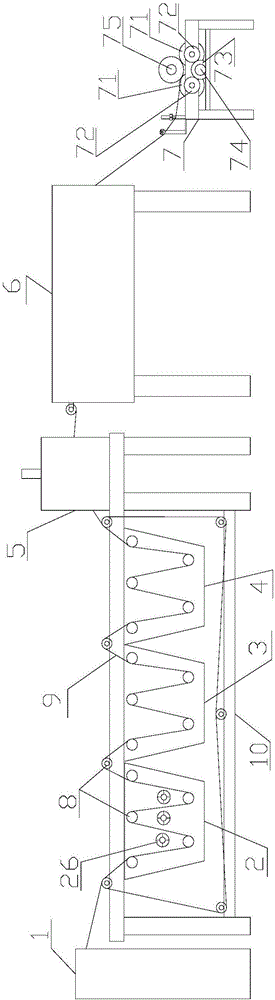

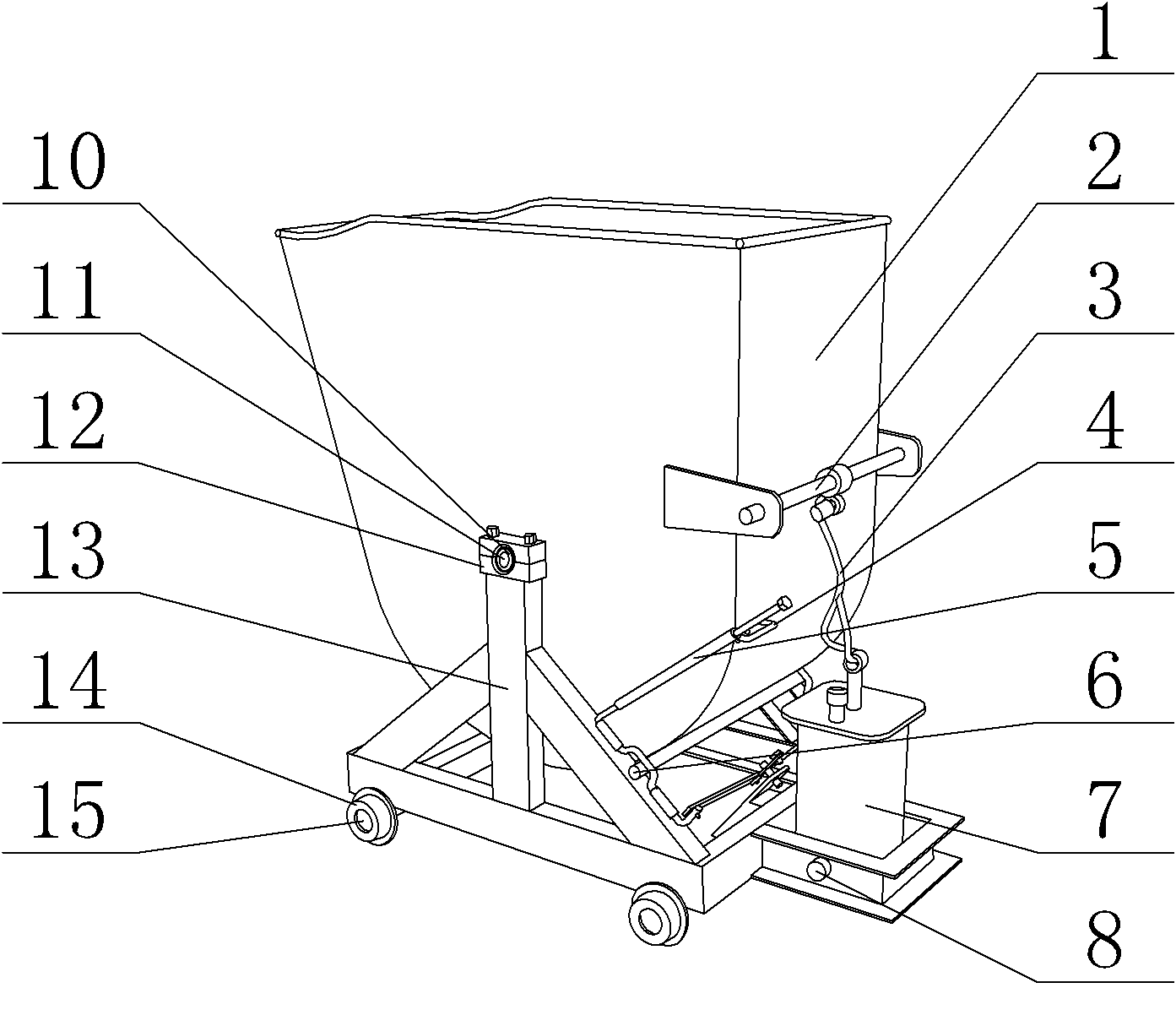

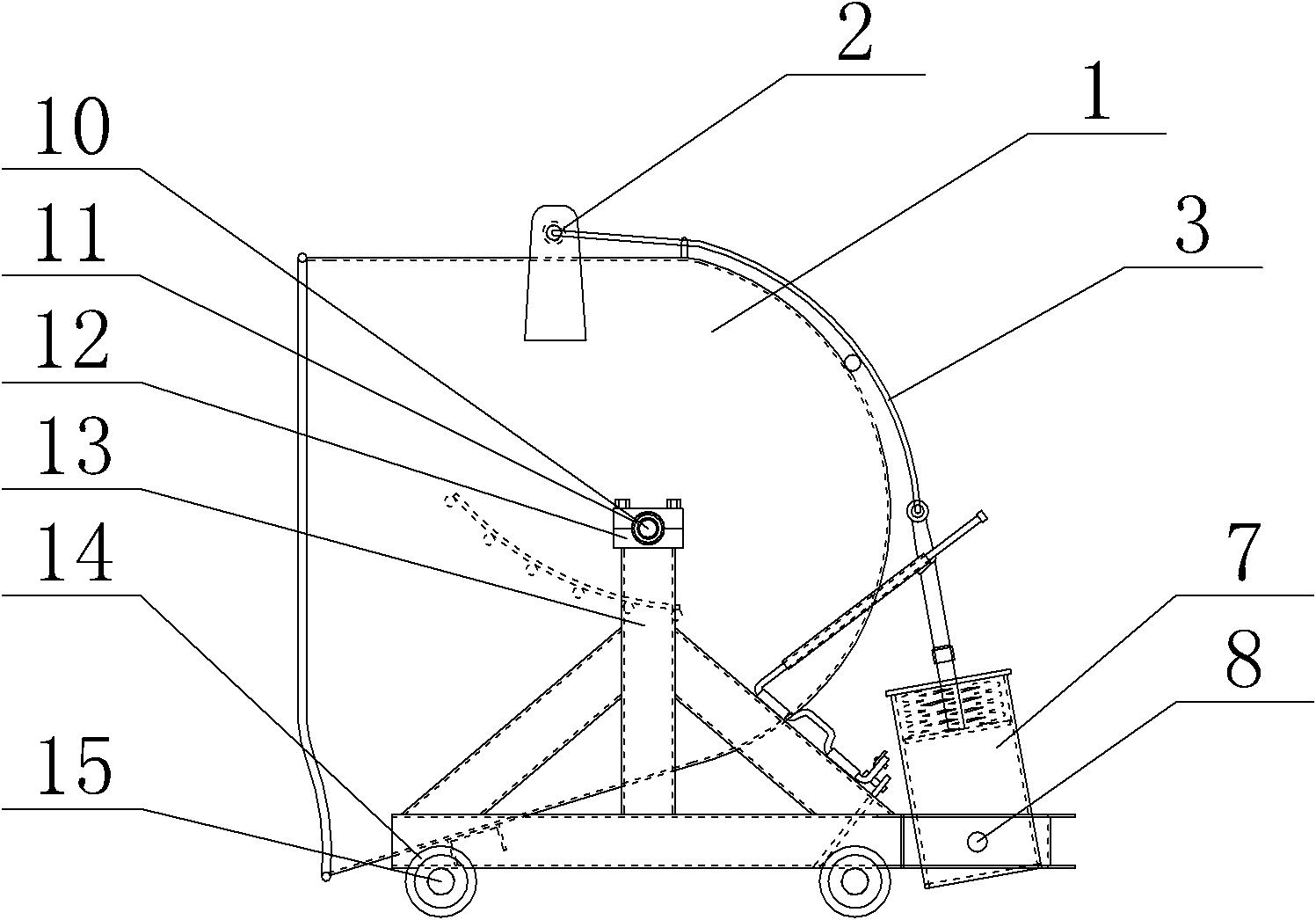

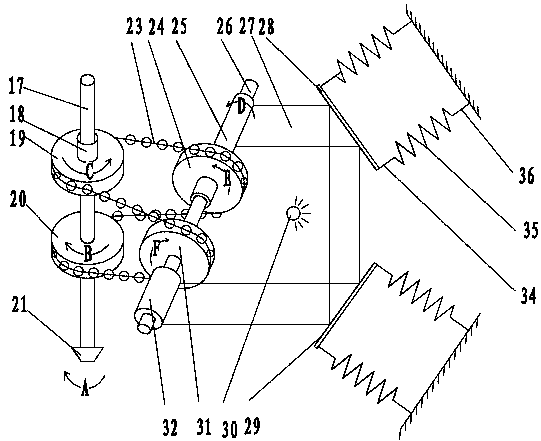

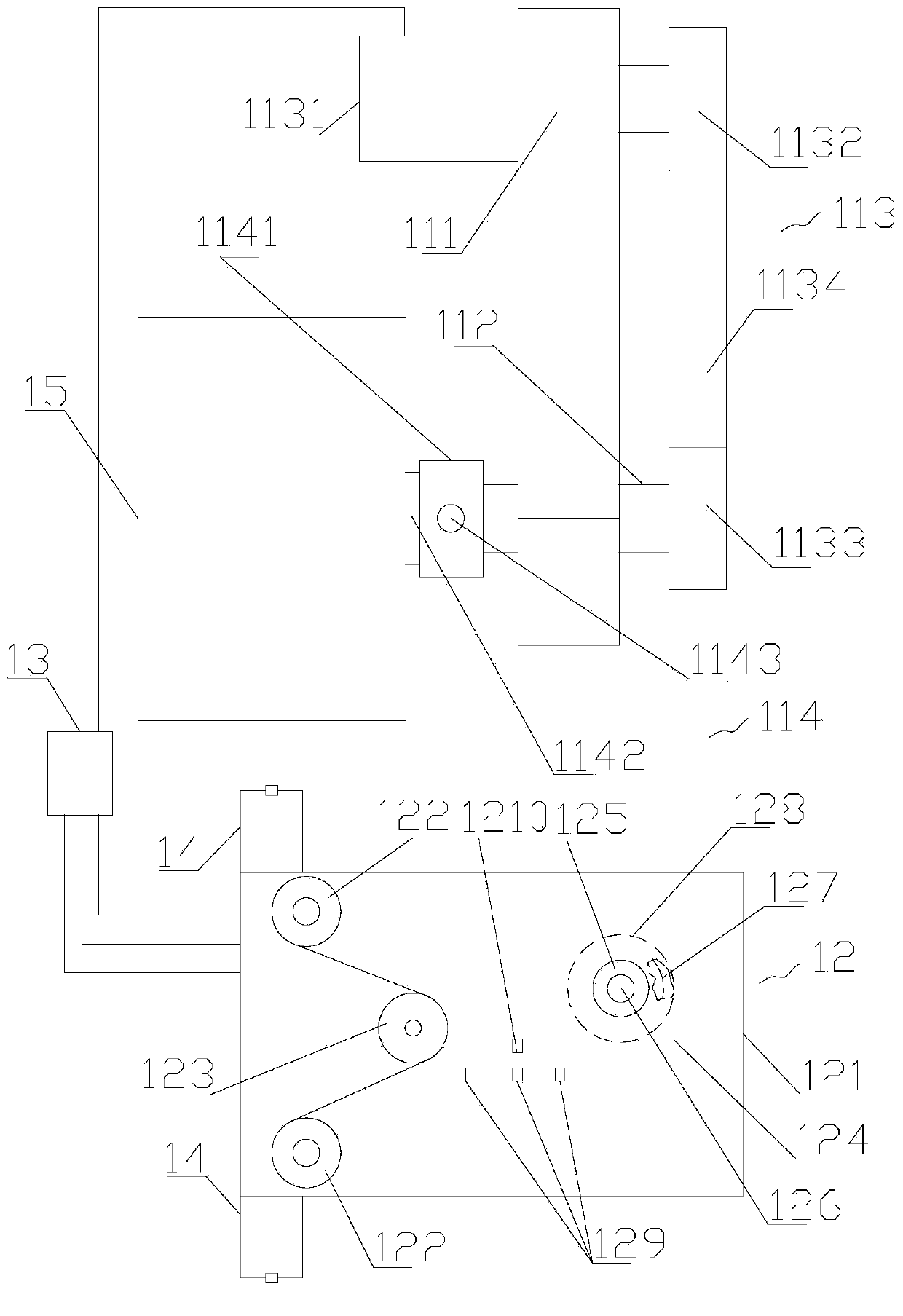

