Treatment Agent for Elastic Fiber and Its Utilization

A technology of elastic fiber and treatment agent, which is applied in fiber treatment, fiber type, textiles and papermaking, etc. It can solve the problems of poor adhesion, insufficient adhesion and insufficient smoothness of treatment agents, and achieve excellent smoothness, Excellent unwinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

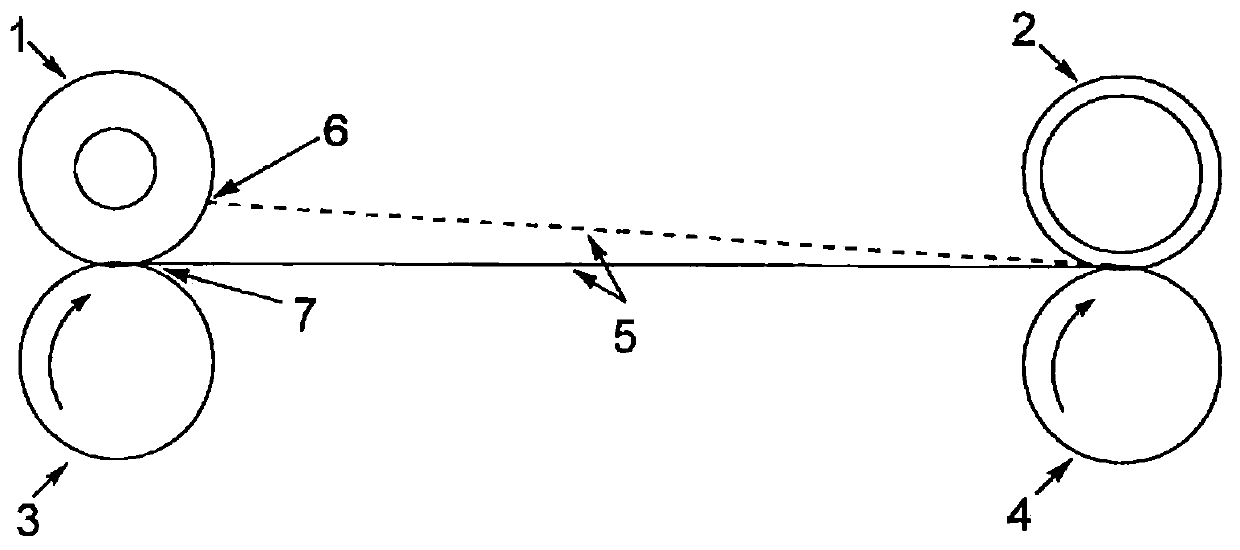

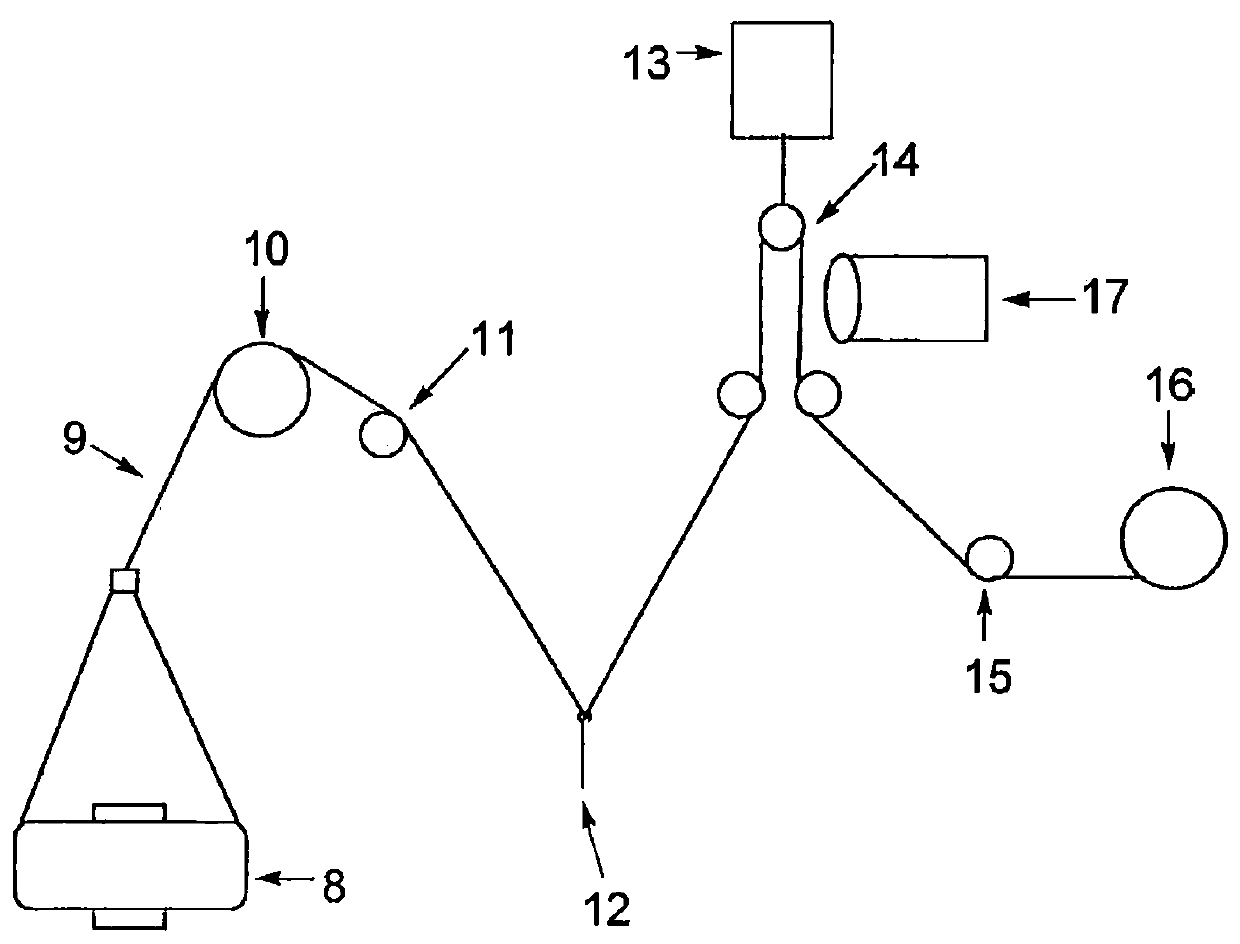

Image

Examples

Embodiment 1~29、 comparative example 1~8

[0143] Reaction of polytetramethylene ether glycol with an average molecular weight of 1600 and 4,4'-diphenylmethane diisocyanate at a molar ratio of 1:2, followed by a dimethylformamide solution of 1,2-diaminopropane For chain extension, a dimethylformamide solution