Polyurethane elastic yarn and manufacturing method thereof

A polyurethane elasticity, polymer technology, applied in the direction of one-component polyurethane rayon, rayon manufacturing, one-component synthetic polymer rayon, etc., can solve the problem of high cost, achieve excellent productivity, excellent unwinding, The effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0133] The PTMG of the MDI and the number average molecular weight is 1800 is loaded into the container, so that the molar ratio is MDI / PTMG = 1.58 / 1, reacts at 90 ° C, dissolve the resulting reaction product in N, N-dimethylacetamide (DMAC). Next, a DMAC solution comprising ethylenediamine and diethylamine is added to a solution that dissolves the above reaction product, thereby preparing a polyurethane urea solution in the polymer in the polymer.

[0134] After that, "Metachlor (Registered Trademark)" 2390 manufactured by DuPontCorporation manufactured by the oxidative inhibitor (DuPontCorporation) is used as the 2- [4 of the UV absorber , 6-bis (2,4-dimethylphenyl) -1,3,5-triazine-2-yl] -5- (octoxy) phenol (Cytec Corporation) "Cyasorb" (Registered Trademark) "1164) mixed with a mass ratio of 3: 2 to prepare DMAC solution (concentration: 35% by mass), and used as an additive solution (35% by mass).

[0135] The polyurethaneurea solution and the additive solution were mixed i...

example 2

[0138] The treatment agent (B1) of 25% polydimethylsiloxane, 73% mineral oil and 2% ST-Mg is prepared as a treatment agent that winds the polyurethane elastic yarn.

[0139] The wound yarn produced in the same manner as in Example 1, except that the treatment agent (B1) of 1% dry mass (B1) is applied to the polyurethane elastic yarn during the winding period.

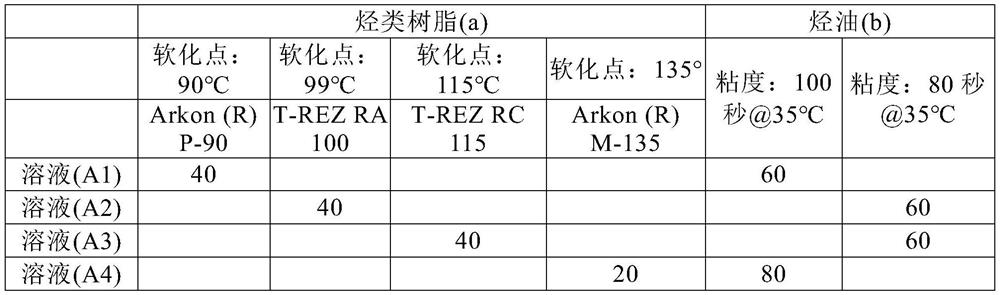

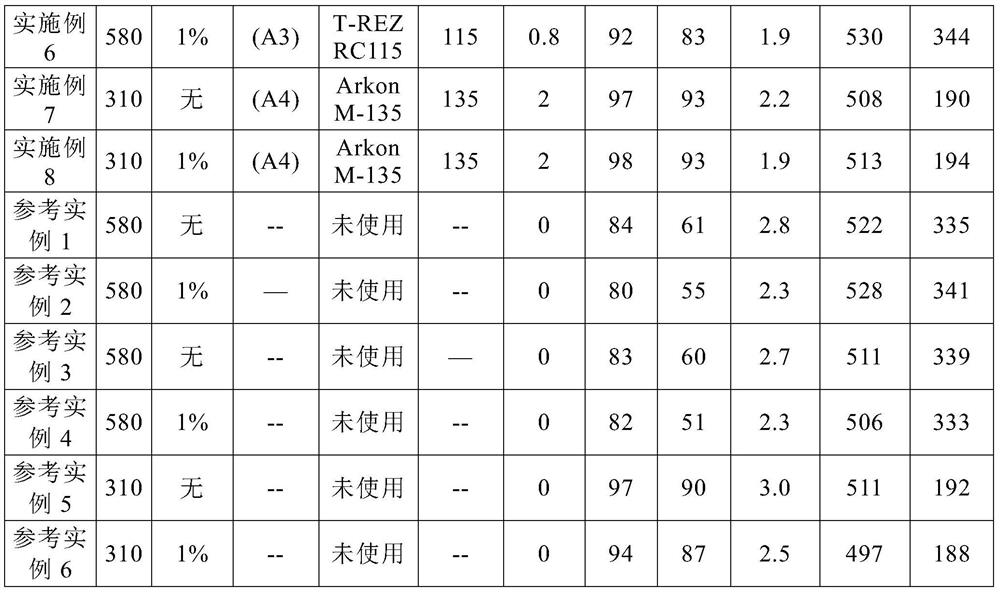

[0140] Examples 3 to 6, Reference Examples 1 to 4

[0141] The yarn yarn is produced from the polyurethane elastic yarn by the polyurethane elastic yarn in the same manner as in Example 1 or Example 2, and the type and / or inclination ratio of the component is changed as shown in Table 1.

[0142] Examples 7 to 8 and Reference Examples 5 to 6

[0143] The wound yarn of 4.5 kg of polyethylene elastic yarns is produced in a manner similar to other examples and reference examples, and the specification is changed to 310 (32 filaments) as shown in Table 1.

[0144] Various evaluation results of the produced yarns are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com