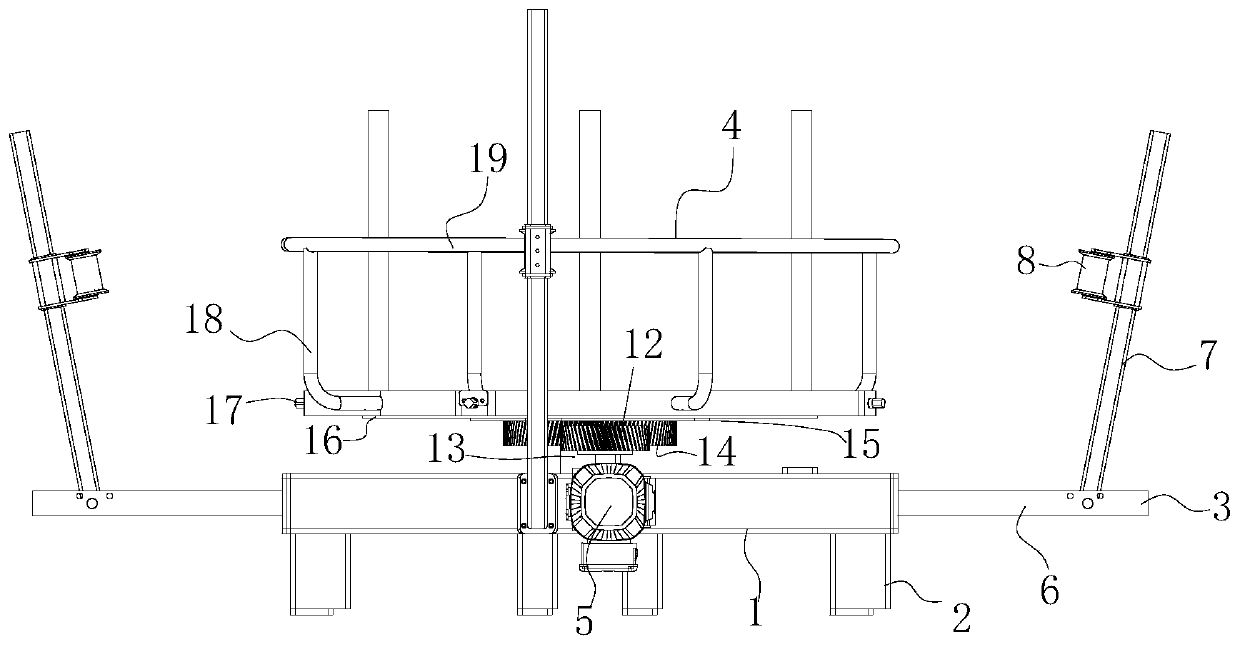

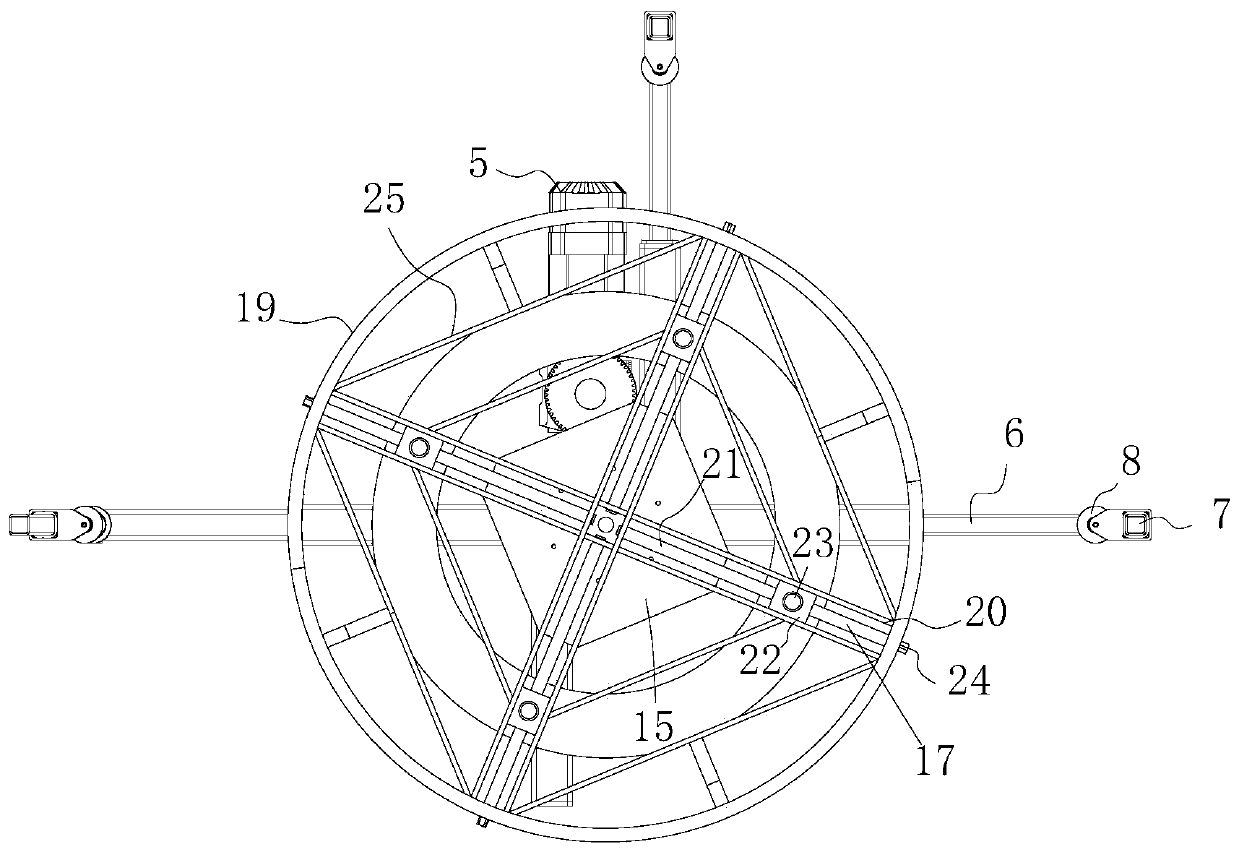

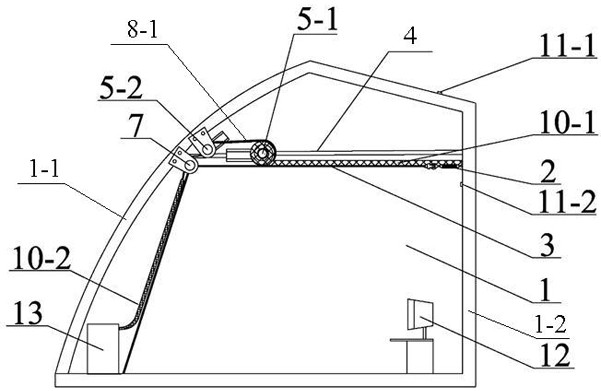

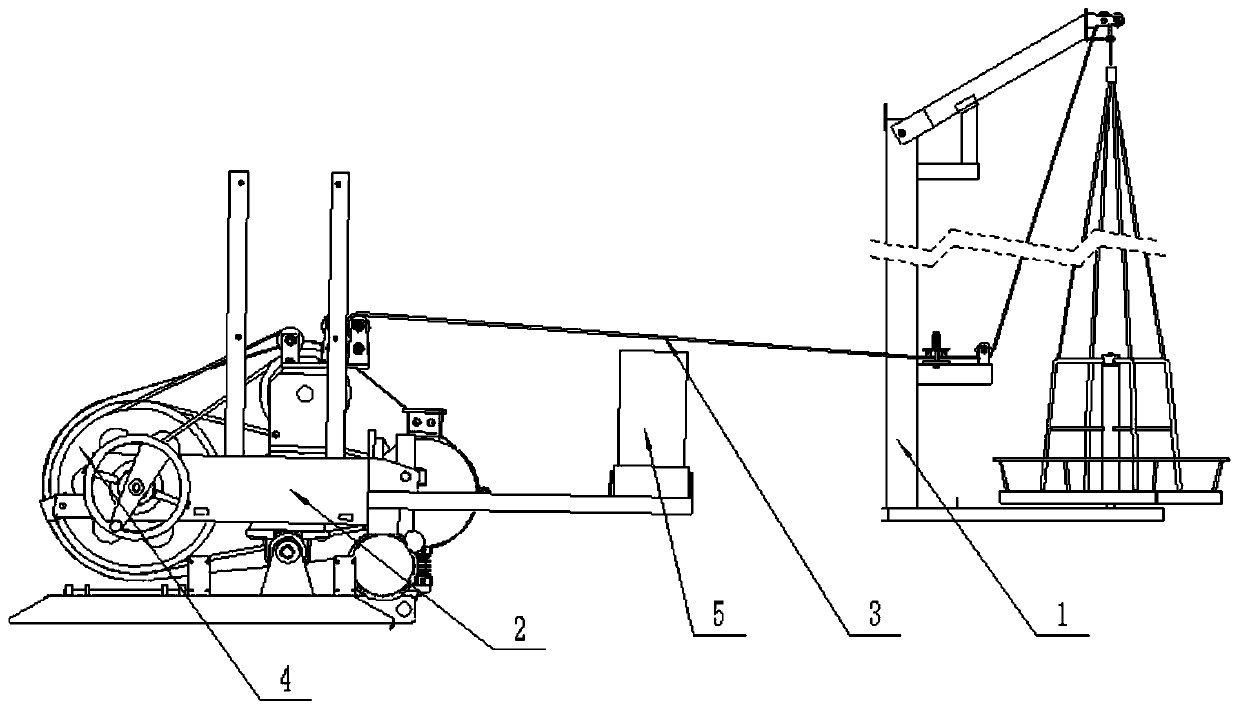

