Conic tube and rolling method thereof

A bobbin and cone-shaped technology, which is applied in the field of yarn guiding to form a conical bobbin package, can solve the problems of bobbin rotation fluctuation and uncontrollability, and achieve the effects of reducing the number of bobbins, preventing entanglement, and increasing the winding length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

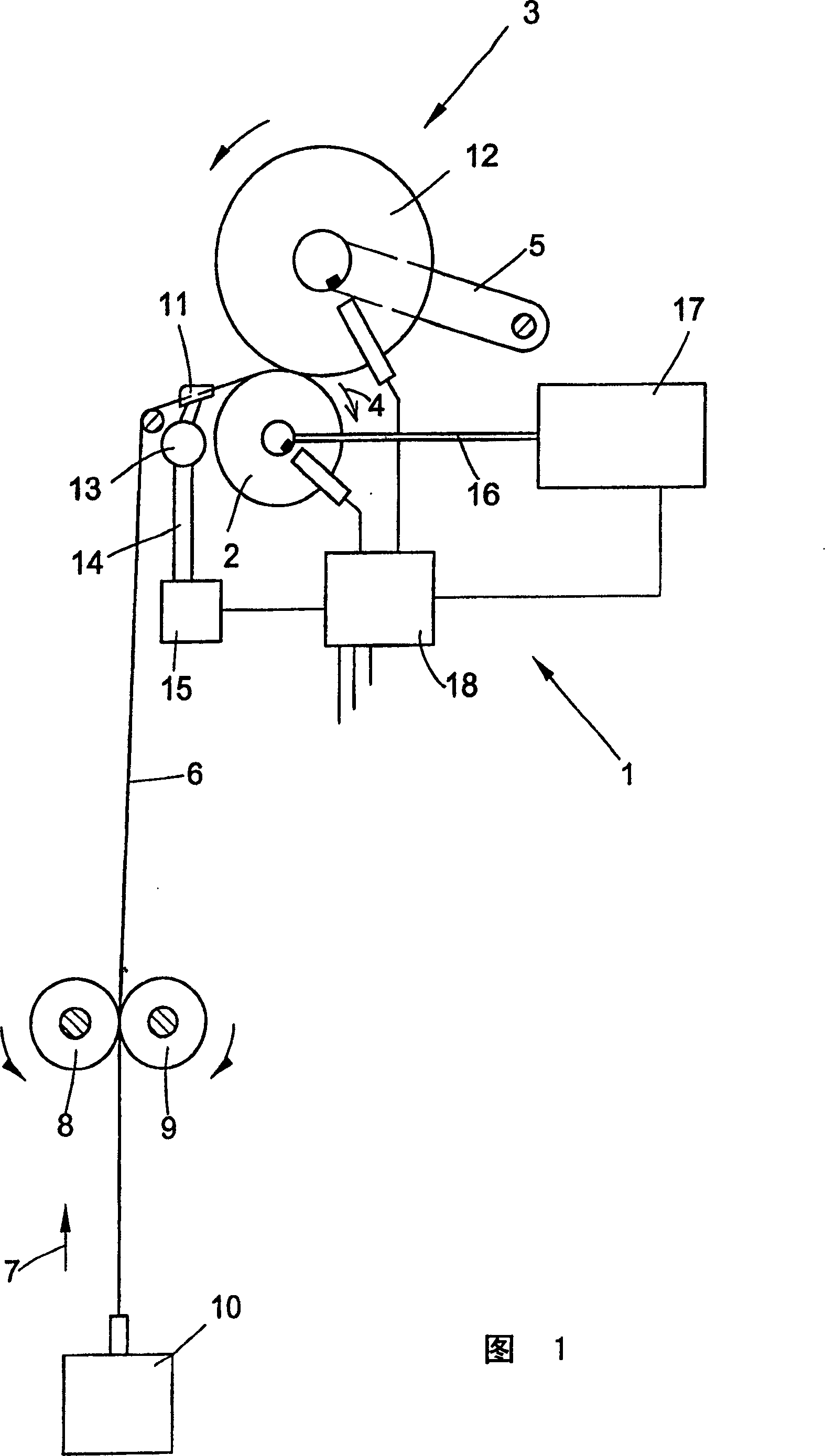

[0023] Figure 1 shows a winding device for the production of conical packages on a rotor spinning machine. The winding device 1 has a drum 2 which drives a conical bobbin 3 by means of friction. Drum 2 rotates in the direction of arrow 4. The bobbin 3 is supported by a rotatable bobbin carrier 5 and rests against the drum 2 . Roller 2 is under pressure. The yarn 6 is drawn in the direction of the arrow 7 by means of the cooperating yarn delivery roller pair 8, 9 from the winding position of the spinning box 10 at a constant yarn speed, and the yarn is wound into a bobbin by means of a reciprocating yarn guide 11 3 in a roll of 12. The yarn guide 11 is a part of the reciprocating mechanism 13, which is connected to the motor 15 through an effective connector 14, and is driven by the motor. The drum 2 is driven by the shaft of the motor 17 . Motors 15 and 17 are all controlled by a microprocessor, and the intersection angle α of the conical bobbin 3 is related to the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com