with a polymer concentration of 33% was obtained as a spinning stock solution. In addition, the concentration of the spinning stock solution was 1900 mPa·S (measurement temperature: 30° C.).

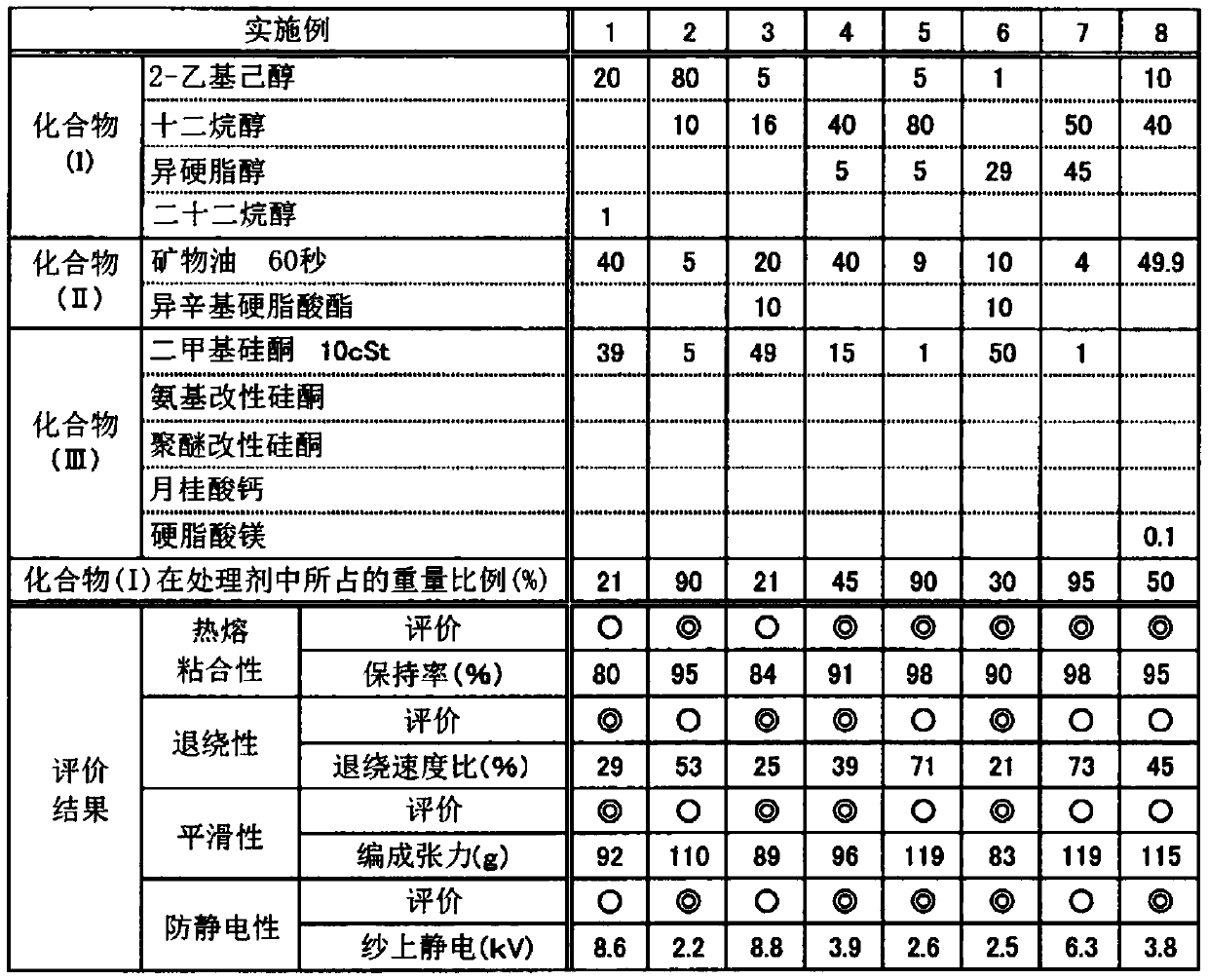

[0144] For the case that does not contain metal soap (calcium laurate, magnesium stearate), after mixing the components described in Tables 1 to 3, stir at 20 to 40°C for 30 minutes, for the case containing metal soap (calcium laurate, magnesium stearate), In the case of magnesium stearate), the metal soap after mixing and stirring was pulverized by the above-mentioned wet mill to obtain the elastic fiber treatment agents of Examples 1-29 and Comparative Examples 1-8, respectively. Components used in Examples and Comparativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com