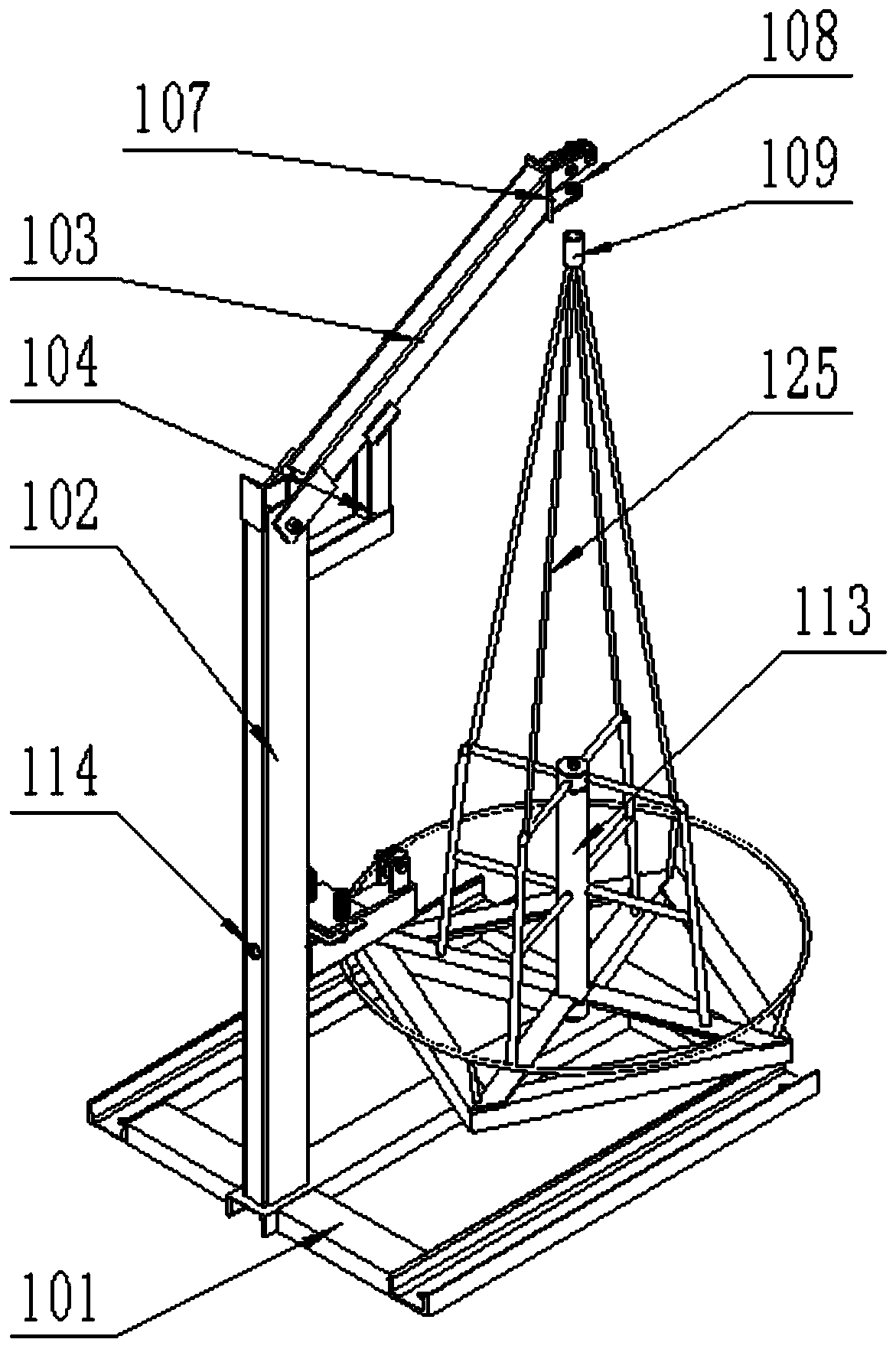

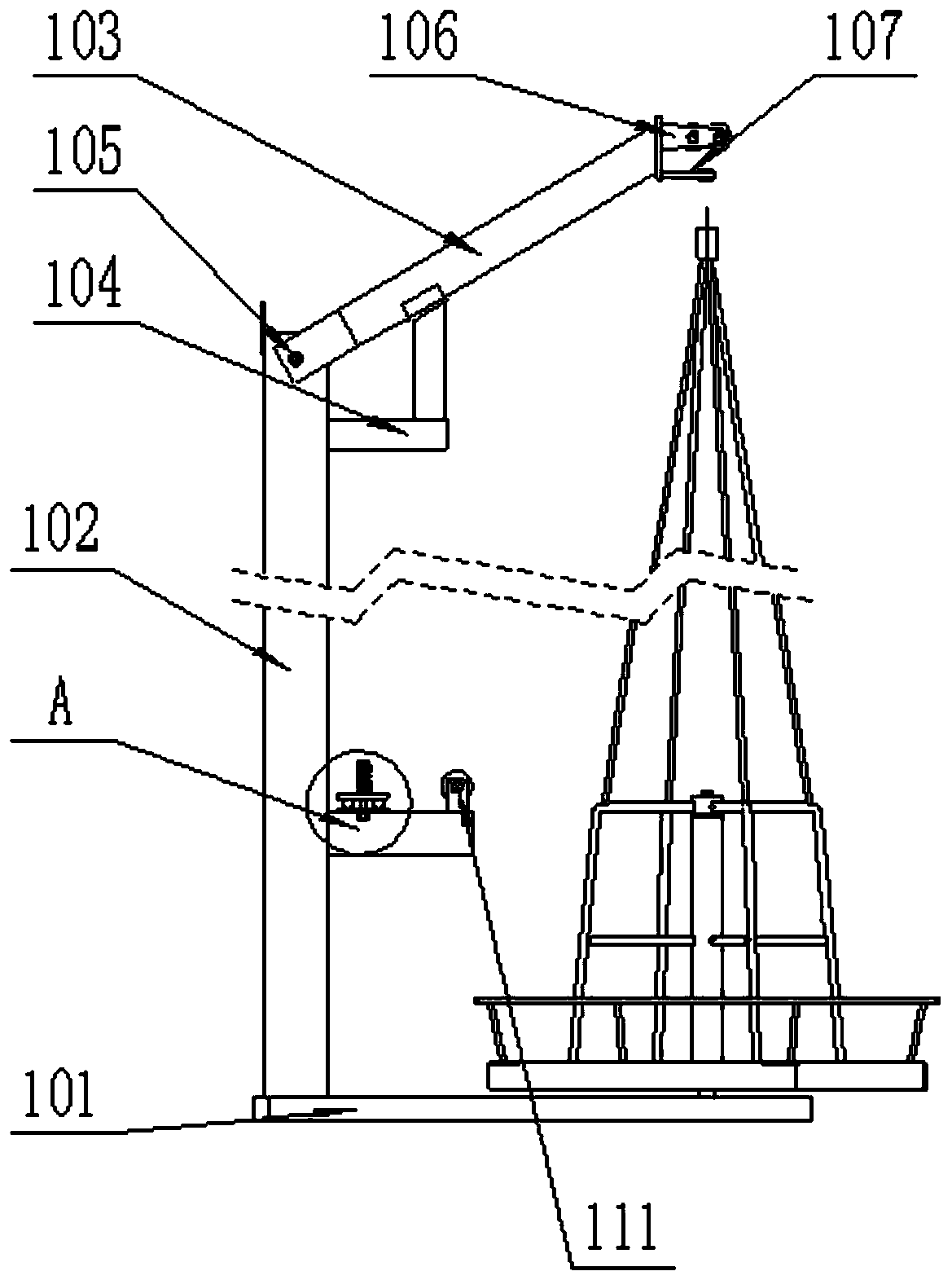

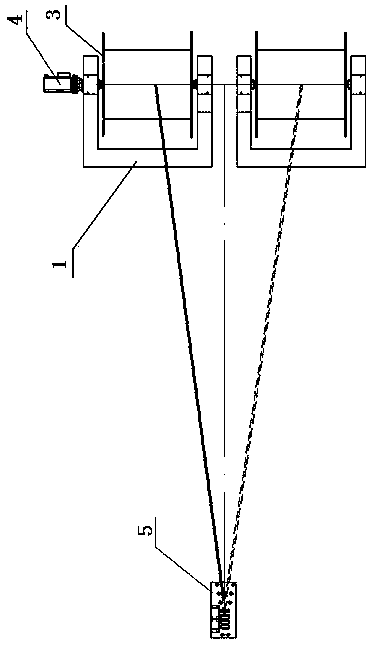

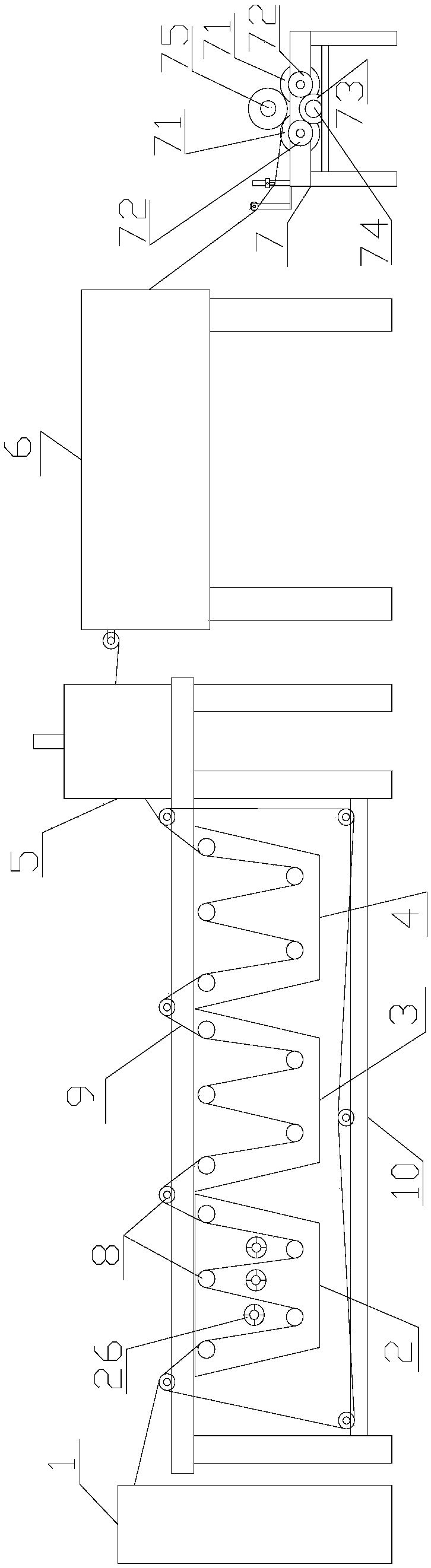

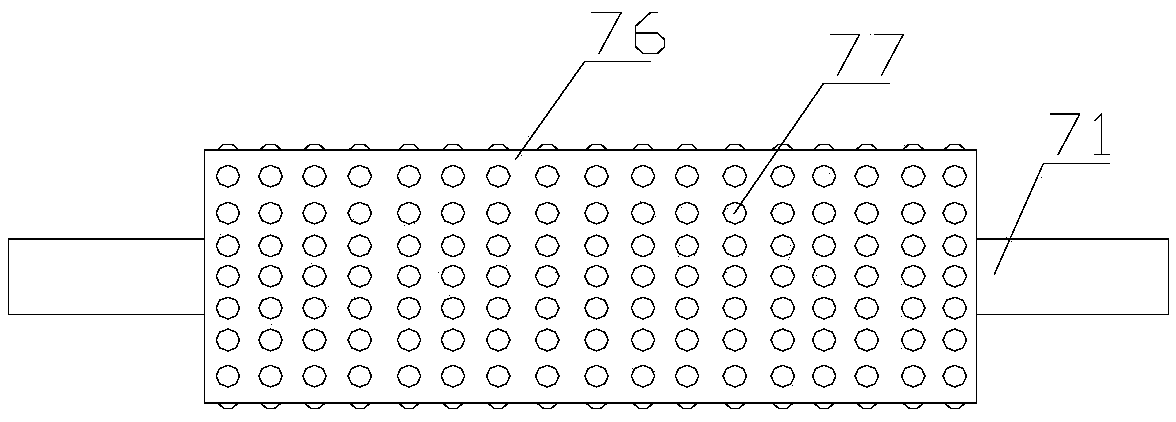

