A kind of spandex spinning finish with uniform unwinding inside and outside and its preparation method

A spinning oil agent and unwinding technology, which is applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve the problems of large differences in unwinding properties of spandex sheets, easy edge collapse, weak adsorption, etc., and achieve good antistatic Performance and unwinding properties, increased force, and improved surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

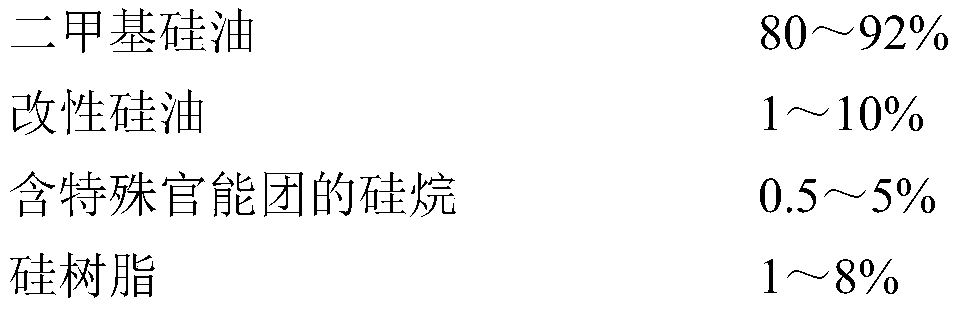

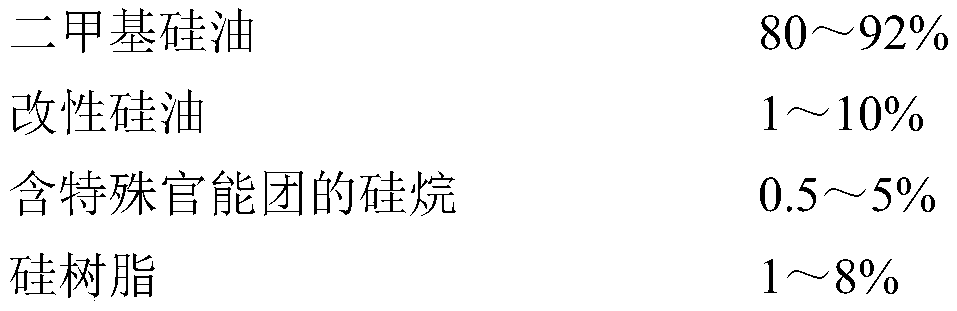

[0045] 85% by weight of dimethyl silicone oil (kinematic viscosity at 25 degrees Celsius is 10mPa.s), 8% by weight of amino modified silicone oil (kinematic viscosity at 25 degrees Celsius is 200mPa.s), 2% by weight of ammonia Propyl triethoxy silane, 5% by weight of methyl vinyl silicone resin (M:Q = 0.7) were sequentially added to the stirring and dispersing device and stirred for 1 hour to obtain colorless and transparent component A; 85% by weight Of mineral oil (kinematic viscosity 10mPa.s at 40 degrees Celsius), 6% by weight of isooctyl stearate, 5% by weight of sorbitan fatty acid ester, 3% by weight of fatty alcohol polyoxygen Potassium vinyl ether phosphate, 1% by weight of 12-hydroxy magnesium stearate were added to the reaction kettle, and stirred at a temperature of 80°C at 300r / min for 1 hour to obtain a light yellow transparent component B; Slowly add the component A of 1 part of the component B, and stir at 300r / min for 0.5h at room temperature to obtain the span...

Embodiment 2

[0053] 90% by weight of dimethyl silicone oil (kinematic viscosity at 25 degrees Celsius is 10mPa.s), 5% by weight of amino modified silicone oil (kinematic viscosity at 25 degrees Celsius is 500mPa.s), 1.5% by weight of ammonia Ethylaminopropyltrimethoxysilane, 3.5% by weight of methyl vinyl silicone resin (M:Q=0.8) were sequentially added to the stirring and dispersing device and stirred for 1 hour to obtain colorless and transparent component A; Parts by weight of mineral oil (kinematic viscosity at 40 degrees Celsius is 10mPa.s), 8% by weight of isooctyl oleate, 6% by weight of glycerol monostearate, 4% by weight of fatty alcohol polyoxygen Vinyl ether ammonium sulfate, 2% by weight of 12-hydroxy magnesium stearate were added to the reaction kettle, stirred at a temperature of 90 ℃ at 400r / min for 2 hours to obtain a light yellow transparent component B; Component A is slowly added to 1 part of component B, and stirred at 400r / min for 1h at room temperature to obtain spande...

Embodiment 3

[0061] 88% by weight of dimethyl silicone oil (kinematic viscosity at 25 degrees Celsius is 10mPa.s), 7% by weight of amino modified silicone oil (kinematic viscosity at 25 degrees Celsius is 800mPa.s), 1% by weight of ammonia Ethylaminopropyltrimethoxysilane, 1% by weight of aminopropylmethyldiethoxysilane, 3% by weight of methyl vinyl silicone resin (M:Q=0.7) are sequentially added to the stirring and dispersing device Stir for 1 hour in the middle to obtain colorless and transparent component A; combine 84% by weight of mineral oil (kinematic viscosity at 40 degrees Celsius is 10mPa.s), 7% by weight of isooctyl palmitate, 4% by weight of Polyethylene glycol monooleate, 3.5% by weight of fatty alcohol polyoxyethylene ether phosphate diethanolamine salt, and 1.5% by weight of 12-hydroxystearate magnesium are added to the reactor at 85°C Stir at 300r / min for 1.5h to obtain light yellow transparent component B; slowly add 1 part of component A to 1 part of component B, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com