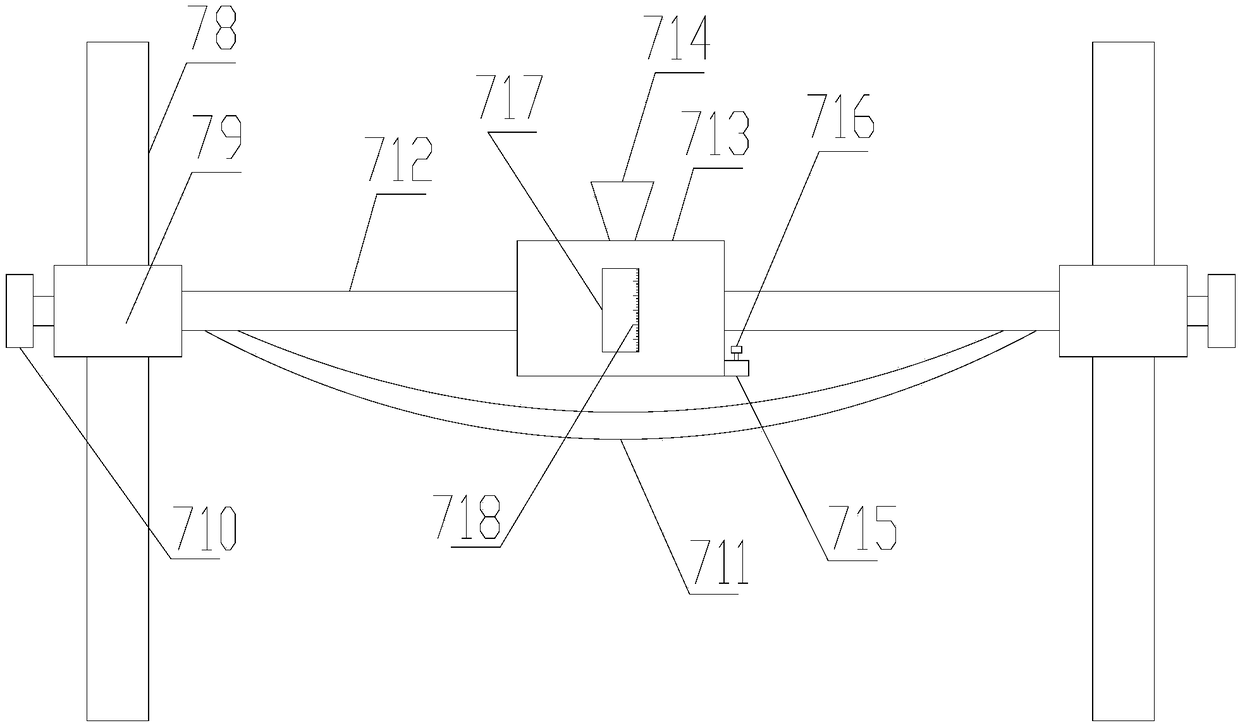

Wire winding and arrangement machine

PendingCN111498592AIncrease the speed of unwindingAvoid intertwiningFilament handlingWinding machineMachine

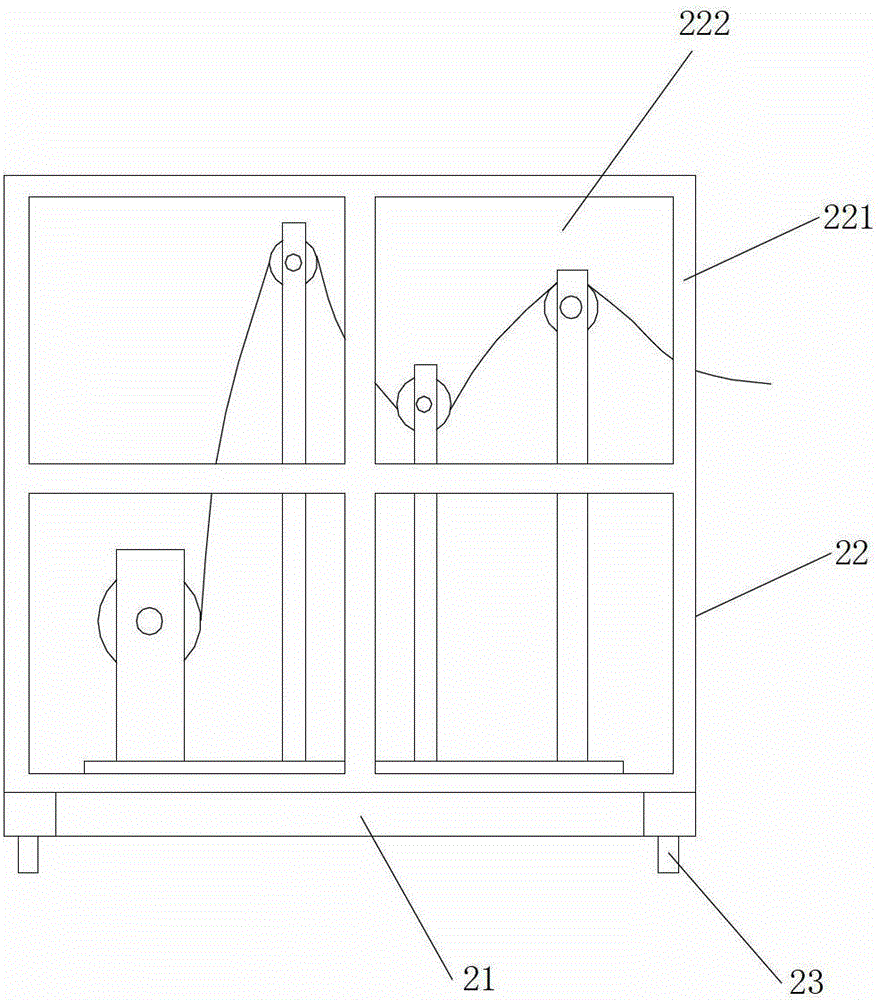

The invention discloses a wire winding and arrangement machine, and relates to the field of steel wire processing equipment. The wire winding and arrangement machine comprises a wire guide mechanism and a wire arrangement mechanism. The wire guide mechanism and the wire arrangement mechanism are arranged in the steel wire conveying direction. The wire guide mechanism comprises a base. A supportingmechanism is arranged on the base and comprises a supporting shaft and a conical supporting frame. The supporting shaft is upwards arranged on the base, and the conical supporting frame sleeves the supporting shaft in a rotating mode. A vertical rod is upwards arranged on the side, corresponding to the supporting shaft, of the base, and an upper rotating arm assembly is arranged on the top of thevertical rod in an inclined and upward mode. The wire arrangement mechanism comprises a wire winding machine bottom frame and a wire winding machine upper frame. A rotating shaft is arranged on the wire winding machine bottom frame in a rotating mode, the wire winding machine upper frame is arranged on the rotating shaft, and a lifting driving mechanism is arranged on the wire winding machine bottom frame. A winding drum pressing assembly which is used for tightly clamping a steel wire winding drum is arranged at the end, deviating from the wire guide mechanism, of the wire winding machine upper frame, and a wire arrangement device assembly is arranged at the end, close to the wire guide mechanism, of the wire winding machine upper frame. The wire winding and arrangement machine has the advantages of being good in steel wire arrangement effect and high in steel wire guiding and conveying stability.

Owner:HENAN ZHONGBANG WEIYE TECH CO LTD

a textile machine

ActiveCN108100774BAutomatic tension controlEfficient change of unwinding speedFilament handlingYarnControl system

The invention discloses a spinning device. The spinning device comprises a spool, wherein the outer surface of the spool is provided with a light-reflecting substance, and the spool is installed on abearing of a yarn sending system; a photoelectric sensor, wherein the receiving end of the photoelectric sensor is installed corresponding to the spool; a spring, wherein the spring is installed on the bearing; a control system, wherein the control system controls the spring to generate a resistance force to the bearing, and the control system is in the communication connection with the photoelectric sensor, wherein while the photoelectric sensor detects the light-reflecting substance on the spool, a signal for reducing the resistance force is sent to the control system. The spinning device iscapable of solving a technical problem in the prior art that a thick yarn cannot be effectively regulated because a tensioner in the prior art only regulates the tension of a spun yarn effectively, so that the deformation of the yarn is caused, sudden stretching or shortening accidents happen frequently in a knitting process, and the device cannot perform the normal knitting.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

a textile equipment

ActiveCN108149364BEasy to moveIncrease productivityCircular loomsHealdsProgrammable logic controllerEngineering

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Yarn winding device

A technology for making it possible to continue winding while yarn jointing is carried out is provided. A yarn supplying portion 3 for unwinding a spun yarn Y from a yarn supplying bobbin B, a winding section 5 for winding the spun yarn Y to form a package P, an accumulator 7 provided between the yarn supplying portion 3 and the winding section 5 to store the spun yarn Y, and a yarn end drawing mechanism W for drawing out the yarn end of the stored spun yarn Y to the yarn supplying portion 3 side at the time of bobbin change of the yarn supplying bobbin B, yarn cutting, or yarn breakage are provided.

Owner:MURATA MASCH LTD

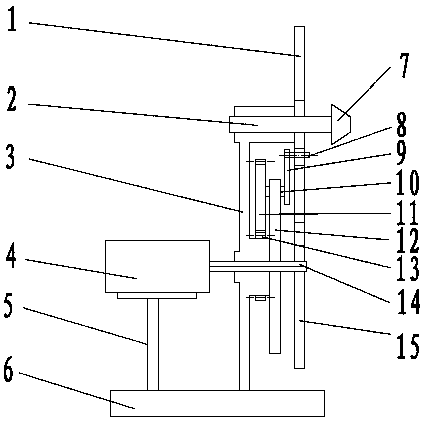

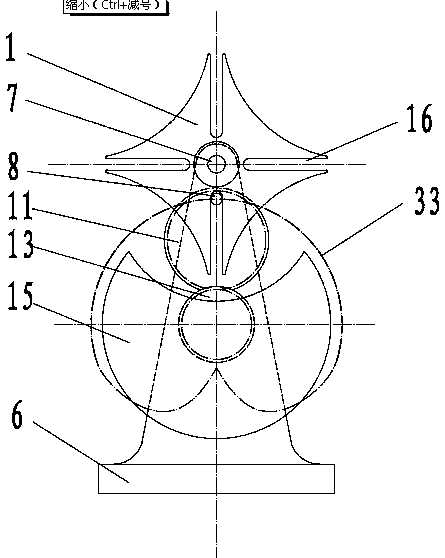

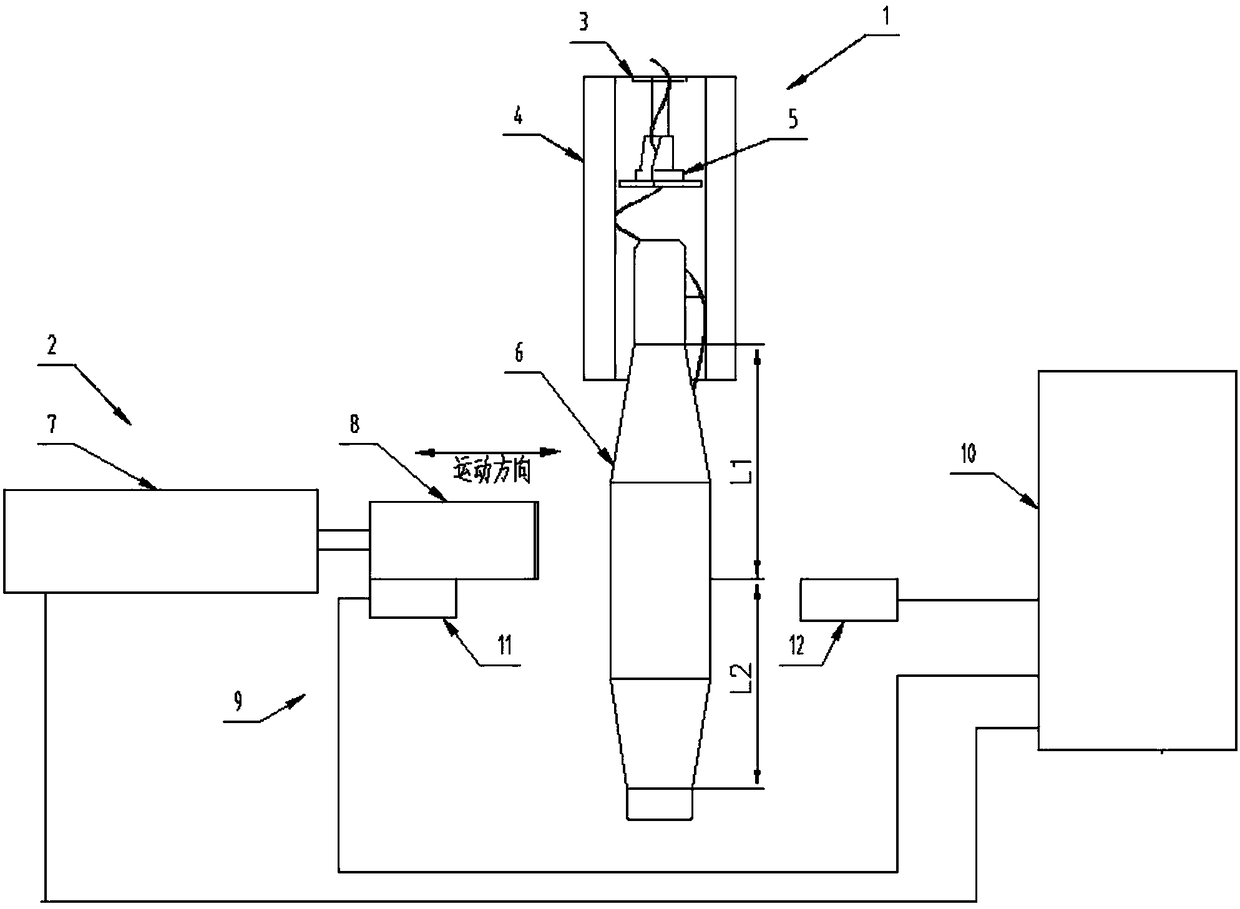

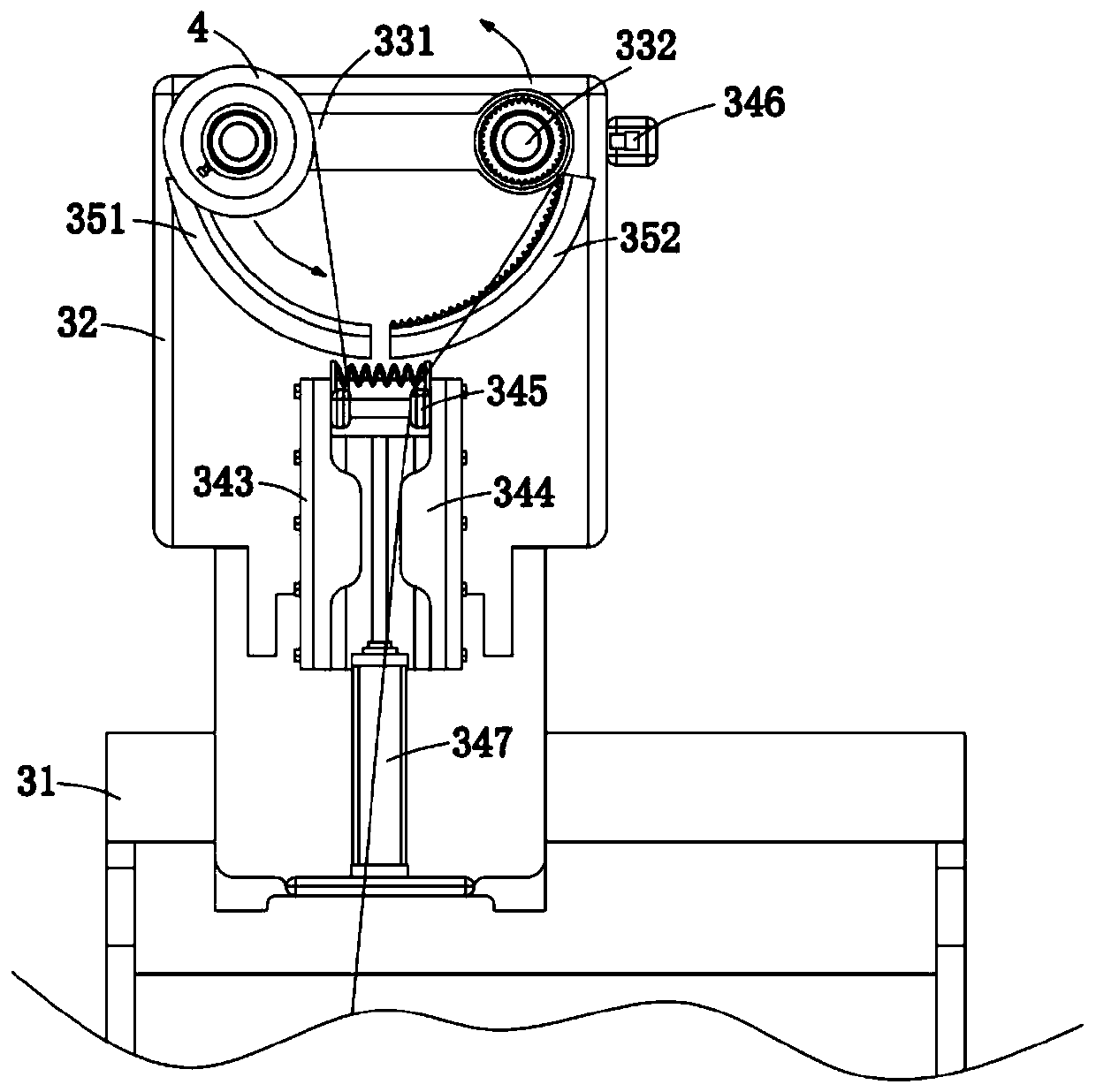

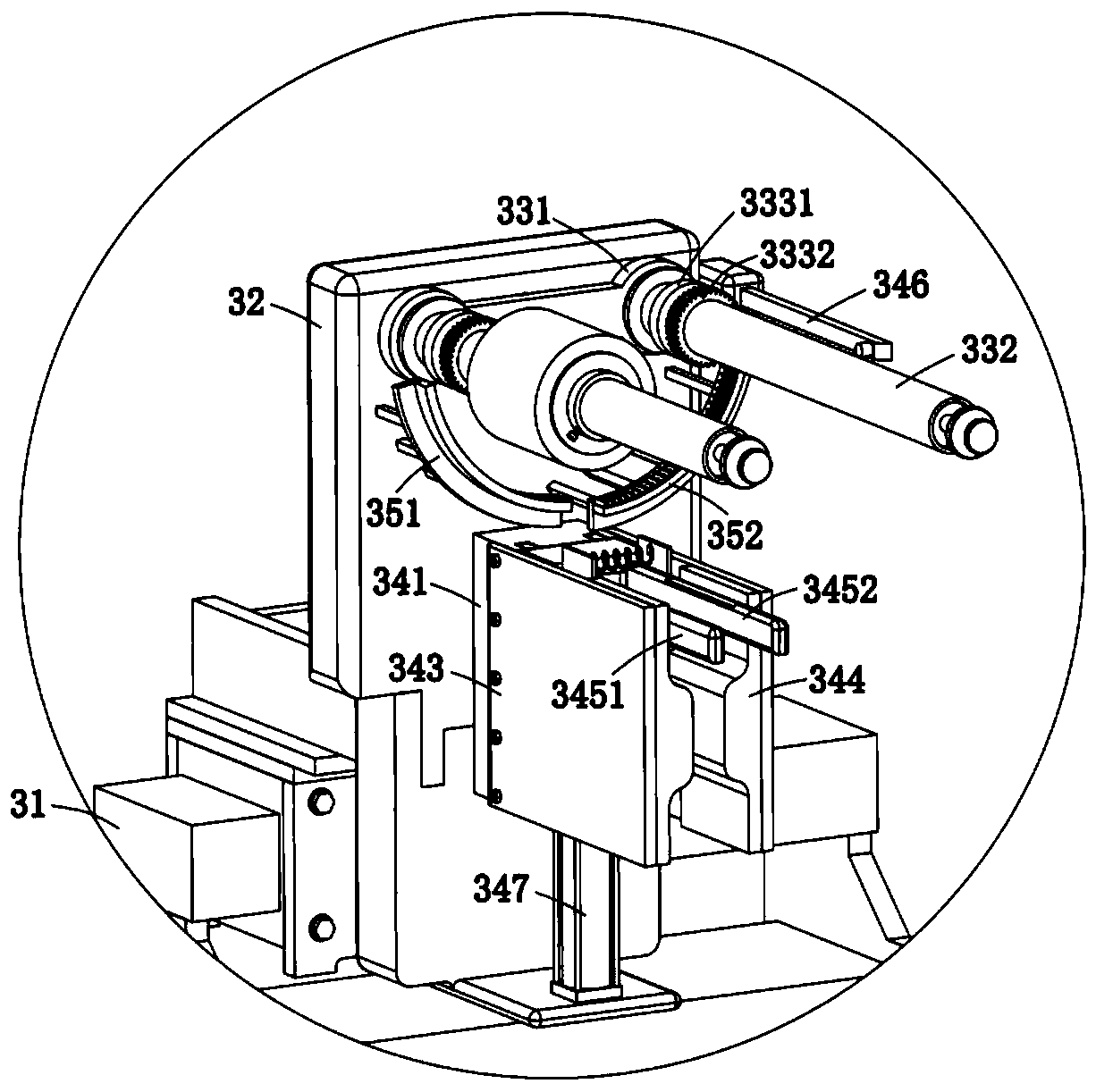

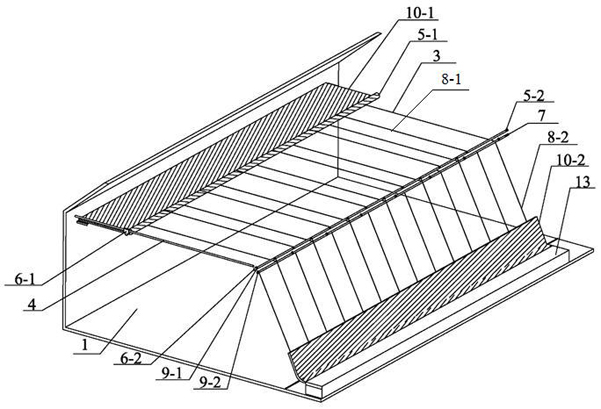

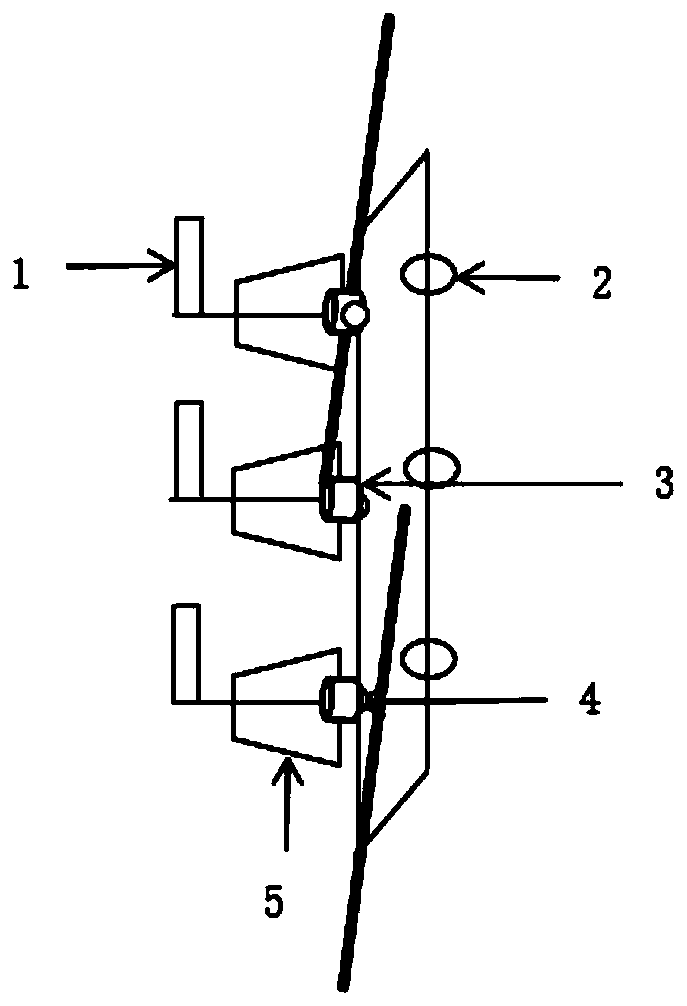

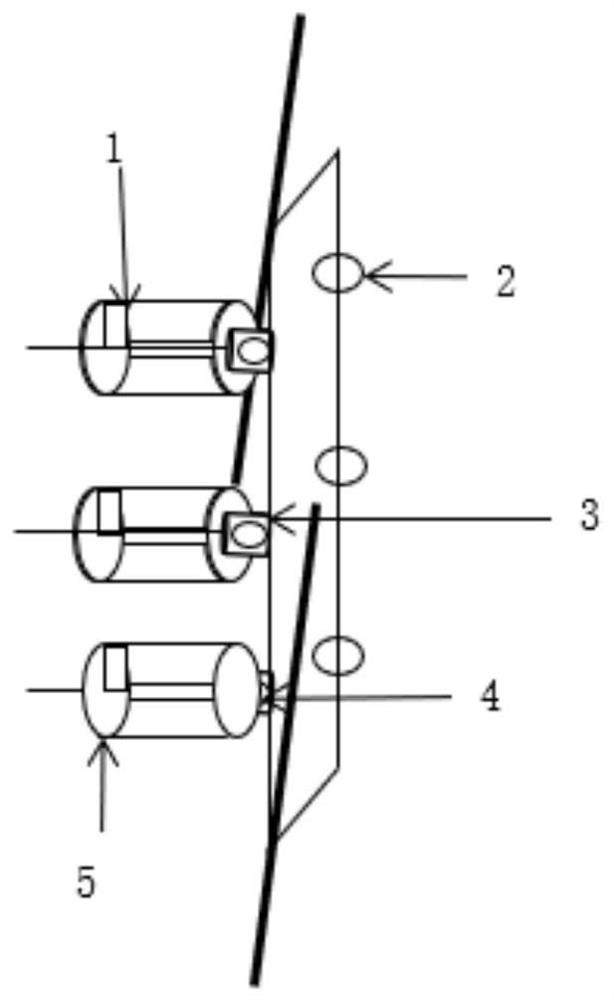

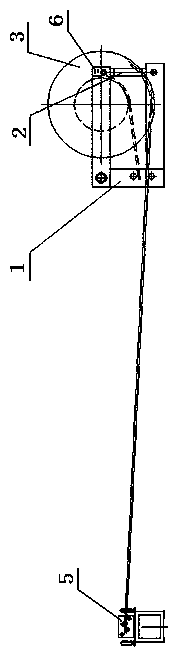

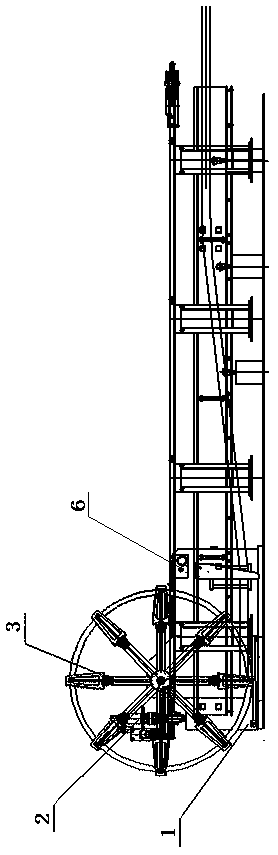

Intelligent and flexible heat preservation double-pipe unwinding mechanism and unwinding method

PendingCN109502417AReasonable inner diameterIncrease unwinding speedFilament handlingElectric machineryStator

The invention provides an intelligent flexible heat preservation double-pipe unwinding mechanism and an unwinding method. At present, a flexible heat preservation double-pipe unwinding mechanism in heating and cooling fields is still in an empty stage, and along with the increasing of market requirements, the design of the flexible heat preservation double-pipe unwinding mechanism urgently needs to be solved to meet the requirements of development. The intelligent flexible heat preservation double-pipe unwinding mechanism comprises an unwinding platform (1) and a guide mechanism (5), the unwinding platform is of a frame structure, and the interior of the frame structure is of a W-shaped groove structure. A motor (4) is fixed to a middle position frame of a W-shaped groove, two executing mechanisms (3) are separately mounted in two side grooves, the motor is separately connected with the two executing mechanisms through couplers, the executing mechanisms are provided with eight slidingblock devices, the eight sliding block devices are arranged at equal angles to the center, cylinder stators (2) are fixed to brackets on the right side of the executing mechanisms, and a control panel(6) is mounted on the upper right part of a frame of the unwinding platform.

Owner:HARBIN LOGSTOR ENERGY SAVING TECH

A non-woven fabric dyeing production line

InactiveCN103820962BAvoid shakingPrevent fallingSucessive textile treatmentsTextile treatment machine arrangementsEngineeringNonwoven fabric

The invention discloses a non-woven fabric dying production line which comprises an uncoiling device, a dying cylinder, a cleaning cylinder, dry-rolling device, a drying device, a coiling device, a plurality of guide rollers, net belts and a first frame body. The uncoiling device, the dying cylinder, the cleaning cylinder and the dry-rolling device are arranged on the first frame body in sequence. The coiling device is arranged in rear of the drying device, and the dying cylinder, the cleaning cylinder and the first frame body are provided with the guide rollers. The net belts are arranged on the guide rollers in a tensioning mode. Compared with the prior art, the good cleaning effect can be achieved, the dying quality of a product is not affected, the size of an exhaust opening can be adjusted, the normal temperature in drying non-woven fabric in a drying oven and the coherence of the whole production process are guaranteed, production efficiency is not affected, crimples are avoided, the overall attractiveness and the coiling quality of the non-woven fabric are ensured, slippage in transmission can also be avoided, the transmission rate is guaranteed, the uncoiling speed can be prevented from being higher than the belt supporting speed of the net belts, water removing is even, the normal water removing effect is achieved, and the drying effect is not affected.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213BPrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

A flexo printing machine automatic roll change continuous lamination equipment

ActiveCN111392473BRealization of membrane changeMovement speed has beenPrinting press partsWebs handlingIndustrial engineeringSupport plane

The invention relates to a flexo printing machine automatic roll changing and continuous film coating equipment, which includes a frame, a film coating assembly, and an automatic roll changing part; The part includes a support frame, a mounting frame, a roll changing assembly, a film changing assembly and a control mechanism; the device pastes the new protective film on the unwinding roller to the protective film on another unwinding roll through the film changing assembly. The automatic roll change of the protective film is realized at the tail, and the position of the two unwinding rollers after the film change is reversed by the roll changer assembly to prepare for the next film change. The efficiency and quality of the coating is improved, and the automatic roll change of the protective film is realized through the film changing module to maintain the continuity of the coating during the flexo printing process.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

An improved non-woven dyeing production line

ActiveCN106120213BIncrease frictionGuaranteed tensionSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersProduction lineEngineering

The invention discloses an improved non-woven fabric dyeing production line. The improved non-woven fabric dyeing production line comprises an unreeling device, a dye vat, a transition area, a washing vat, a rolling device, an oven, a reeling device, multiple guide rollers, mesh belts and a frame body. The unreeling device, the dye vat, the transition area, the washing vat, the rolling device, the oven and the reeling device are sequentially arranged from front to back, and the dye vat, the transition area and the washing vat are arranged on the frame body; the guide rollers are arranged in the dye vat, the transition area and the washing vat and on the frame body, and the mesh belts are tensioned on the guide rollers; the unreeling device comprises a seat body, multiple rollers, two rails, an unreeling shaft, two guide seats, a sliding seat, a connecting seat, a regulating screw, a regulating disc, first bearings, second bearings, a regulating pressure applying device and two supporting bodies. Compared with the prior art, fixation and detachment can be convenient, fixing reliability is high, working efficiency is improved, product quality is improved, and the reeling degree of density of non-woven fabric is good.

Owner:ZHEJIANG KINGSAFE INTERLINING

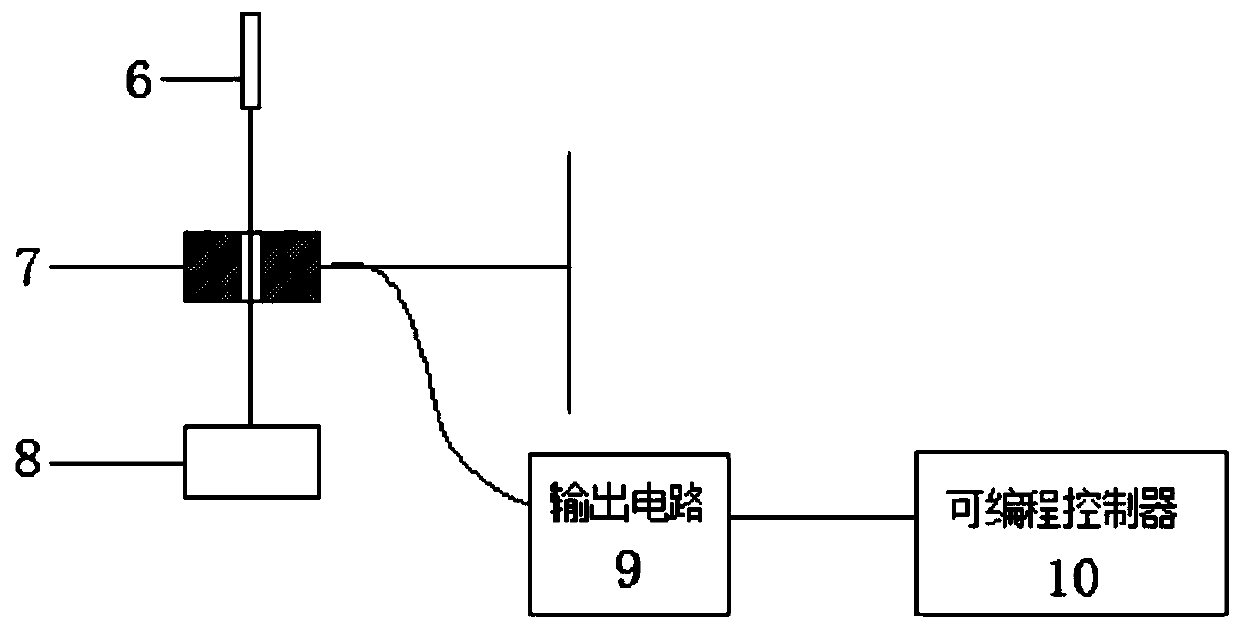

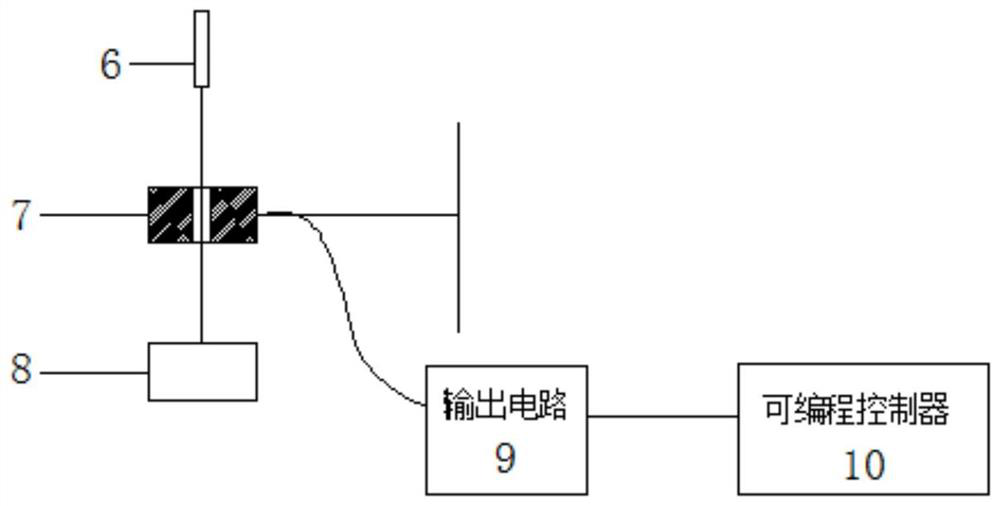

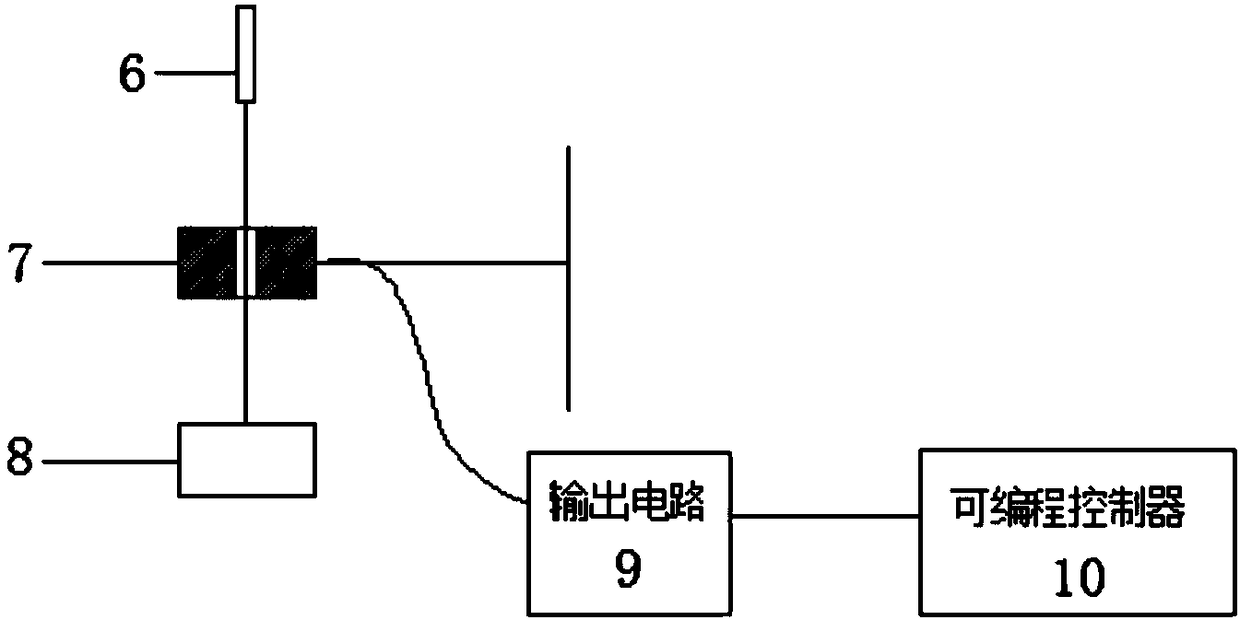

Textile equipment

ActiveCN108149364ASolve the problem of taking up a lot of spaceIncrease productivityCircular loomsHealdsState of artProgrammable logic controller

The invention discloses textile equipment. The textile equipment comprises a slide channel, a slide block, a harness wire guide rod, a harness wire, an output circuit and a programmable logic controller, wherein the slide block is arranged on the slide channel, the harness wire guide rod is arranged on the slide block, and the harness wire is arranged on the guide rod and moves on the slide channel under the effect of the harness wire guide rod and the slide block; the output circuit is arranged on a harness wire motion path, and the programmable logic controller is connected with the output circuit and controls contacTS of the output circuit to be switched on and switched off, so that the harness wire is moved. The technical problems in the prior art that since a circular weaving machinefor weaving dual-layer canister cloth in the prior art is large in occupied space, inconvenient to operate and monotonous in production variety, the moving direction of the hook face slide channel needs to be changed when flower patterns are changed, and the utilization rate of a machine is not high are solved.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

The in-situ construction method of large-scale movable jib tower cranes in super high-rise buildings is converted from internal climbing to external hanging

The invention provides a construction method of a super high-rise building large movable arm tower crane in-situ converted from inner climbing to outer hanging. A tower body of the tower crane is arranged between an inner wall and an outer wall of a core cylinder through a support beam mechanism; the support beam mechanism includes a support beam structure consisting of two bearing main beams and two bearing secondary beams; and the bearing main beams are fixedly joined with base tooth blocks of a bracket arranged on the outer wall of the core cylinder through beam tooth blocks thereof. The construction method comprises the following steps: a lower support rod is arranged below the support beam mechanism nearest the top end of the outer wall, and is aslant vertically supported between the outer side ends of the bearing main beams and the inner wall; the outer wall shrinks above next support beam mechanism with a lower height; and the steps are repeated until the outer wall totally shrinks. The construction method solves such technical problems as slow reshipment speed and delayed construction period in conversion from inner climbing conditions to outer hanging conditions, achieves convenience for in-situ conversion of the tower crane from inner climbing to outer hanging, and improves the total construction benefit.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Method for conveying concrete by adopting track trolley with buffer unloading and empty bucket restoration

Owner:CHINA FIRST METALLURGICAL GROUP

Polishing equipment for printing ink transfer medium

The invention provides polishing equipment for a printing ink transfer medium. The polishing equipment comprises an unwinding roller; a polishing assembly located on one side of the unwinding roller; and a winding roller, wherein the polishing assembly is located between the unwinding roller and the winding roller. The unwinding roller is arranged on a clutch, the polishing assembly comprises a plurality of polishing rollers and a plurality of guide rollers, a pressure sensor is arranged on the portion, close to the unwinding roller, of the polishing roller, and the pressure sensor is connected with the clutch. According to the polishing equipment for the ink transfer medium, the flatness of the ink transfer medium can be improved.

Owner:KOMPASS TECH INC

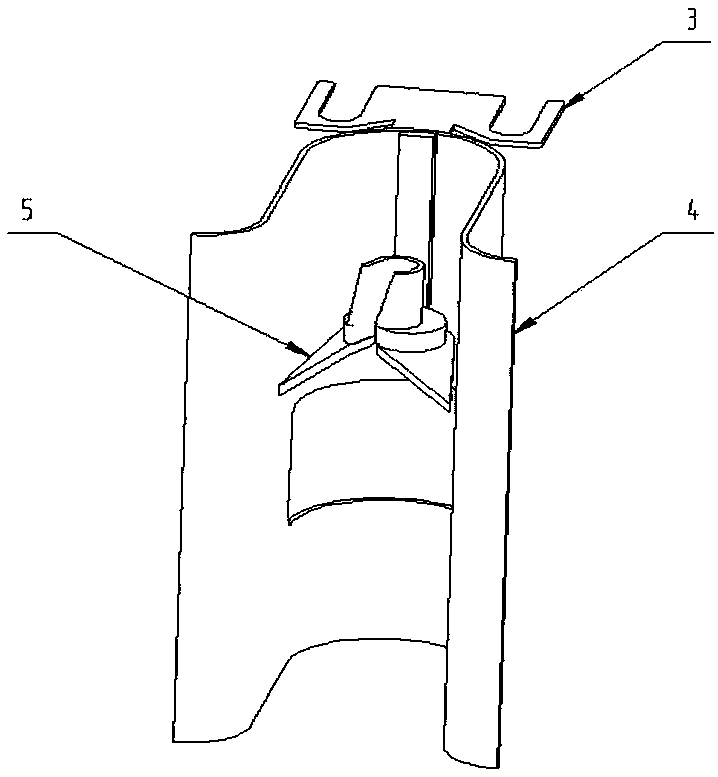

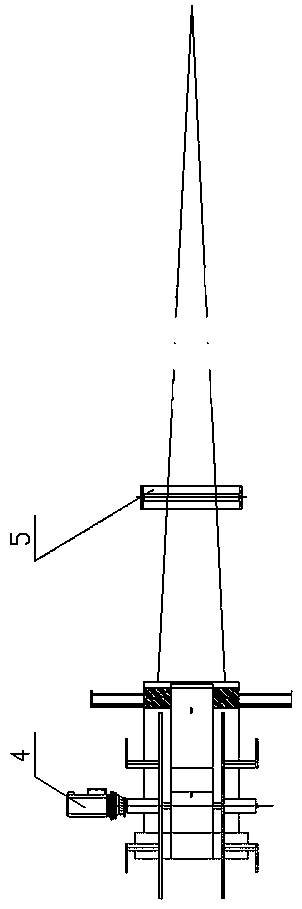

Intelligent flexible thermal-insulation single tube unreeling mechanism and unreeling method

PendingCN109455571AImprove unwinding efficiencyReduce in quantityFilament handlingThermal insulationElectric machine

The invention discloses an intelligent flexible thermal-insulation single tube unreeling mechanism and an unreeling method. In production, time and labour power are wasted and production efficiency isreduced in a production process as a flexible thermal-insulation single tube in the existing heat supply and cold supply field mainly adopts conventional mechanical type manual regulation on thermal-insulation tube unreeling during an unreeling link. The intelligent flexible thermal-insulation single tube unreeling mechanism consists of an unreeling platform (1) and a guide mechanism (5), whereinthe unreeling platform is of a framework structure; an unreeling performing mechanism (3) is mounted inside the framework structure; the unreeling performing mechanism is provided with 8 slide blockdevices which are arranged at an equal angle with respect to the centre position; an air cylinder (2) is fixedly arranged on a right side bracket of the unreeling performing mechanism; one side framework of the unreeling platform is fixedly equipped with a motor (4) through a bolt; the motor is connected with the unreeling performing mechanism through a connecting shaft; and a control panel (6) ismounted at the right upper side of the framework of the unreeling platform. The unreeling method is used for the intelligent flexible thermal-insulation single tube unreeling mechanism.

Owner:HARBIN LOGSTOR ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com